Cleaning mop

A mop and cleaning technology, which is applied in the field of mop with retractable handle, can solve the problems such as difficulty in putting on and taking off the cleaning tray and mop, uneven force, setting obstacles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The structure of embodiment 1 mop

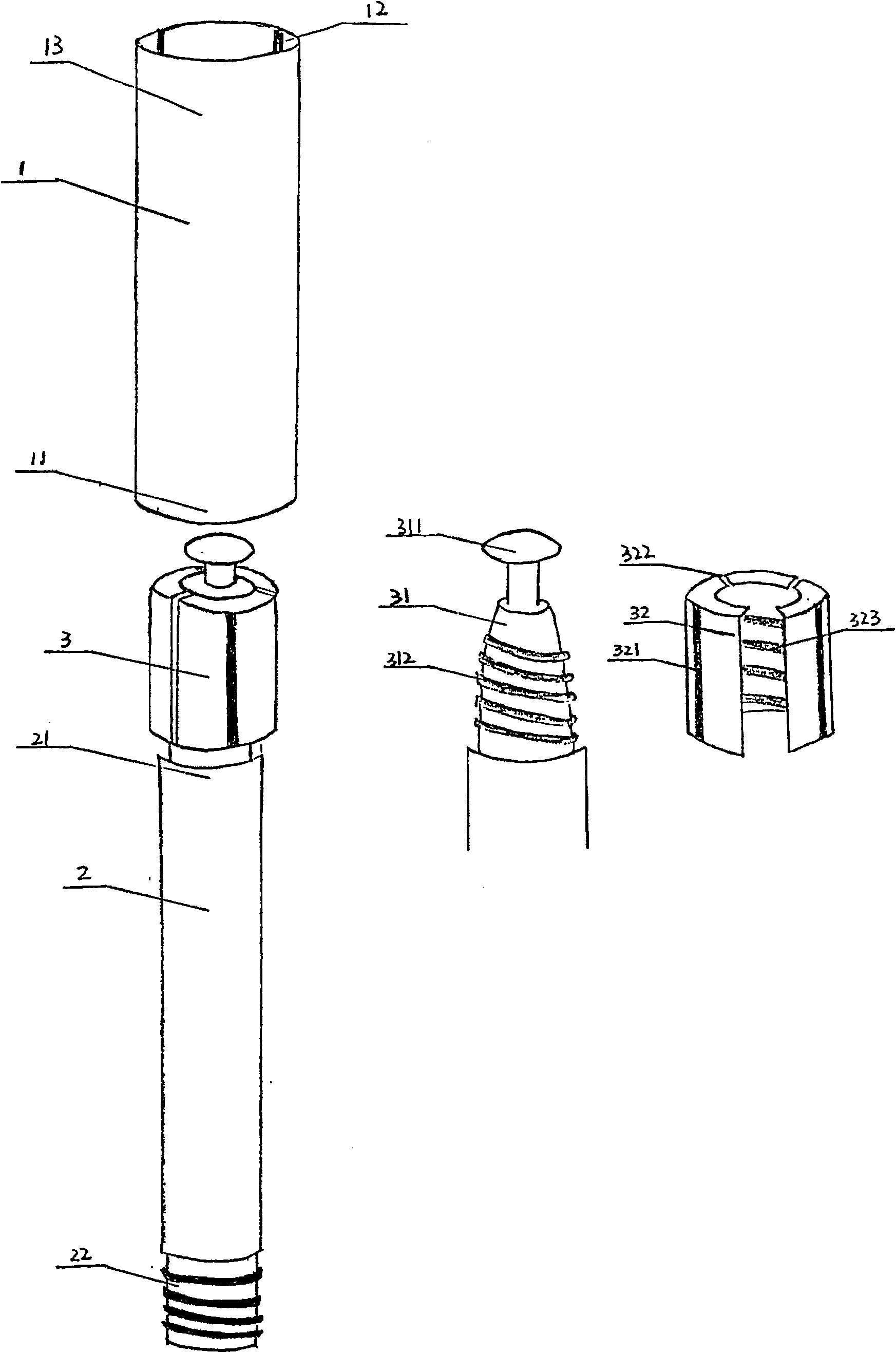

[0059] mop handle

[0060] The mop handle of the present invention is as figure 1 As shown, the handle includes a main rod tube 1 and a secondary rod tube 2, the diameter of the secondary rod tube 2 is smaller than the main rod tube 1, and the upper tube end 21 of the secondary rod tube 2 is inserted into the lower tube of the main rod tube 1 within terminal 11;

[0061] The inner wall of the main rod tube 1 is provided with 2-9 ridges 12 with a thickness of 0.1-0.5 mm (more preferably, 0.1-0.4 mm) in parallel in the radial direction; the width of the ridges is 0.5 -4mm, preferably 1-2mm;

[0062] The upper pipe end 21 of the auxiliary rod pipe 2 is provided with a positioning member 3, and the positioning member 3 includes a screw shaft 31 fixed on the upper pipe end 21 of the auxiliary rod pipe 2, and a movably sleeved The radially non-closed elastic helical sleeve 32 on the helical shaft 31, the top of the helical shaft 31 form...

