Electrodialysis control method, device and water purification equipment

A control method and technology of water purification equipment, applied in the direction of electrodialysis, separation method, control/manipulation system, etc., can solve the problems such as the temperature of the first glass of water cannot be reached, and the ion concentration increases, so as to meet the health requirements of drinking water and solve the problems Effects of deposit fouling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The first embodiment of the present invention provides an exemplary solution: providing a lower bias voltage to continuously supply the pressure during shutdown to make the electrodialysis membrane stack work, thereby solving the problem that the total dissolved solid value of the first cup of water is too high.

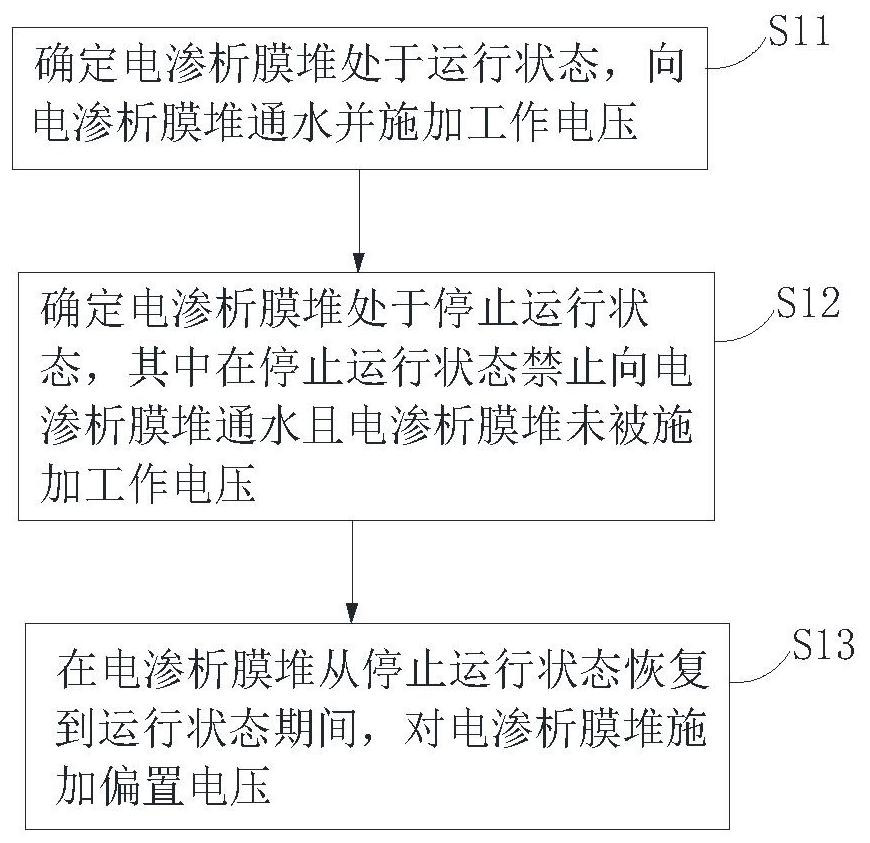

[0068] see Figure 4 , Figure 4 It is a flow chart of the control method of electrodialysis provided by the first embodiment of the present invention. In this embodiment of the present invention, the method to be executed in Embodiment 1 is:

[0069] Step S21: confirming that the electrodialysis membrane stack is in an operating state, passing water to the electrodialysis membrane stack and applying a working voltage;

[0070] Step S22: It is determined that the electrodialysis membrane stack is in a stopped operation state, and a bias voltage is applied to the electrodialysis membrane stack.

[0071] It can be understood that when the electrodialysis memb...

Embodiment 2

[0105] The second embodiment of the present invention provides an exemplary solution: do not pass water before each operation, apply a bias voltage to run for a period of time, and then pass water to apply the working voltage, so as to solve the problem that the total dissolved solid value of the first cup of water is too high .

[0106] see Figure 10 , Figure 10 It is a flow chart of the control method of electrodialysis provided by the second embodiment of the present invention. In the embodiment of the present invention, the method to be executed in the second embodiment is:

[0107] Step S31, confirming that the electrodialysis membrane stack is in a running state, passing water to the electrodialysis membrane stack and applying a working voltage;

[0108] Step S32, determining that the electrodialysis membrane stack is in a stopped operation state, wherein in the stopped operation state, it is forbidden to pass water to the electrodialysis membrane stack and the work...

Embodiment 3

[0141] The third embodiment of the present invention provides an exemplary solution: the other methods are the same as the first and second embodiments, but only the water is passed for a preset time after each stop, so as to solve the total dissolved solid value of the first cup of water. too high problem.

[0142] Specifically, the present invention is described on the basis of the method provided in the second embodiment. After the electrodialysis membrane stack is stopped, water is input to the frequently reversed electrodialysis membrane stack for cleaning, so as to avoid deposition of the membrane stack, and can Dilute the high concentrated water to prevent the concentrated water from penetrating into the fresh water area.

[0143] In order to explain this scheme more clearly, it is also explained through a control experiment:

[0144] Control group: the total dissolved solid value of the municipal water fed into the electrodialysis membrane stack was 500 ppm, the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com