Steel with high mechanical strength and wear resistance

A technology with mechanical strength and high wear resistance, applied in the field of steel with high mechanical strength and high wear resistance, it can solve the problems of reducing the impact resistance of the workpiece and the fragile area of strong bending load resistance, processing or welding difficulties and other problems

Active Publication Date: 2009-03-18

INDUSTEEL FRANCE

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, high levels of strong carbide-forming elements, such as molybdenum and vanadium, must be present to cause sufficiently hardened and temperature-stable secondary precipitates, and this does have the disadvantage of leading to the formation of seams in those Elemental neutralization is highly segregated in carbon and is therefore very hard and very brittle

Furthermore, they constitute frangible zones, albeit localized, which can considerably reduce the impact resistance and the resistance to severe bending loads of the workpiece

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment n021

[0221] Example n 0 21: Si=0.9% thermal conductivity=20.6W / m / K

Embodiment n028

[0222] Example n 0 28: Si=0.2% thermal conductivity=25.1W / m / K

Embodiment n022

[0223] Example n 0 22: Si=0.8% thermal conductivity=21.3W / m / K

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

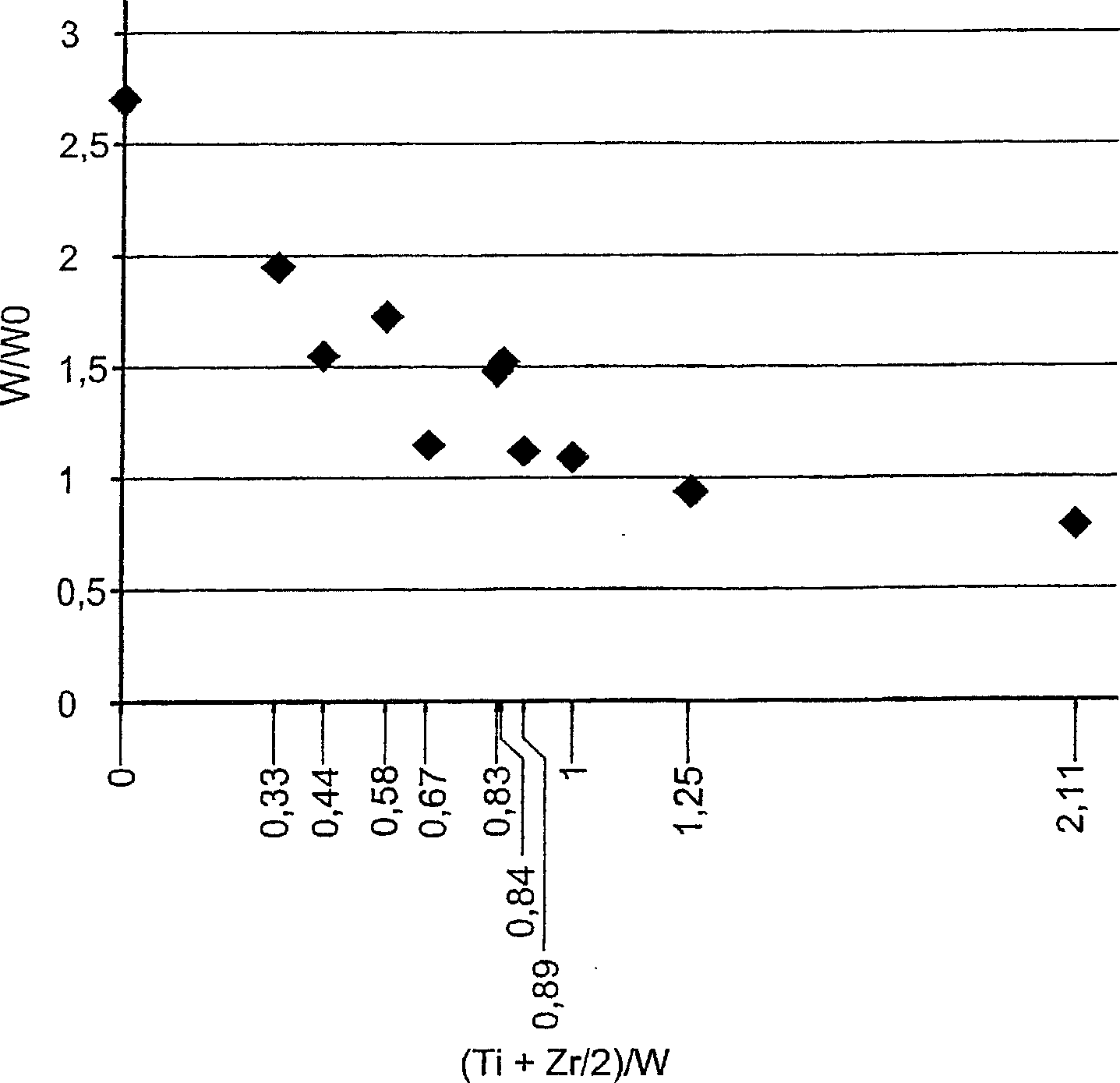

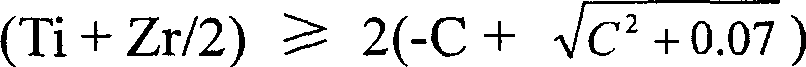

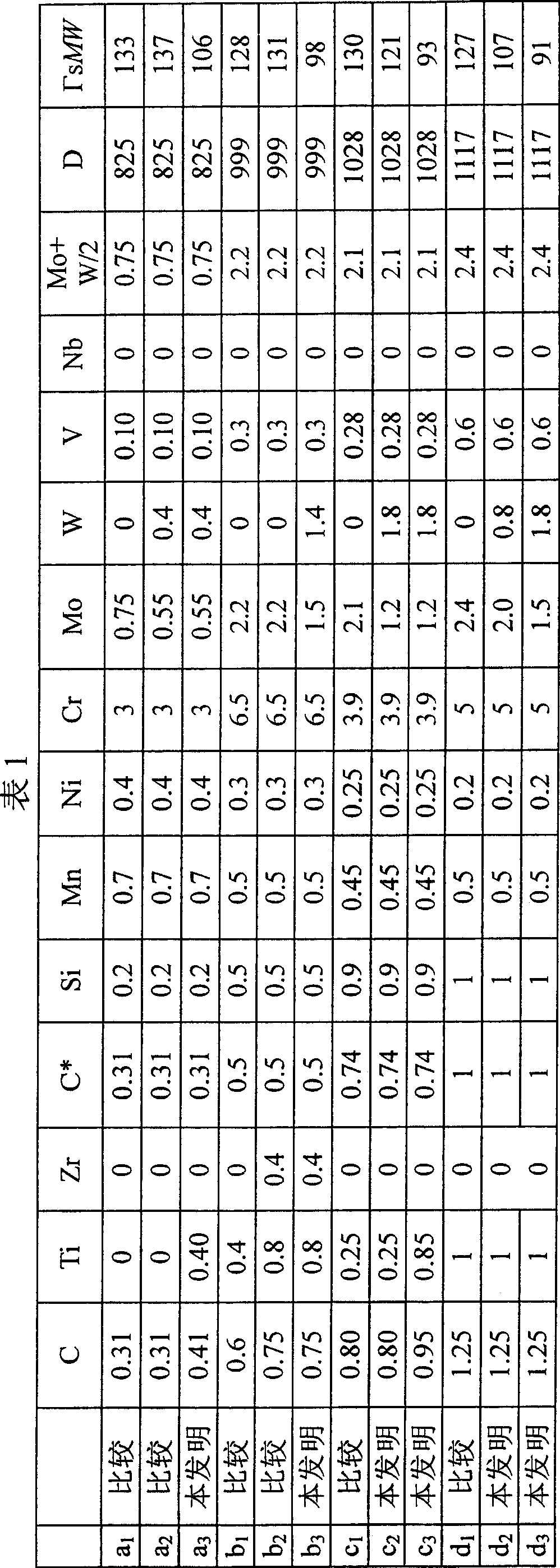

The present invention relates to a steel with high mechanical strength and high wear resistance. More specifically, the present invention relates to a method for reducing the segregation joints of steels having high mechanical strength and high wear resistance, and having the following weight composition: 0.30%≤C≤1.42%; 0.05%≤Si ≤1.5%; Mn≤1.95%; Ni≤2.9%; 1.1%≤Cr≤7.9%; +Nb / 2+Ta / 4≤1.45%; less than or equal to 0.1% boron, less than or equal to 0.19% (S+Se / 2+Te / 4), less than or equal to 0.01% calcium, less