Metalloid cooker for electromagentic furnace

A non-metallic and induction cooker technology, applied in home appliances, kitchen appliances, applications, etc., can solve the problems of complicated operation, inability to heat non-metallic cookers, and inability to achieve precise control, so as to reduce the interference of cognitive factors and achieve precise control , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

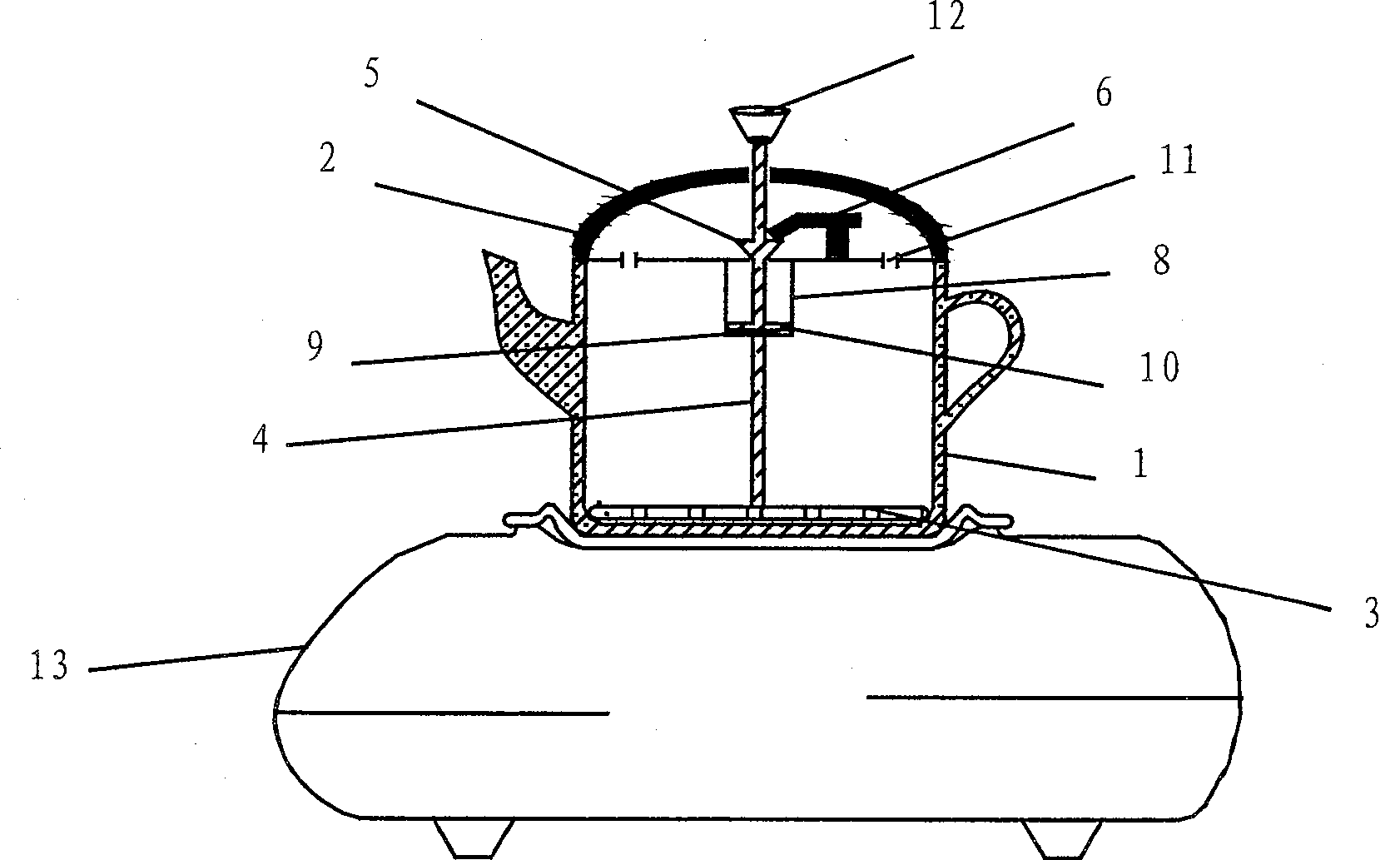

[0019] Embodiment 1: as figure 1 with 2 Shown, a kind of non-metal cooker for electromagnetic oven, comprises non-metal container 1 and the magnetic conduction heating body 3 that is arranged in this container, is provided with hollow cover 2 on the top of non-metal container 1, and the bottom of cover 2 is provided with There is a spring chamber 8 with a built-in compression spring 9. The magnetically conductive heating body 3 is provided with a central shaft 4 passing through the spring chamber 8 and extending out of the cover 2. A compression spring plate is provided on the central shaft 4 in the spring chamber 8. 10. The compression spring 9 is located between the compression spring plate 10 and the bottom of the spring chamber 8; a fixed pin 5 is provided on the central shaft 4 in the cover body 2, and a bimetallic pin 5 is provided on the inner bottom of the cover body 2 to cooperate with the fixed pin 5 A locator, the locator is a bimetal 6 with one end fixed on the in...

