Base for low pressure discharge lamps

A technology for low-pressure discharge lamps and lamp caps, applied in discharge lamps, discharge tubes, circuits, etc., can solve the problems of flammability, complicated manufacturing process, poor thermal conductivity, etc., and achieve the effect of not being easy to catch fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

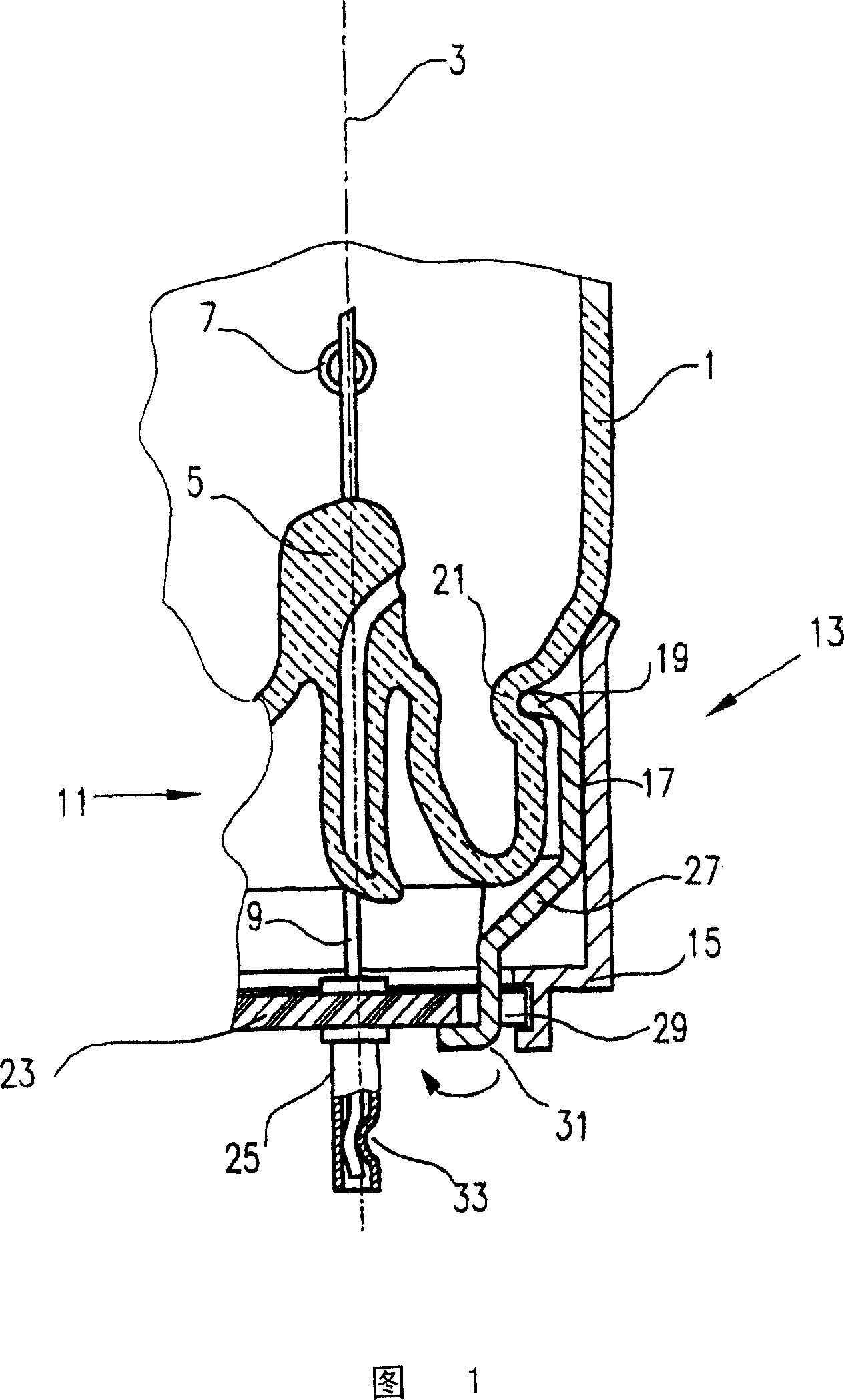

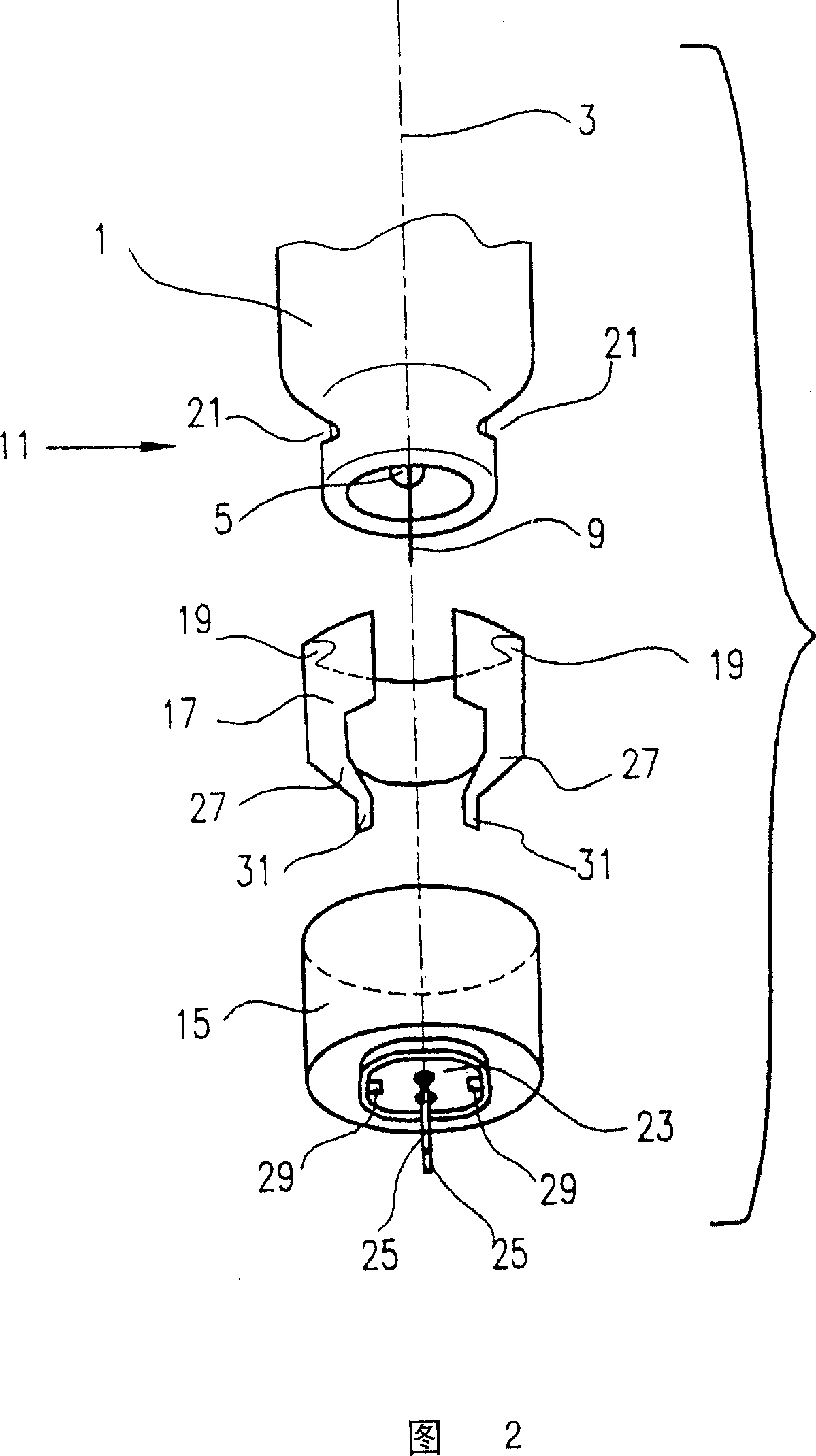

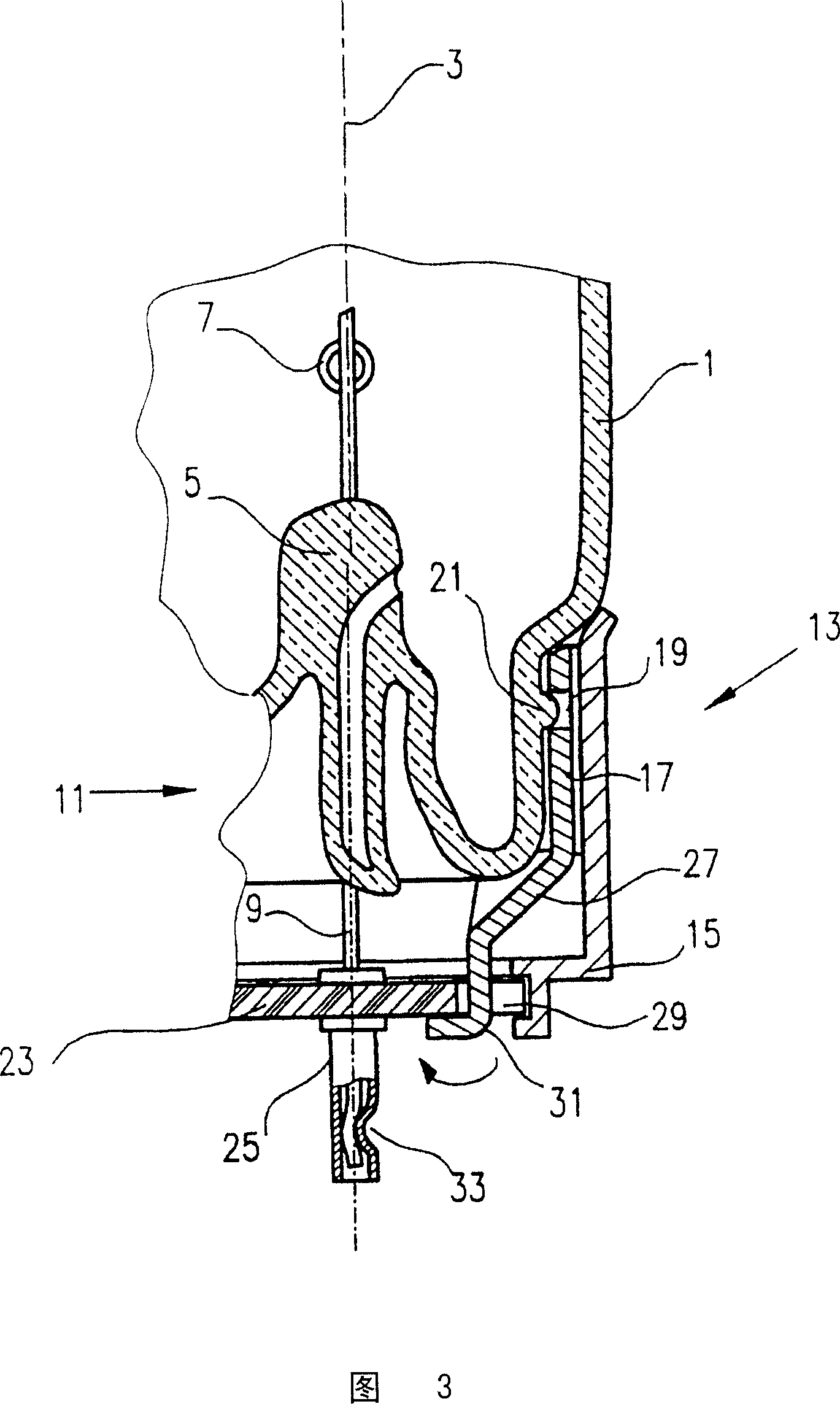

[0013] Referring now to Figure 1, there is shown a cap 13 mounted on one end of a low pressure discharge lamp. The lamp comprises a glass envelope 1 with an axis 3 . Although not shown in the figures, the capsule 1 is coated with phosphorus on its inner surface and filled with the inert gas and mercury required for the discharge, in a manner known to those skilled in the art. The capsule 1 is hermetically sealed and includes a rod-like portion 5 having a current lead-in terminal 9 embedded therein and an electrode 7 mounted thereon. In order to form the well-defined shape for the end of the low-pressure discharge lamp, the seal is made by using a mold during the glass melting process. This shape is characterized by a sealing zone 11 extending axially from the capsule 1 , which is smaller in diameter than the capsule 1 . The base 13 fitted to the sealing area 11 comprises a base housing 15 made of metal, for example aluminium. An insulator 23 made of fiberglass plastic is at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com