Method for automatically zeroizing a universal edger stand

A technology of edge rolling machine and stand, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve problems such as unusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further details and advantages of the invention will become apparent from the following detailed description of a number of non-limiting embodiments with reference to the accompanying drawings, in which:

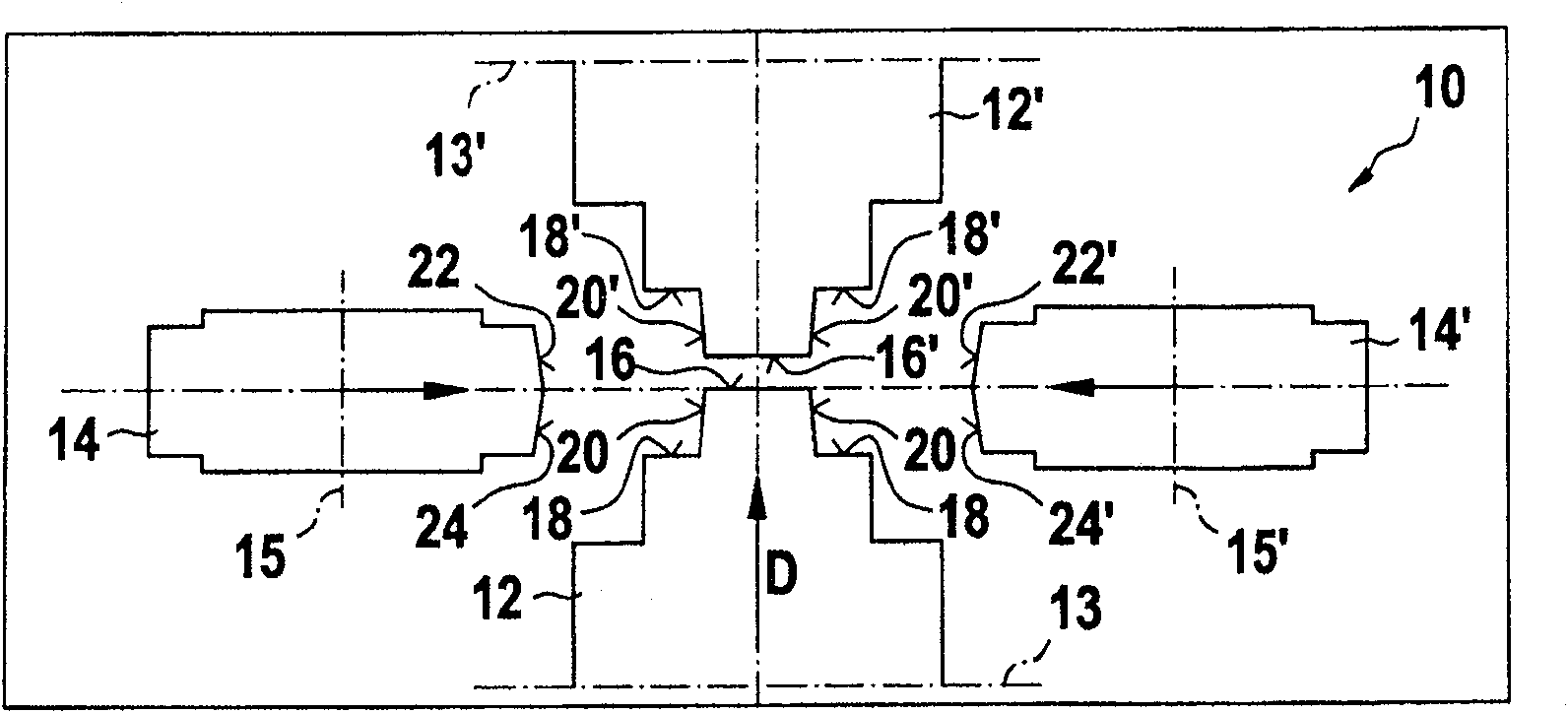

