Relay with protection cover

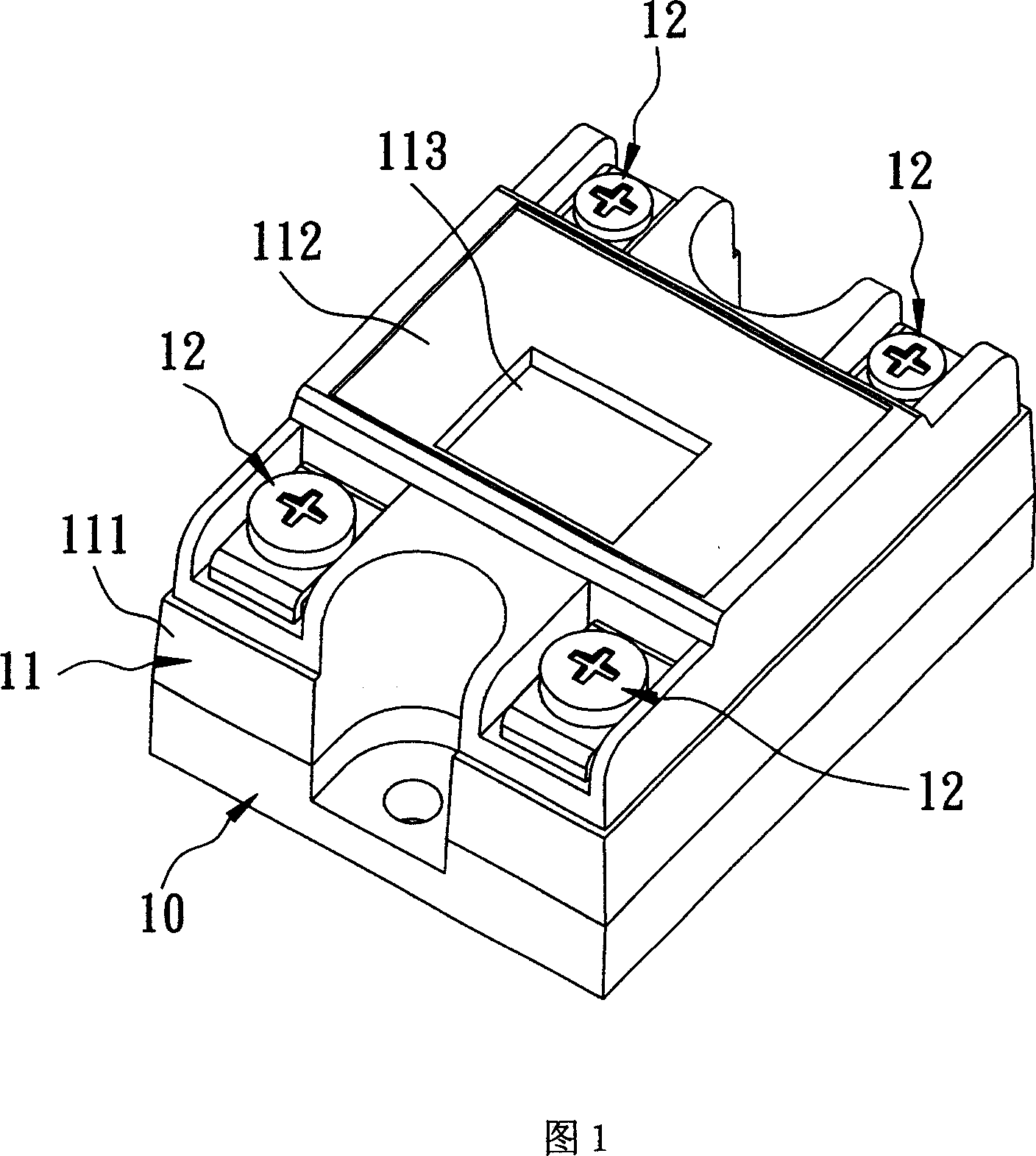

A protective cover and relay technology, applied in the direction of relay ventilation/cooling/heating, relay base/shell/cover, etc., can solve the problems of inconvenient observation of filling degree, easy shaking of the shell 11, overflow of sealing glue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

