Method for detecting 3D defects on surface of belt material

A technology of strip surface and detection method, applied in the direction of measuring device, material analysis, material analysis by optical means, etc., can solve the problems of inability to obtain the contour shape of defects, inability to detect defects, and too late to deal with them, so as to shorten the initial inspection. The effect of time, imaging speed, and imaging space is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

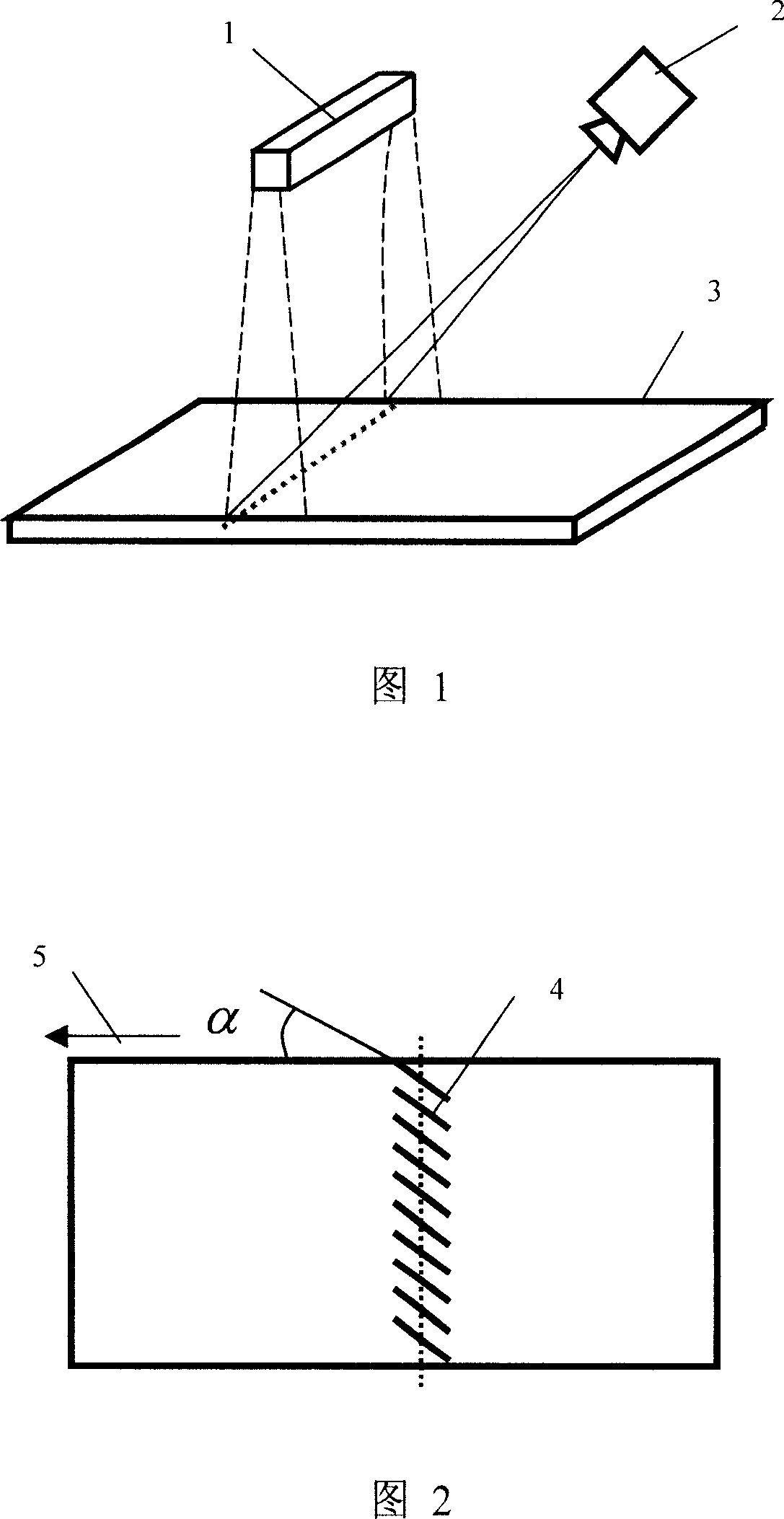

