High pressure resistance element

A high-voltage resistor and component technology, applied in the field of high-voltage resistor components, can solve problems such as corona discharge, insufficient local insulation, and easy vibration, etc., and achieve the effects of increasing insulation endurance, preventing insulation damage, and avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

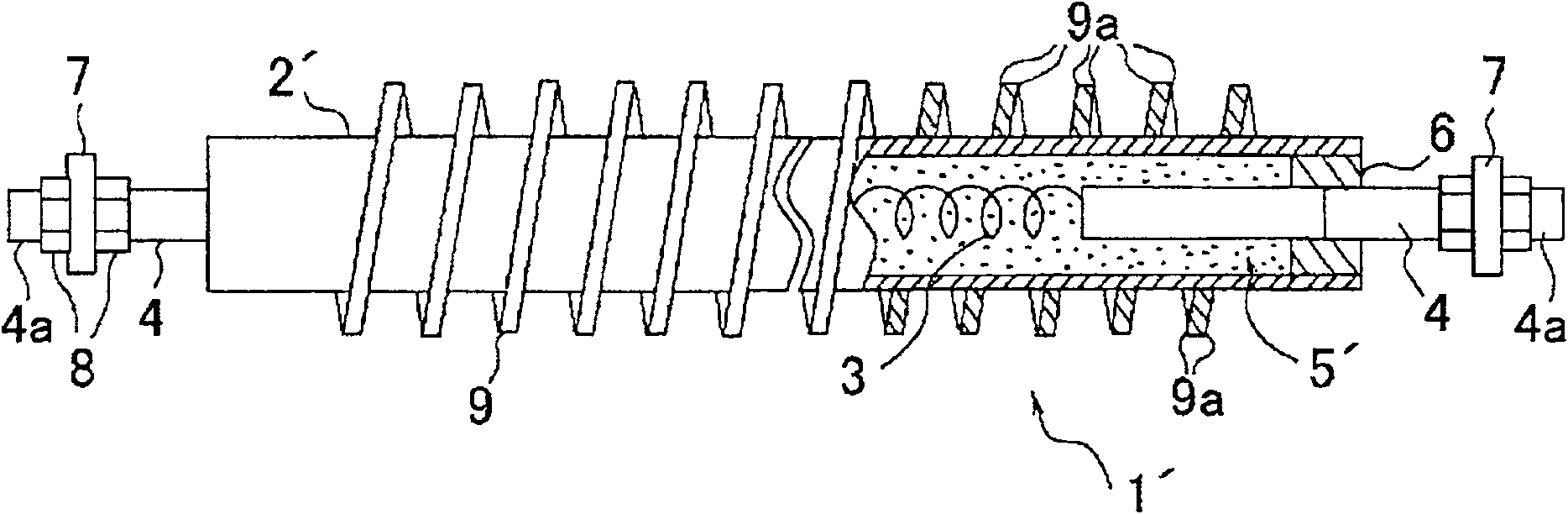

[0049] Embodiments of the present invention will be described with reference to the drawings.

