Patents

Literature

48results about How to "Prevent excessive temperature rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

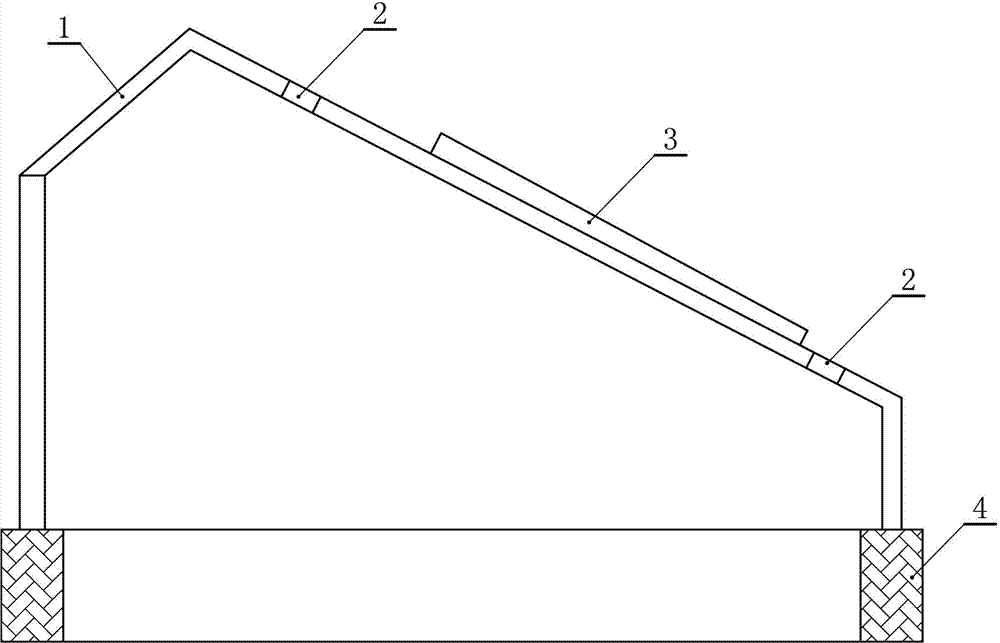

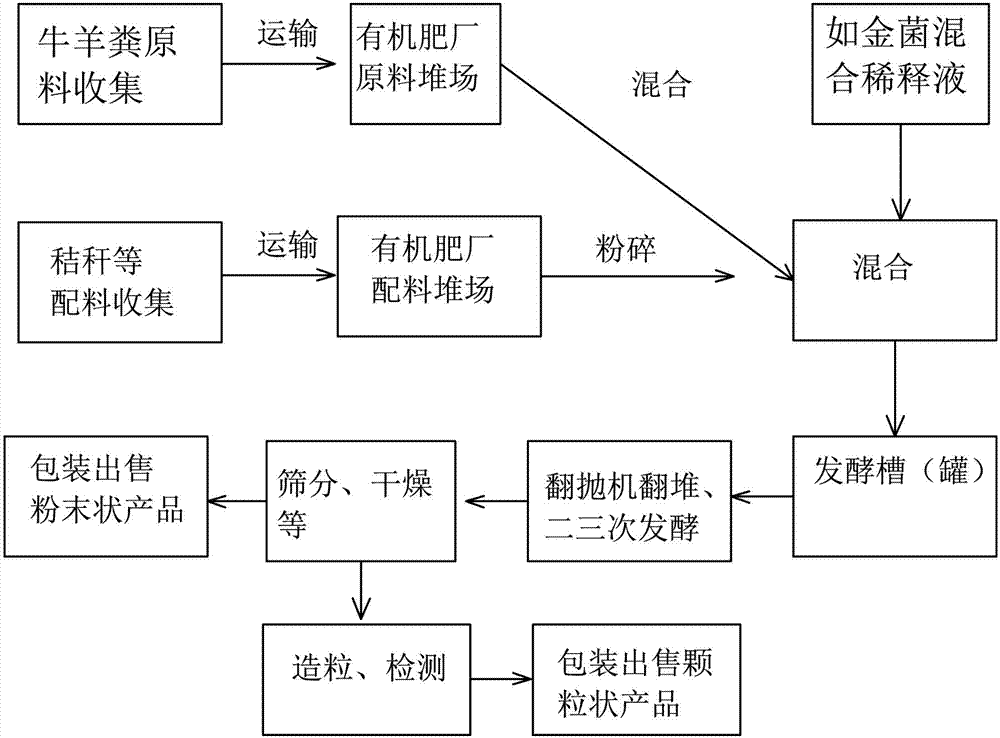

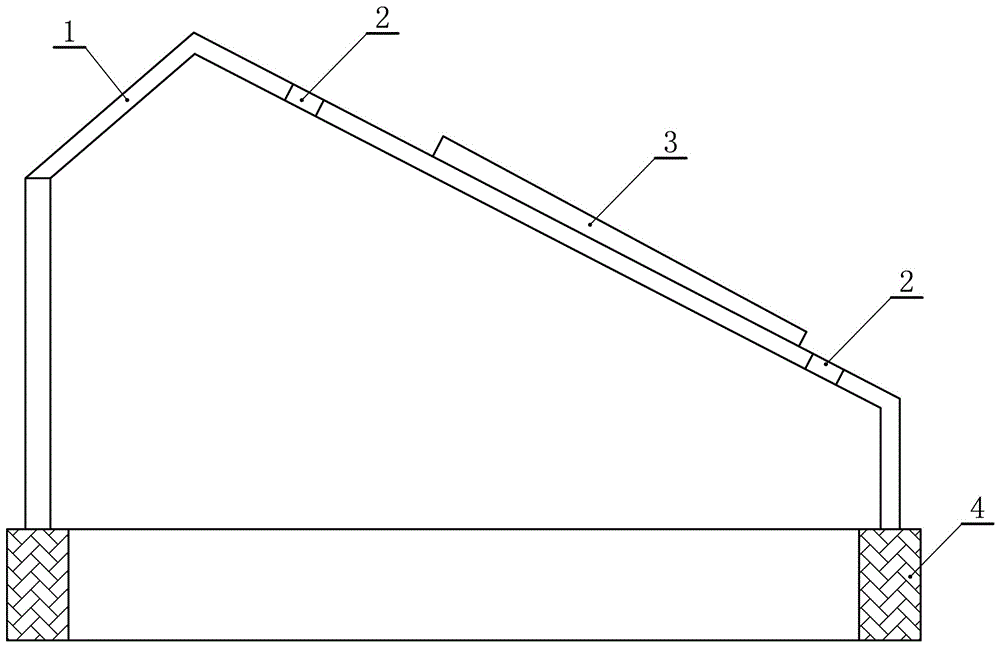

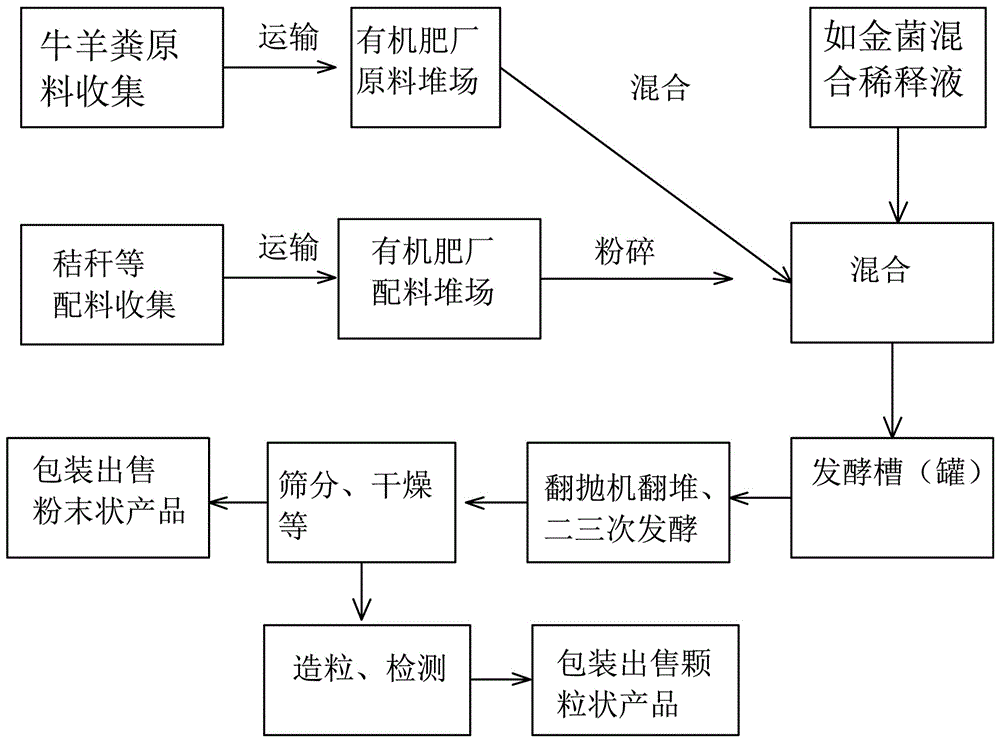

Method for breeding beef cattle and mutton sheep standardly on large scale through photovoltaic facilities

InactiveCN104115756AEfficient use ofEffective spaceFood processingLivestock managementAgricultural scienceGreenhouse

A method for breeding beef cattle and mutton sheep standardly on a large scale through photovoltaic facilities includes the four parts that first, a photovoltaic facility greenhouse is built, maize seedlings or high-quality green forage grass Zea mexicana is produced throughout the year to be used as green fodder of beef cattle and mutton sheep; second, the beef cattle and the mutton sheep are bred and bio-organic fertilizer is produced standardly on a large scale through the photovoltaic facility greenhouse; third, photovoltaic power generation is performed for self use, and excessive electricity is connected into the state grid; fourth, a beef cattle and mutton sheep traceable system is built, and foods are made safe and sanitary. Through the method, not only can solar resources be effectively utilized to output clean and green energy, but also efficient planting and breeding can be achieved, by-products are processed into organic fertilizer, and a new path is provided for green agricultural production. Because a full-frame high-standard support system is adopted for the photovoltaic agricultural greenhouse and photovoltaic modules are arranged on the greenhouse, the space of the greenhouse can be effectively utilized, power utilized in the greenhouse can be supplied through a photovoltaic power station, and equivalently, stereoscopic production is formed on the land with the same area.

Owner:丁志强 +3

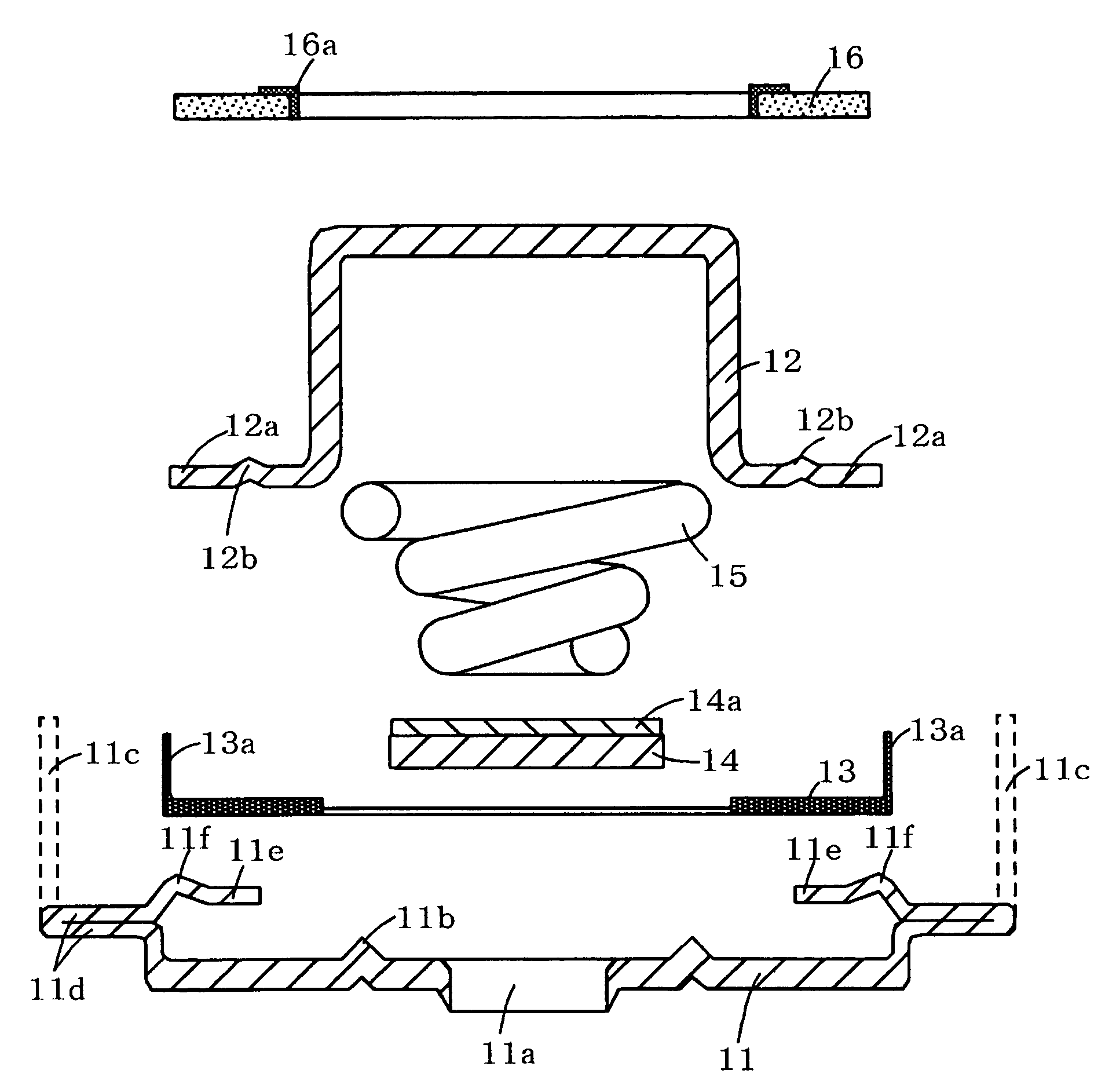

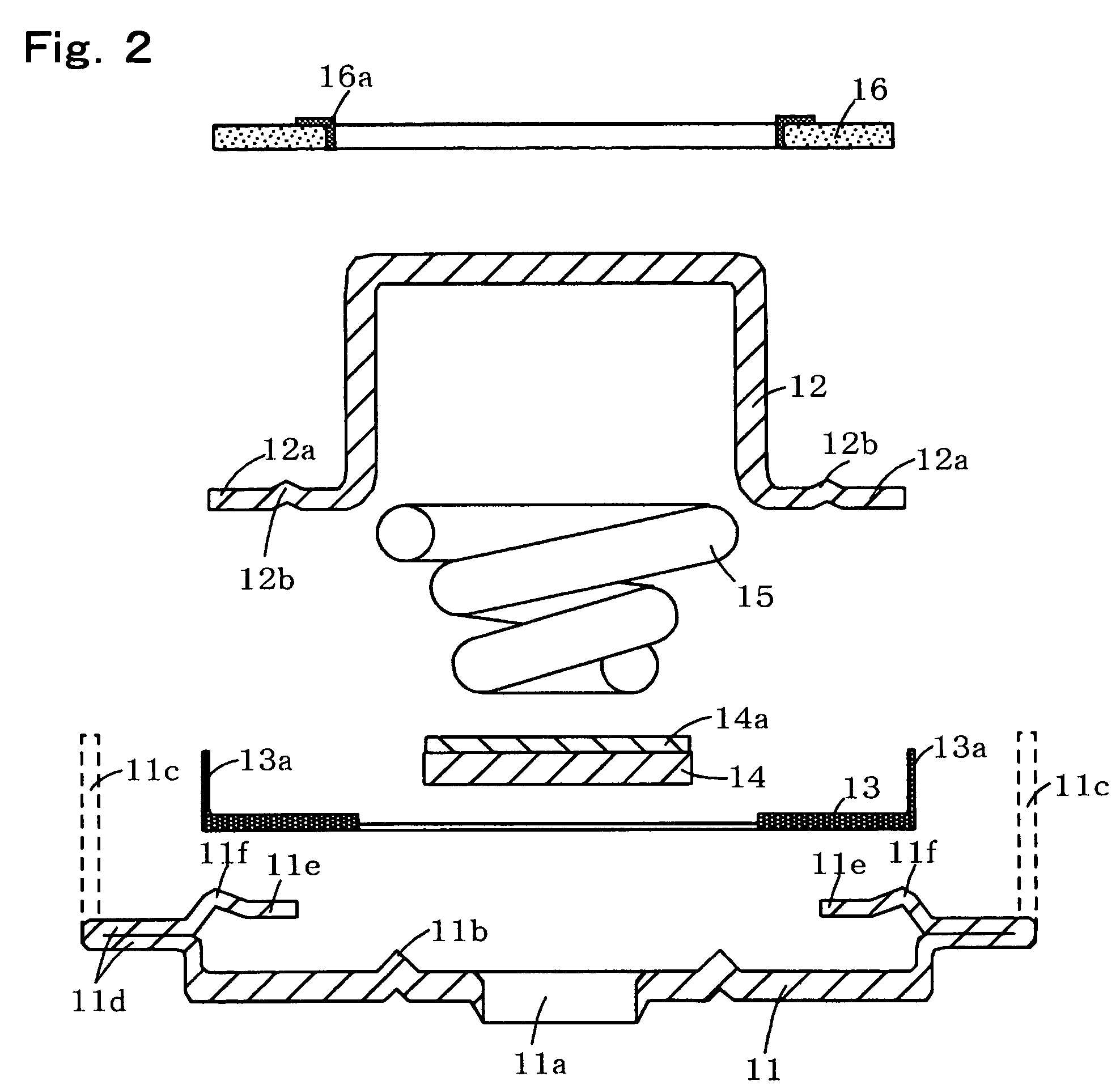

Hermetically sealed battery

InactiveUS20050026033A1Easy to expandPrevent pressureCell temperature controlSecondary cell gas removalOperations securityEngineering

A hermetically sealed battery with an opening-sealing unit 10 according to the present invention comprises a PTC element ring 16 elastically clamped between the flange 12a of a positive electrode cap 12 and a fold portion 11d formed at the peripheral portion 11c of a bottom plate 11, such that when the temperature of the PTC element rises due to overcurrent or overheating, the PTC element ring 16 can easily expand, thereby tripping the large current with its resistance capacity increased to a predetermined level at a predetermined temperature, thereby enhancing operational security of the battery.