Embodiment 2

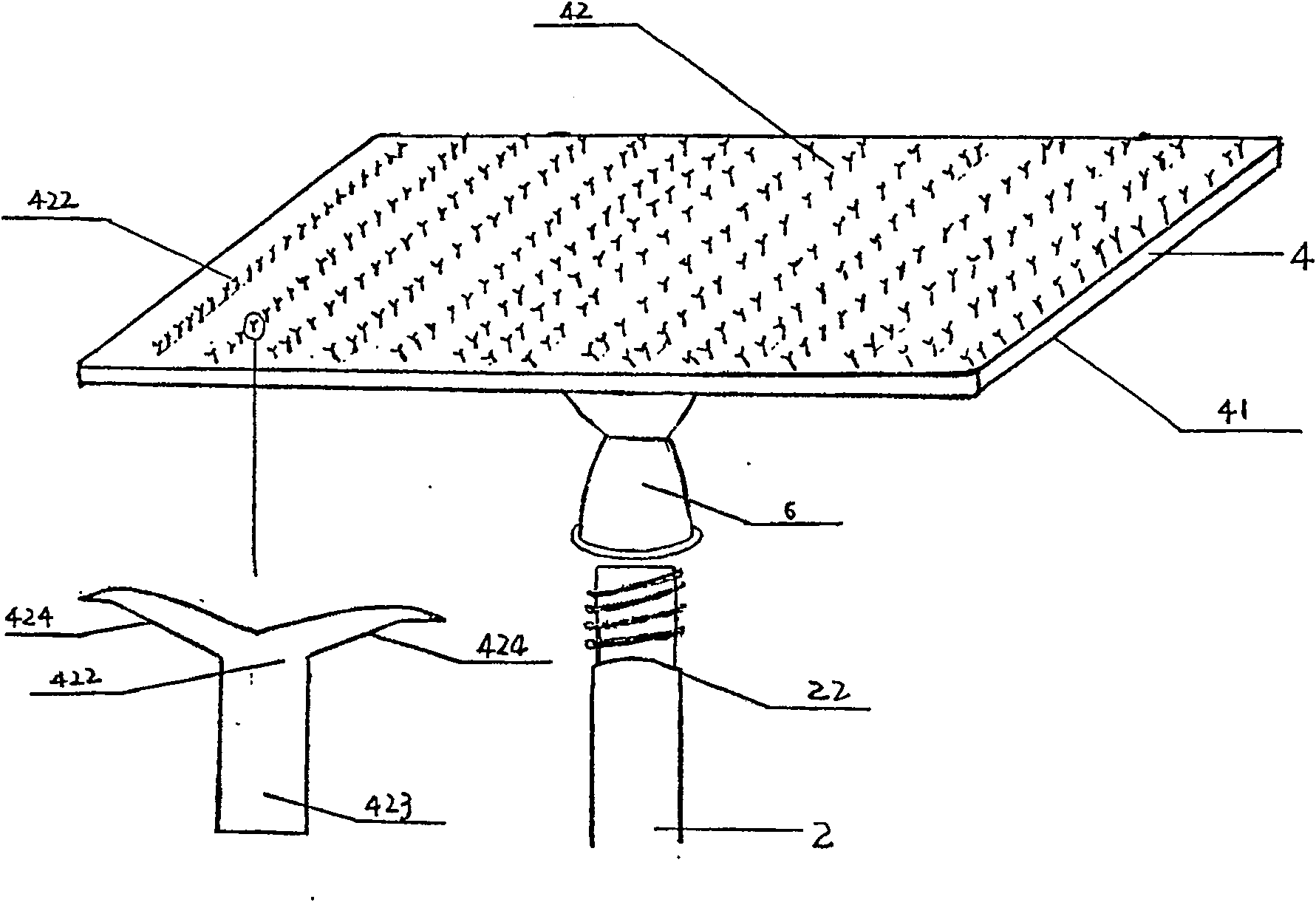

[0107] Embodiment 2 Telescopic adjustment of the mop handle

[0108] When using the mop of the present invention, first adjust the handle of the mop to a suitable length, specifically, including the steps of: inserting the upper tube end 21 of the secondary rod tube 2 into the lower tube end 11 of the main rod tube 1 , so that the sub-rod tube 2 moves in the main rod tube 1, and when it moves to an appropriate position, the sub-rod tube 2 is rotated, thereby driving the elastic helical sleeve 32 sleeved on the helical shaft 31 along the inner diameter of the helical shaft 31 The gradually increasing thread 312 rotates, and after rotating to a certain degree, the groove 322 on the elastic helical sleeve 32 fits with the convex strip 12 on the inner wall of the main rod tube 1, thereby preventing the elastic helical sleeve 32 from continuing rotate. The cross-sectional view of the main rod pipe 1 is as Figure 5 Shown in A; the cross-sectional view of the matching of the elast...

Embodiment 3

[0110] The stress test of embodiment 3 mop handle

[0111] Determination of the torque of the main rod tube and the secondary rod tube:

[0112] When the secondary rod tube is pulled to the top, tie the top of the main rod tube, and apply a torque at an appropriate point in the middle of the secondary rod tube without slipping. This torque is the torque of the main rod tube and the secondary rod tube.

[0113] Determination of the push-pull force after the telescopic rod is locked:

[0114] Fully stretch the main rod tube and the auxiliary rod tube, tighten them with a torque of 7kgf.cm, and push back the thrust at the top;

[0115] Fully compress the main rod tube and the sub rod tube, tighten it with 7kgf.cm torque, and pull it out at the top.

[0116] When the telescopic rod is retracted with a torque of 10kgf.cm, one end is tied to the handle, and the other end is tied to the lower end. The vertical force value is the axial tension of the telescopic rod.

[0117] testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com