Washing and drying machine

A technology for washing and drying machines and washing tanks. It is applied to washing devices, other washing machines, and washing machines with containers. It can solve problems such as heat resistance, unexpectable steam penetration effect, and hard texture, and suppress excessive temperature rise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

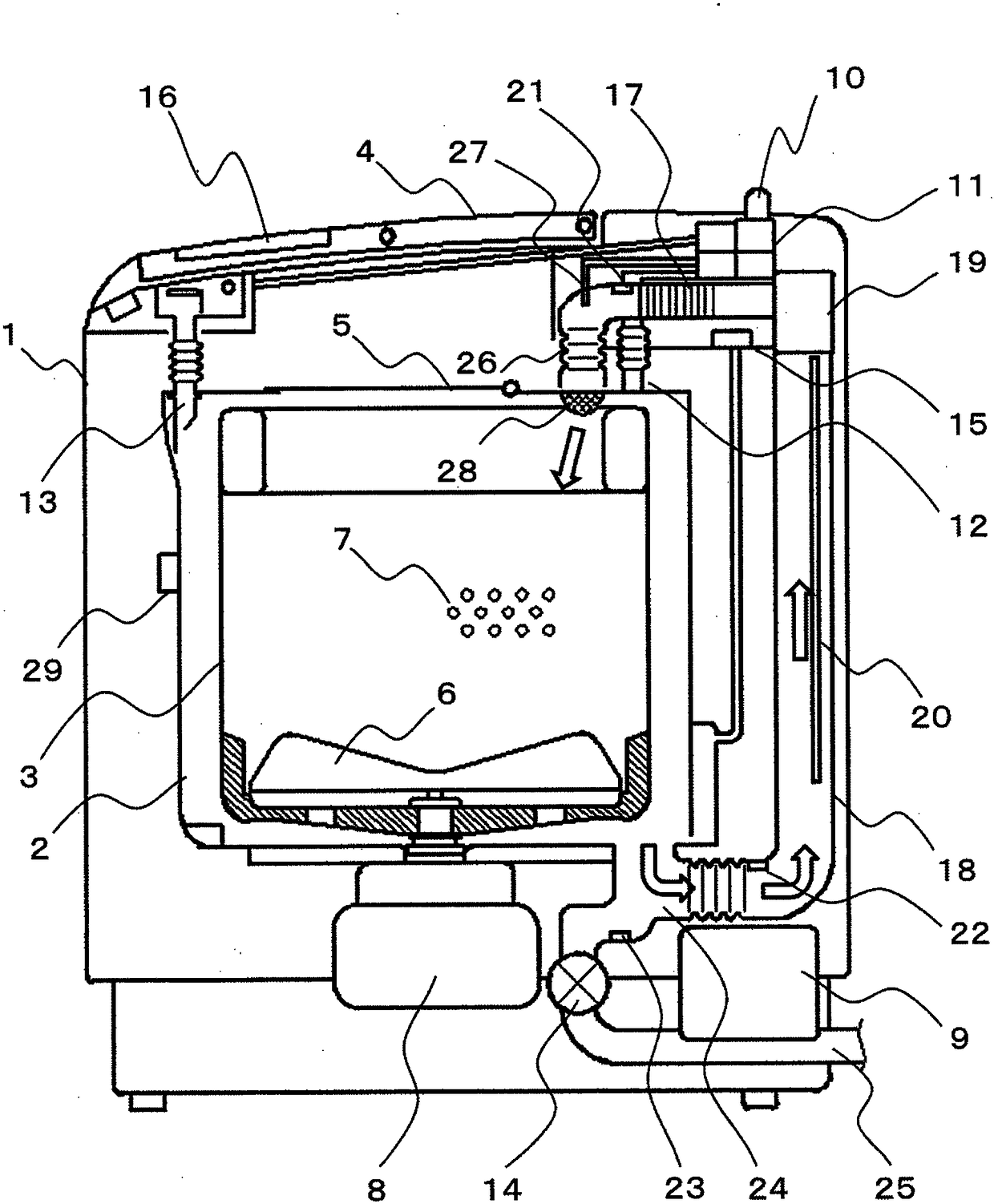

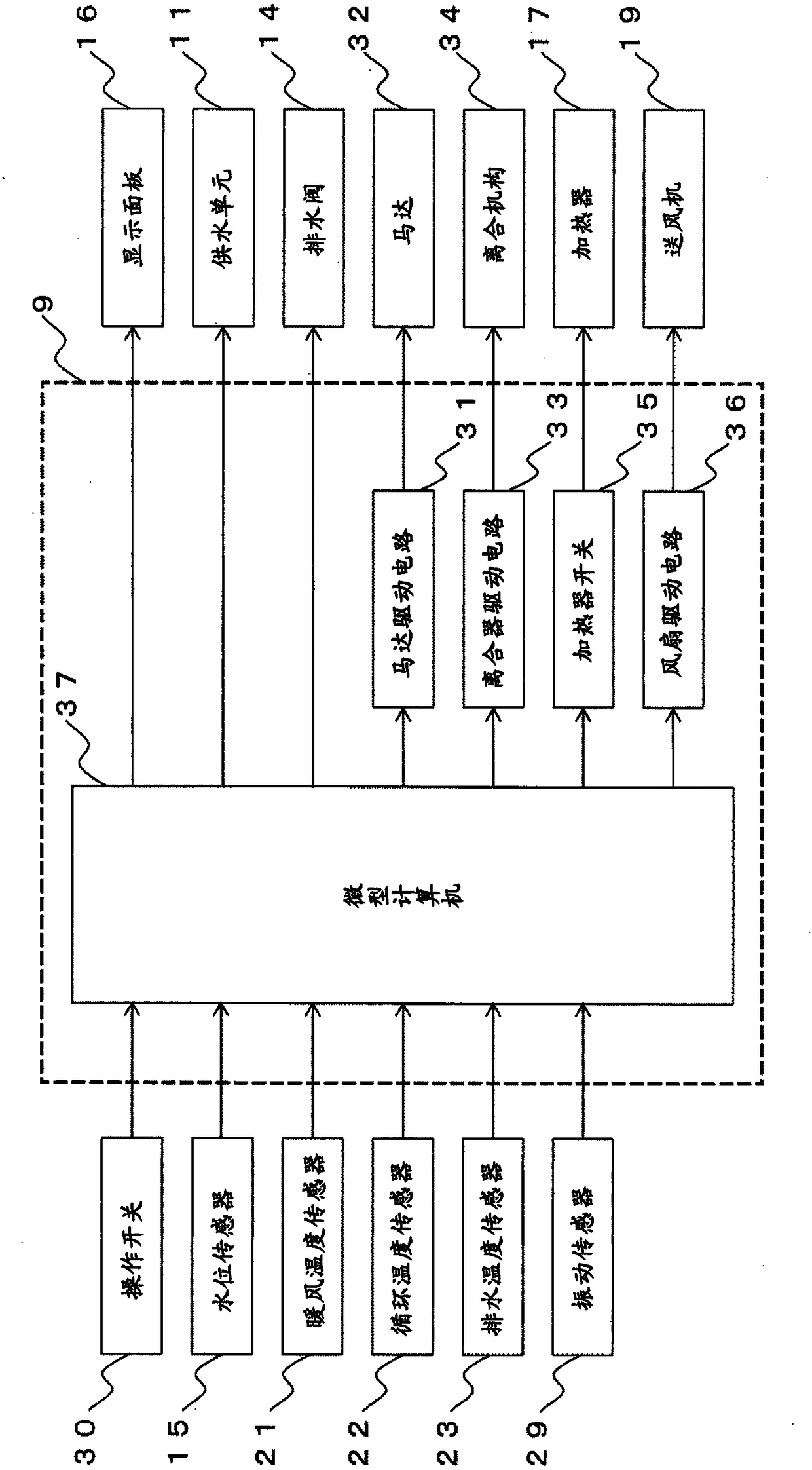

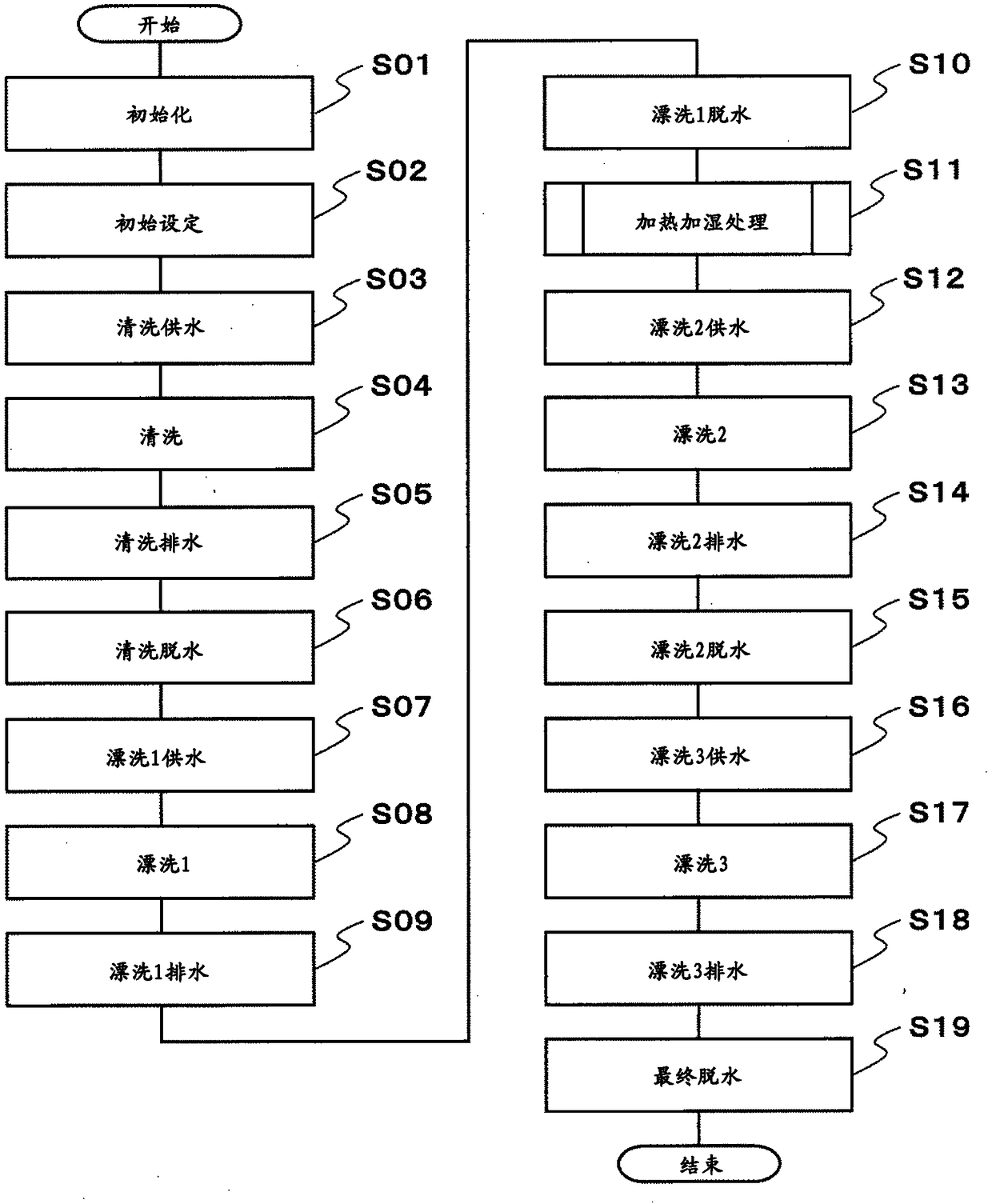

[0024] Below, according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 order will be described.

[0025] figure 1 It is a longitudinal sectional view showing the structure of the washing and drying machine according to the embodiment of the present invention, figure 2 It is a functional block diagram of the washing and drying machine in embodiment of this invention.

[0026] In the outer frame 1 of the washing and drying machine, an outer tank 2 for storing washing water is arranged, and the outer tank 2 is supported in a vibration-proof manner by four suspension members (not shown) hanging from the upper corners of the outer frame 1 , and arranged in the central part of the outer frame 1 along the longitudinal direction. The washing tank 3 disposed in the outer tank 2 is formed in a bottomed cylindrical shape long in the axial direction using a stainless steel plate. Through-holes 7 for passing water and ventilation are formed in ...

Embodiment 2

[0090] During heating as in Example 1, when the temperature of the warm air is detected by the warm air temperature sensor 21 and exceeds 80°C, the intermittent spraying of water mist is started. , instead the intermittent spraying of water mist is started after heating for a predetermined time.

[0091] Specifically, as Figure 7As shown in the flow chart of FIG. 2 , the driving device 8 is controlled to rotate the washing tank 3 at a low speed (step S501 ). And the control part 9 controls the fan drive circuit 36, operates the blower 19, and supplies air into the washing tub 3 (step S502).

[0092] After that, the control unit 9 controls the heater switch 35 to be turned on, and makes the heater 17 perform a strong operation (step S503 ). While starting the strong operation of the heater 17, start the strong operation timer (step S516), judge the amount of blankets and quilts as laundry (step S516), and set the heating time corresponding to the amount of laundry.

[0093]...

Embodiment 3

[0101] The difference of the heating and humidification process in other embodiments is that, in the case of not having the spray nozzle 27 and the mist net 28 as in the embodiment 1 or 2, the main water supply solenoid valve of the water supply unit 11 is opened to supply tap water to carry out Cooling and humidification of laundry.

[0102] The main water supply solenoid valve of the water supply unit 11 can supply 10 to 15 L of tap water per minute, but because it is necessary to keep the blanket and bedding as washings to cool and the temperature at which the mites die, it is turned on for 2 seconds and then turned off 208 Seconds of intermittent water supply. The ON / OFF time allocation is a control scheme, which measures the time it takes for water to reach a predetermined water level during the washing process or rinsing process, determines the water pressure, and selects and sets from a plurality of time allocations, thereby It is possible to prevent the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com