Owner:KAWANO KATSUYA +3

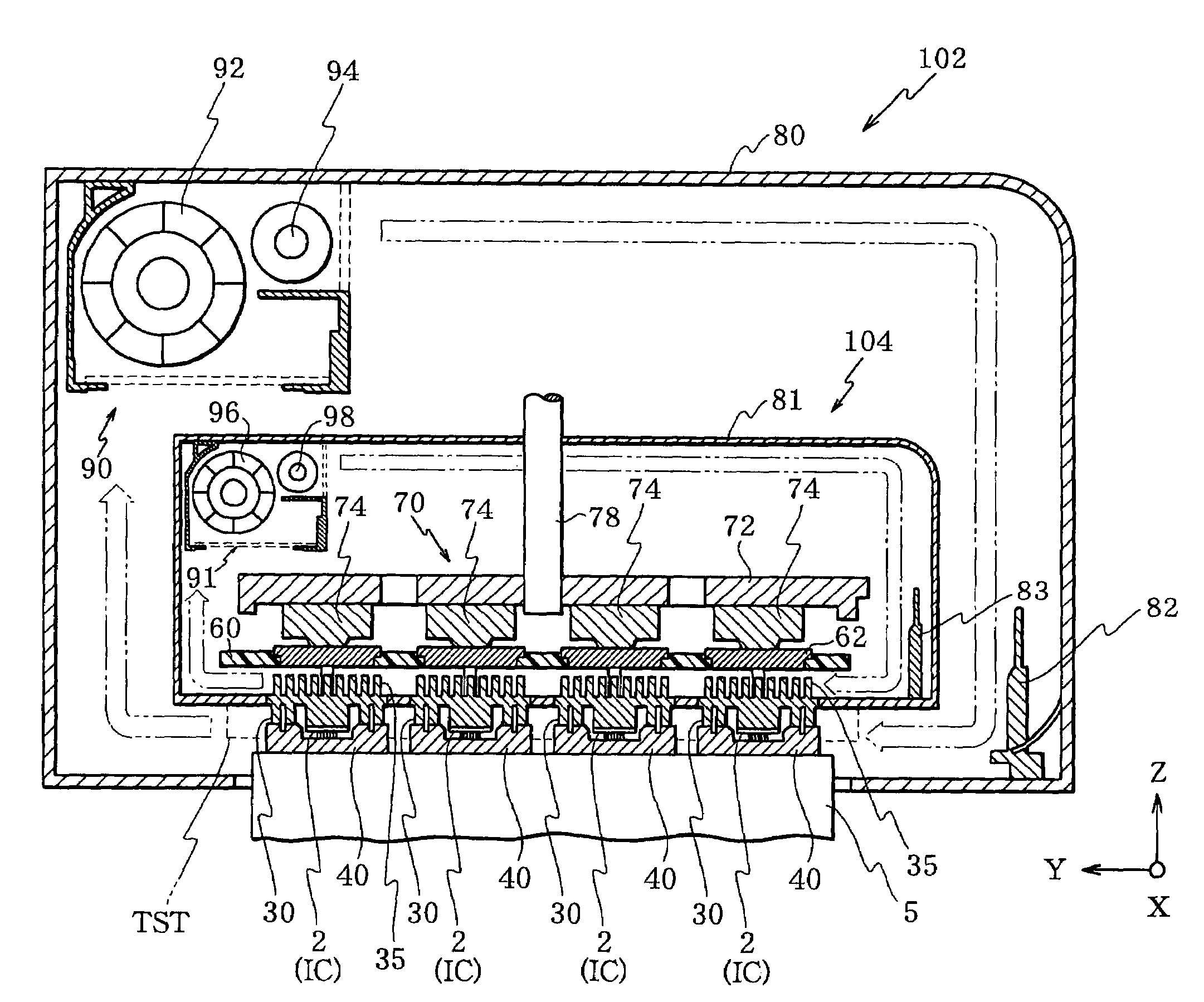

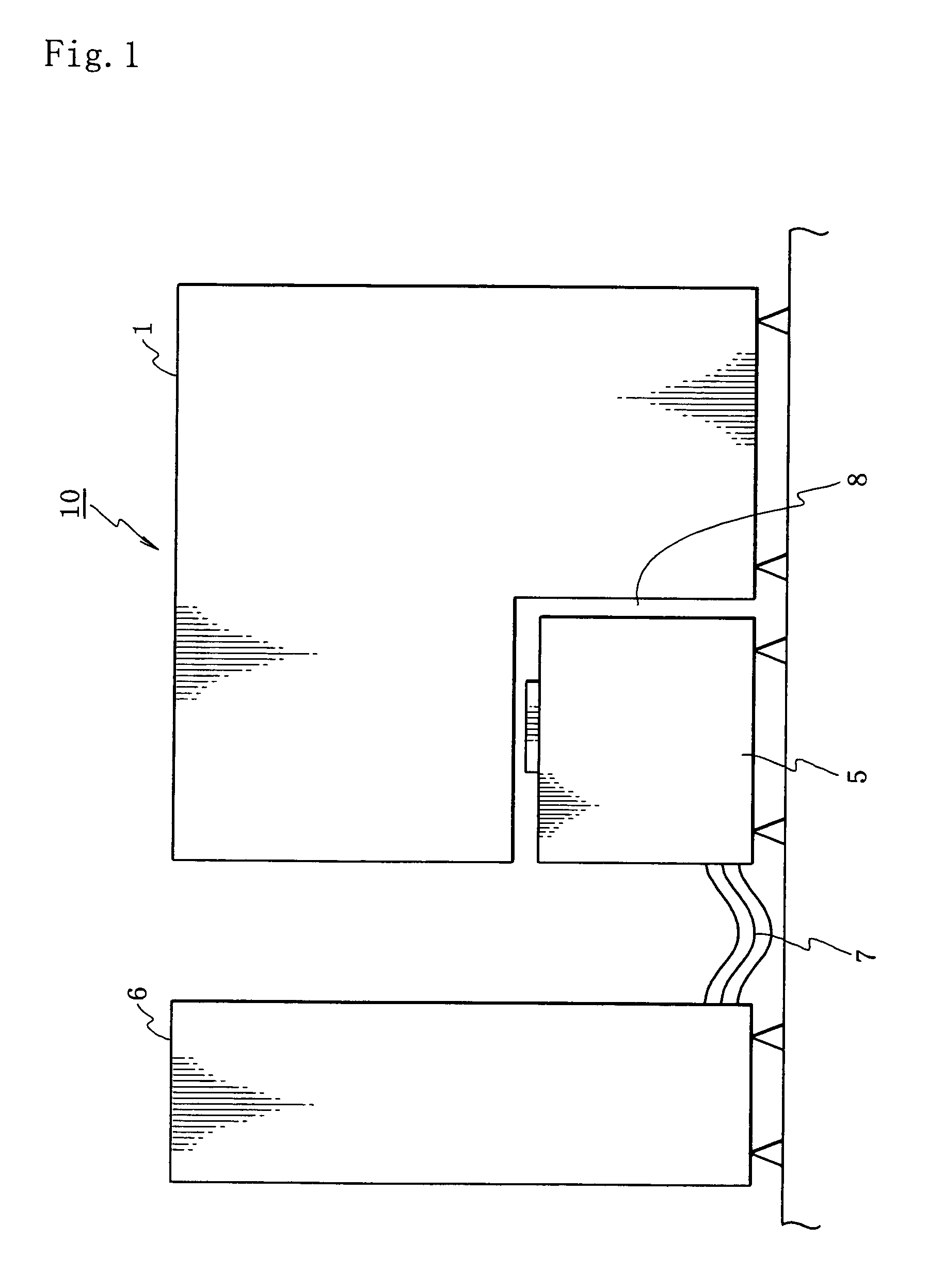

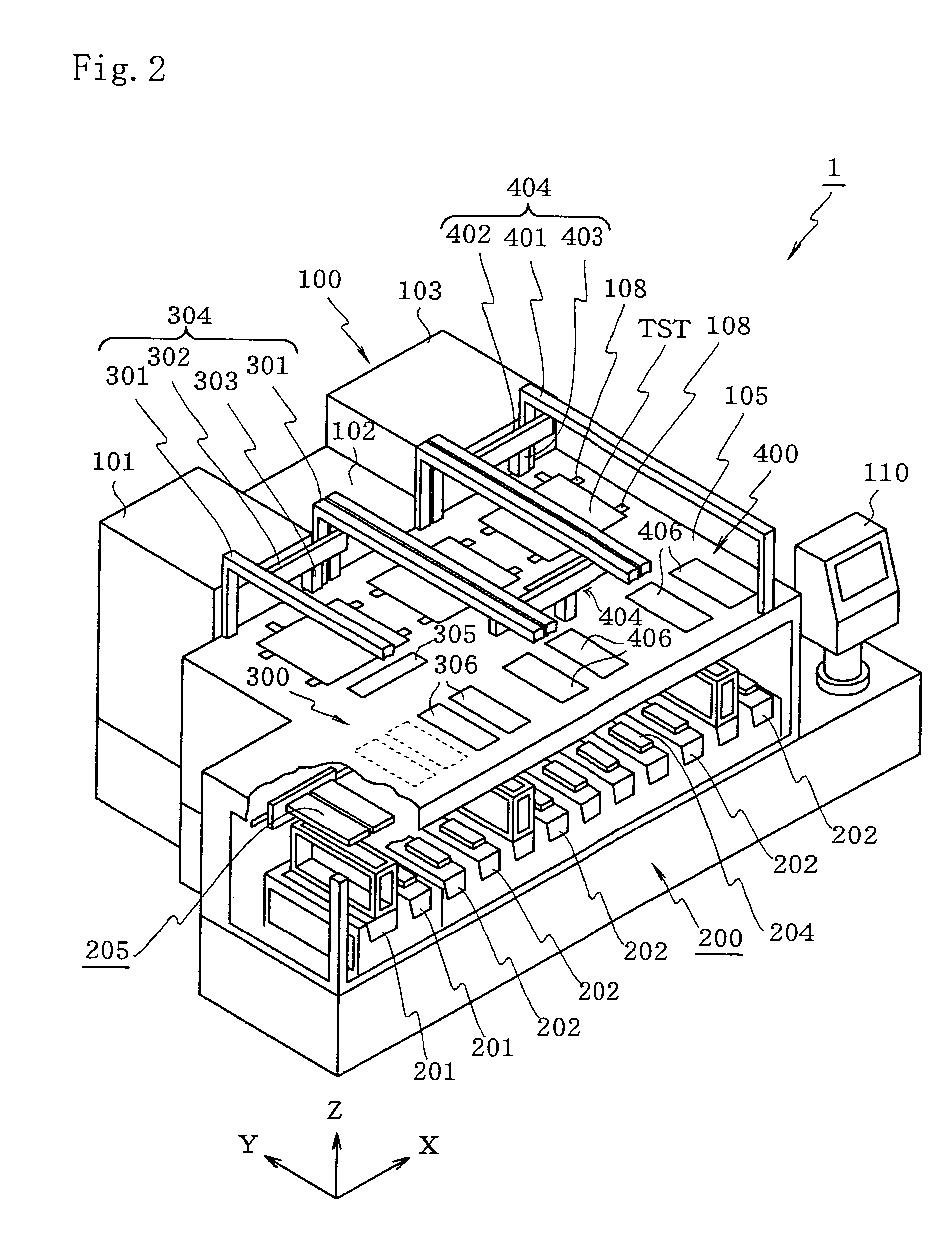

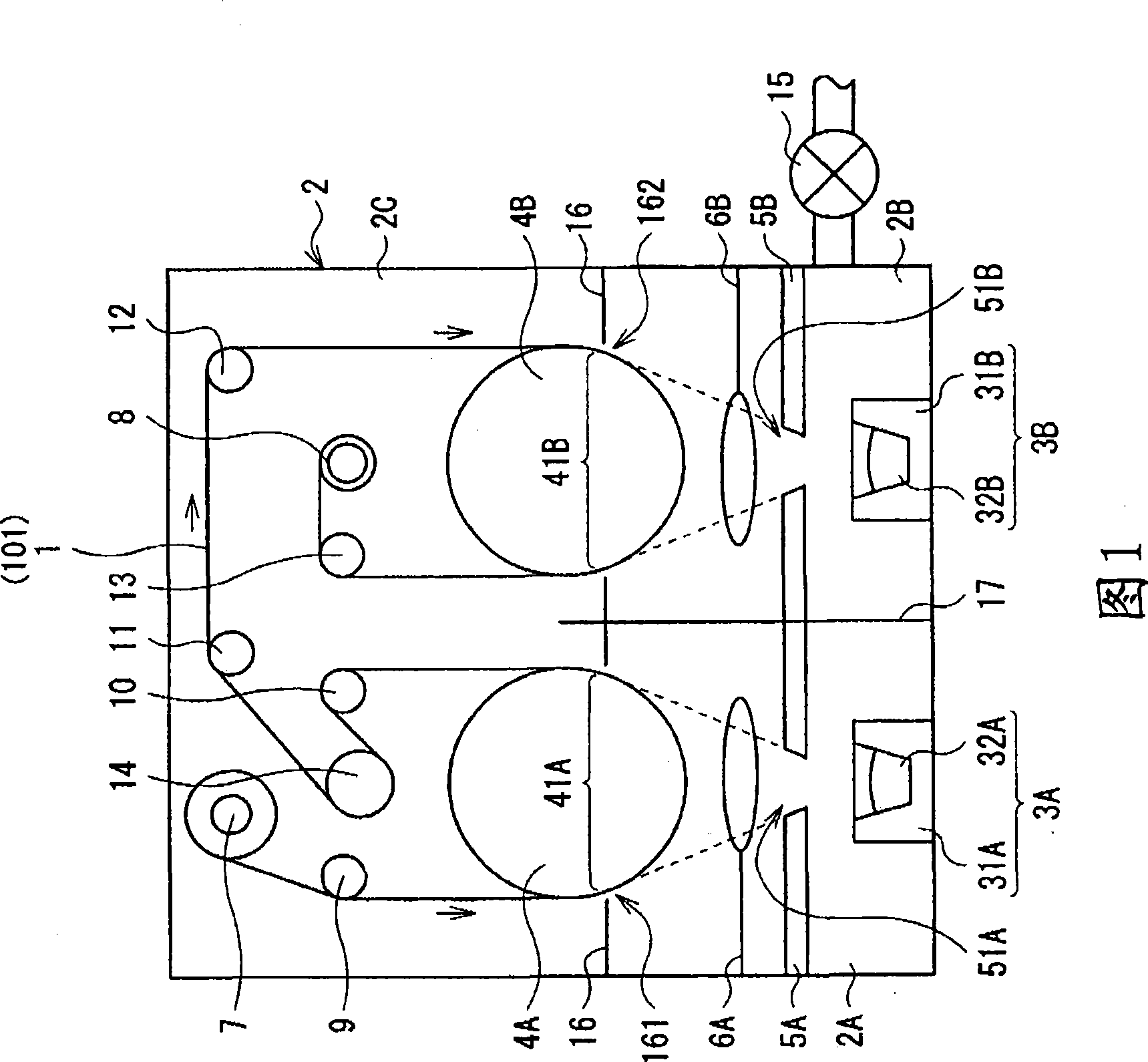

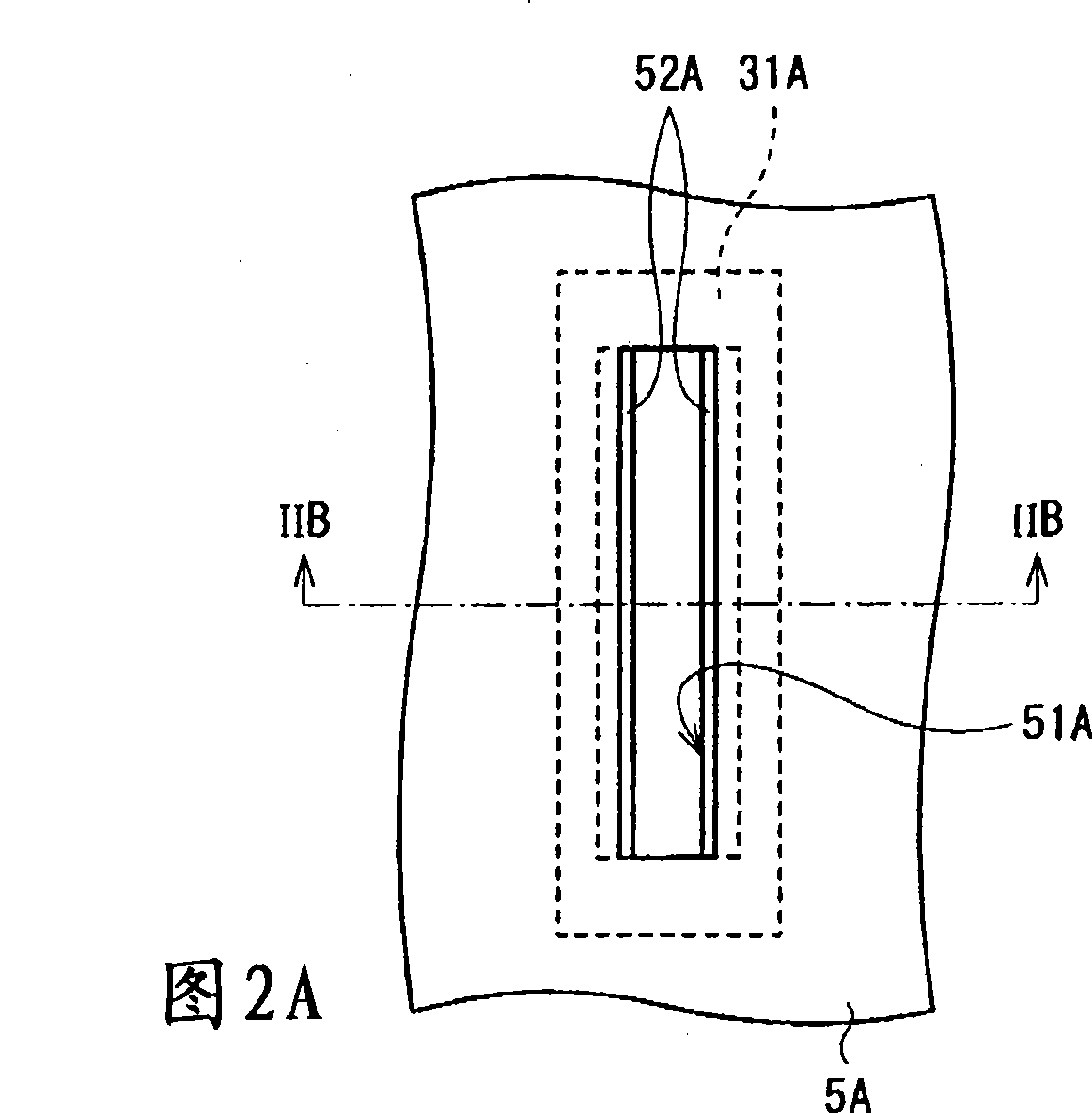

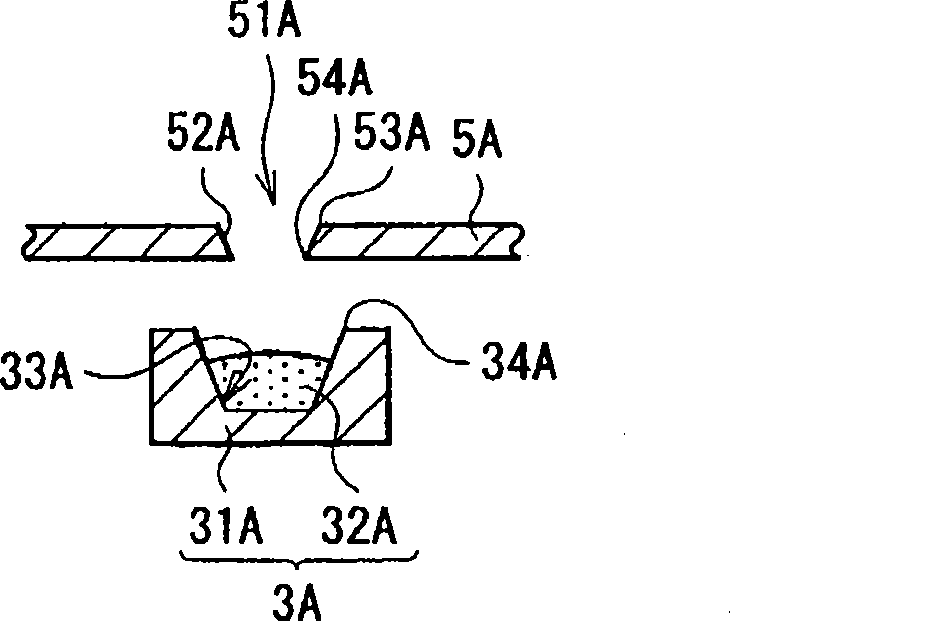

Apparatus for handling electronic components and method for controlling temperature of electronic components