Embodiment 2

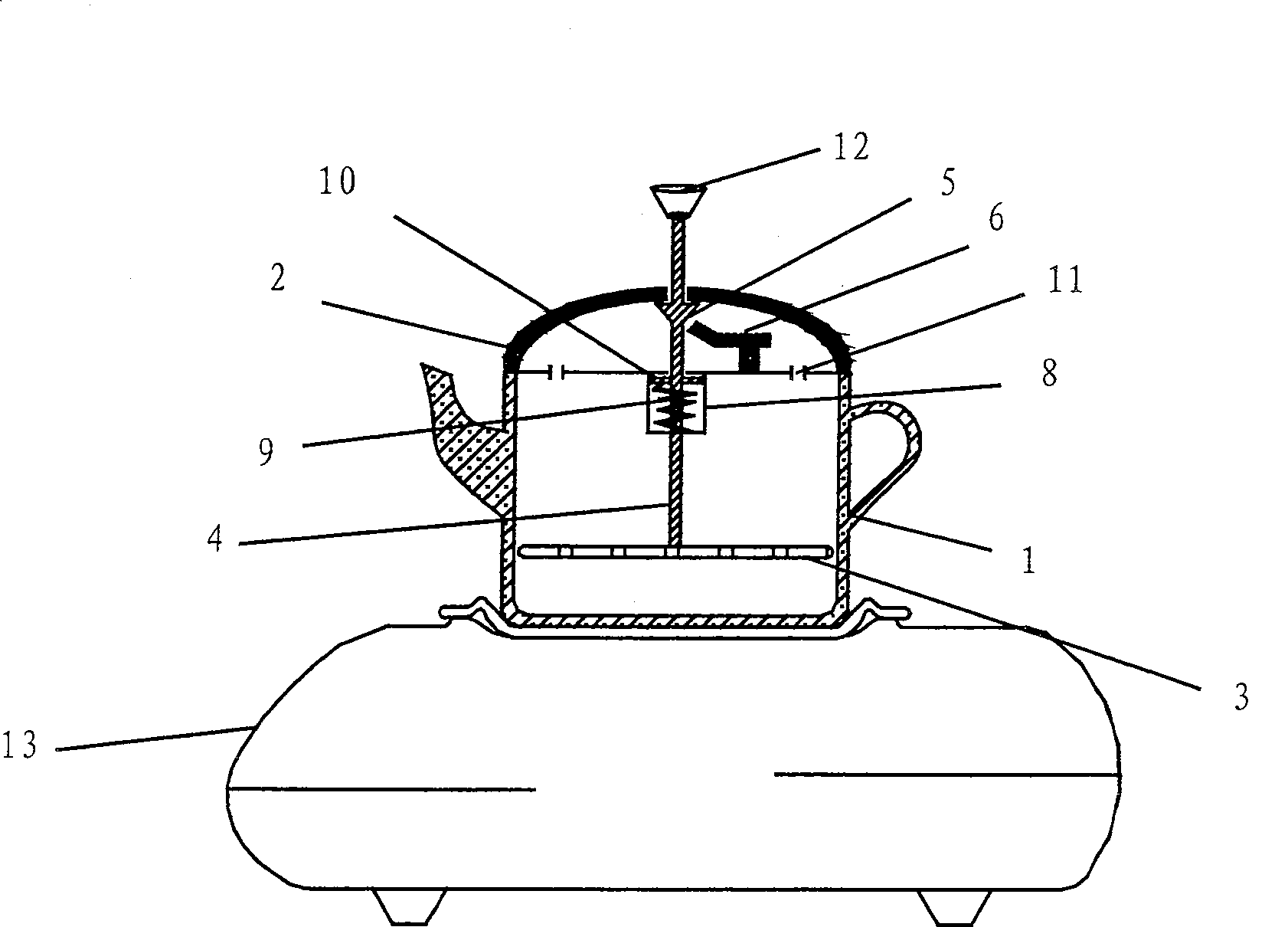

[0022] Embodiment 2: as image 3 with 4 Shown, a kind of non-metal cooker for electromagnetic oven, comprises non-metal container 1 and the magnetic conduction heating body 3 that is arranged in this container, is provided with hollow cover 2 on the top of non-metal container 1, and the bottom of cover 2 is provided with There is a spring chamber 8 with a built-in compression spring 9. The magnetically conductive heating body 3 is provided with a central shaft 4 passing through the spring chamber 8 and extending out of the cover 2. A compression spring plate is provided on the central shaft 4 in the spring chamber 8. 10. The compression spring 9 is located between the compression spring plate 10 and the bottom of the spring chamber 8; a fixed pin 5 is provided on the central shaft 4 in the cover body 2, and a bimetallic pin 5 is provided on the inner bottom of the cover body 2 to cooperate with the fixed pin 5 A locator, the locator is a bimetal coil spring 7 fixed at the bot...

