Collision stopper for suspension apparatus

A technology of suspension device and limiter, which is applied in the direction of suspension, transportation and packaging, cantilever installed on pivot, etc., to achieve the effect of preventing abnormal sound, preventing unpleasant abnormal sound and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

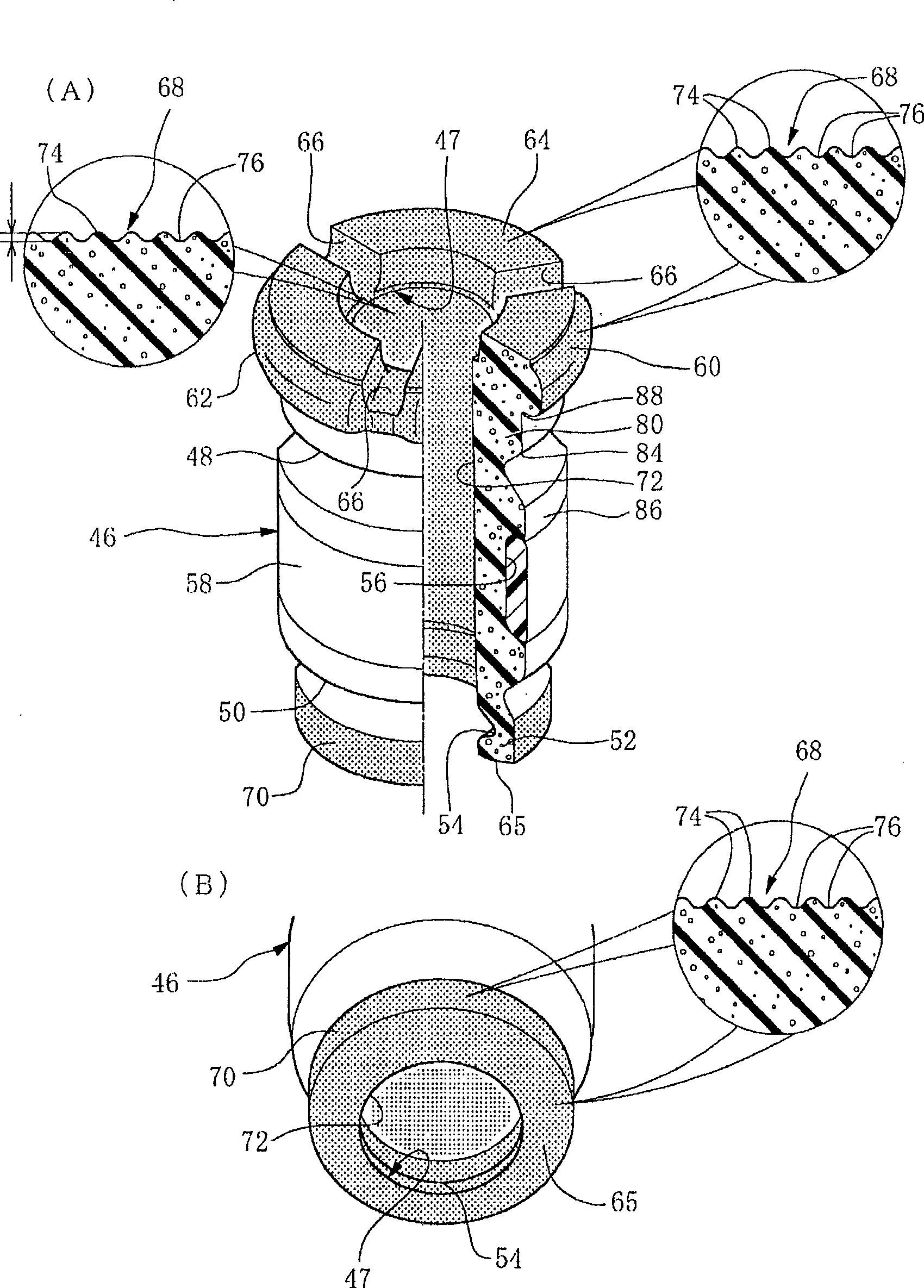

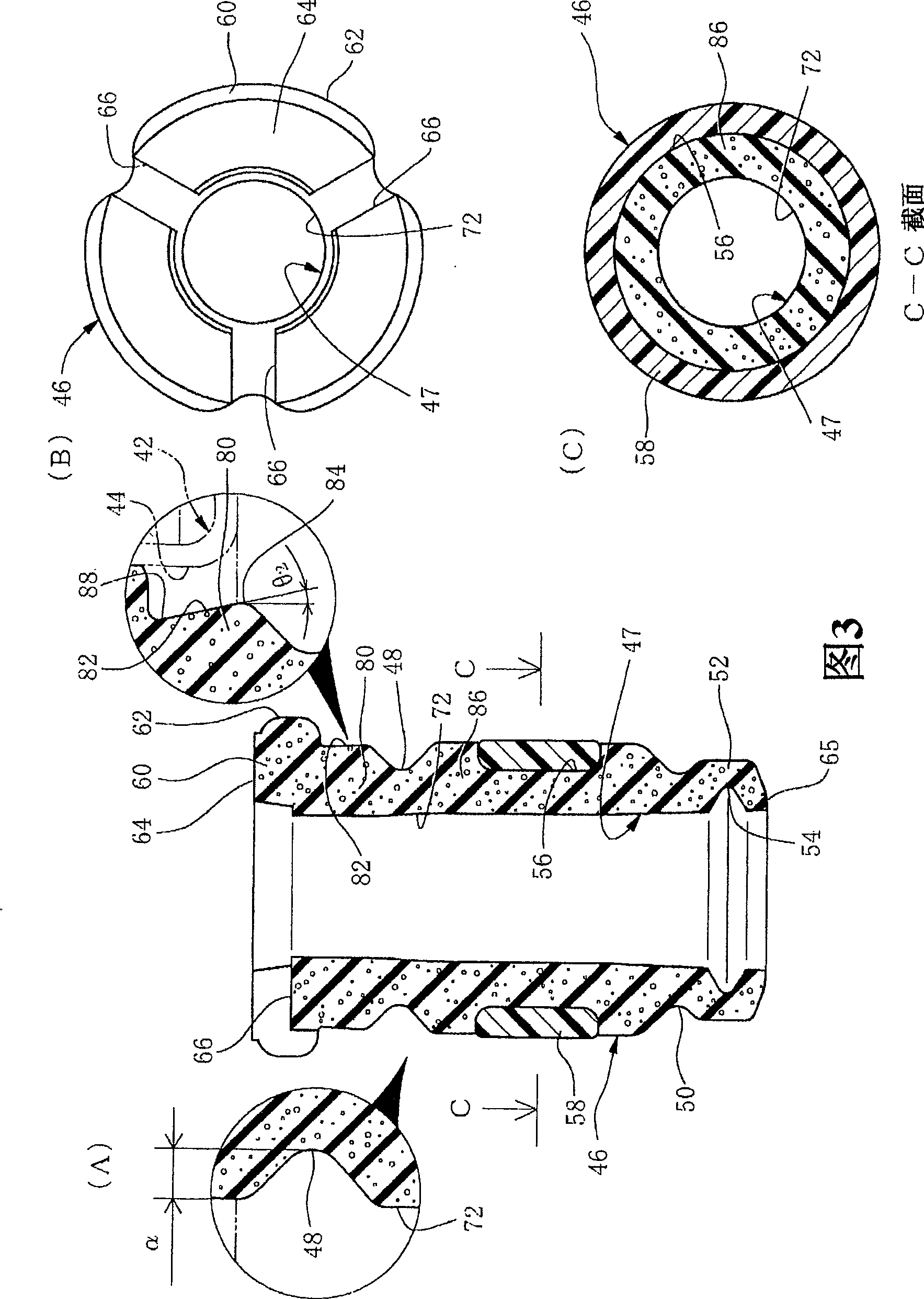

[0045] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