InactiveUS6972581B2Prevent excessive temperature riseMore temperatureSemiconductor/solid-state device testing/measurementElectronic circuit testingTemperature controlEngineering

A handler 1 is provided with an inner chamber 104 containing inside thereof heat sinks 40 of pushers 30, a temperature adjusting unit 91 for controlling the atmosphere temperature inside the inner chamber 104, a test chamber 102 containing inside thereof sockets 40 located on the test head 5 and the inner chamber 104, and a temperature adjusting unit 90 for controlling the atmosphere temperature inside the test chamber 102. With such a handler 1, the temperature control can be conducted so that the temperature of electronic components is brought close to the set temperature of the target test.

Owner:ADVANTEST CORP

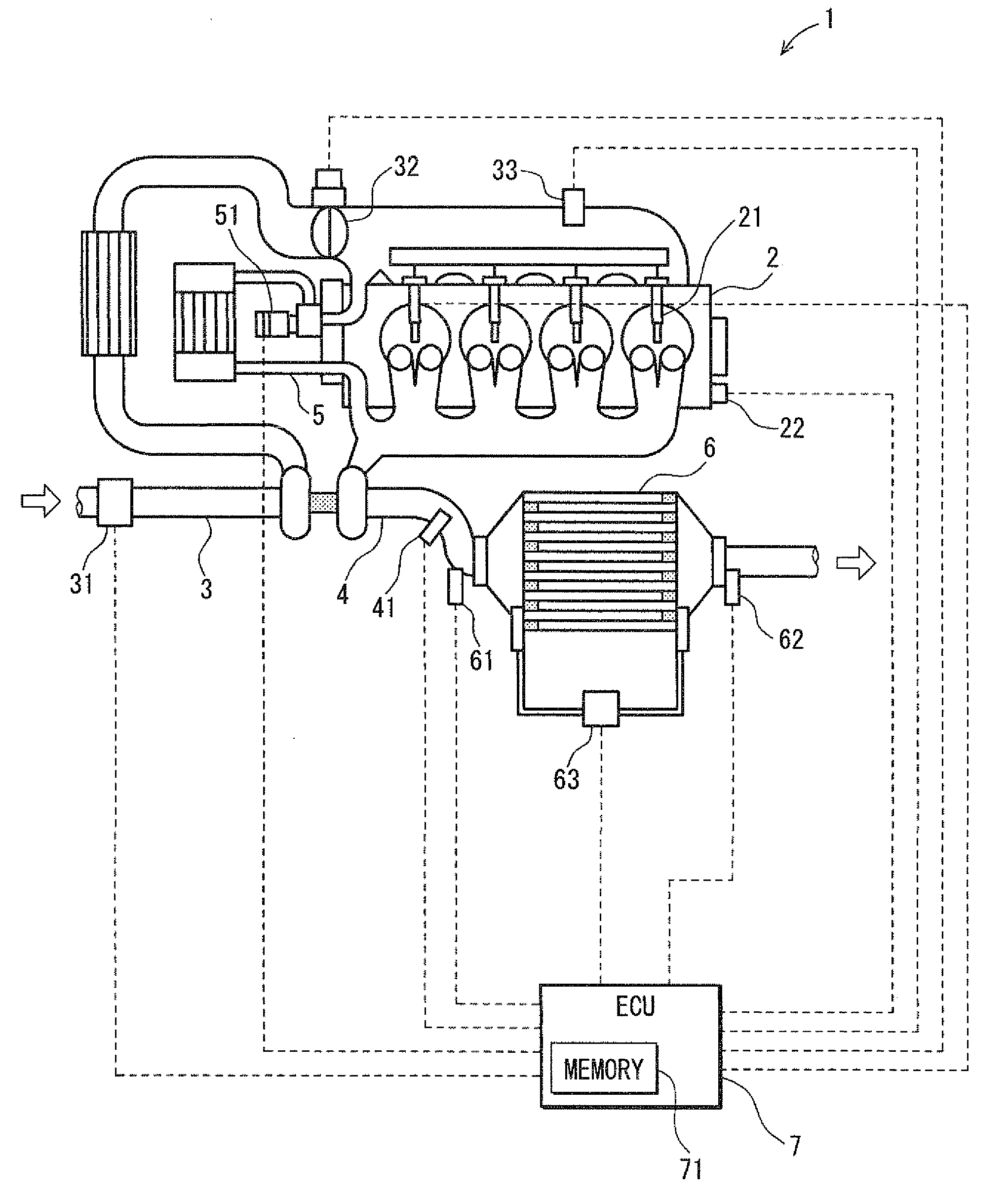

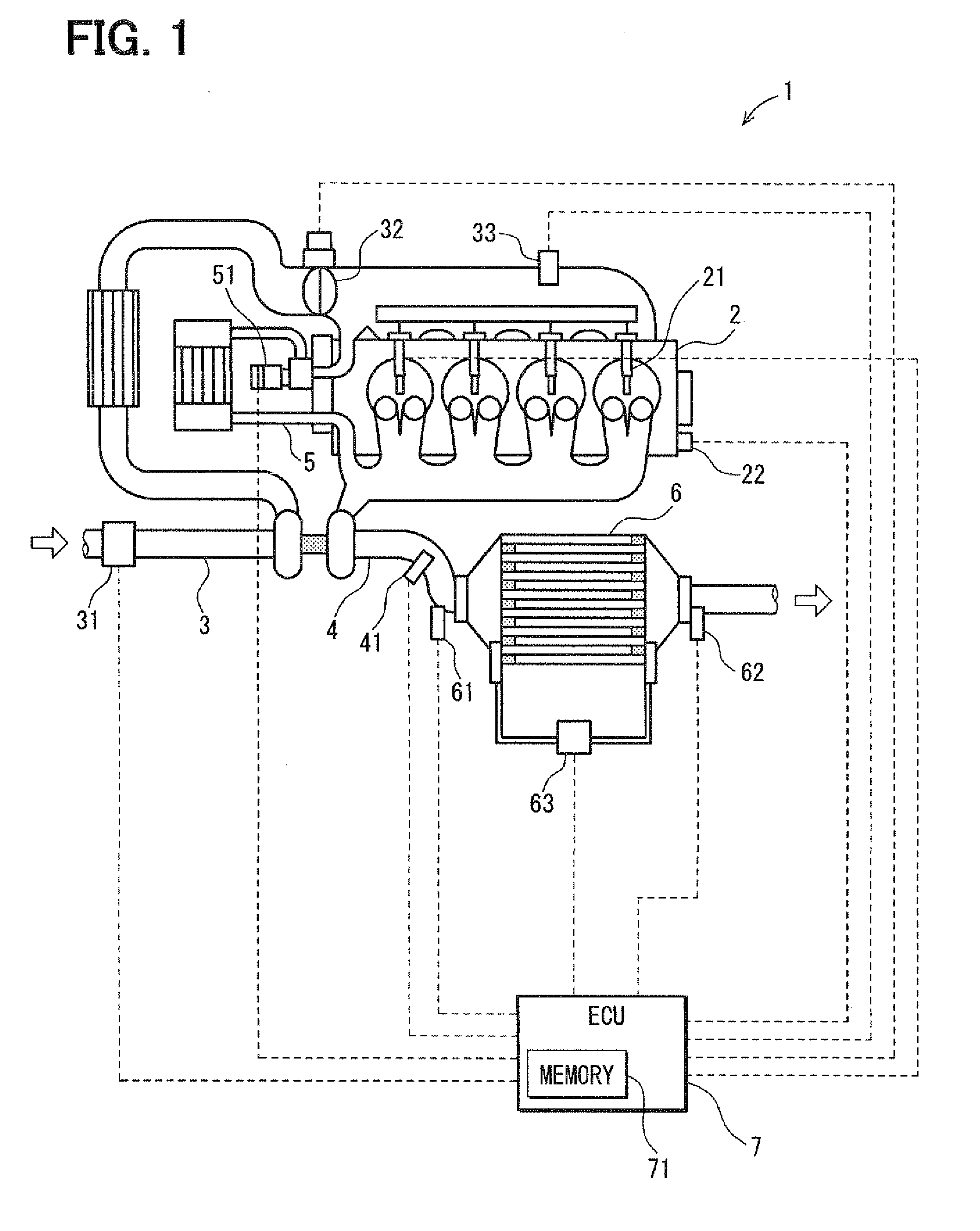

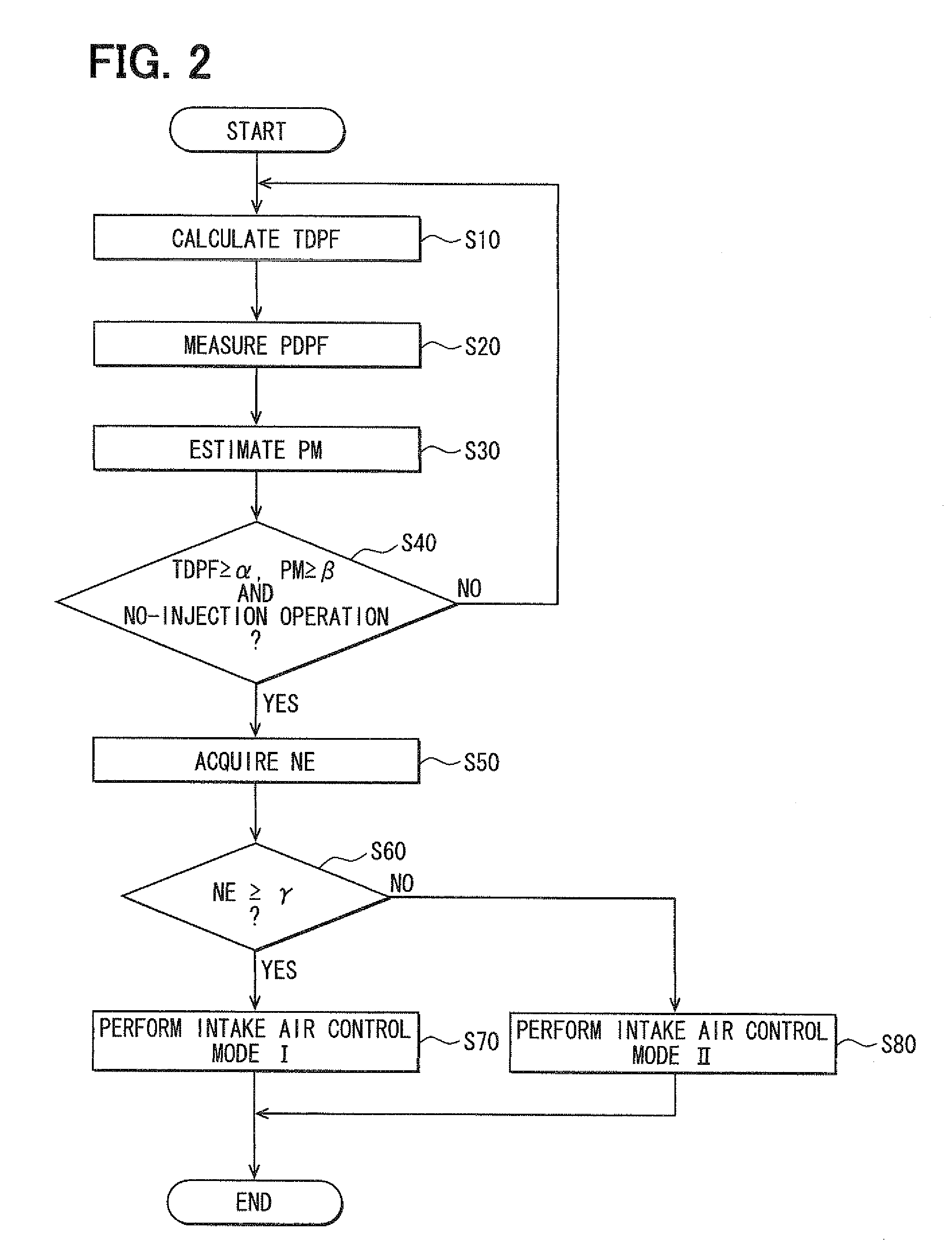

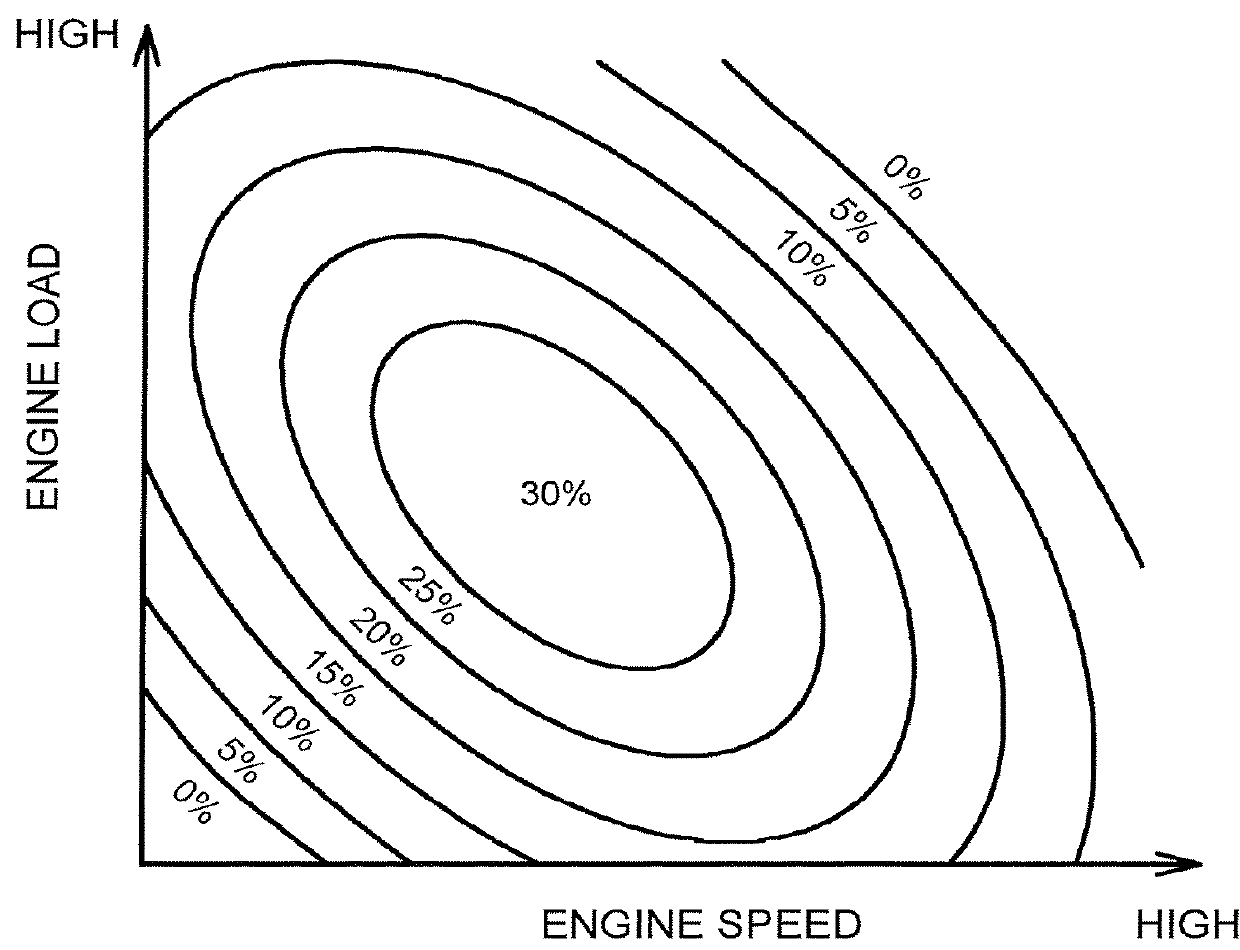

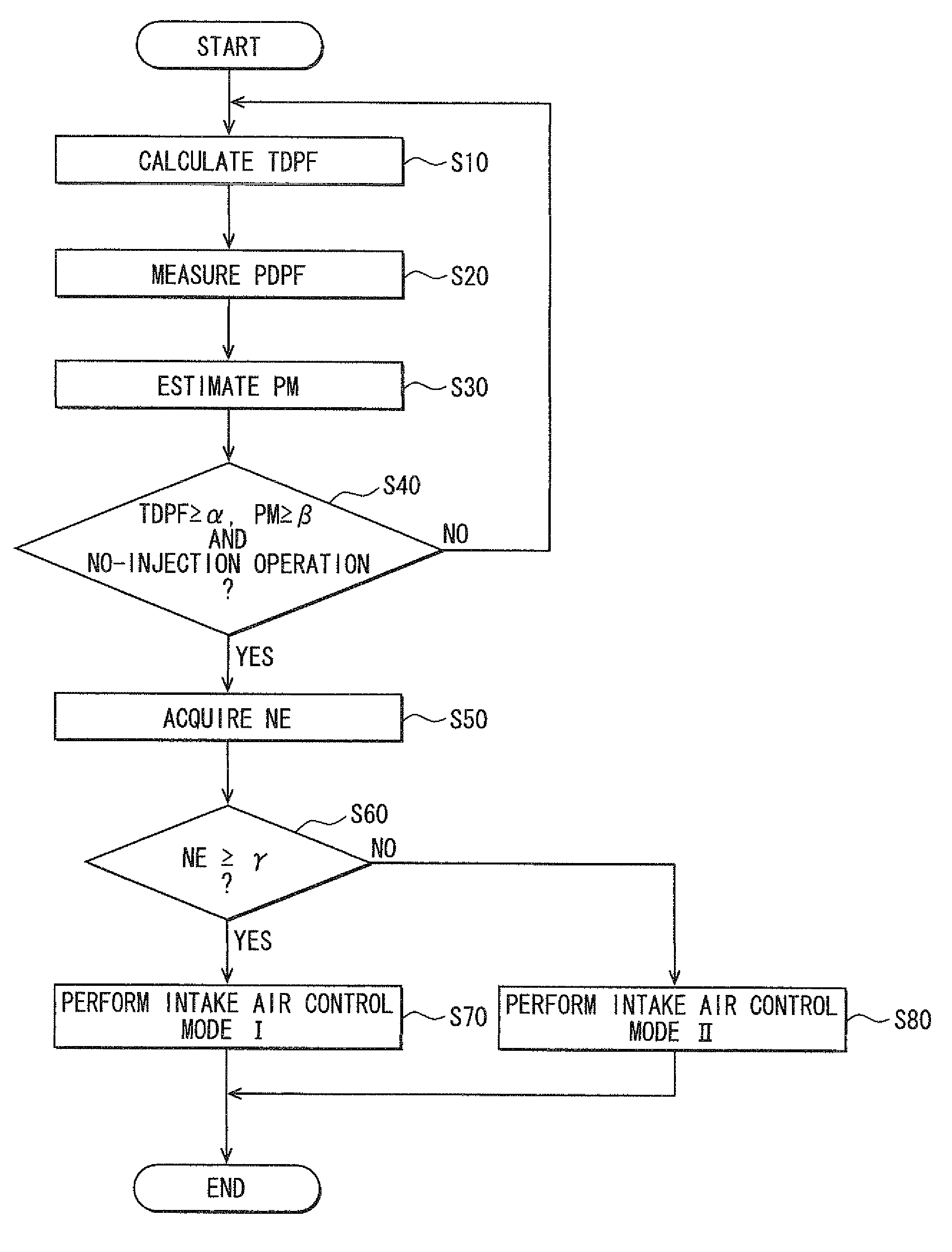

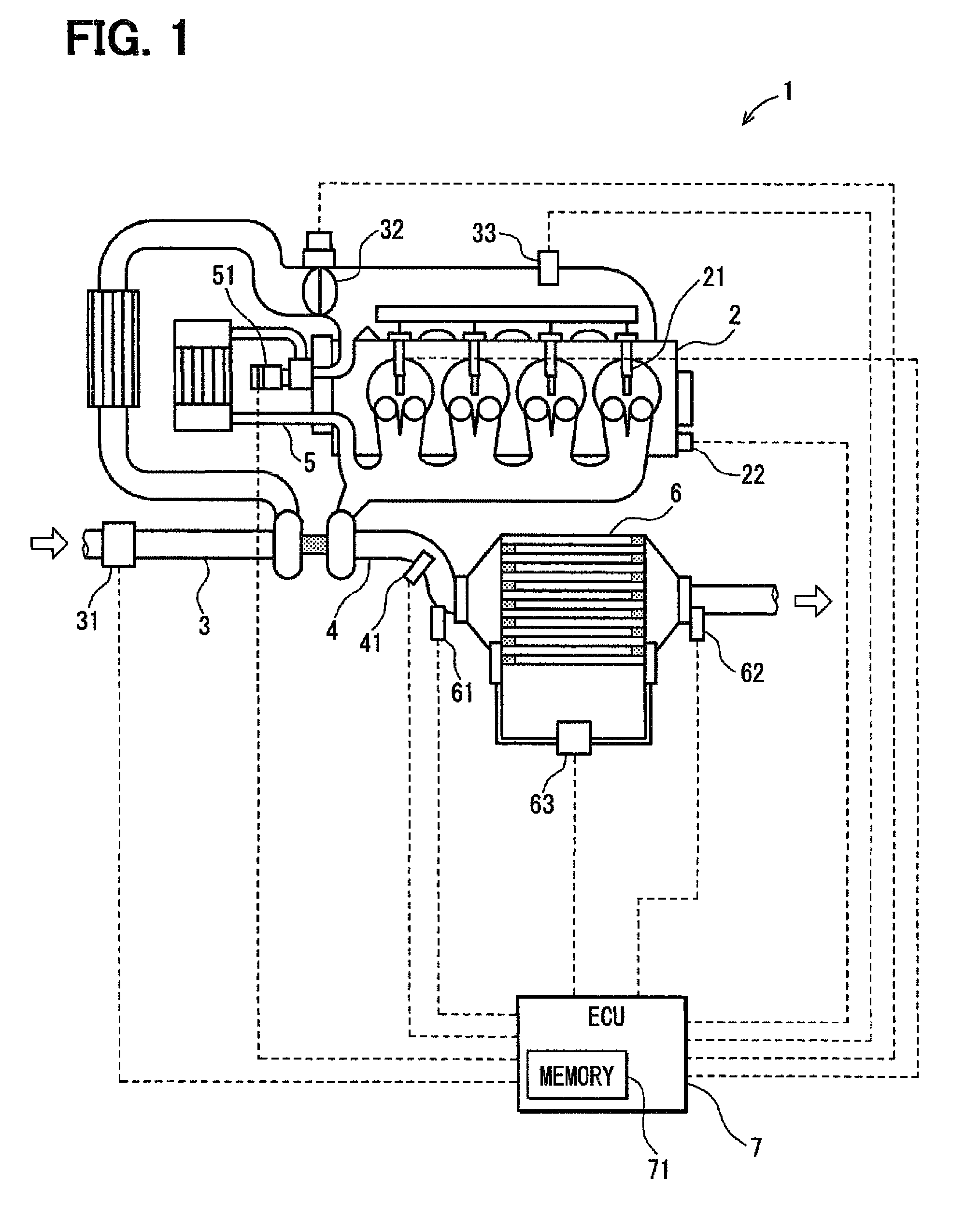

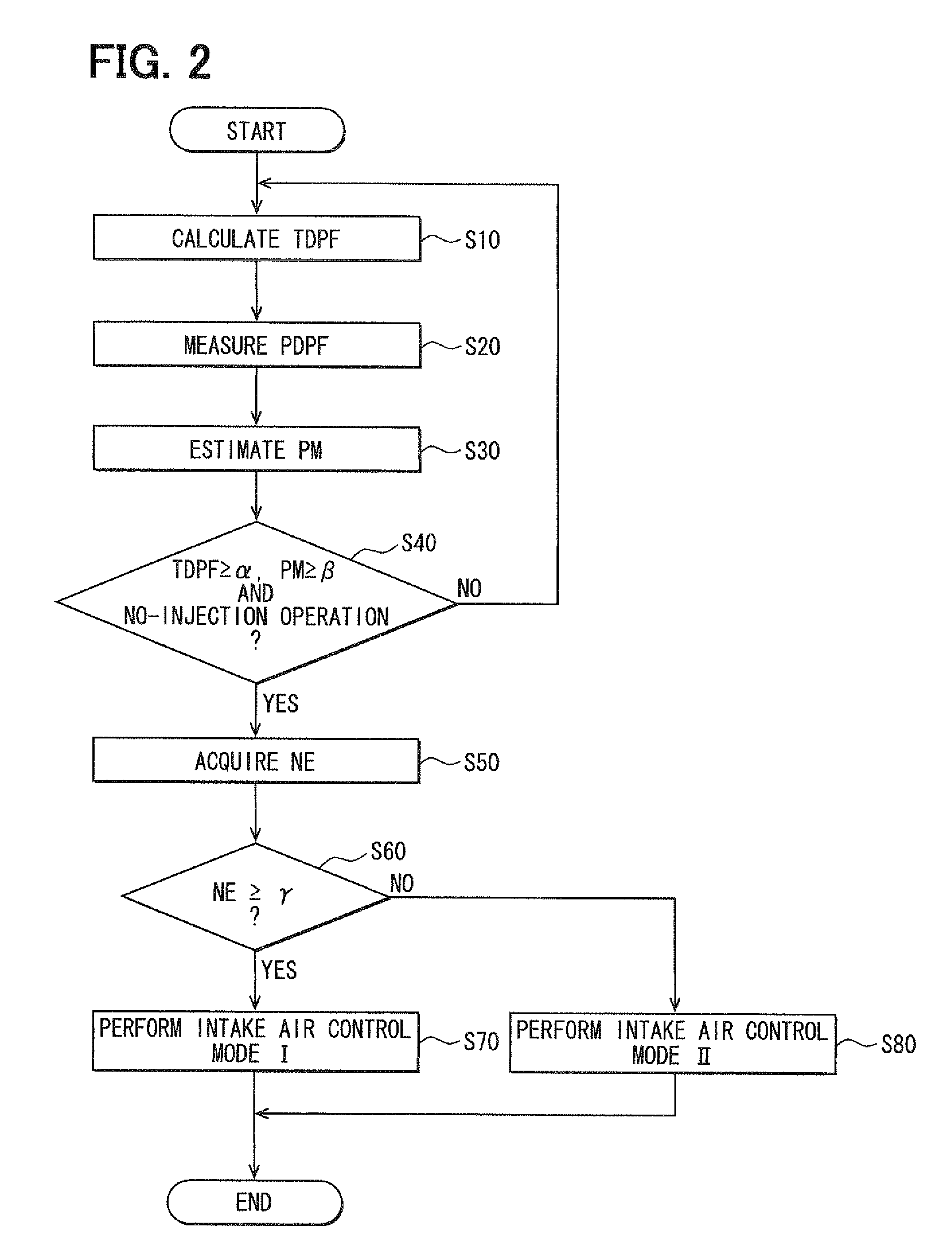

Exhaust gas purification device of internal combustion engine

ActiveUS20090178390A1Enhanced inhibitory effectEliminate the effects ofCombination devicesElectrical controlParticulatesExternal combustion engine

A first intake air control mode of setting an intake throttle valve to (or close to) a fully-opened state and setting an EGR valve to (or close to) a fully-closed state is performed when DPF temperature and a particulate matter deposition quantity are greater than corresponding predetermined values respectively, a no-injection operation state exists, and engine rotation speed is higher than a corresponding predetermined value. A second intake air control mode of setting the intake throttle valve to (or close to) a fully-closed state and setting the EGR valve to (or close to) a fully-opened state is performed when the DPF temperature and the particulate matter deposition quantity are greater than the corresponding predetermined values respectively, the no-injection operation state exists, and the engine rotation speed is lower than the corresponding predetermined value.