Embodiment 3

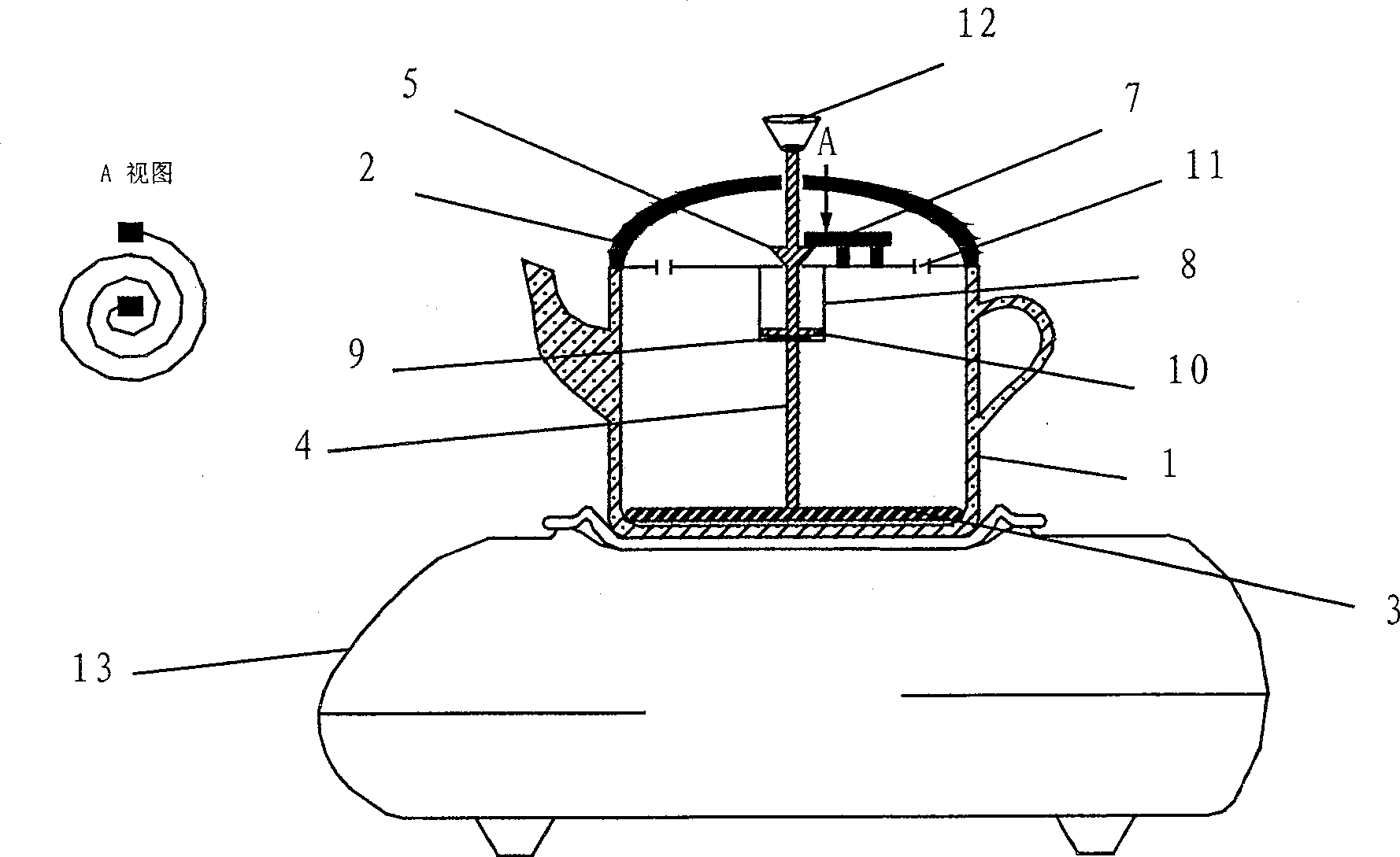

[0025] Embodiment 3: as Figure 5 with 6 Shown, a kind of non-metal cooker for electromagnetic oven, comprises non-metal container 1 and the magnetic conduction heating body 3 that is arranged in this container, is provided with hollow cover 2 on the top of non-metal container 1, and the bottom of cover 2 is provided with There is a spring chamber 8 with a built-in compression spring 9. The magnetically conductive heating body 3 is provided with a central shaft 4 passing through the spring chamber 8 and extending out of the cover 2. A compression spring plate is provided on the central shaft 4 in the spring chamber 8. 10. The compression spring 9 is located between the compression spring plate 10 and the bottom of the spring chamber 8; a fixed pin 5 is provided on the central shaft 4 in the cover body 2, and a bimetallic pin 5 is provided on the inner bottom of the cover body 2 to cooperate with the fixed pin 5 A locator, the locator is a bimetallic curved sheet 14 whose two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com