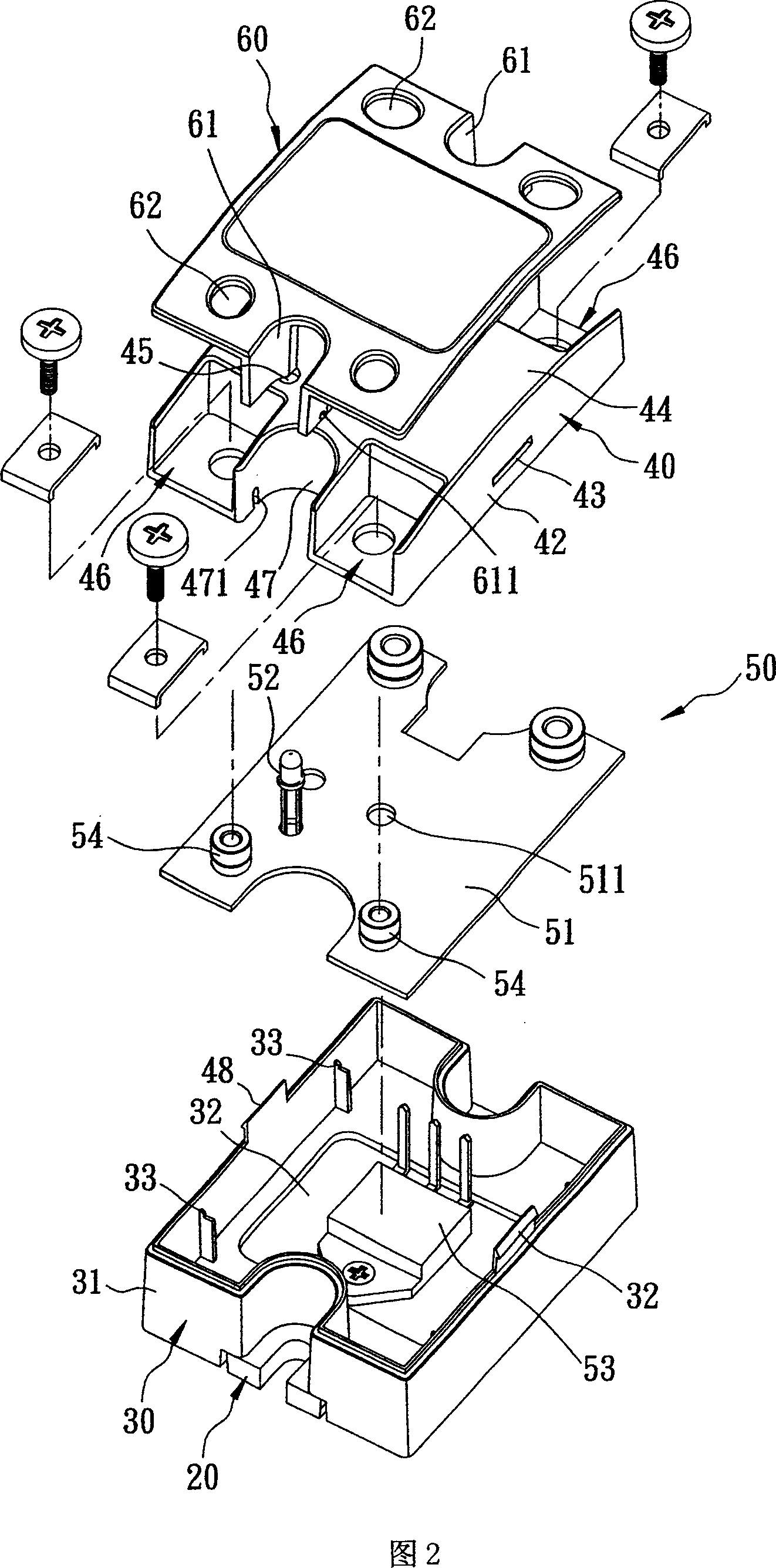

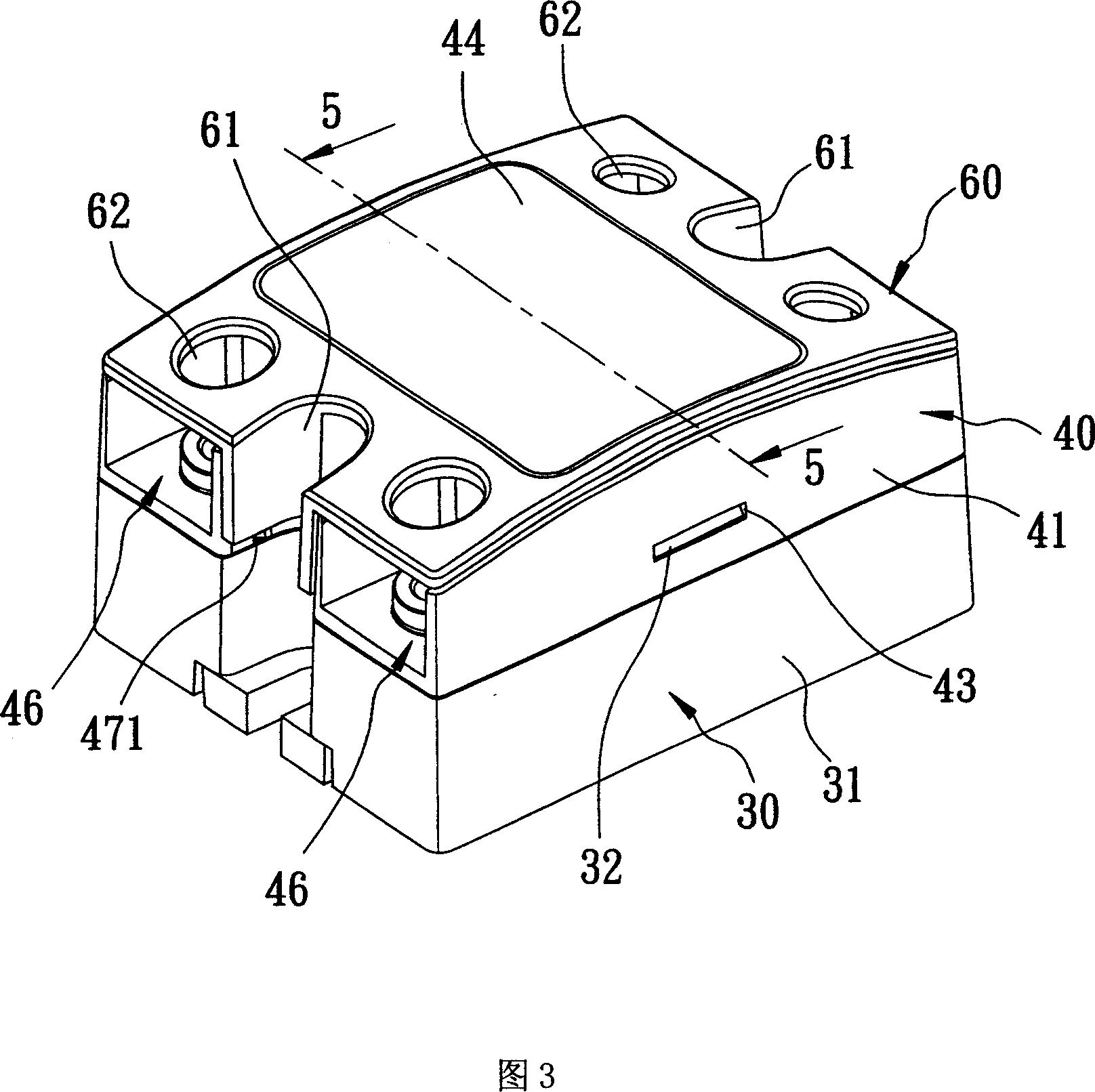

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] As shown in FIGS. 2 , 3 , and 4 , a preferred embodiment of the relay with a protective cover of the present invention includes a bottom plate 20 , a housing 30 , a shell 40 , a control unit 50 , and a protective cover 60 .

[0027] As shown in FIGS. 2 , 3 and 5 , the bottom plate 20 is a heat dissipation plate and includes a bottom wall 21 and a connecting wall 22 .

[0028] The bottom wall 21 has a first plate surface 211 , a second plate surface 212 opposite to the first plate surface 211 , and a surrounding surface 213 connected to the first and second plate surfaces 211 , 212 .

[0029] The connecting wall 22 protrudes from the surrounding surface 213 and has a concave portion 221 extending to the surrounding surface 213 and being concave relative to the second plate surface 212 .

[0030] The casing 30 is directly embedded in the periphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com