Owner:DENSO CORP

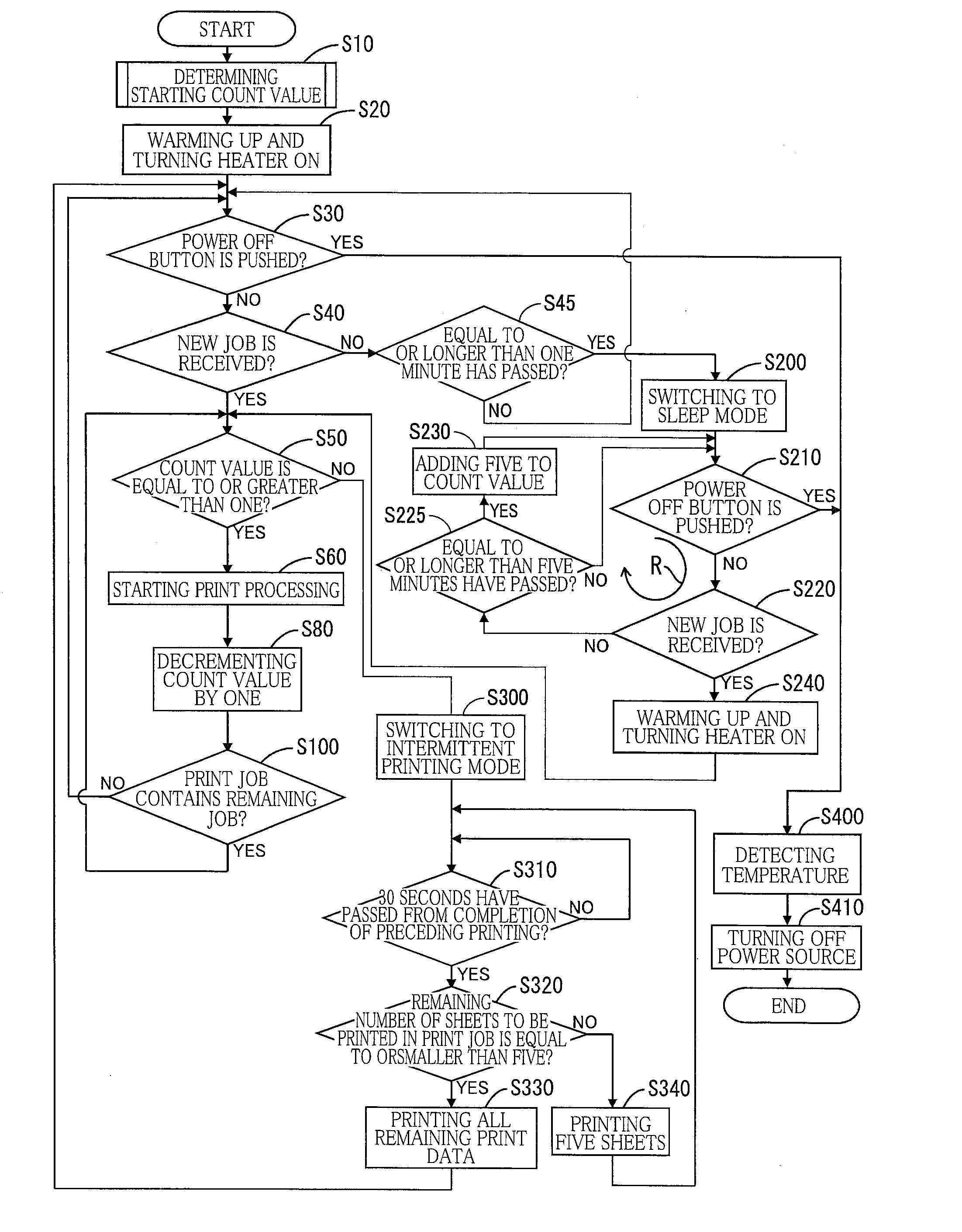

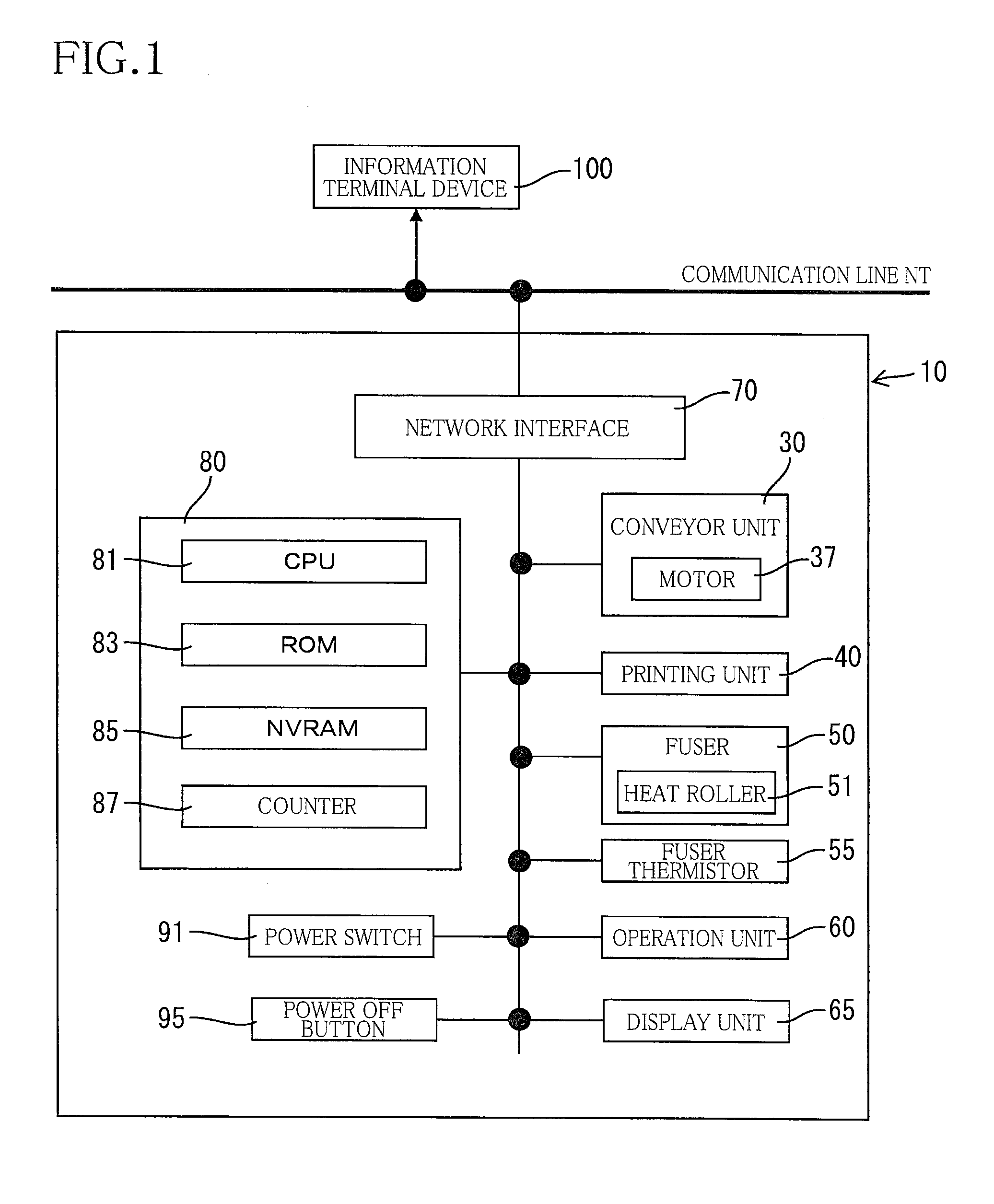

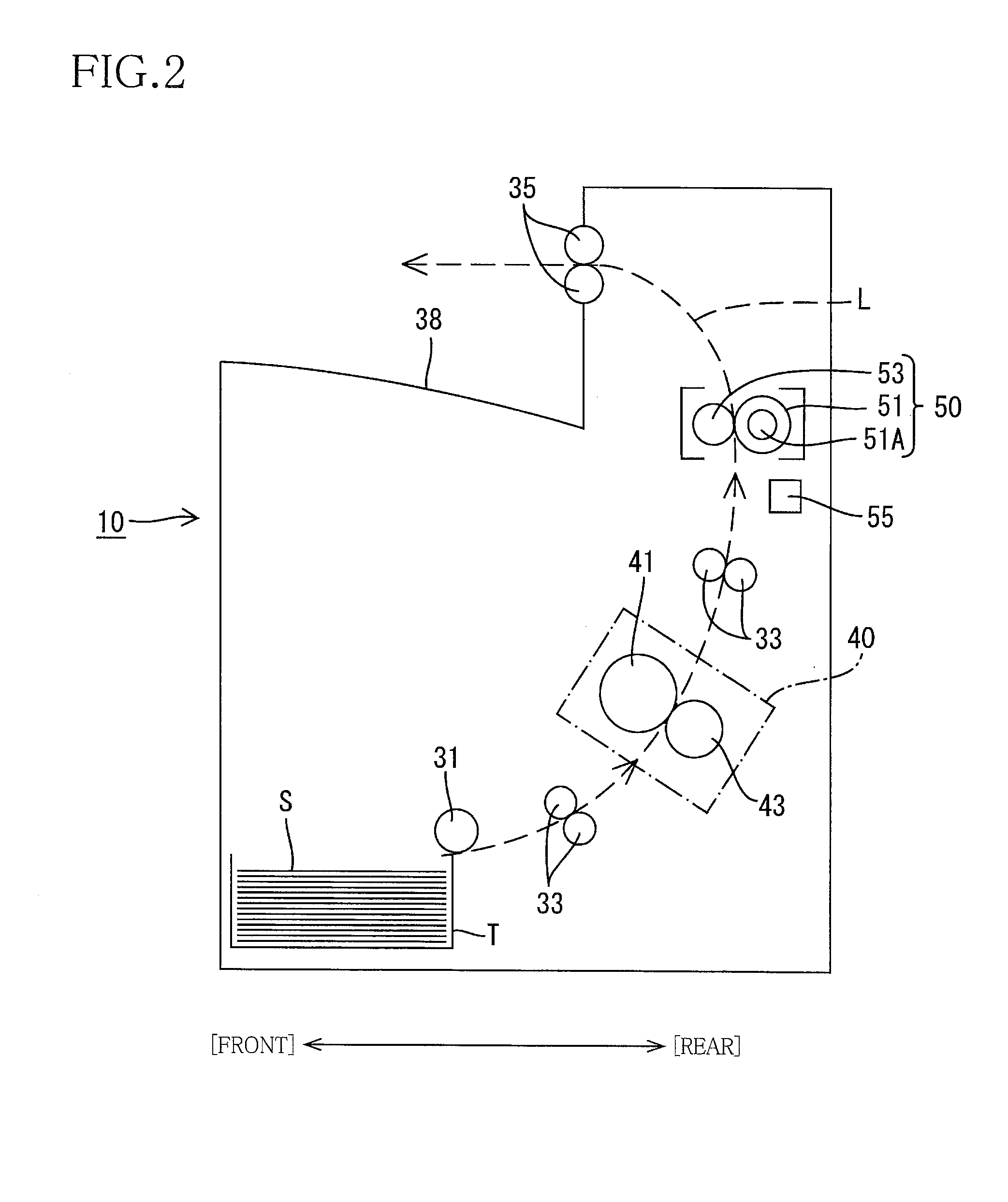

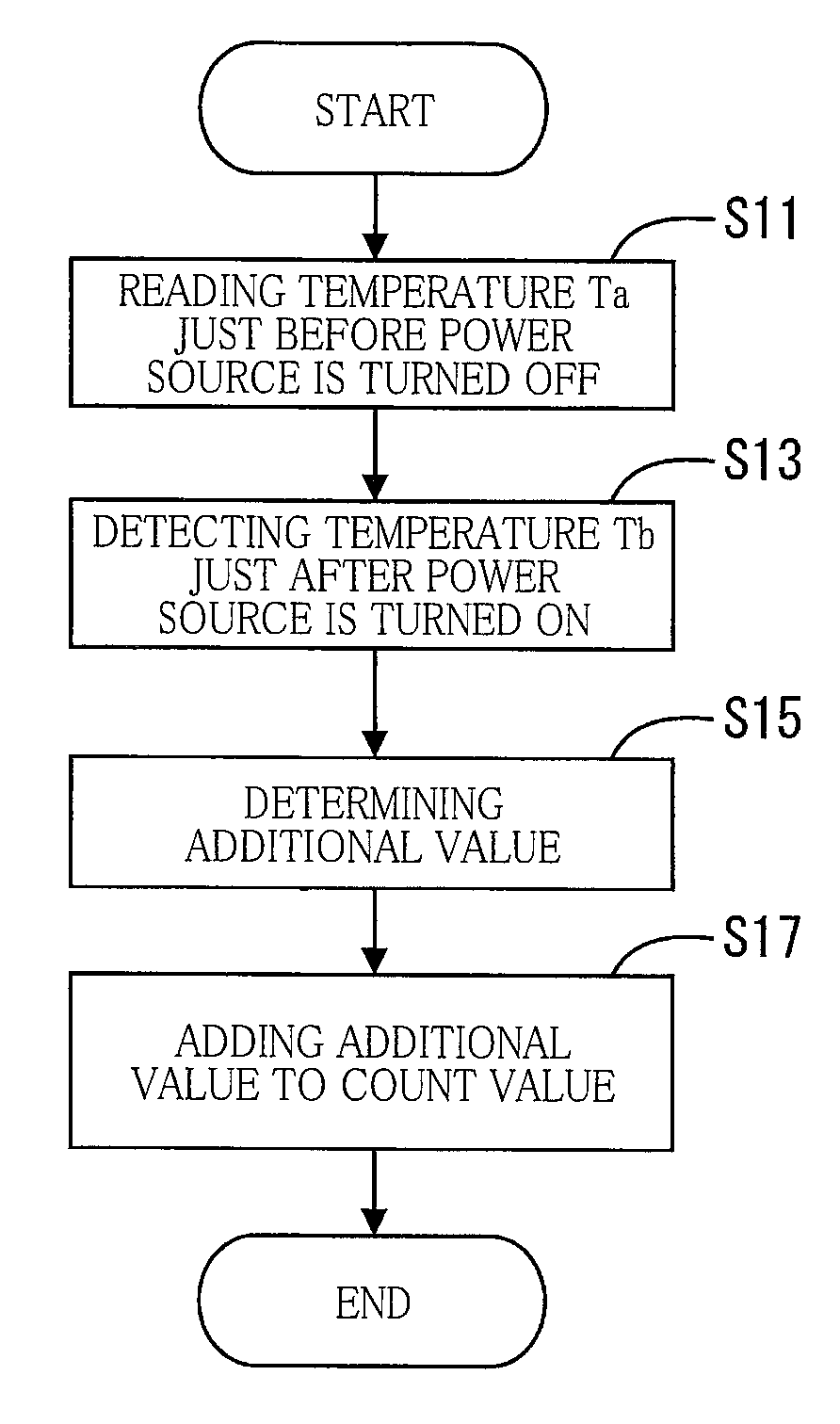

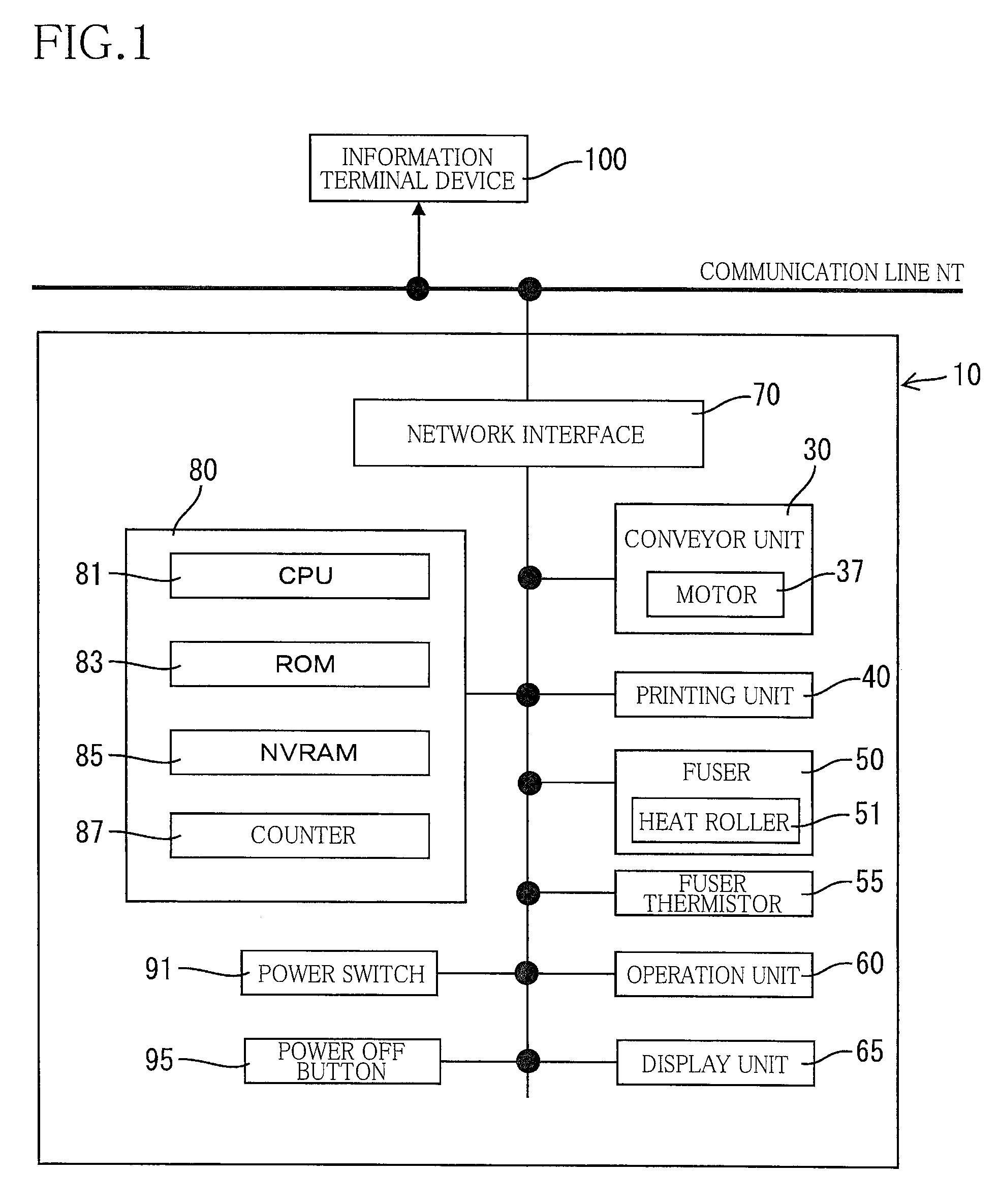

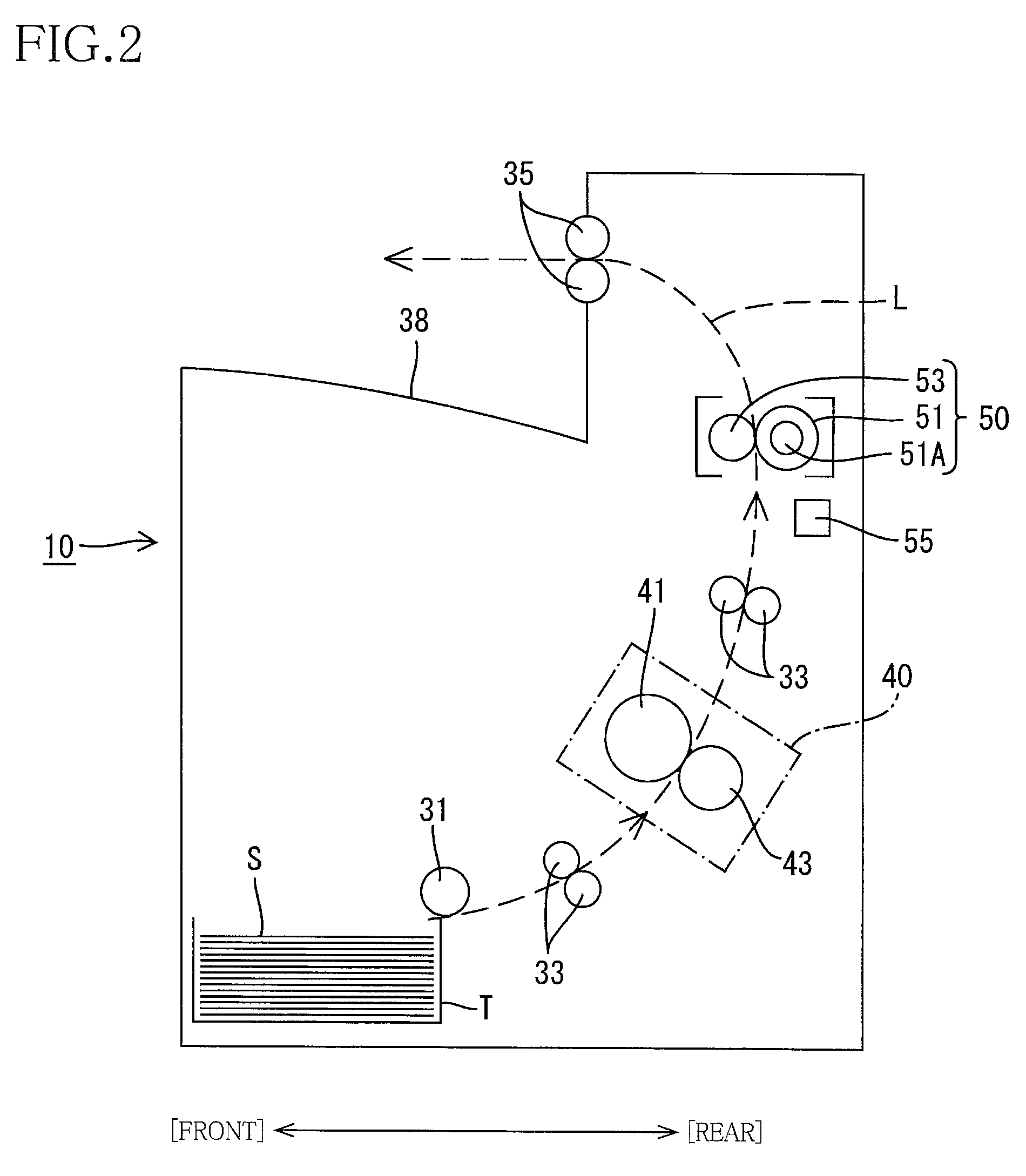

Printing apparatus

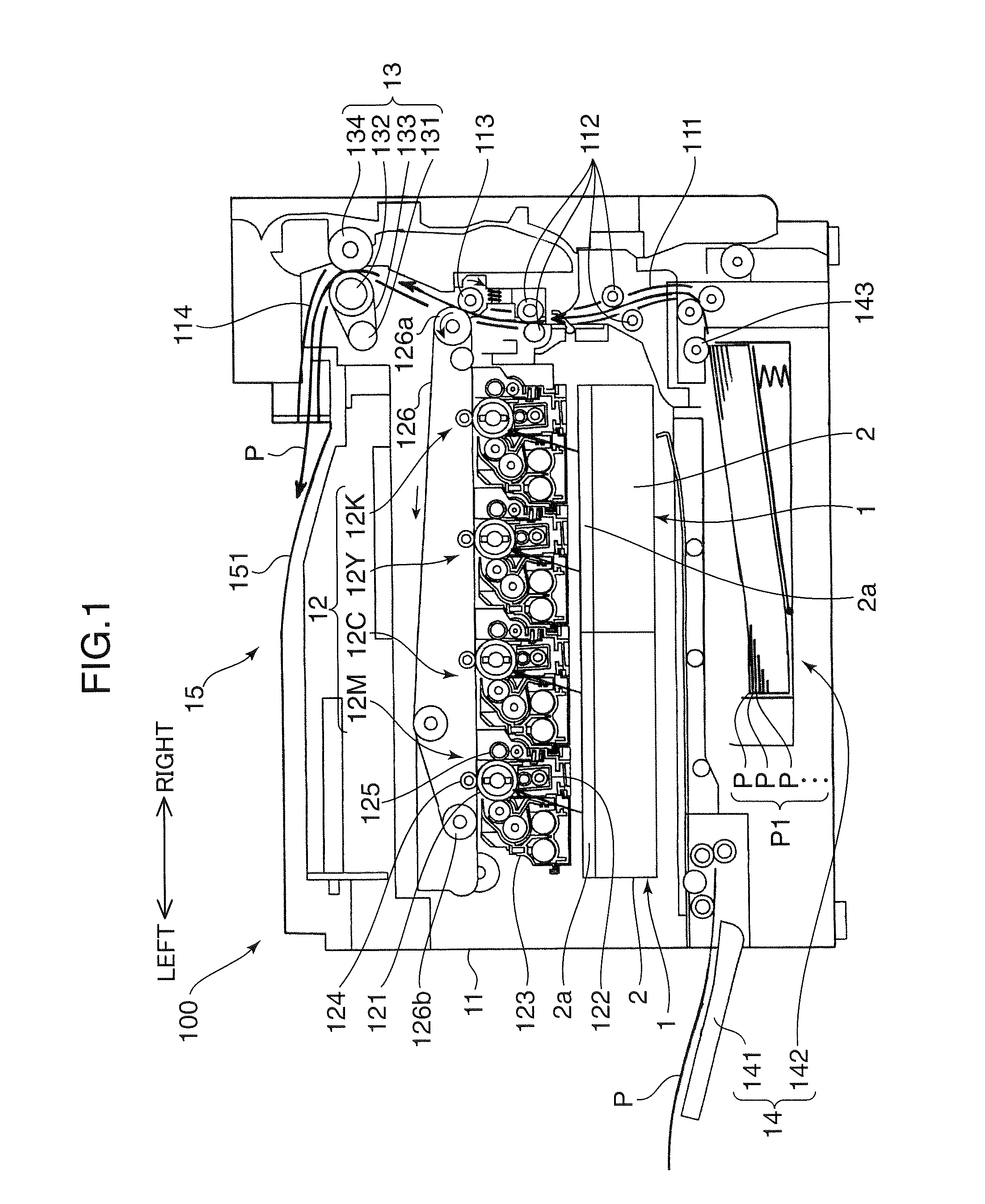

ActiveUS20140064766A1Productivity of printing is reducedDecrease productivityElectrographic process apparatusEngineeringElectrical and Electronics engineering

A printing apparatus includes: a printing device configured to print an image on a sheet; a temperature detector configured to detect a temperature in the printing apparatus; and a controller. The controller executes: a first processing in which the controller changes a first indicator based on printing performed by the printing device; a second processing in which the controller changes the first indicator based on a first temperature detected by the temperature detector at a first point in time and a second temperature detected by the temperature detector at a second point in time; and a third processing in which the controller suppresses a rise in the temperature in the printing apparatus when the first indicator reaches a predetermined value.

