Cover member fastening method and fastening structure for a head cover

A technology for cylinder head cover and cover parts, which is applied to engine components, engine sealing, engine sealing devices, etc., can solve the problems of poor vibration and noise prevention effect, difficult abutting parts, and difficulty in maintaining uniform sealing surfaces, and achieves suppression of The effect of vibration transmission, reduction of contact area, and reduction of vibration transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

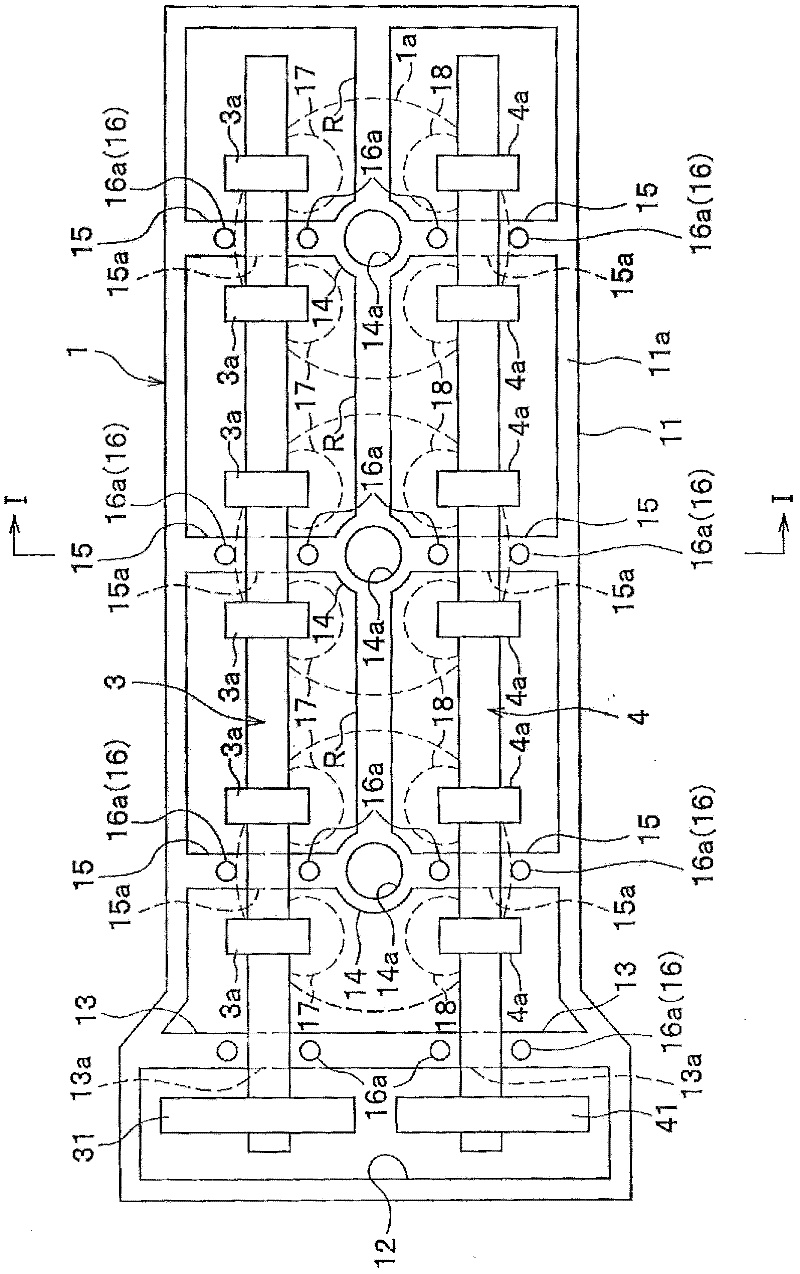

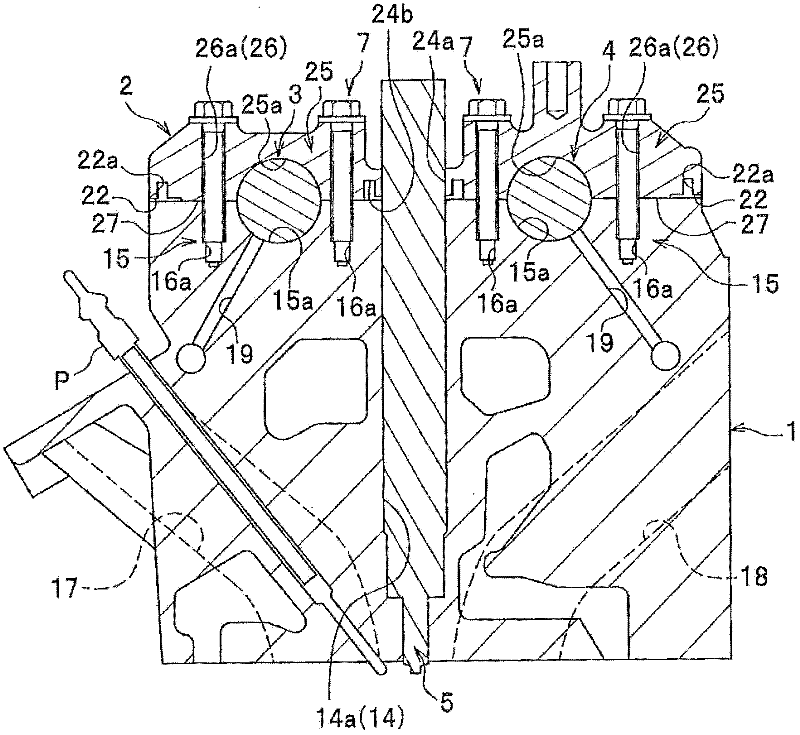

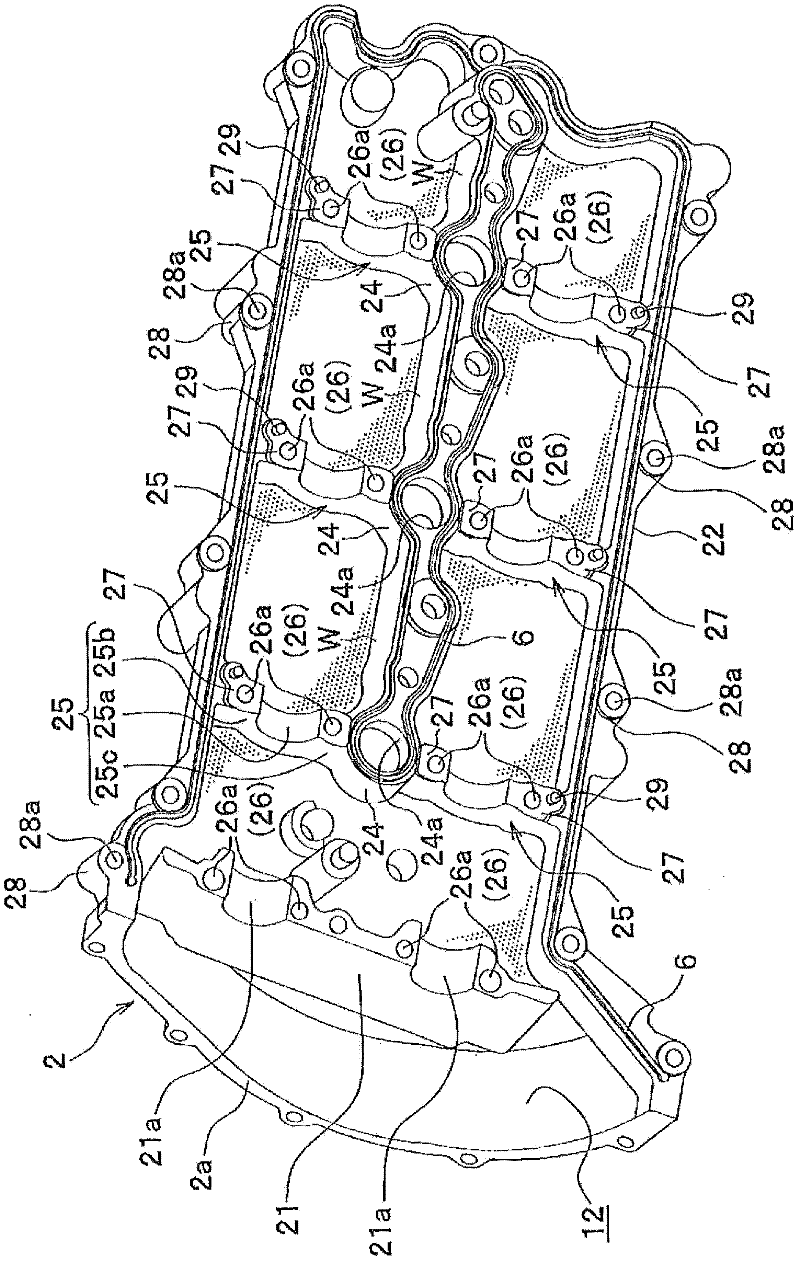

[0034] Embodiments of the present invention will be described in detail with reference to the drawings. In the description, the same reference numerals are assigned to the same elements, and overlapping descriptions are omitted. Also, when directions are shown in the description, sometimes the figure 1 The shown axial direction of the camshafts 3 and 4 is referred to as the longitudinal direction, and the direction perpendicular to the axis is referred to as the lateral direction. And, will figure 1 The axial direction (direction perpendicular to the paper surface) of the shown combustion chamber 1a will be described as the vertical direction.

[0035] Such as figure 1 , figure 2As shown, a cylinder head 1 is a part of an inline three-cylinder engine, and holds an intake-side camshaft 3 and an exhaust-side camshaft 4 in a rotatable manner. Around the cylinder head 1, an outer peripheral wall 11 is provided in a square frame shape, and a cylinder head side mounting surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com