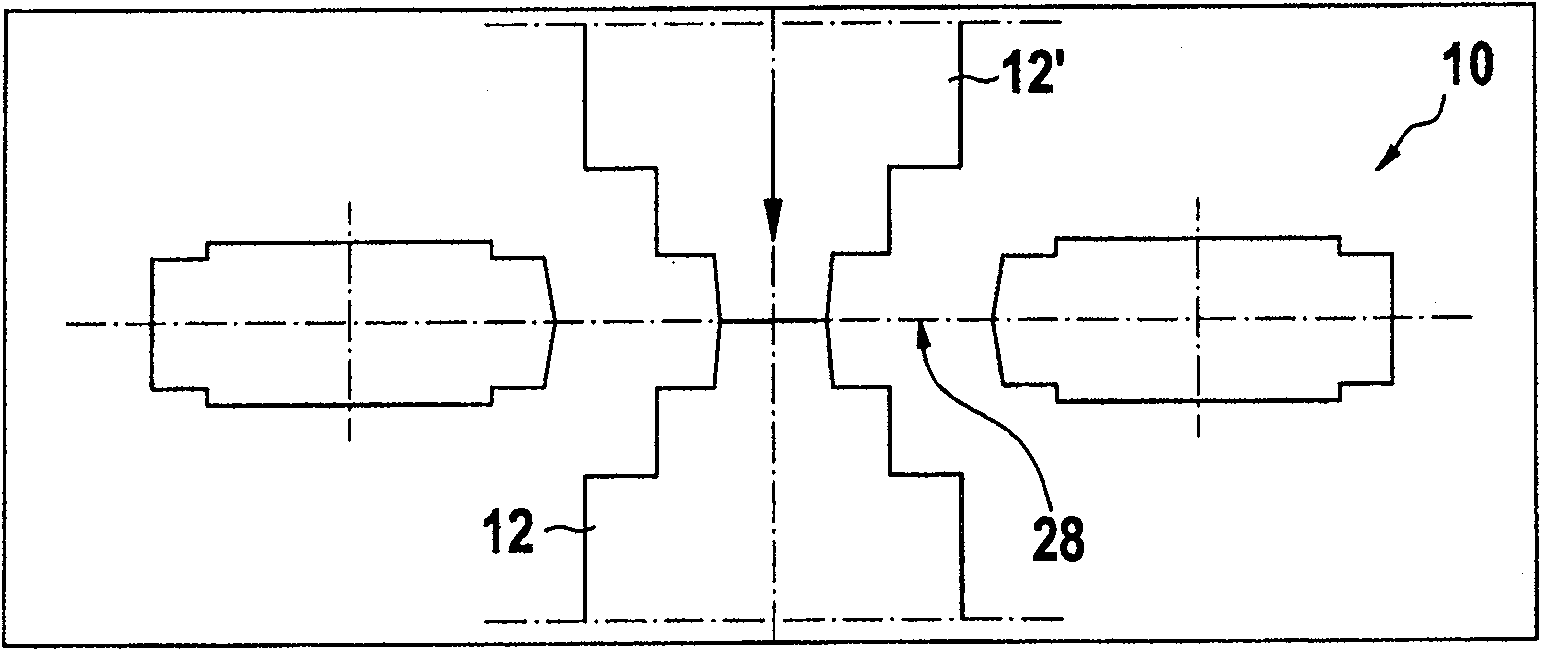

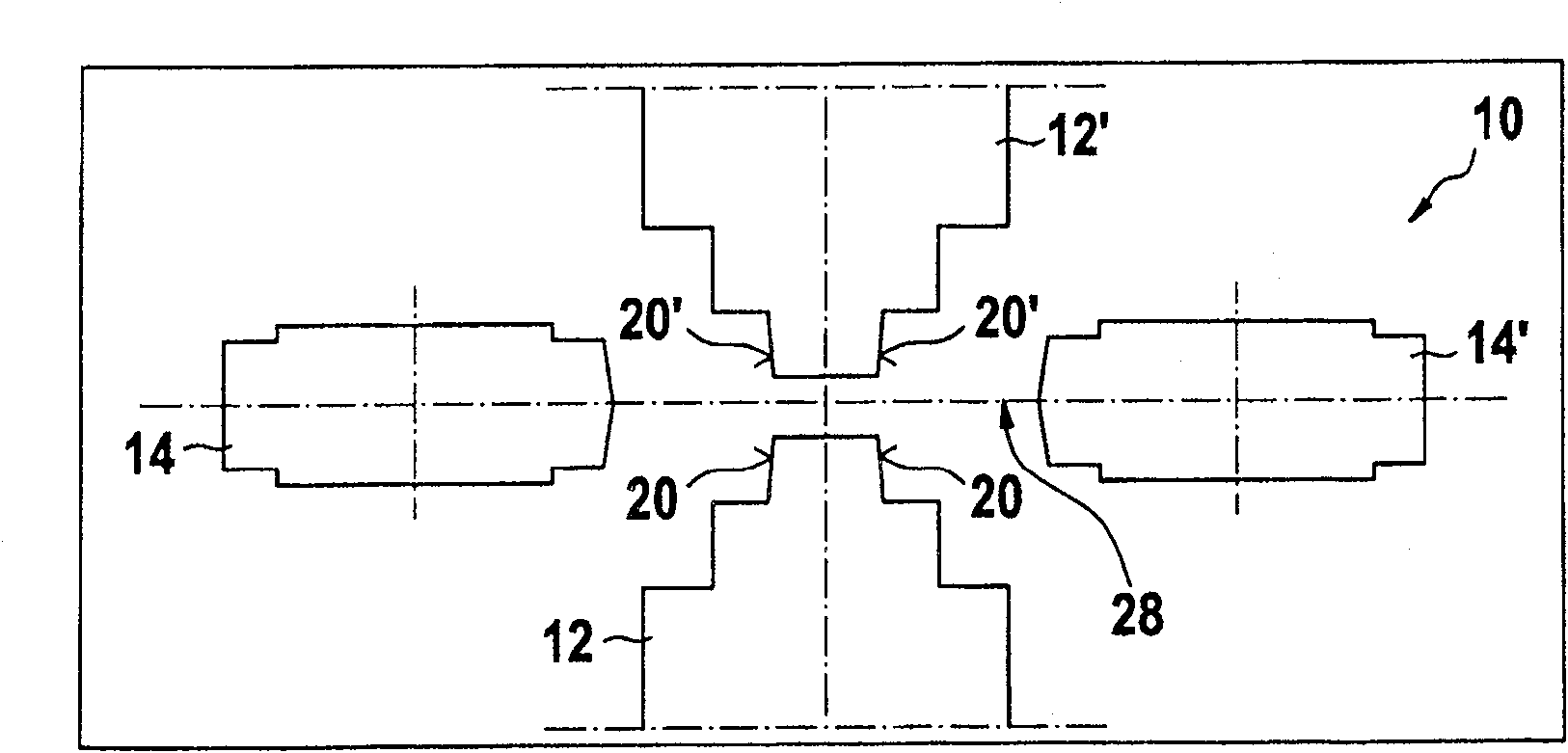

[0021] Figure 1 to Figure 6 Schematic illustration of the rolls of a Universal Edger Stand (UE Stand) for rolling H-section products with a web and two flanges, such as H-beams or H-sheet piles Group 10. The roll set 10 includes: a pair of horizontal rolls 12, 12' (only one half shown), each roll 12, 12' having a horizontal axis of rotation 13, 13'; and a pair of vertical rolls 14, 14', each 14, 14' has a vertical axis of rotation 15, 15'. Each horizontal roll 12, 12' has: a cylindrical rolling surface 16, 16' for rolling the H-section web; two shoulder rolling surfaces 18, 18' for flange rolling. The ends are rolled; and the two conical rolled sides 20, 20'. Each vertical roll 14, 14' has a lower conical rolling surface 24, 24' cooperating with one of the two con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com