Owner:BROTHER KOGYO KK

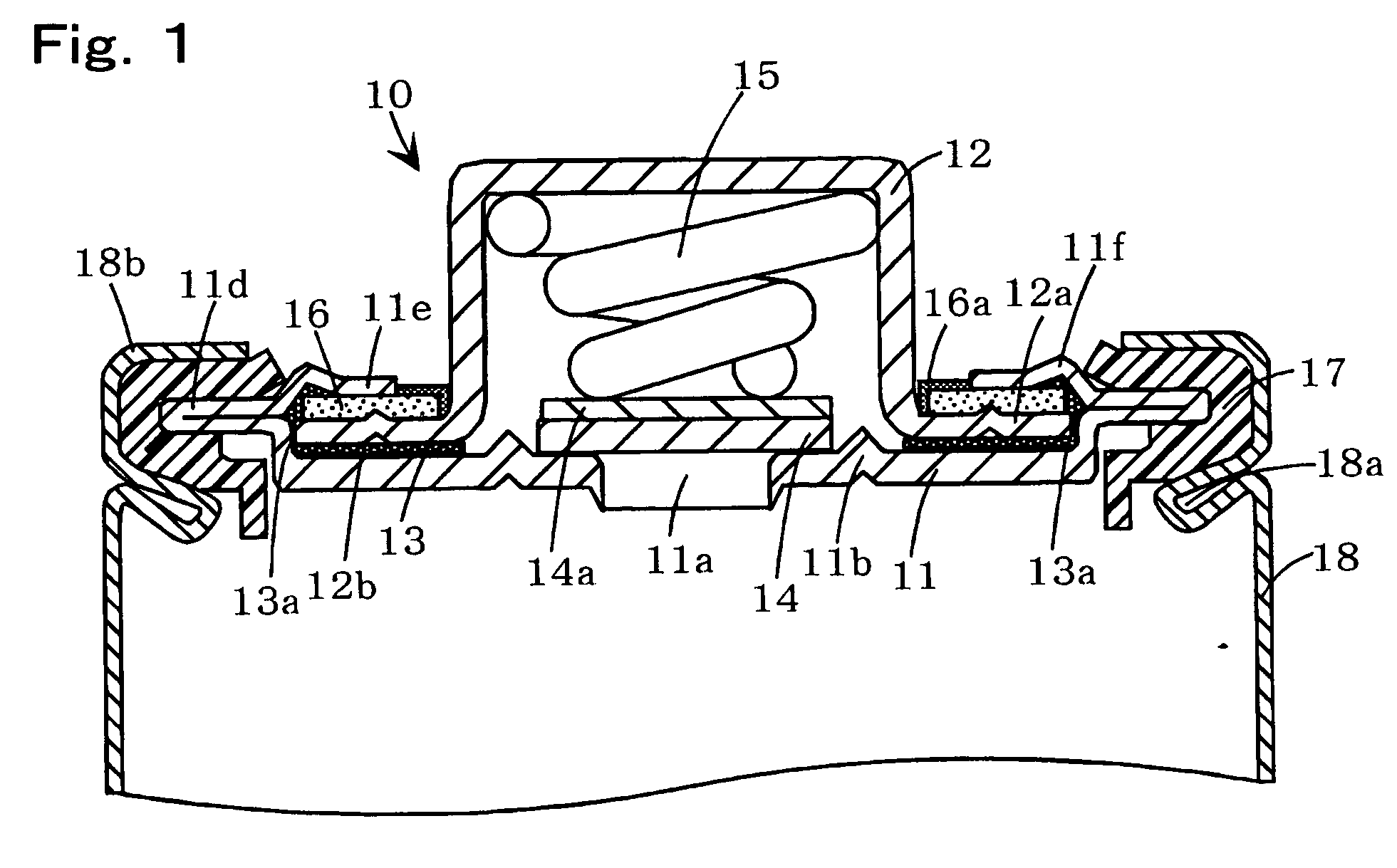

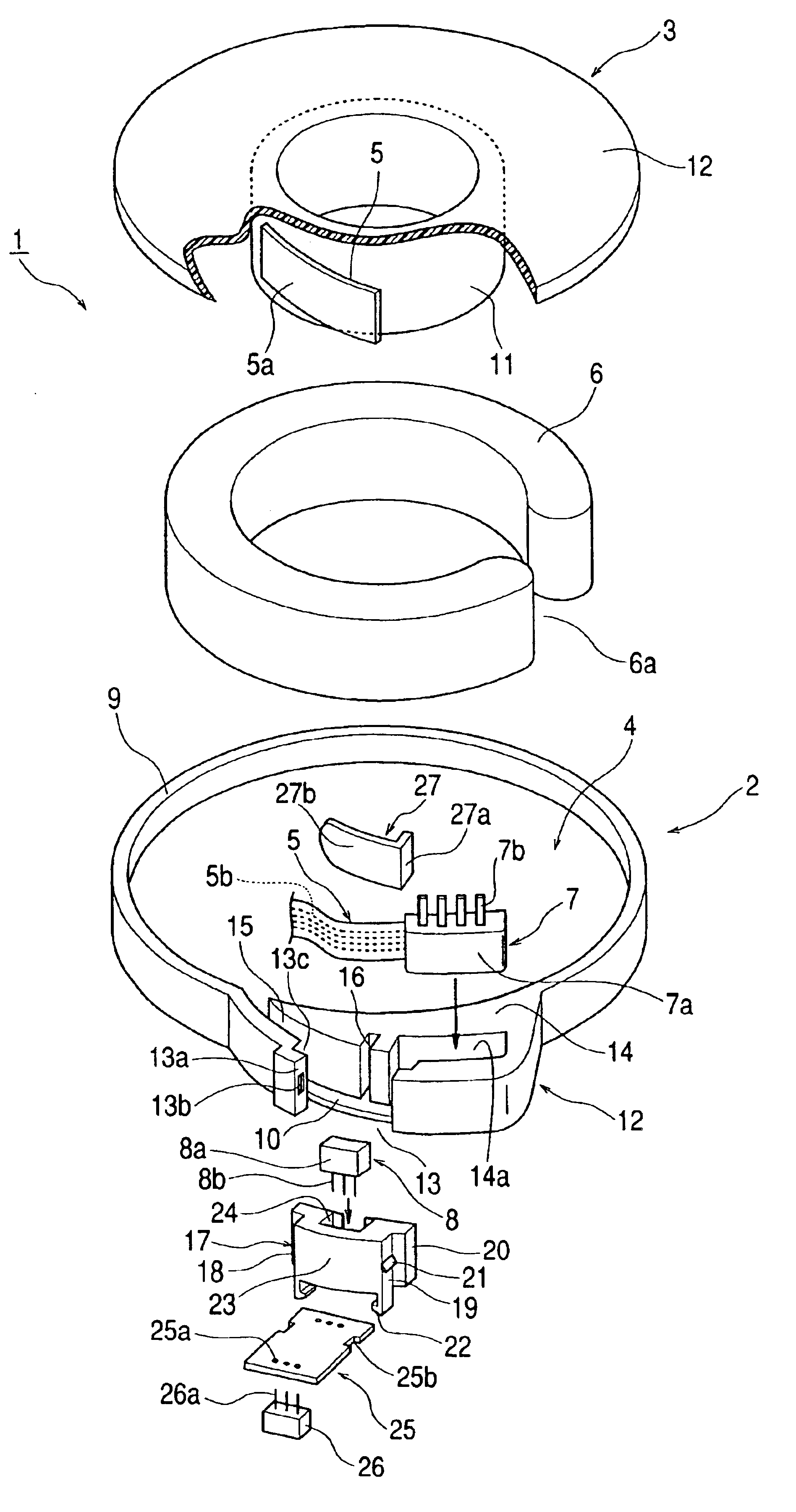

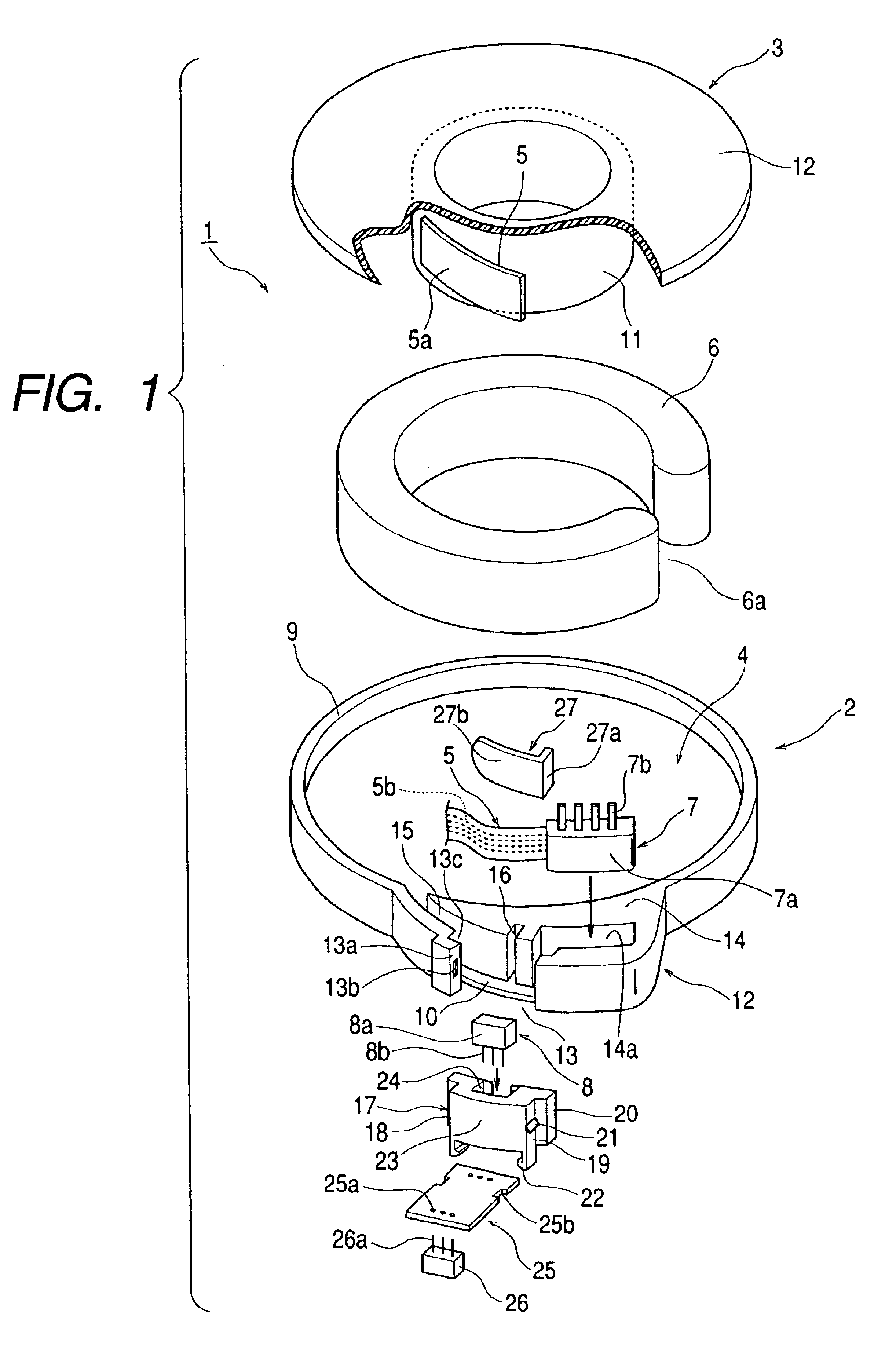

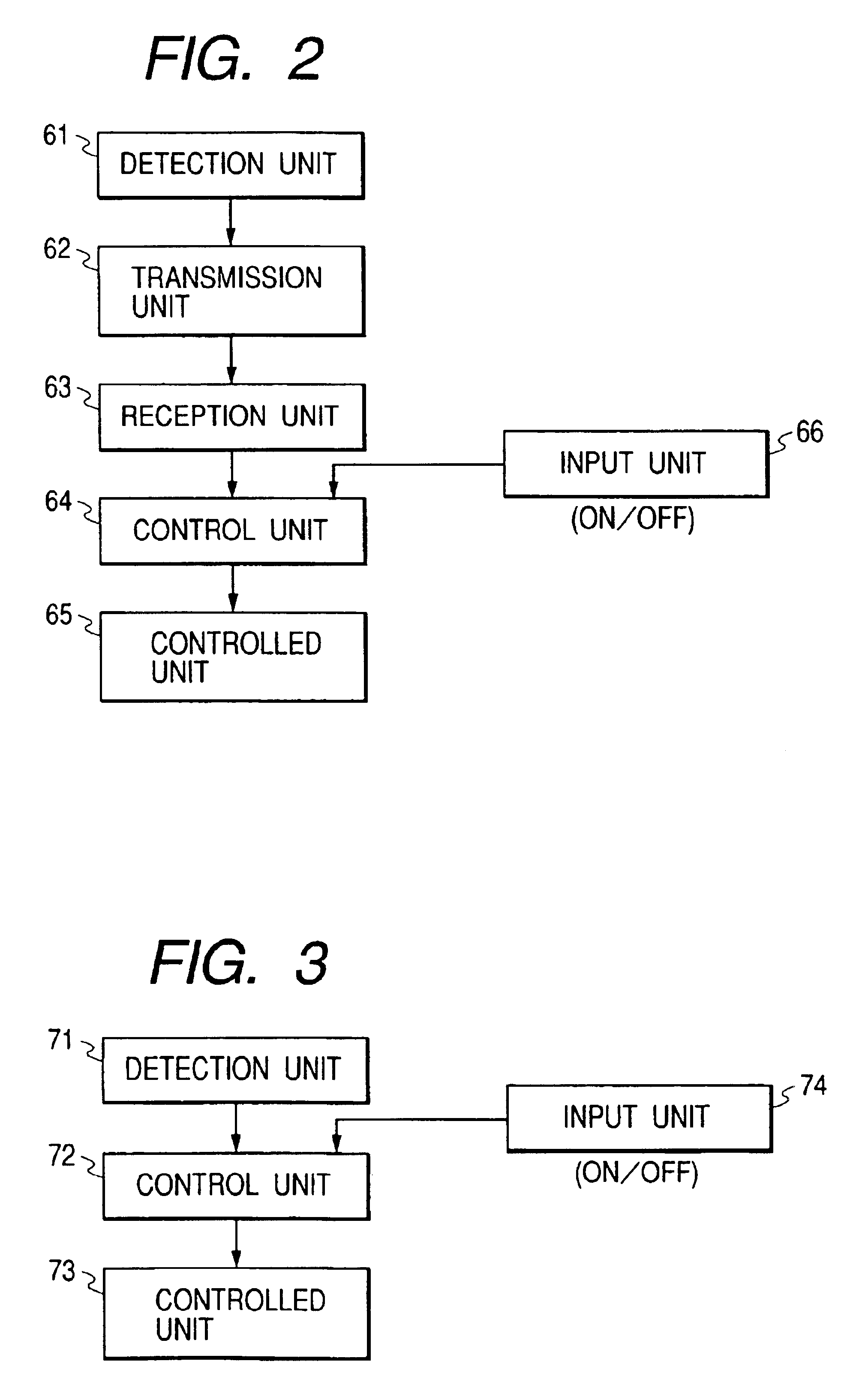

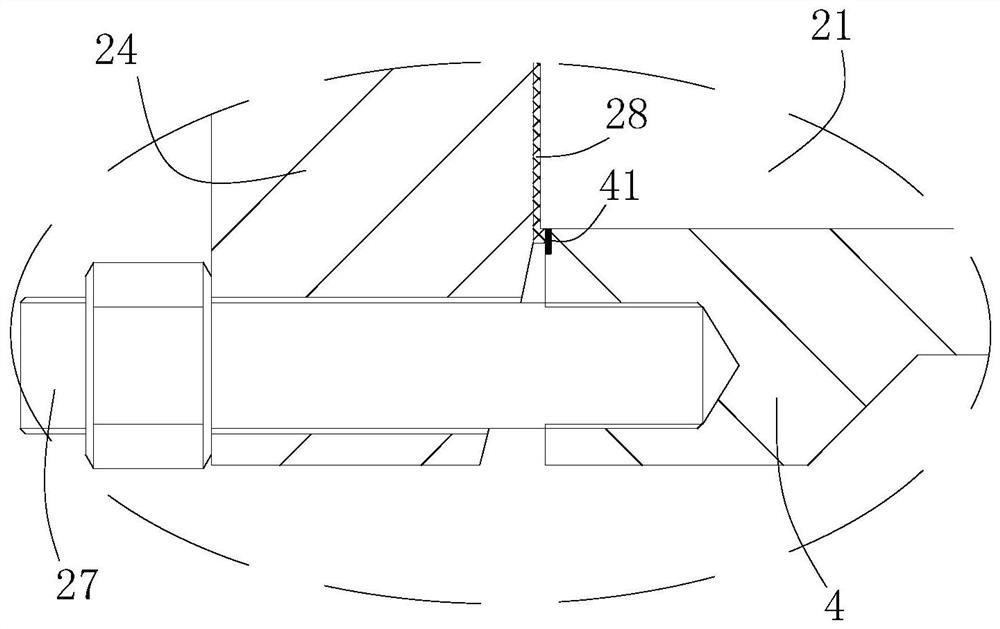

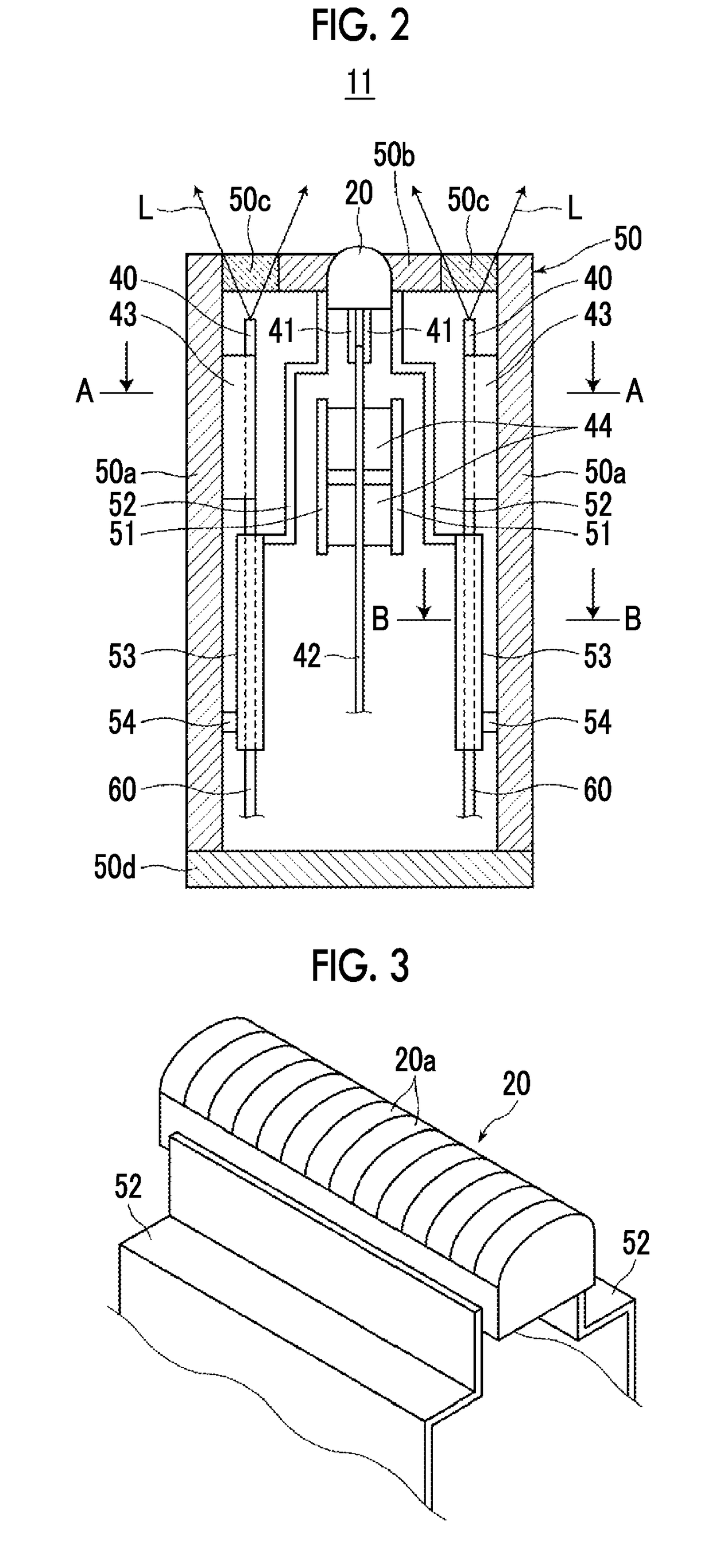

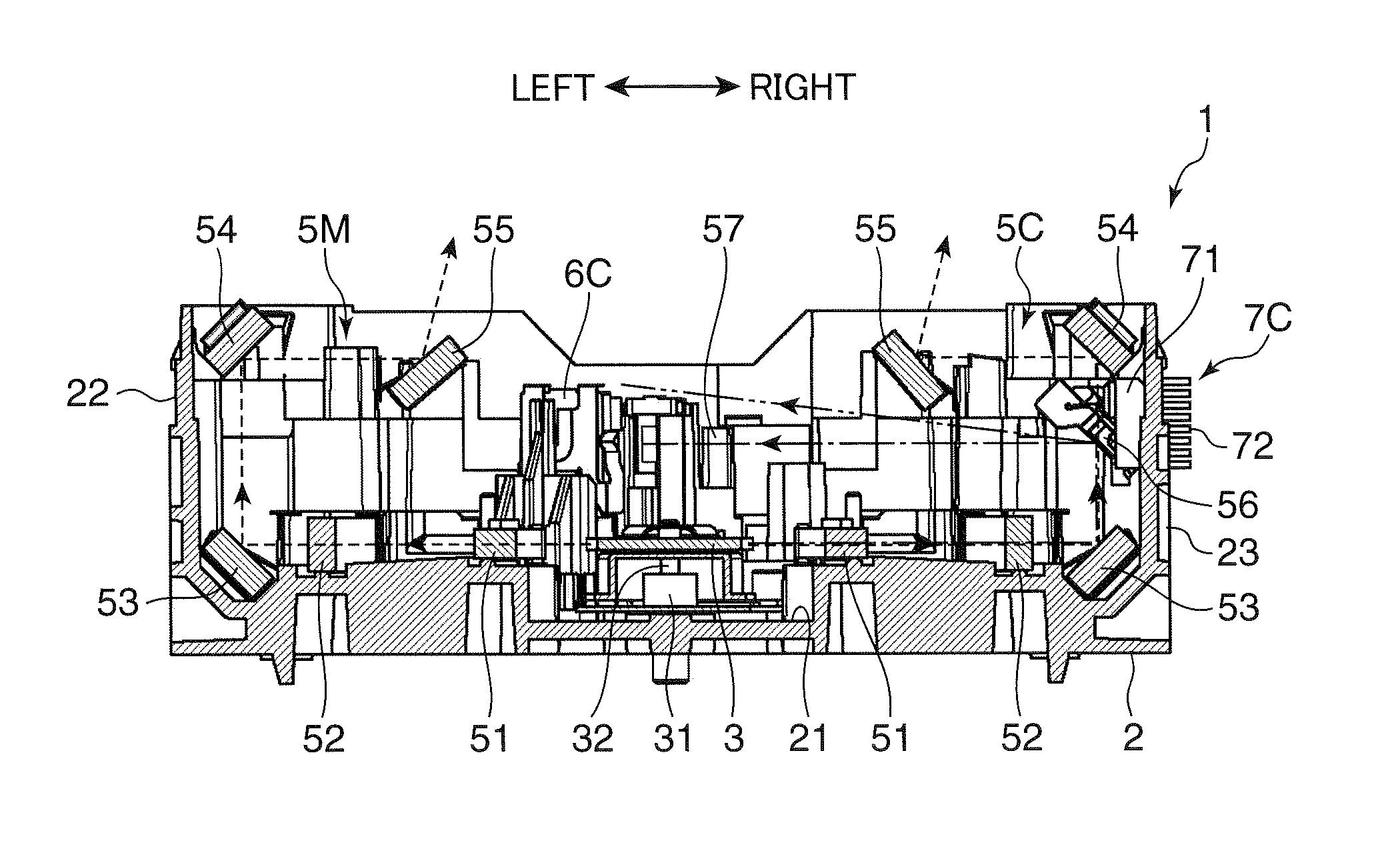

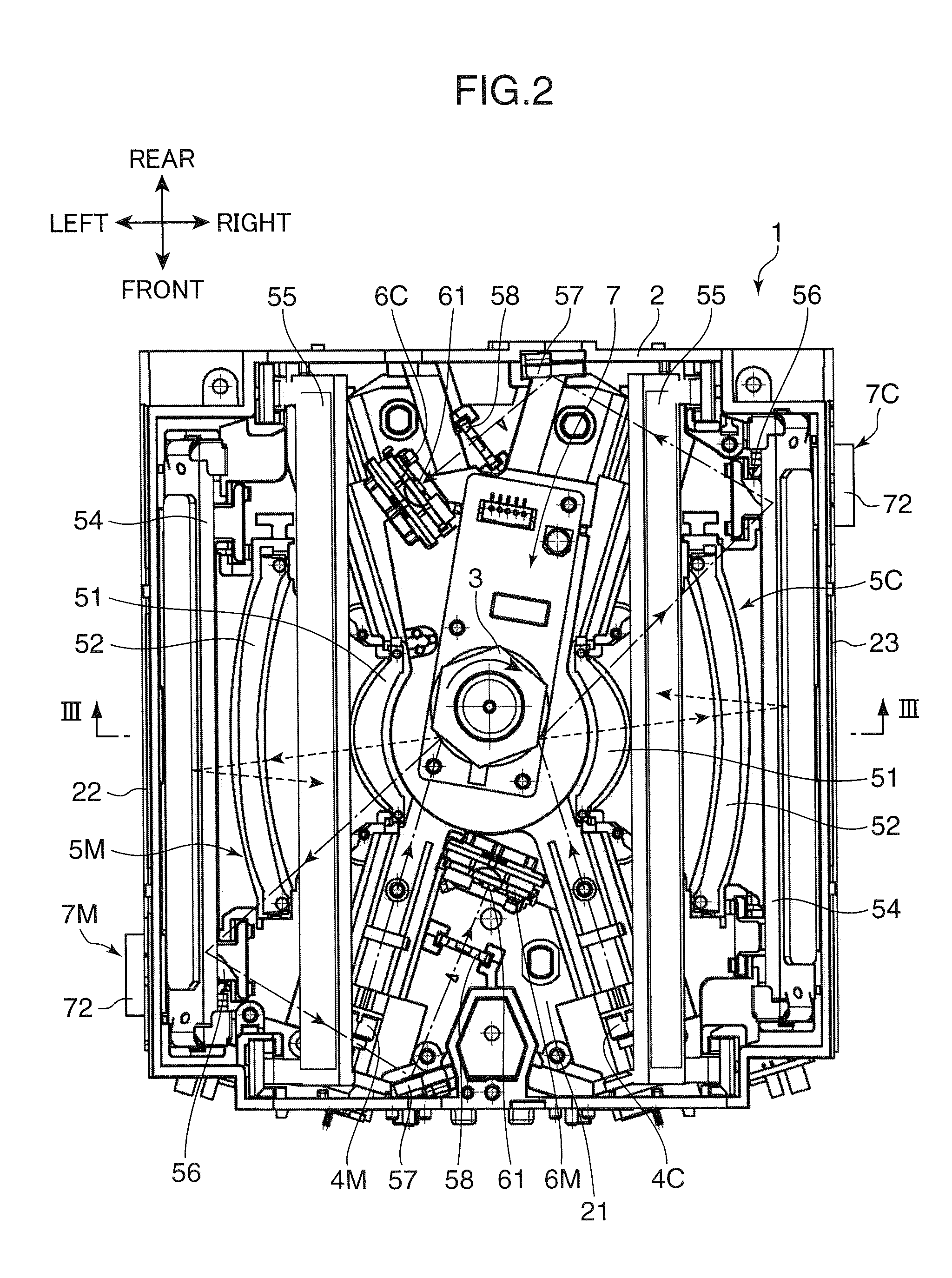

Rotary connector that prevents excessive temperature increase generated in a flexible cable

InactiveUS6843672B2Prevent excessive temperature riseRotary current collectorElectrically conductive connectionsFlexible cable

The rotary connector comprises a stationary housing 11 having a cylindrical portion 17 therein, a movable housing 12 having a cylindrical portion 19 therein provided on the stationary housing so as to be rotatable relatively thereto, and a flexible cable 14 accommodated within a housing section 13 formed between the stationary housing and the movable housing, in which the rotary connector further includes temperature detection means 41 for detecting the temperature of the flexible cable in a state of the temperature detection means being exposed within the housing section.

