Passenger transmitter

A technology of passenger conveying equipment and pedals, which is used in transportation and packaging, escalators, etc., can solve the problems of passengers' riding comfort, and achieve the effect of comfortable riding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

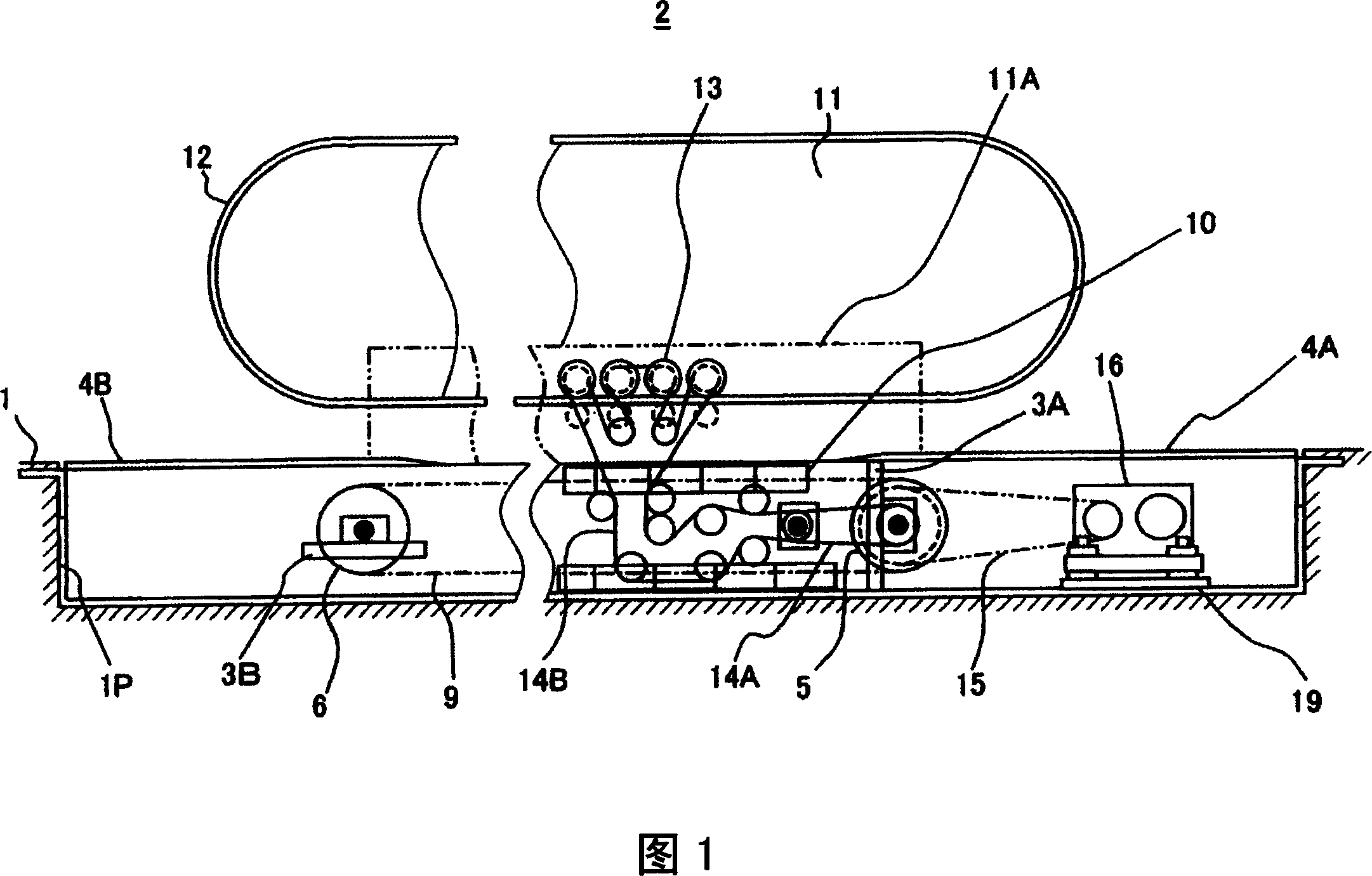

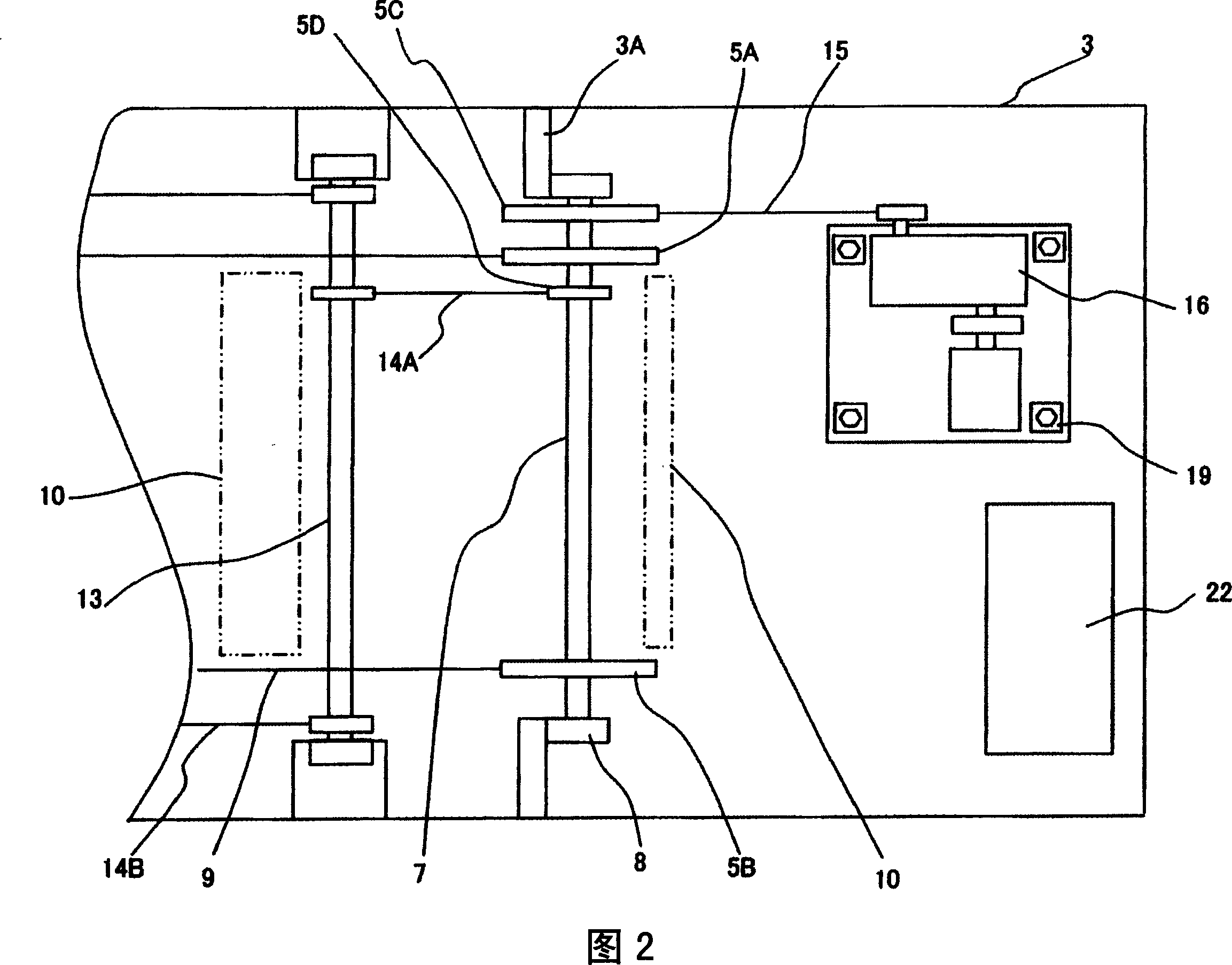

[0044] First, the electric channel 2 in this embodiment is the same as the existing electric channel shown in Fig. 1 and Fig. 2, and has the following structure.

