Rotor brake for a spinning rotor

A brake and rotor technology, applied in spinning machines, open-end spinning machines, continuous winding spinning machines, etc., can solve problems such as contact with the rotor, and achieve the effect of avoiding damage and eliminating sudden overload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

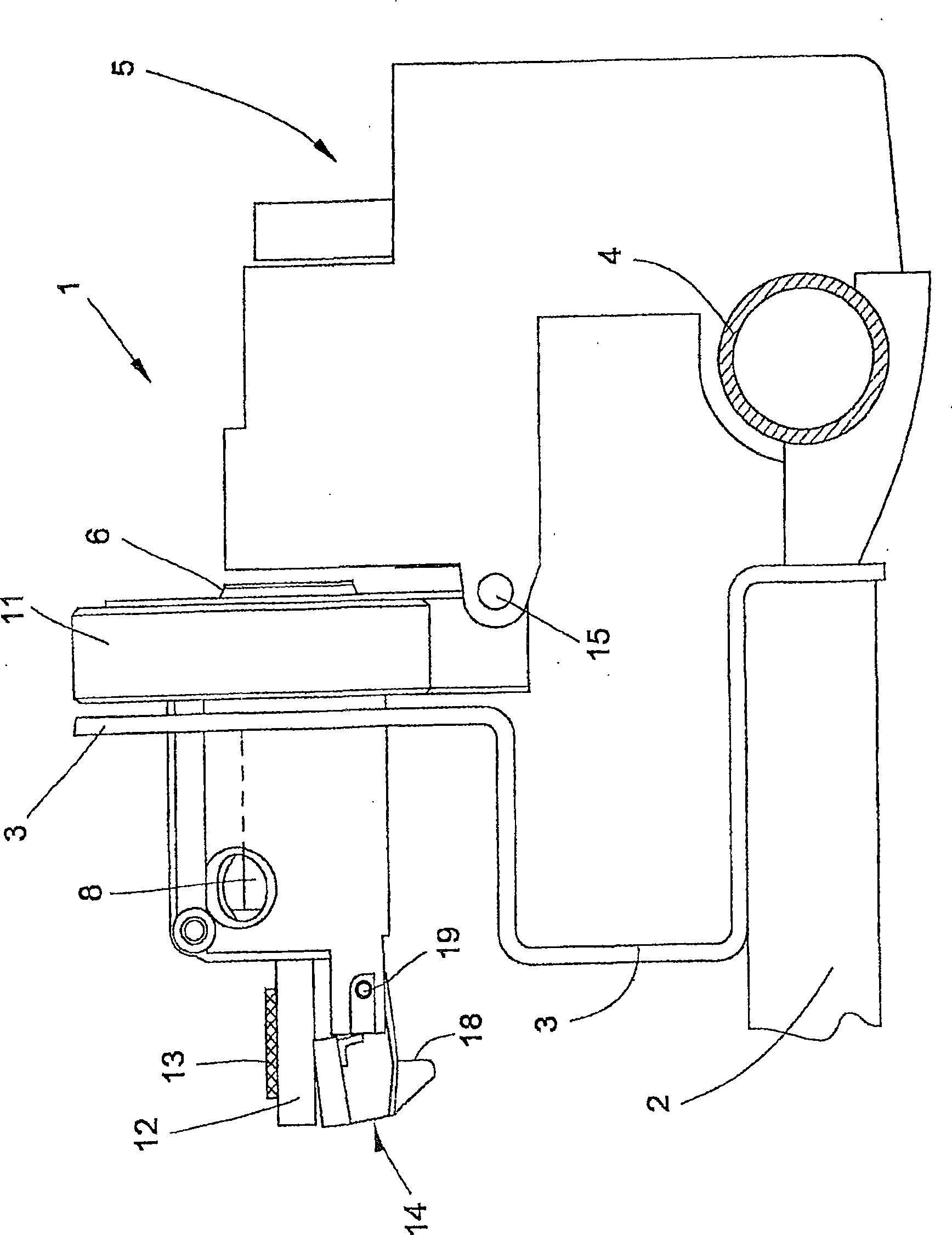

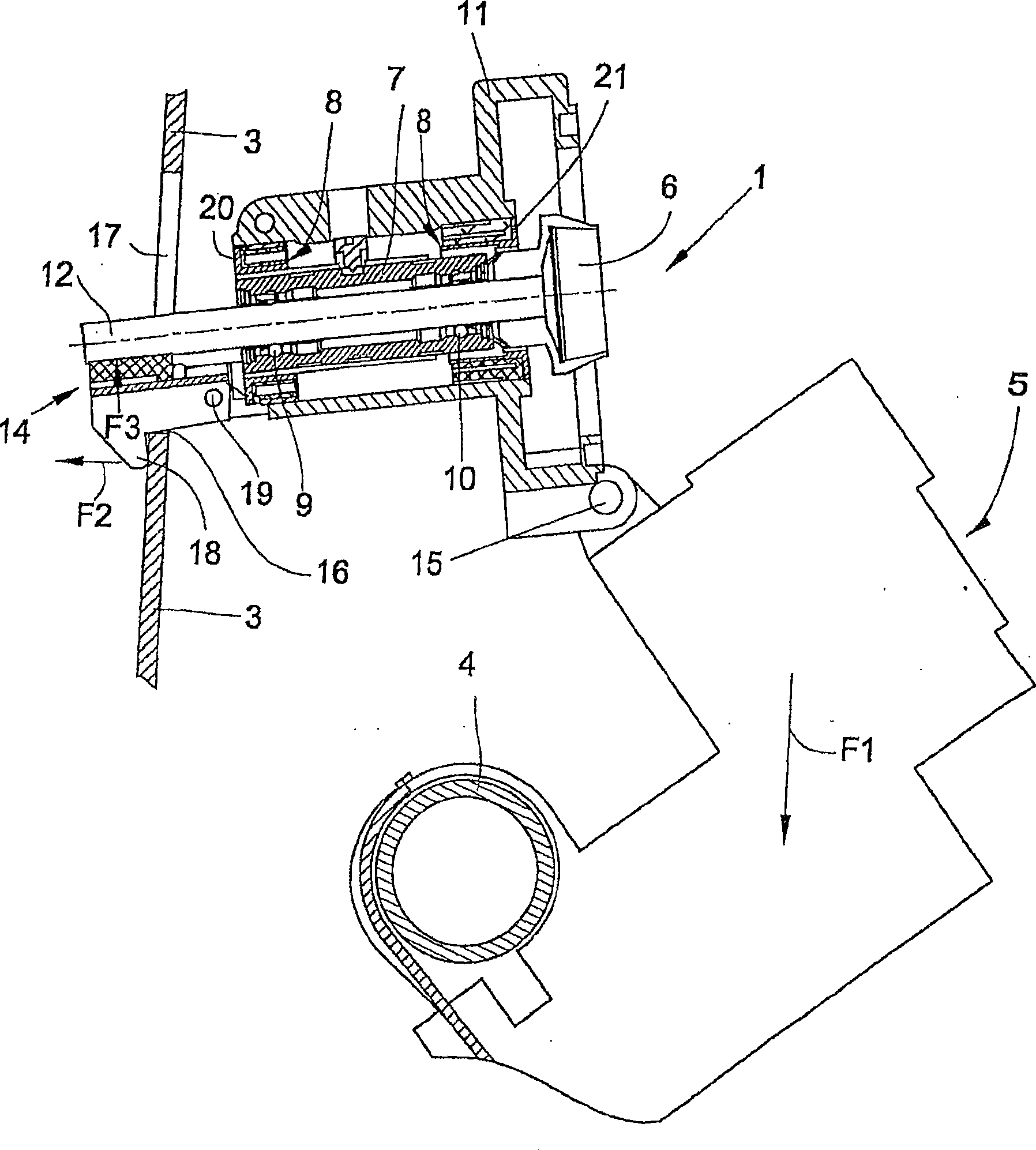

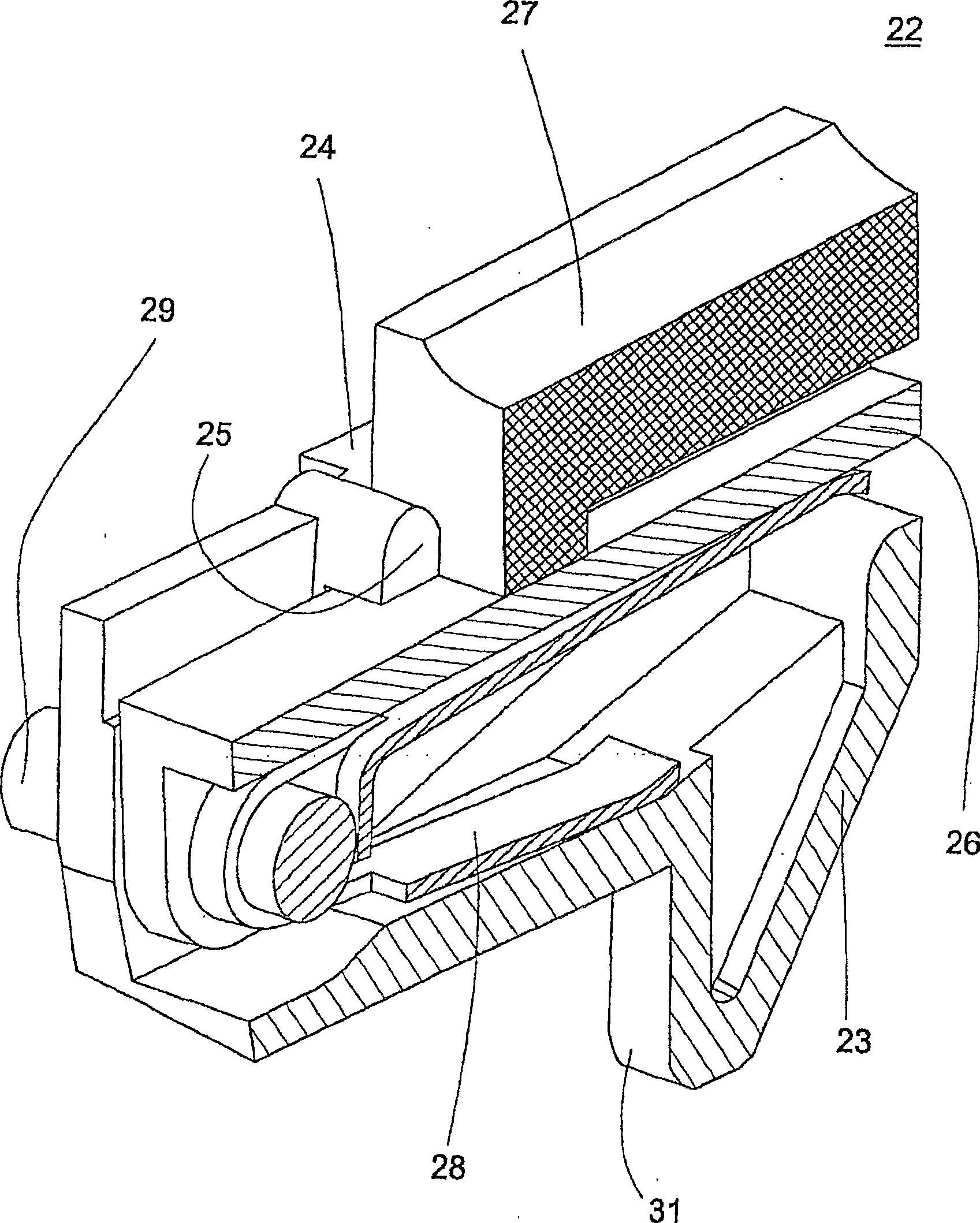

[0022] figure 1 with figure 2 Shows a well-known spinning tank 1. The carrier plate 3 and the pivot tube 4 are fastened to the beam 2 of the rotor spinning machine as part of the frame. The cover 5 includes structural members for fiber supply, fiber opening and fiber feeding to the spinning rotor 6, which are not shown in detail in the drawings. The spinning rotor 6 is installed by a bearing device 7 in the rotor housing, which bearing device includes an elastic shock-absorbing sleeve 8 and ball rows 9 and 10. The elastic shock-absorbing sleeve 8 has supporting flanges 20, 21 on each side, the diameter of these flanges being slightly smaller than the diameter of the hole of the rotor housing 11. The supporting flanges 20 and 21 serve to limit the deflection of the bearing device 7 under load. This prevents the deflection from causing the position of the rotor shaft 12 to tilt (in this tilted position the spinning rotor 6 is in contact with feeding and taking out nozzles, for ex...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap