Function element and its manufacturing method, and electronic equipment using function element, and its manufacturing method

A technology of electronic equipment and functional components, which is applied in the field of electronic equipment and its manufacturing using the above functional components, can solve problems such as time-consuming, and achieve the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

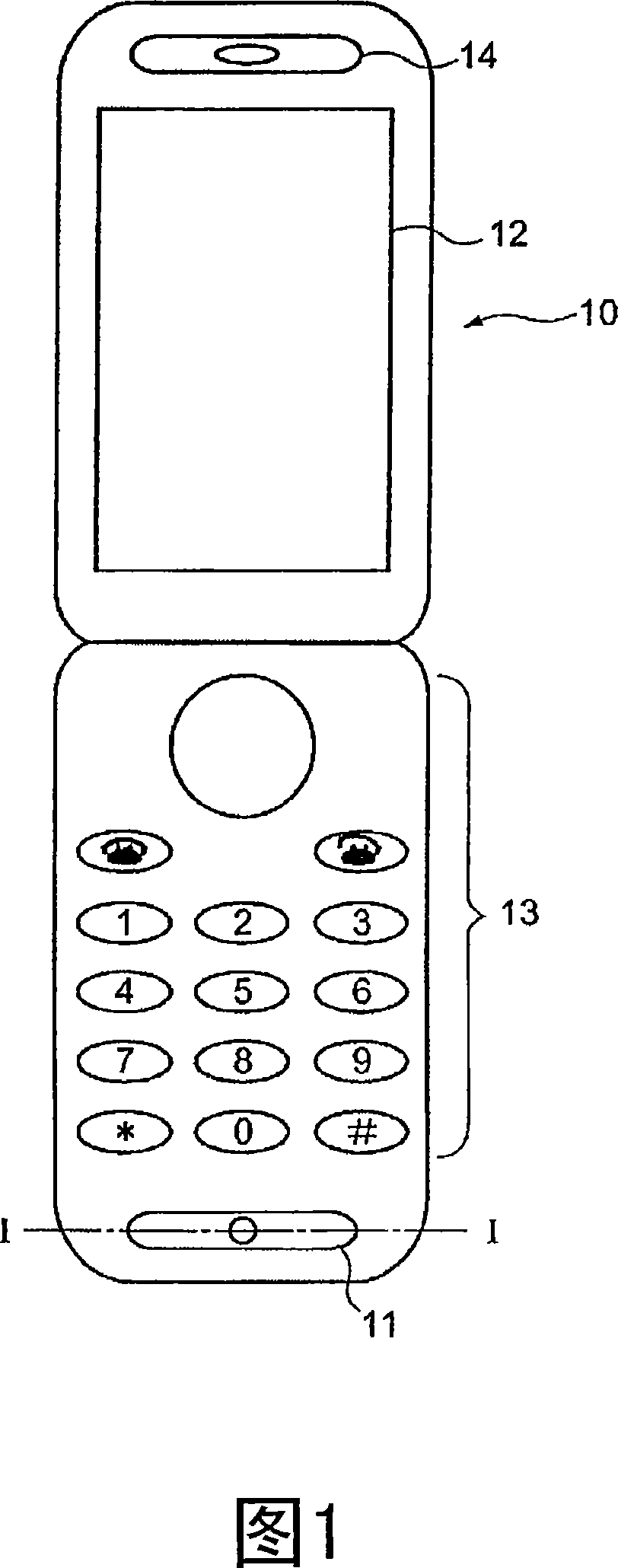

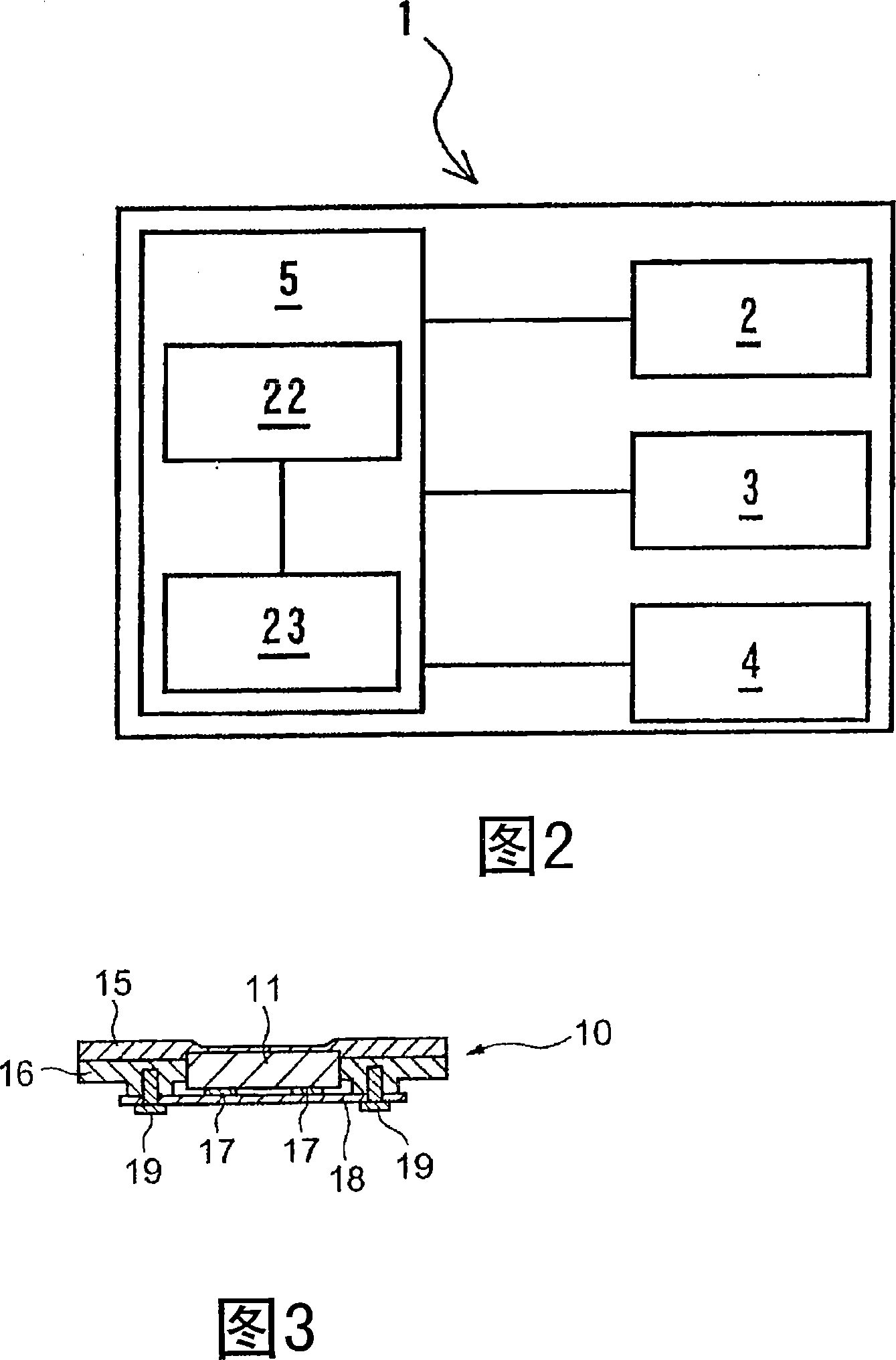

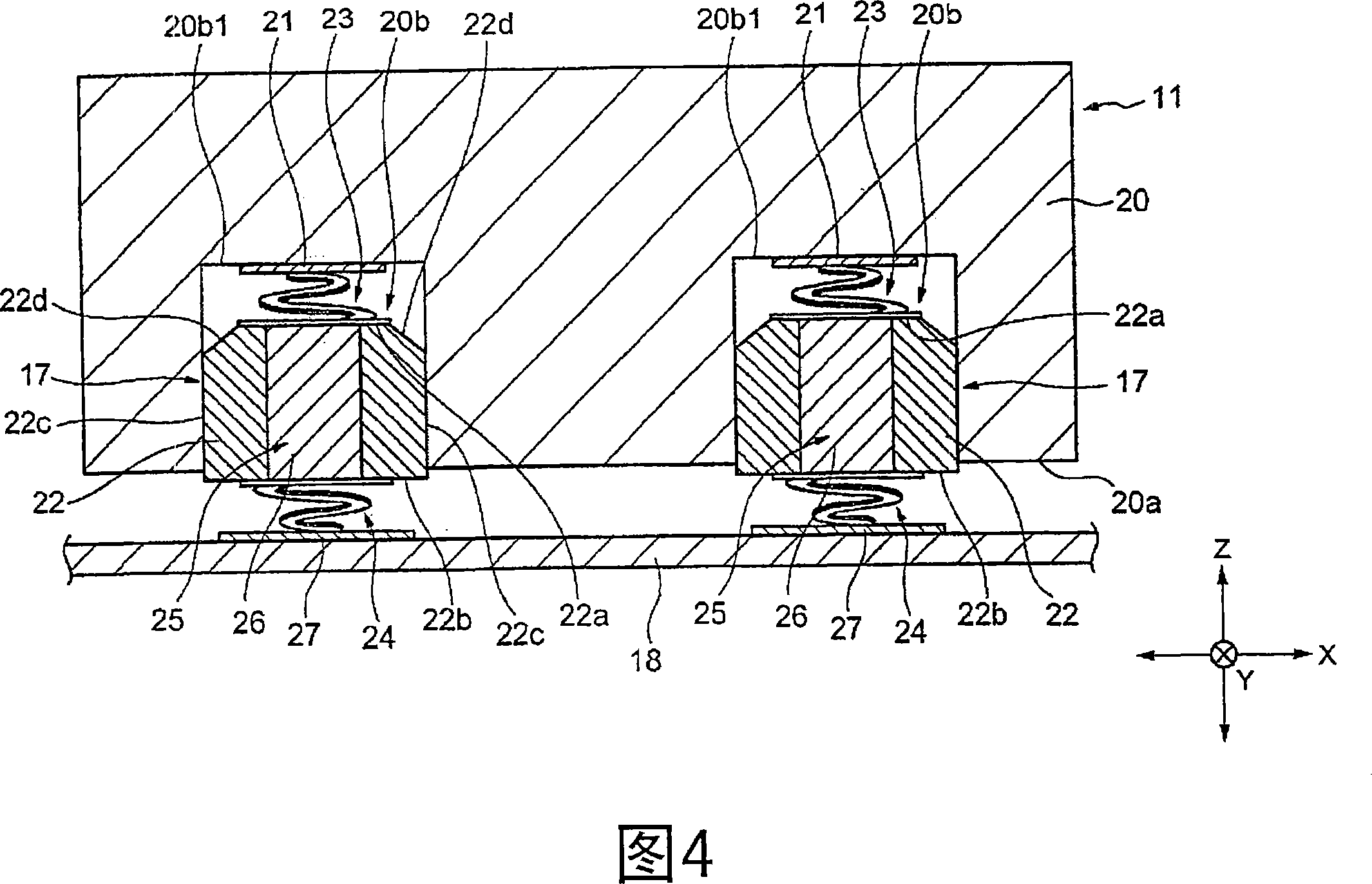

[0061] Fig. 1 is a partial top view of the portable phone; Fig. 2 is a partial top view of the above-mentioned portable phone when the upper casing of the above-mentioned portable phone is removed; Fig. 3 is cut along the I-I line shown in Fig. Partial cross-sectional view of the telephone; Fig. 4 is a diagram for explaining the structure of the functional element (microphone) of the first embodiment of the present invention, which is a partial enlarged cross-sectional view after the partial cross-sectional view shown in Fig. 3 is enlarged; Fig. 5 is a partial enlarged cross-sectional view of the present invention Figure 6 is a diagram for explaining the structure of a functional element (microphone) according to a second embodiment of the present invention, which is a partial enlarged cross-sectional view after enlarging the partial cross-sectional view shown in Figure 3; Figure 7 is The diagram for explaining the structure of the functional element (microphone) according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com