Fluid pressure type pulling and turning steel method

A hydraulic, steel-turning technology, applied in the direction of workpiece manipulation, metal processing equipment, metal rolling, etc., can solve the problems of low reliability, high investment, large floor space, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

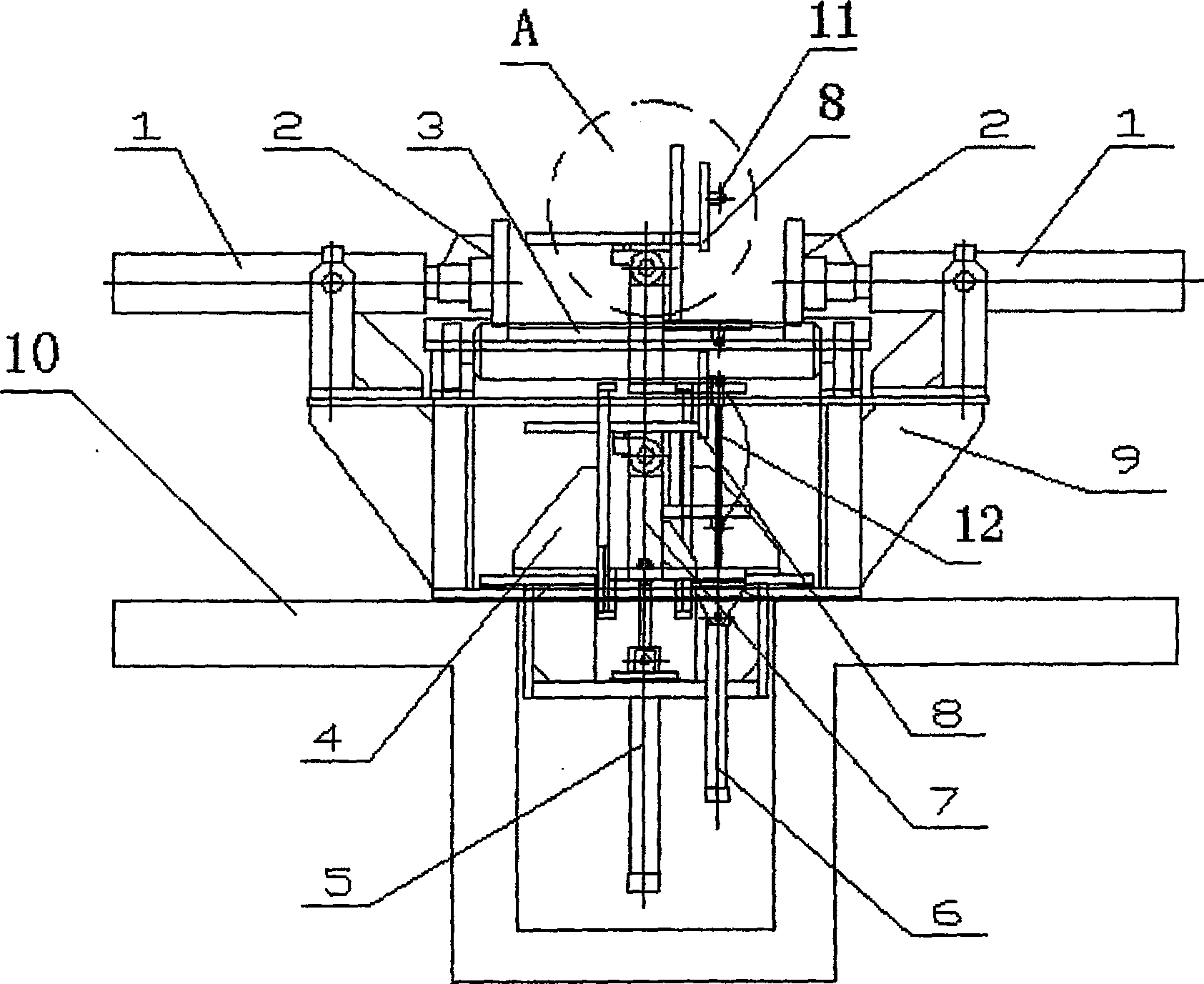

[0013] Such as figure 1 As shown, it includes a body, a power mechanism, a transmission mechanism, and a fixed connection mechanism; its left and right two push plate oil cylinders 1 are fixed on the front and rear roller frame 9 of the machine through the left and right oil cylinder supports, and the front and rear roller frame of the machine 9 is located on the groove frame 10, the push plate oil cylinder 1 is connected with the push plate 2 through the oil cylinder twist lug, the push plate sliding track 3 is installed between the front and rear roller frame 9 of the machine, and the left and right two push plate oil cylinders 1 push the push plate The plate 2 slides on the sliding track 3 of the push plate, which can be single-moved or synchronously moved to make the profile reach the required position; it includes a set of lifting cylinders 5 and a set of turning cylinders 6 fixed in the groove frame 10, and a set of lifting cylinders 6 The oil cylinder 5 and a group of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com