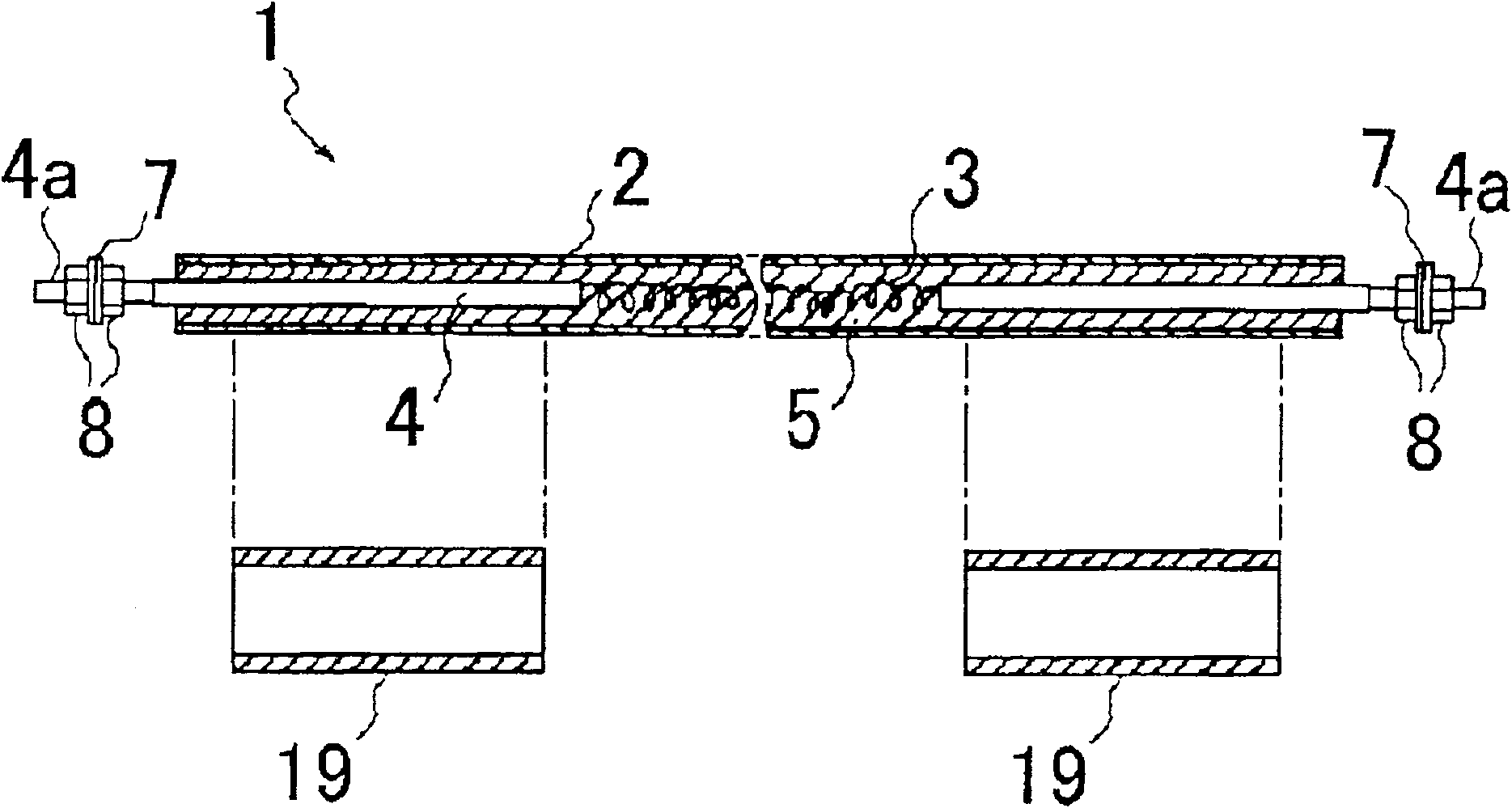

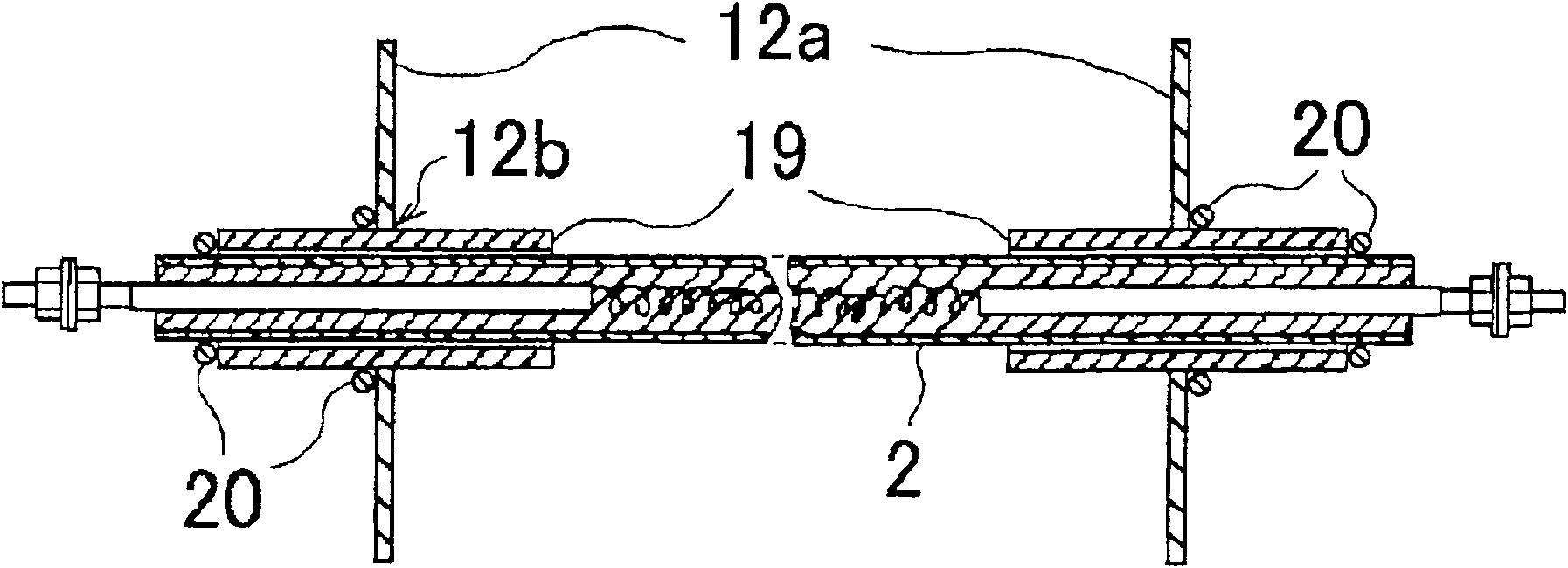

[0050] figure 1 It is a partly omitted cutaway side view showing the high voltage resistance element of the present embodiment with the insulating sleeve removed. figure 2 It is a partly omitted cross-sectional side view showing the mounting state of the distribution board penetrating and straddling both ends.

[0051] In addition, in this embodiment, the same reference numerals are given to the same components, and the same reference numerals without the prime (') at the upper right corner indicate corresponding components of the conventional example.

[0052] In the figure, reference numeral 1 represents the high-voltage resistance element of this embodiment, and reference numeral 2 represents the outer cylinder made of metal. By making the surface smooth and forming a shape that is not easy to discharge, it can satisfy heat dissipation even if there is no spiral knock-off sink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com