Solid flexible seal method for boilers in power plants

A flexible sealing and boiler technology, applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve problems such as affecting the sealing effect and cracking of the sealing layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

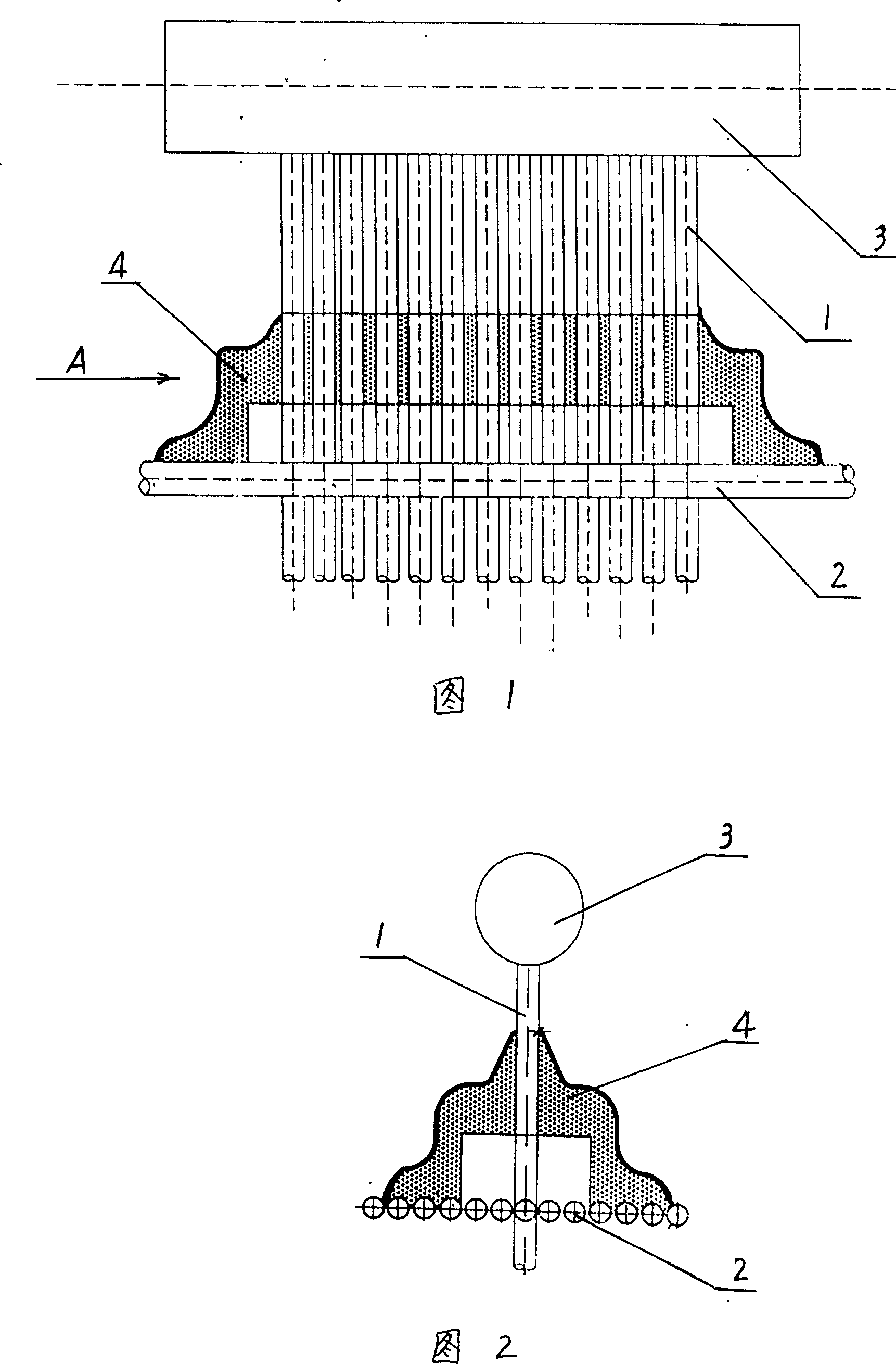

[0010] As can be seen from the accompanying drawings, the present invention includes a water wall 1, a wall pipe 2, a steam drum 3 and a sealing layer 4, and is characterized in that: the wall pipe 2 and the water wall 1 are welded with steel nails, and the sealing layer 4 The ceramic fiber cotton and the steel mesh are sequentially interspersed on the steel nails, and after being bonded to each other, the refractory castable is laid on the steel mesh, and the steel mesh and the steel nails are firmly welded. In this way, the sealing layer 4 forms a three-dimensional sealing body at the leaking part of the boiler. Since the materials used are all flexible materials, they have the characteristics of absorbing and adjusting expansion. When the boiler heats up and expands, it can effectively absorb the expansion. The position expands and expands, and is not rigidly restraining expansion, and this has just certainly solved boiler leakage ash problem, has reached the purpose of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com