Automatic combustor control system for steam power generation station

An automatic combustion and control system technology, applied in the direction of engine starting, controlled combustion, engine components, etc., can solve problems such as wrong operation, wrong control, complex and sensitive burner ignition and extinguishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

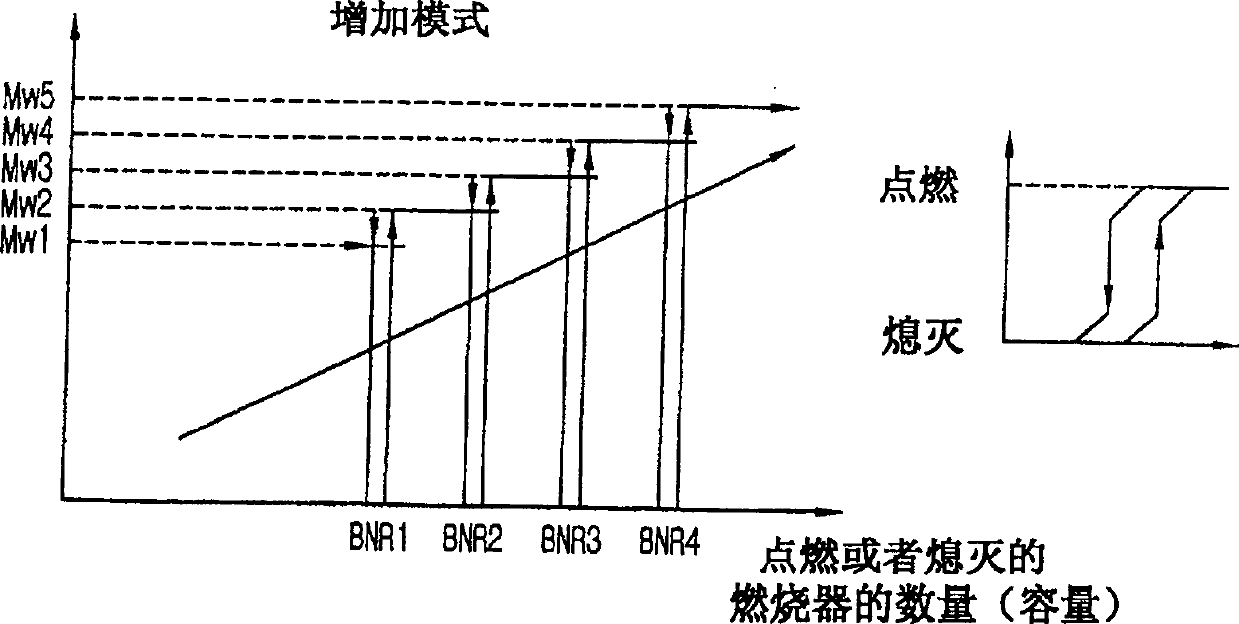

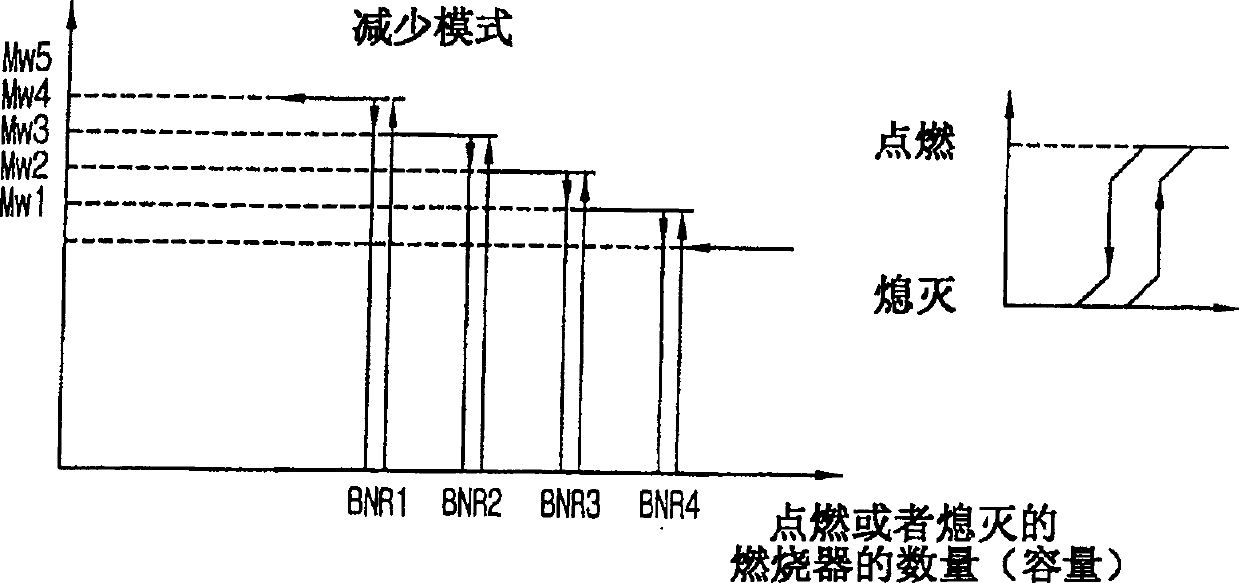

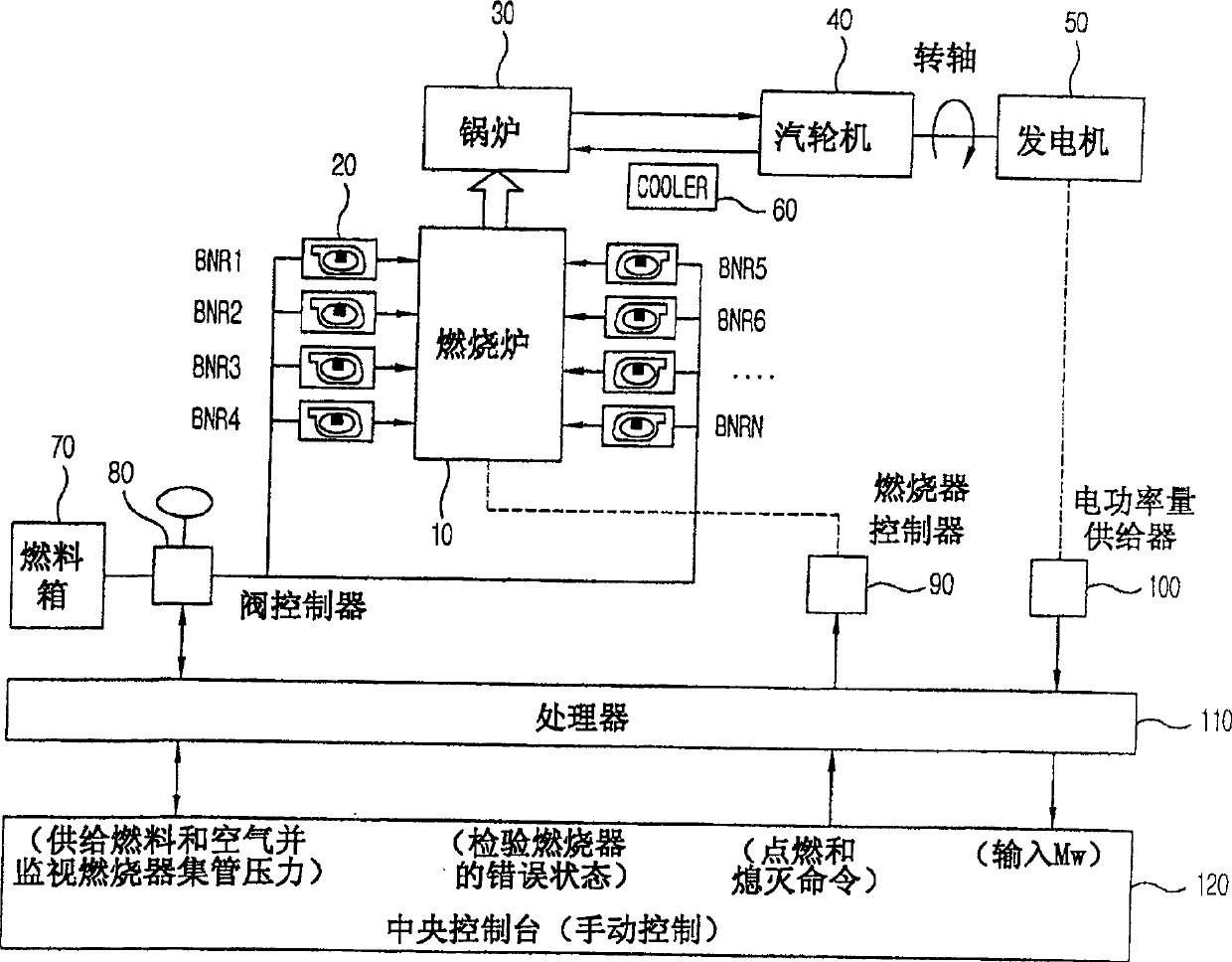

[0027] will refer to the accompanying drawings, namely Figures 4 to 9 , which can be specified in detail based on the characteristic data affecting the ignition and extinguishment of the generator burner (such as the relationship between the output power of the generator and the number of ignited and extinguished burners, the pressure of the burner header and the number of ignited and extinguished burners A preferred embodiment of an automatic burner control system and method thereof for automatically and correctly controlling a group of burners.

[0028] Figure 4 is a block diagram showing a steam power plant.

[0029] Such as Figure 4 As shown, the steam power station includes: a combustion furnace 10, heated by a plurality of burners BNR1 to BNR20; a boiler 30, which uses the combustion furnace 10 to heat water to generate steam; a steam turbine 40, which uses the steam generated by the boiler 30 to rotate; a generator 50 , connected to a rotating shaft of the steam t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com