Self cleaning method for condenser for cooling easily condensate

A technology for condensers and solidified products, applied in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as channel blockage, poor condensation effect of condensers, and inability to run continuously, saving cleaning costs, easy to implement, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

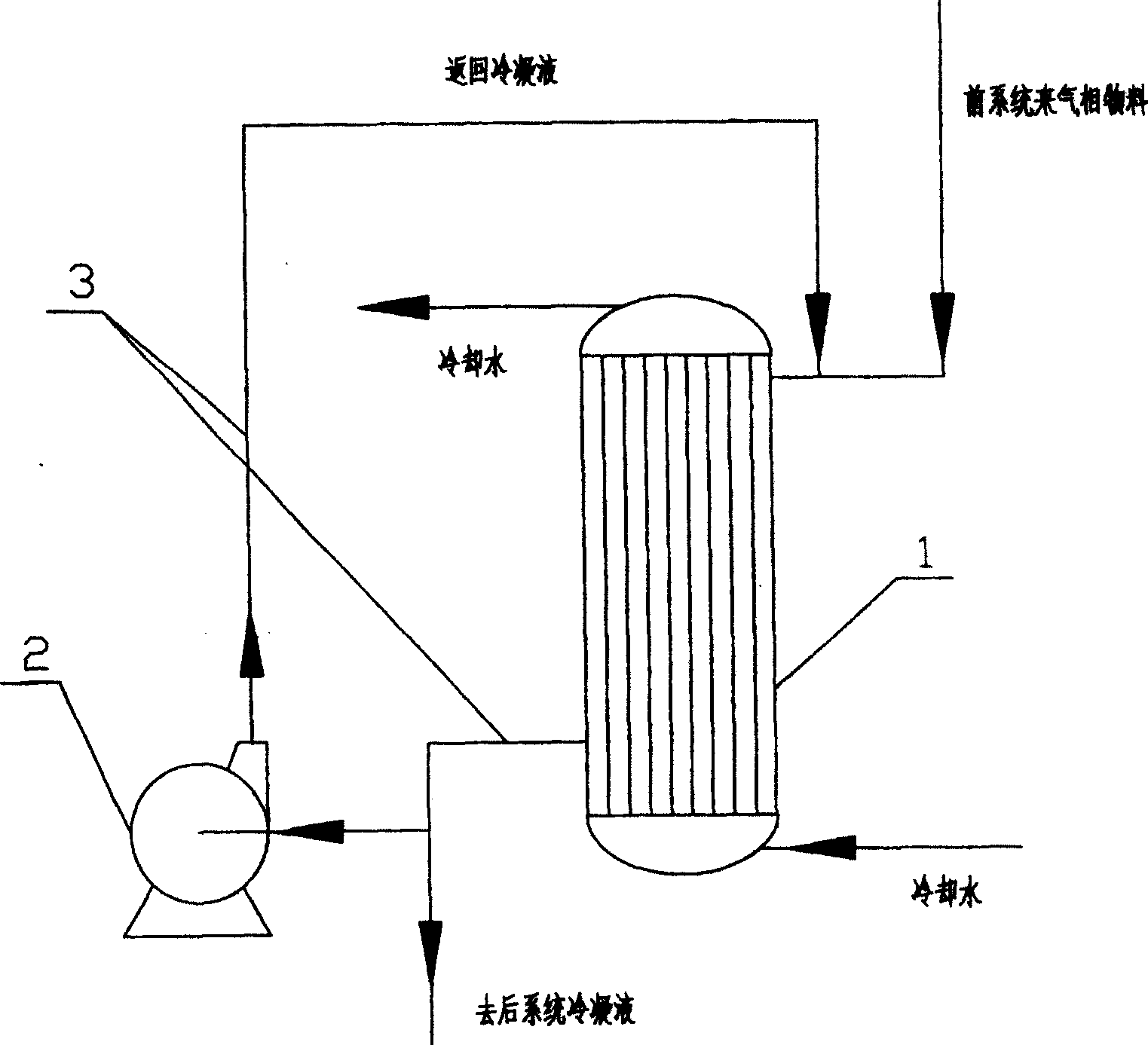

[0023] The structure of the condenser 1 in the present embodiment is as figure 1 As shown, the hydrolysis system used in the urea plant, the former system - steam containing high concentration of ammonia and carbon dioxide from the distillation tower and hydrolyzer, the pressure is 0.3MPa, the temperature is 110°C, the condensate (unsaturated ammonium bicarbonate at 40°C Liquid) total amount is 20 tons / hour; the temperature of cooling water is 30 ℃, flow rate is 600 tons / hour, after taking away reaction heat, the temperature of cooling water out of condenser is 42 ℃; Returned unsaturated ammonium bicarbonate liquid control At 2 tons / hour (10% of the total amount of condensate).

[0024] Such as figure 1 As shown, the former system—distillation tower and hydrolyzer with a pressure of 0.3MPa and a temperature of 110°C containing high-concentration ammonia and carbon dioxide steam is cooled by condenser 1 to form an unsaturated ammonium bicarbonate liquid with a temperature of 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com