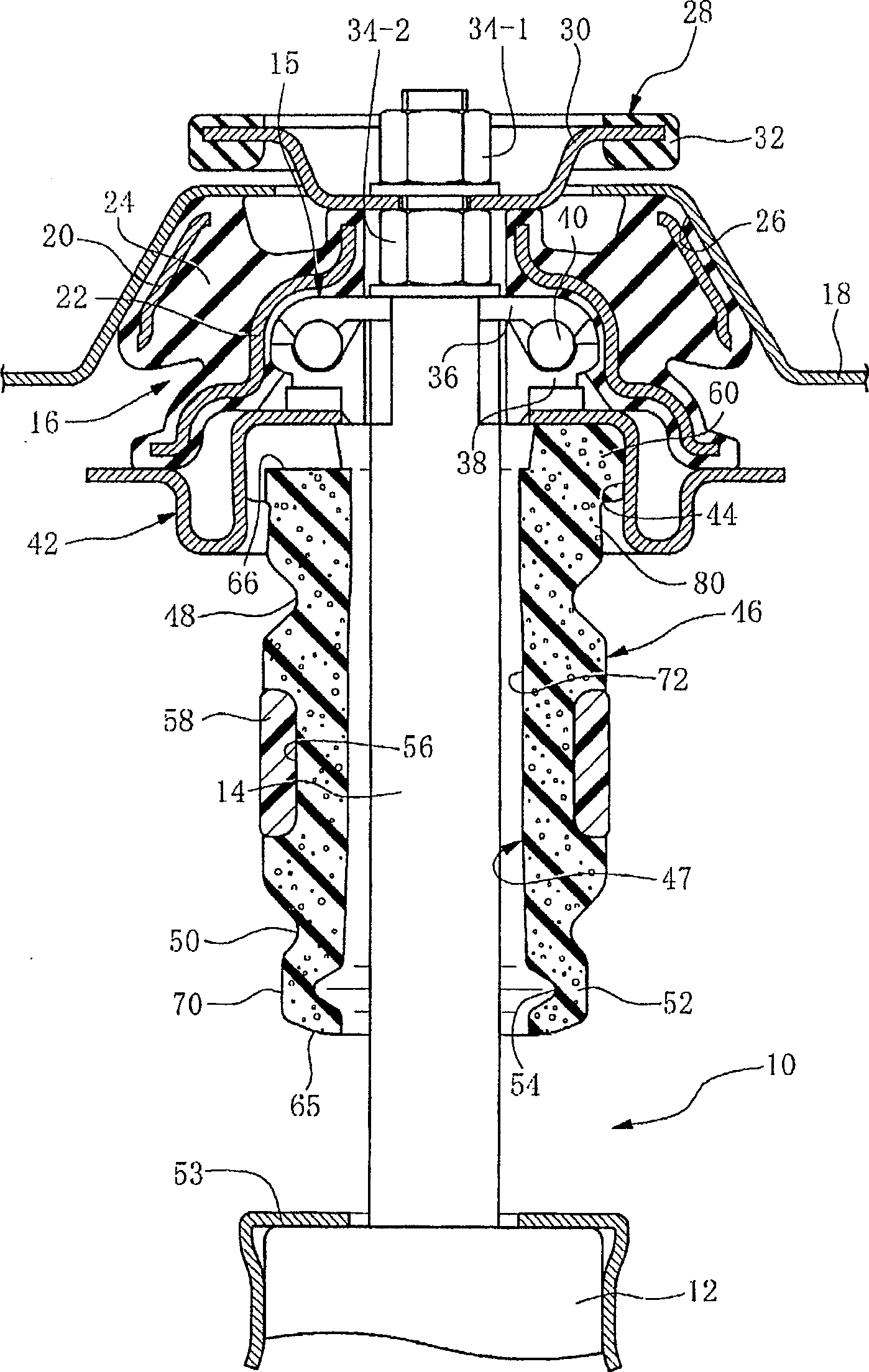

[0046] in figure 1 In the figure, 10 denotes a shock absorber that constitutes the main element of a vehicle suspension device, here a strut type suspension device, 12 denotes a cylinder, and 14 denotes a piston rod protruding upward from the cylinder 12.

[0047] The upper end portion of the piston rod 14 is elastically connected to the vehicle body panel 18 through the bearing 15 and the spool support 16 and rotatably around its axis.

[0048] On the other hand, the lower end of the cylinder 12 is fixed to a knuckle not shown in the figure.

[0049] Therefore, when the lower end of the cylinder 12 is manipulated, the ball joint and the upper end of the piston rod, specifically, the center of the bearing 15, rotates integrally with the wheel, and moves in position. The joint connects the steering knuckle and the steering tie rod.

[0050] That is, in the shock a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com