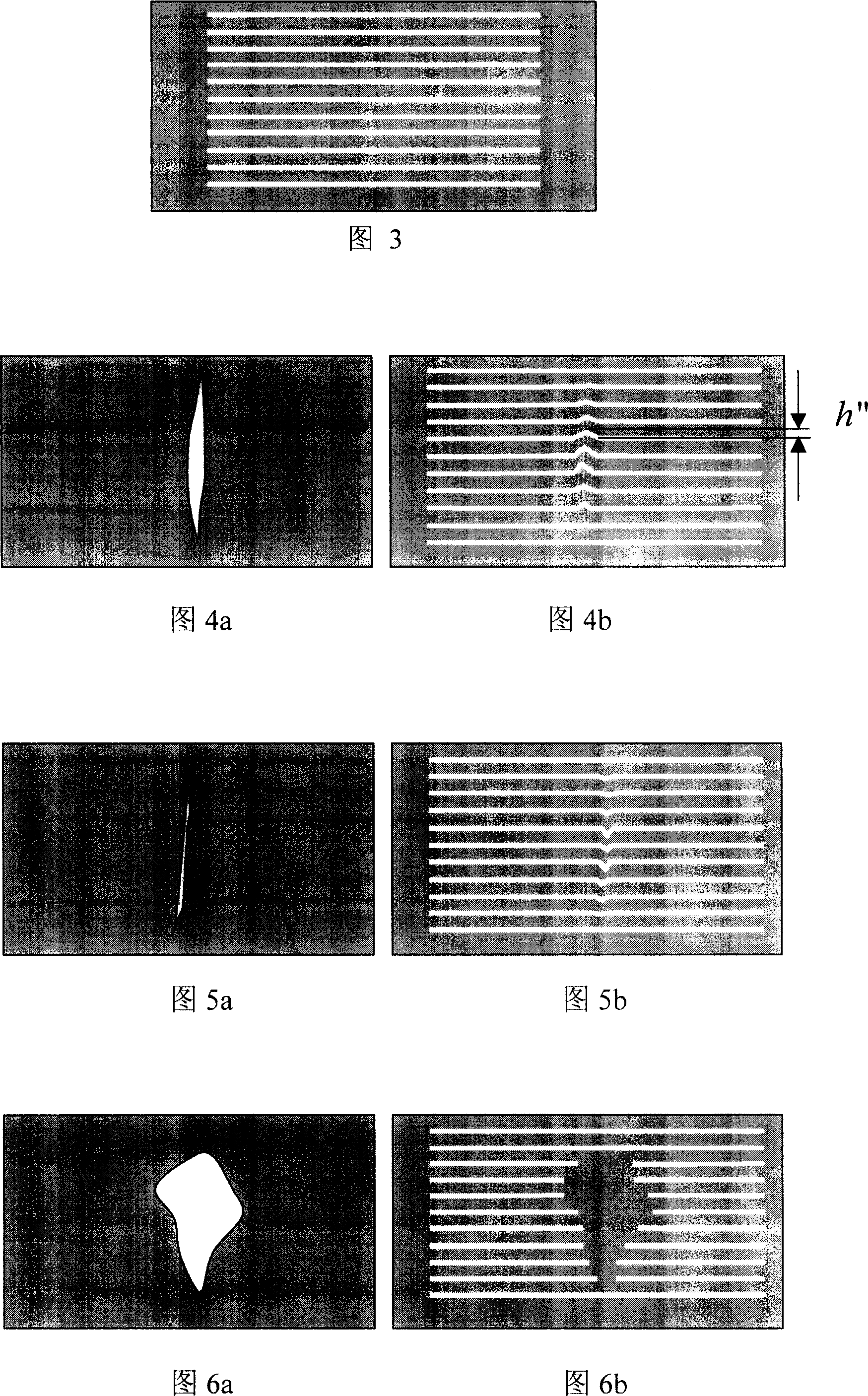

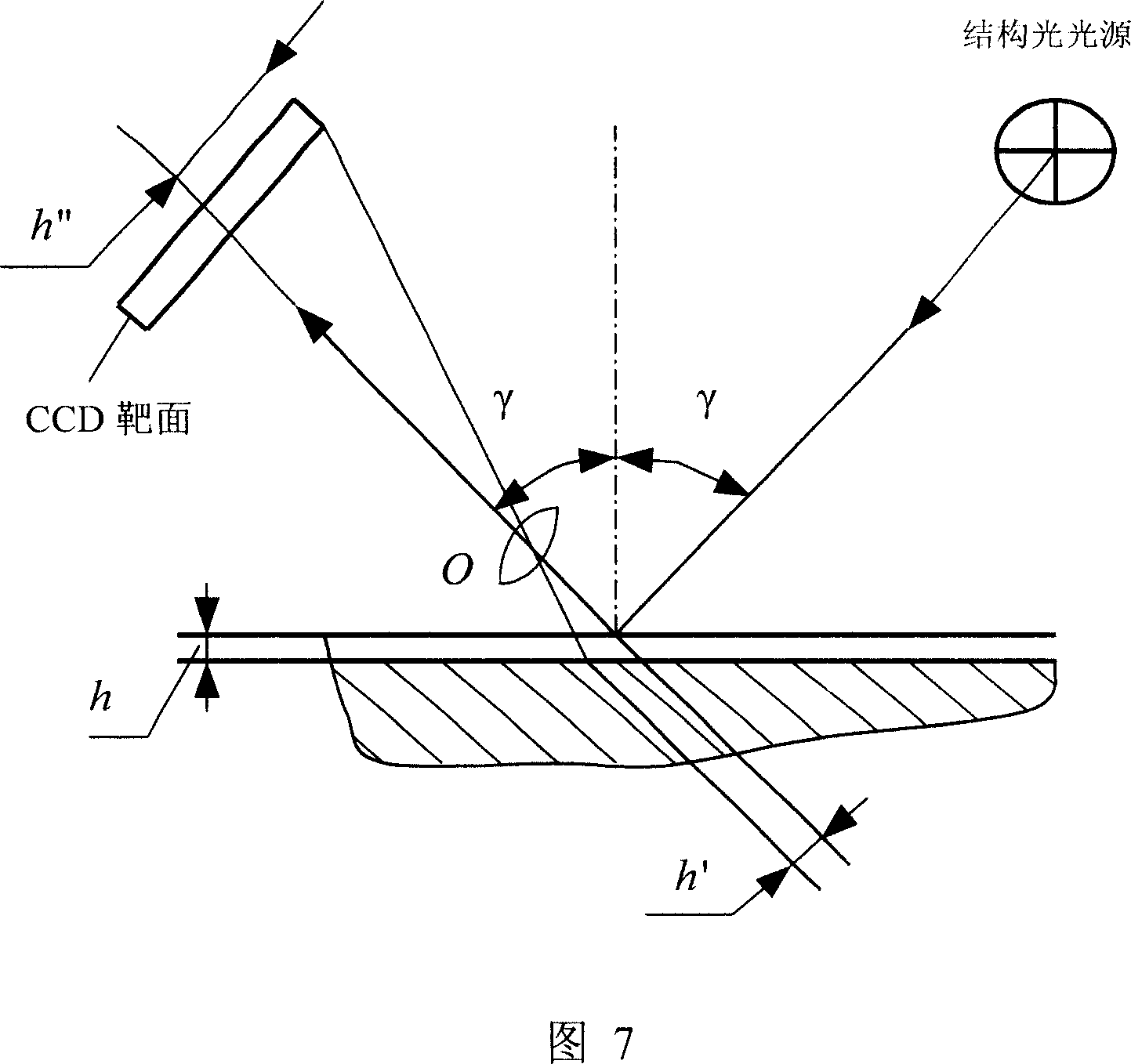

[0020] Referring to Fig. 1 and Fig. 2, a method for detecting three-dimensional defects on the surface of a steel strip is to use a structured light source 1 to project an array of light strips 4 of parallel short oblique lines from the front of the strip 3 to the surface of the moving strip 3, and the reflected light is captured The line-scanning CCD camera 2 placed above the steel strip 3 receives it, conducts preliminary judgment on the collected images, and classifies the defects according to the shape changes of the lines on the images. The light strips 4 of the array of parallel short oblique lines are projected onto the steel strip surface as shown in FIG. 2 . α (0°<α<90°) is the angle between the strip steel movement direction 5 and the light array 4 direction, and the α angle ensures that the strip steel 3 can be accurately detected when the line scan CCD camera 2 (line scan image sensor) is used. Surface three-dimensional defects.

[0021] Referring to Fig. 3, if th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com