Piezoelectric type high-rigidity intermediate frequency vibrating knife handle used for producing hole

A piezoelectric, high-rigidity technology, used in fluids that utilize vibration, manufacturing tools, clamping, etc., can solve the problems of low power of electromagnetic exciters, poor rigidity of process systems, and limited application scope of vibration hole-making technology. Achieve the effect of reducing vibration and noise, reliable performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

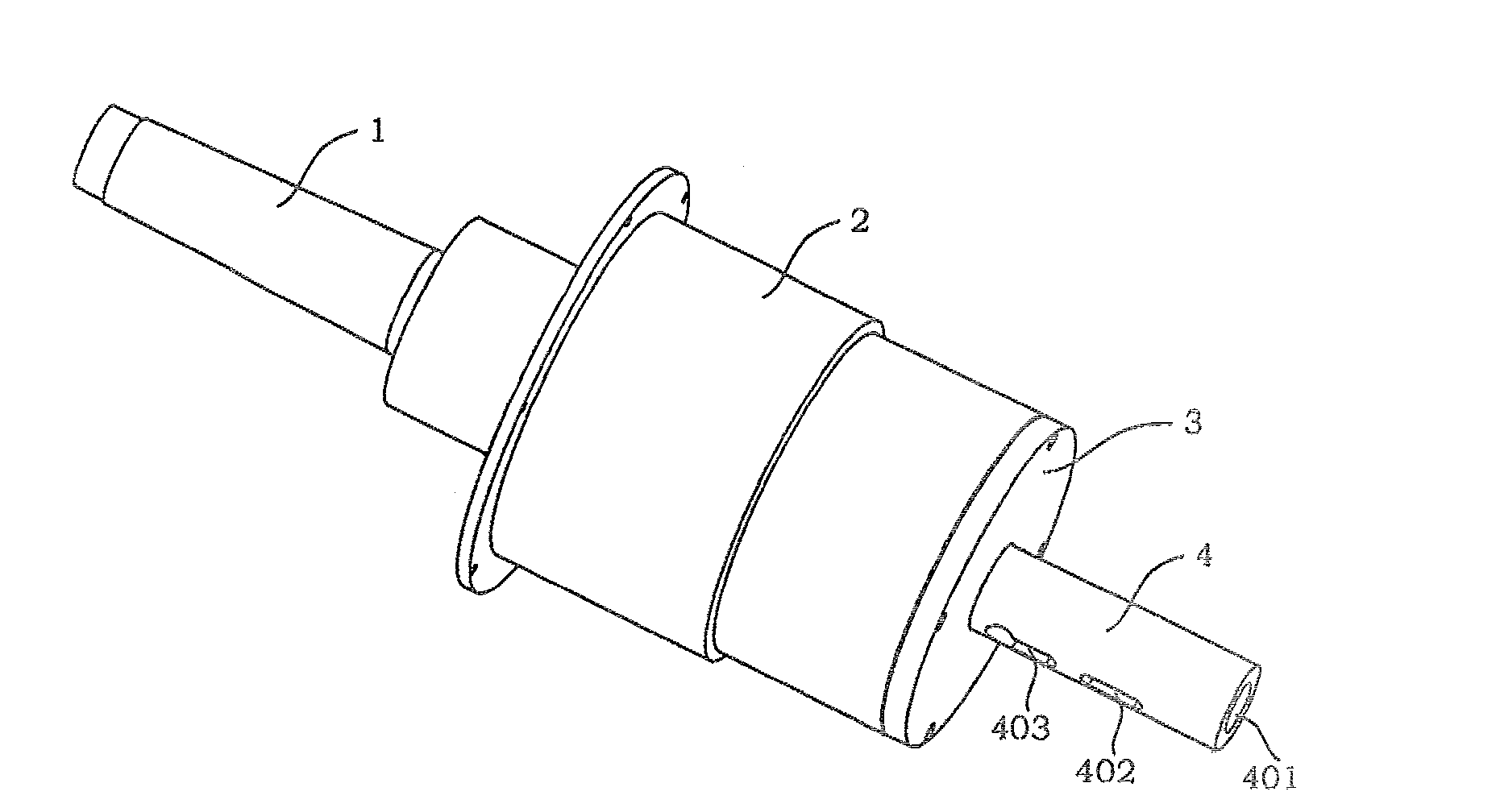

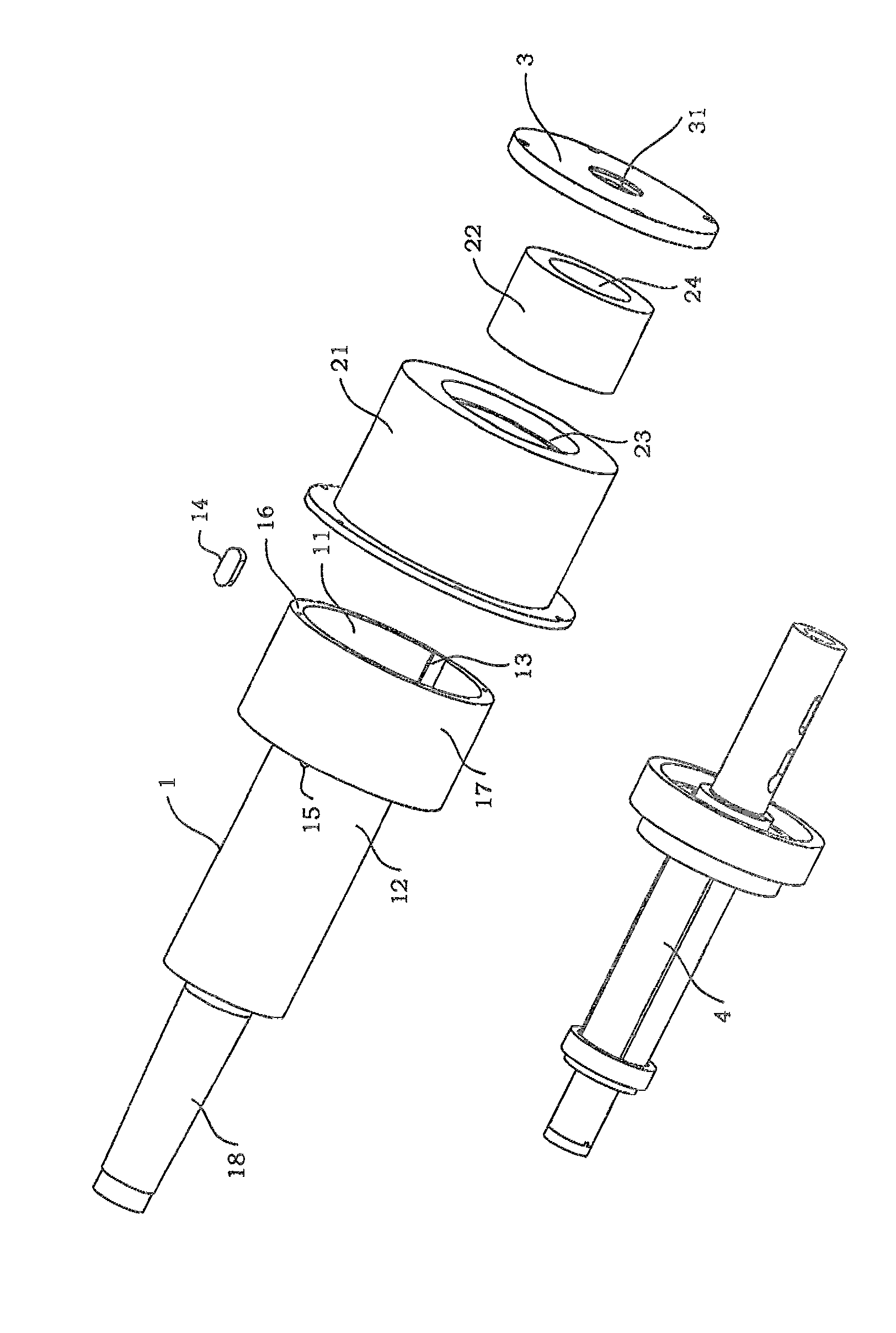

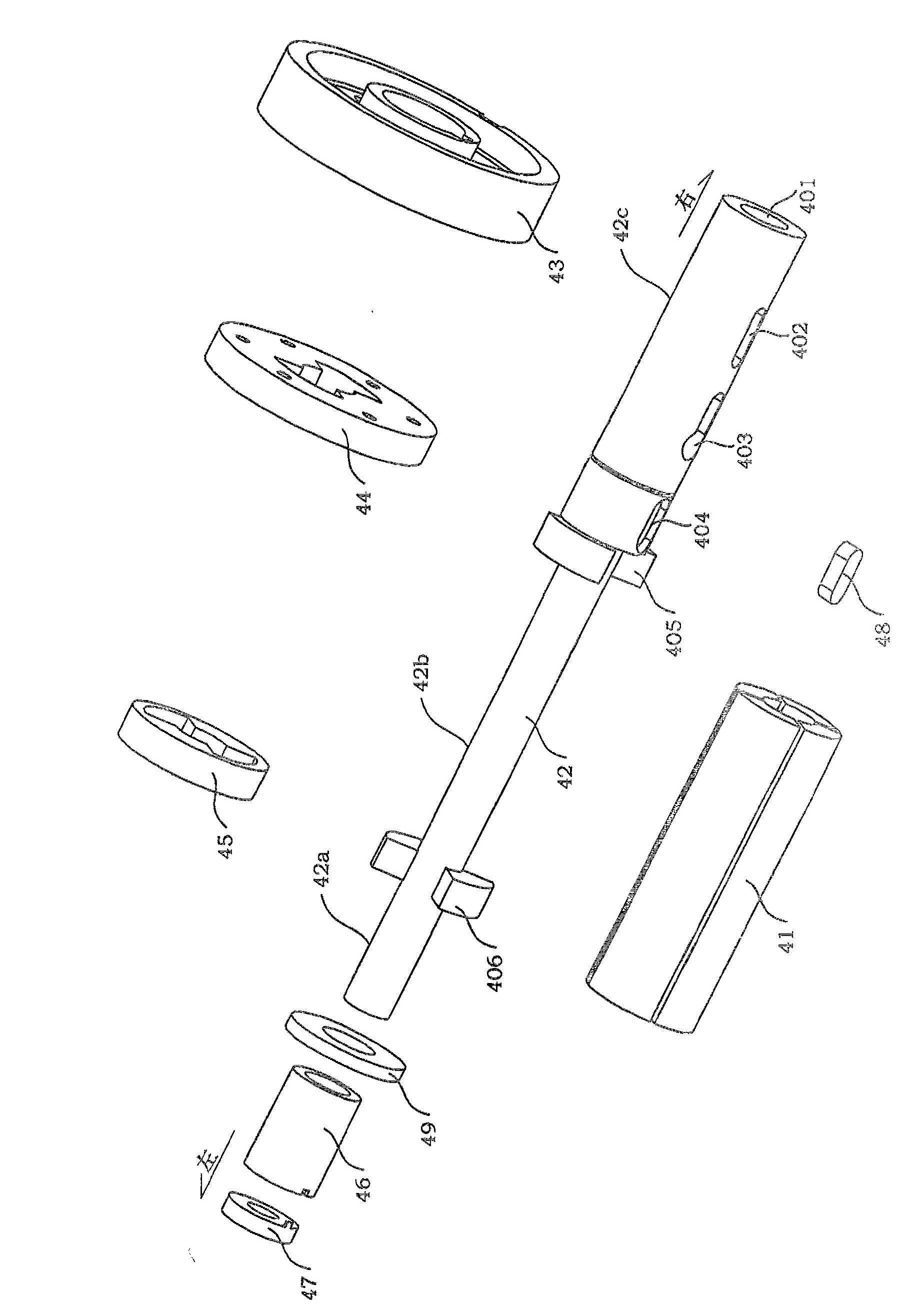

[0018] See figure 1 , figure 2 As shown, the present invention is a piezoelectric high-rigidity medium-frequency vibrating tool holder for vibrating holes, which consists of a Morse cone shell 1, a conductive ring assembly 2, an end cover 3 and a vibrating shaft assembly 4. The vibrating shaft assembly 4 is installed in the Morse cone shell 1, the end cover 3 is installed on the mounting surface 16 of the Morse cone shell 1, and the sealing assembly between the end cover 3 and the Morse cone shell 1 forms a sealed inner cavity 11, ensuring Transformer oil does not leak outside. The Morse cone housing 1 has a wire opening 15 to provide the conductive ring assembly 2 with the power required by the vibrating shaft assembly 4 . The entire vibrating tool holder of the present invention is installed in the main shaft hole of the lathe or the boring machine, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com