than or equal to 0.5% rare earth metals , less than or equal to 1% of aluminum, less than or equal to 1% of copper; the rest is iron and impurities derived from the production of said steel. Said composition also includes: 800≤D≤1150, wherein D=540 (C) 0.25 +245(Mo+3V+1.5Nb+0.75Ta) 0.30 +125Cr 0.20 +15.8Mn+7.4Ni+18Si. According to the present invention, all or part of molybdenum is replaced with twice the proportion of tungsten, so that W≥0.21%, and Ti, Zr and C are adjusted so that after said adjustment Ti+Zr / 2≥0.2W, (Ti+Zr / 2) xC≥0.07, Ti+Zr / 2≤1.49% and D remains constant with a variation range of 5%. The invention also relates to the steel obtained and to the method of producing steel parts.

Description

technical field [0001] The present invention relates to steels with high mechanical strength and high wear resistance. Background technique [0002] In a large number of industries steels with high wear resistance are used. These are steels, for example, that are used to make components for mining equipment and must be wear-resistant. They are also the steels used to make tools for cold forming or forming metal workpieces at moderate temperatures, and these steels must wear wear due to metal-to-metal type friction. For these machining tool applications, the steel must at least retain good properties despite being heated to temperatures which may reach 500°C or 600°C. [0003] In addition to wear resistance, the steels considered here must also have suitable properties in order to be able to be machined or welded. Finally, they must be able to withstand shocks or severe loads. [0004] In general, in order to obtain all the desired properties, it is common to use material...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/44C22C38/50C22C38/46C21D8/00C21D6/00C21D7/13

CPCC22C38/46C21D7/13C21D6/002C22C38/50C22C38/44C22C33/006C22C38/005C22C38/02C22C38/04C22C38/06C22C38/42C22C38/48C22C38/60

Inventor 让·贝居伊诺特多米尼克·维亚勒

Owner INDUSTEEL FRANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com