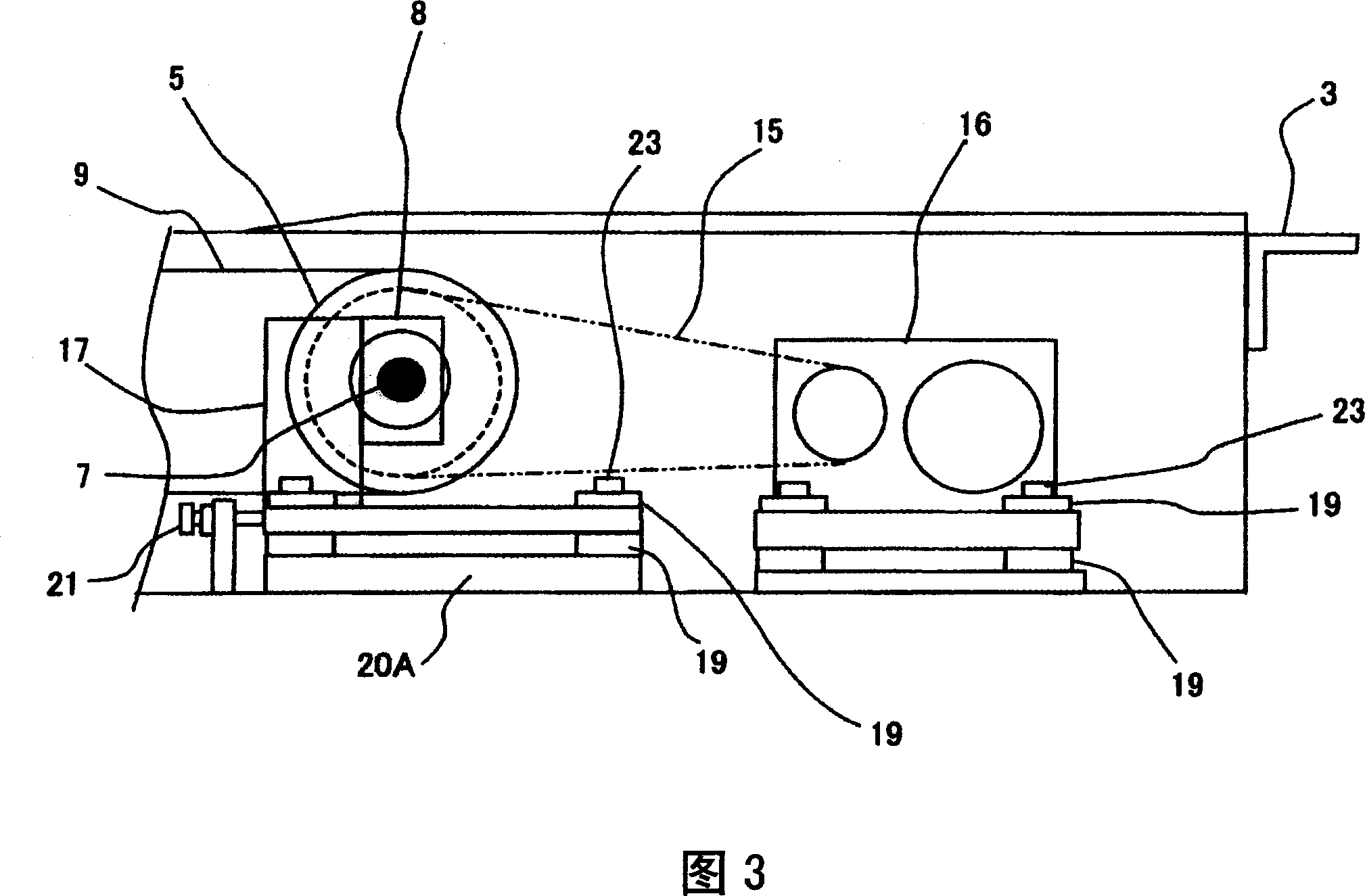

[0045] The motorized tunnel 2, which is one type of passenger conveyance equipment, has a frame formed by a frame body 3 housed in a pit 1P formed on the floor surface 1 of the building, and main equipment is installed in the frame body 3. In addition, on the upper parts of both ends of the frame body 3 in the longitudinal direction, landing floors 4A, 4B flush with the floor surface 1 are respectively provided, and the pedal driving sprocket 5 and the pedal driven sprocket 6 are pivotally supported on these landing floors. Near the lower part of the drop floor 4A, 4B.

[0046] Here, the pedal drive sprocket 5 has a pair of pedal drive sprockets 5A, 5B fixedly spaced apart on the drive shaft 7, and one of the pedal drive sprockets 5A is provided on the inner side in the width direction with a pin coaxial with the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com