Owner:ALPS ALPINE CO LTD

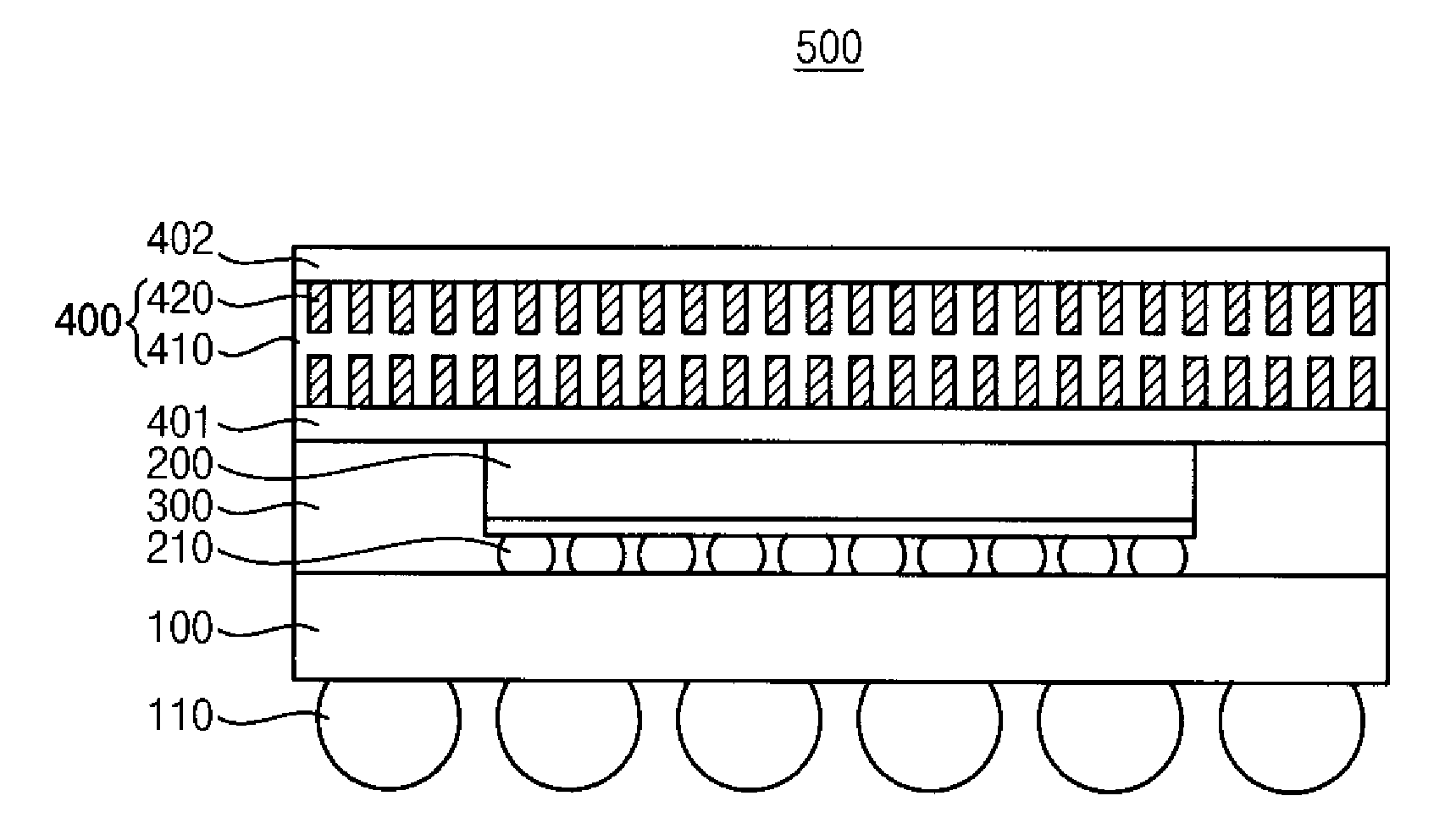

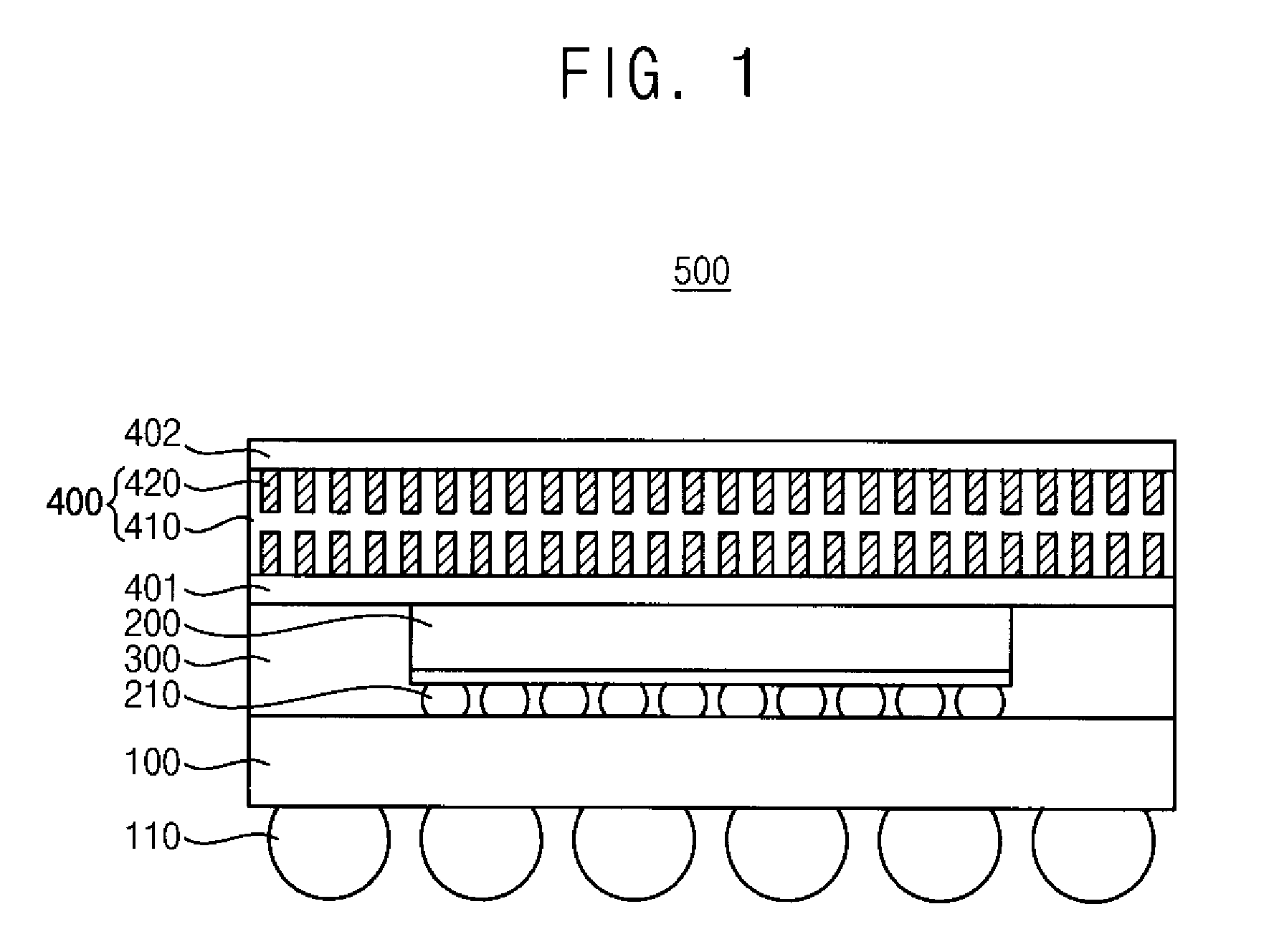

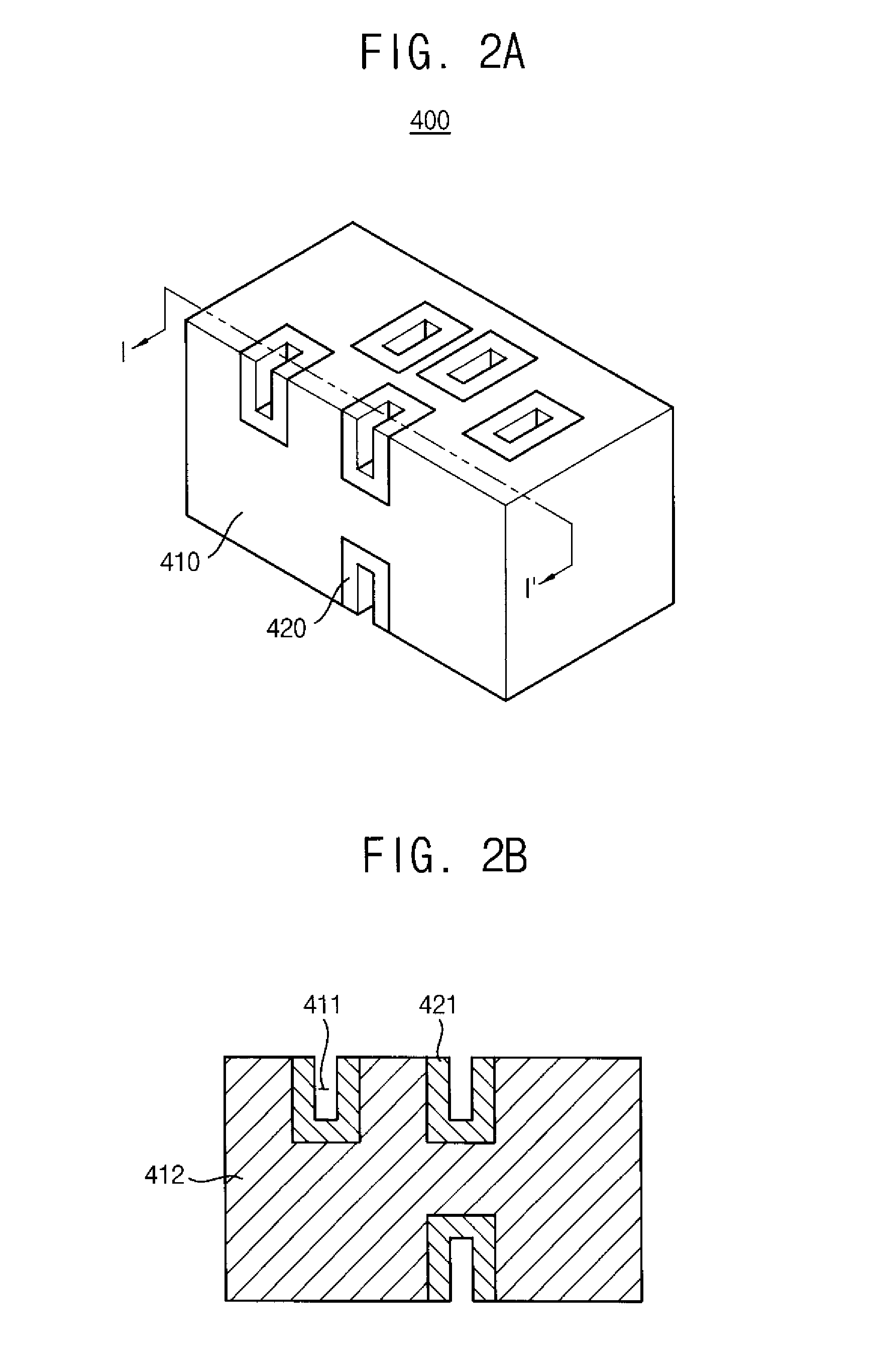

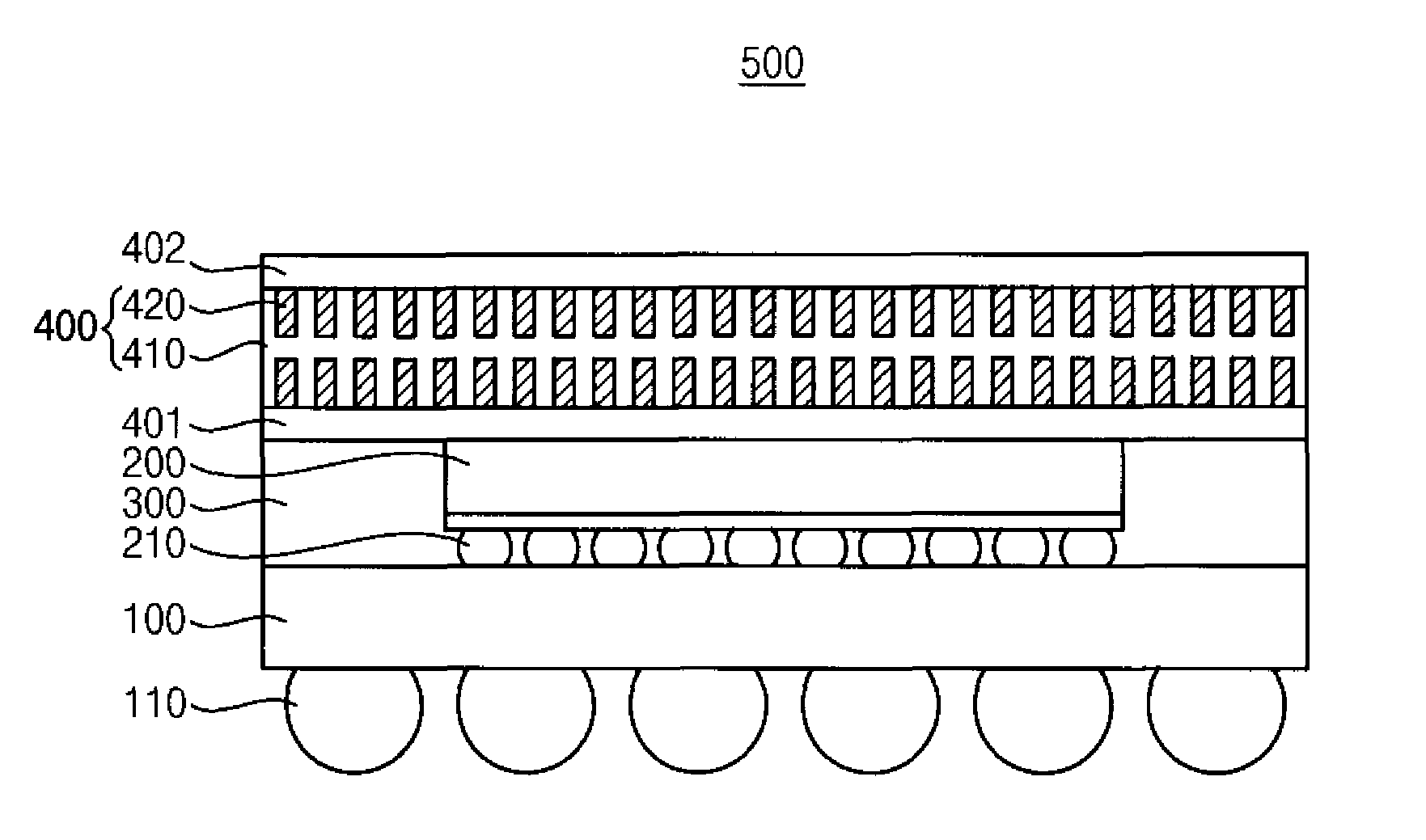

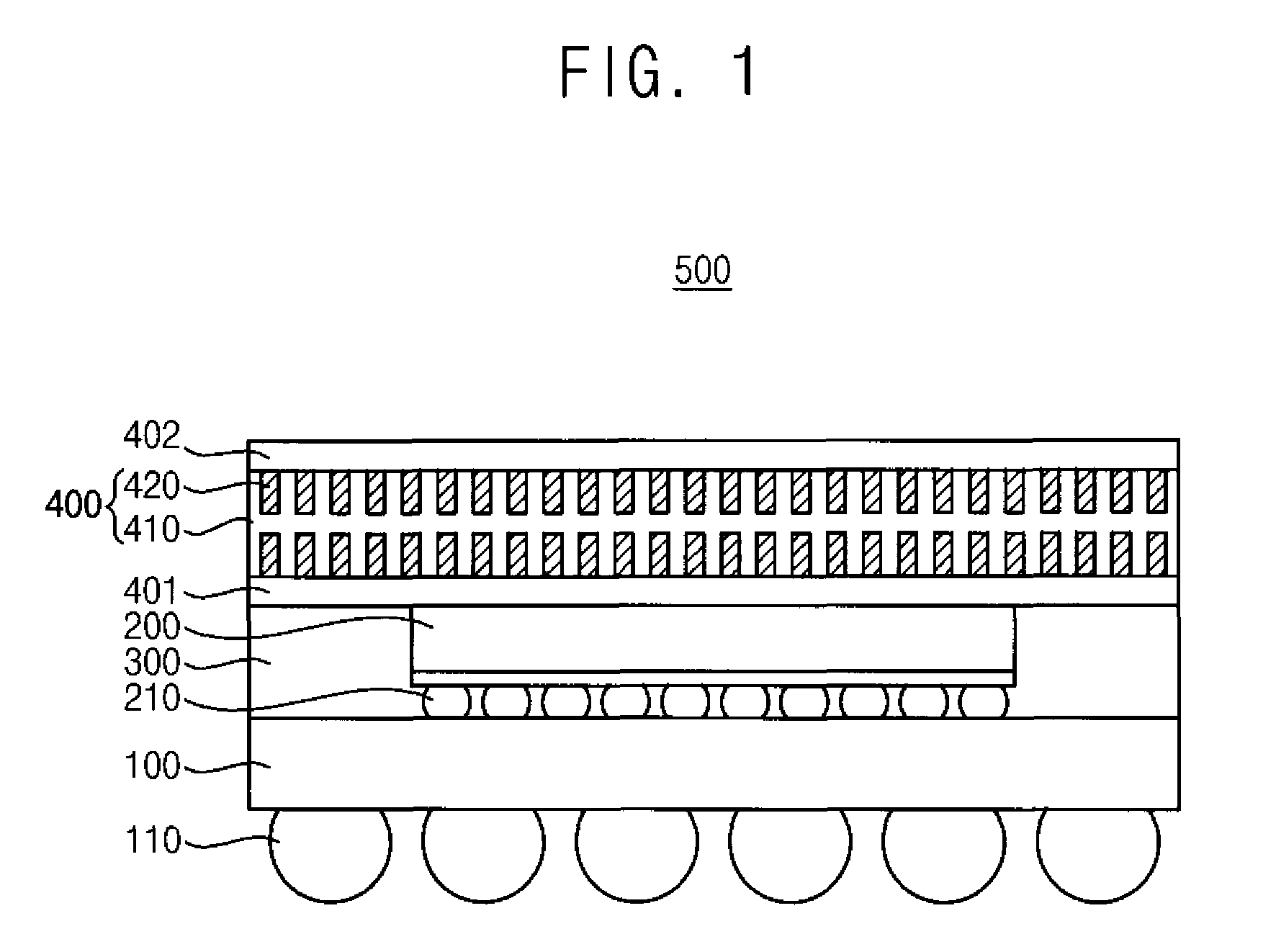

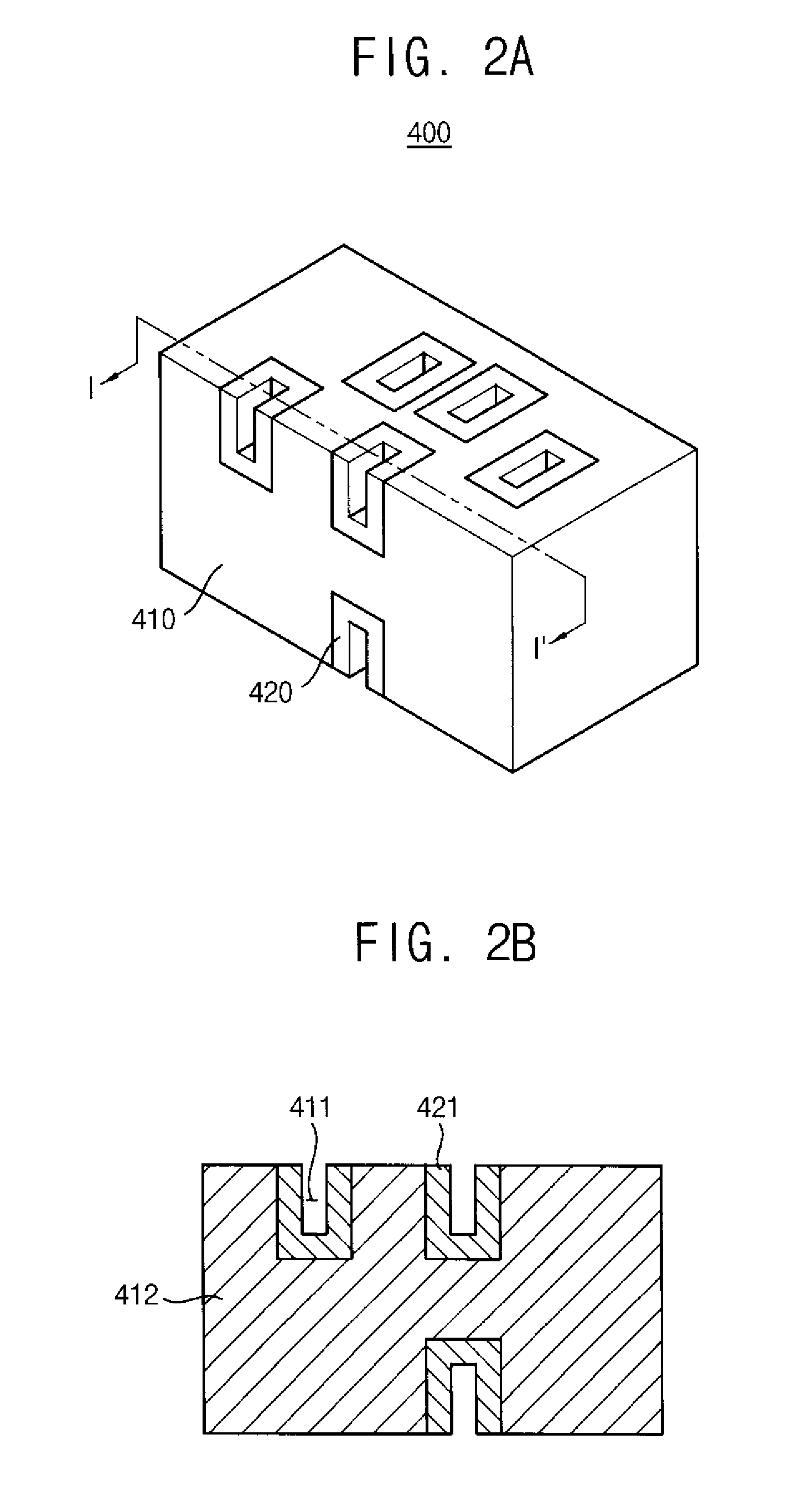

Semiconductor package

ActiveUS20140217576A1Prevent excessive temperature riseSemiconductor/solid-state device detailsSolid-state devicesCritical timeSemiconductor chip

A semiconductor package and a method of manufacturing the same are disclosed, wherein the semiconductor package includes a circuit board, a semiconductor chip mounted on the circuit board, an encapsulant positioned on the circuit board and encapsulating the semiconductor chip to the circuit board, and a thermal dissipating member positioned on the encapsulant and having a heat spreader that dissipates a driving heat from the semiconductor chip and a heat capacitor that absorbs excess driving heat that exceeds a heat transfer capability of the heat spreader, such that when a high power is applied to the package, the excess heat is absorbed into the heat capacitor as a latent heat and thus the semiconductor chip is protected from an excessive temperature increase caused by the excess heat, thereby increasing a critical time and performance duration time of the semiconductor package.

Owner:SAMSUNG ELECTRONICS CO LTD

Evaporation apparatus, method of manufacturing anode using same, and method of manufacturing battery using same

ActiveCN101381857AAvoid temperature riseLess radiant heatFinal product manufactureVacuum evaporation coatingEvaporationVapor phase

An evaporation apparatus that is capable of stably forming a good quality thin film and is highly suitable for mass production is provided. The evaporation apparatus include an evaporation source discharging an evaporation material by heating, a retention member retaining an evaporation object, and a heat shield member that is located between the evaporation source and the evaporation object retained by the retention member, has an opening for passing the evaporation material in a state of vapor phase from the evaporation source to the evaporation object, and shields the evaporation object from part of radiation heat of the evaporation source. The heat shield member is located closer to the evaporation source than to the retention member.

Owner:MURATA MFG CO LTD

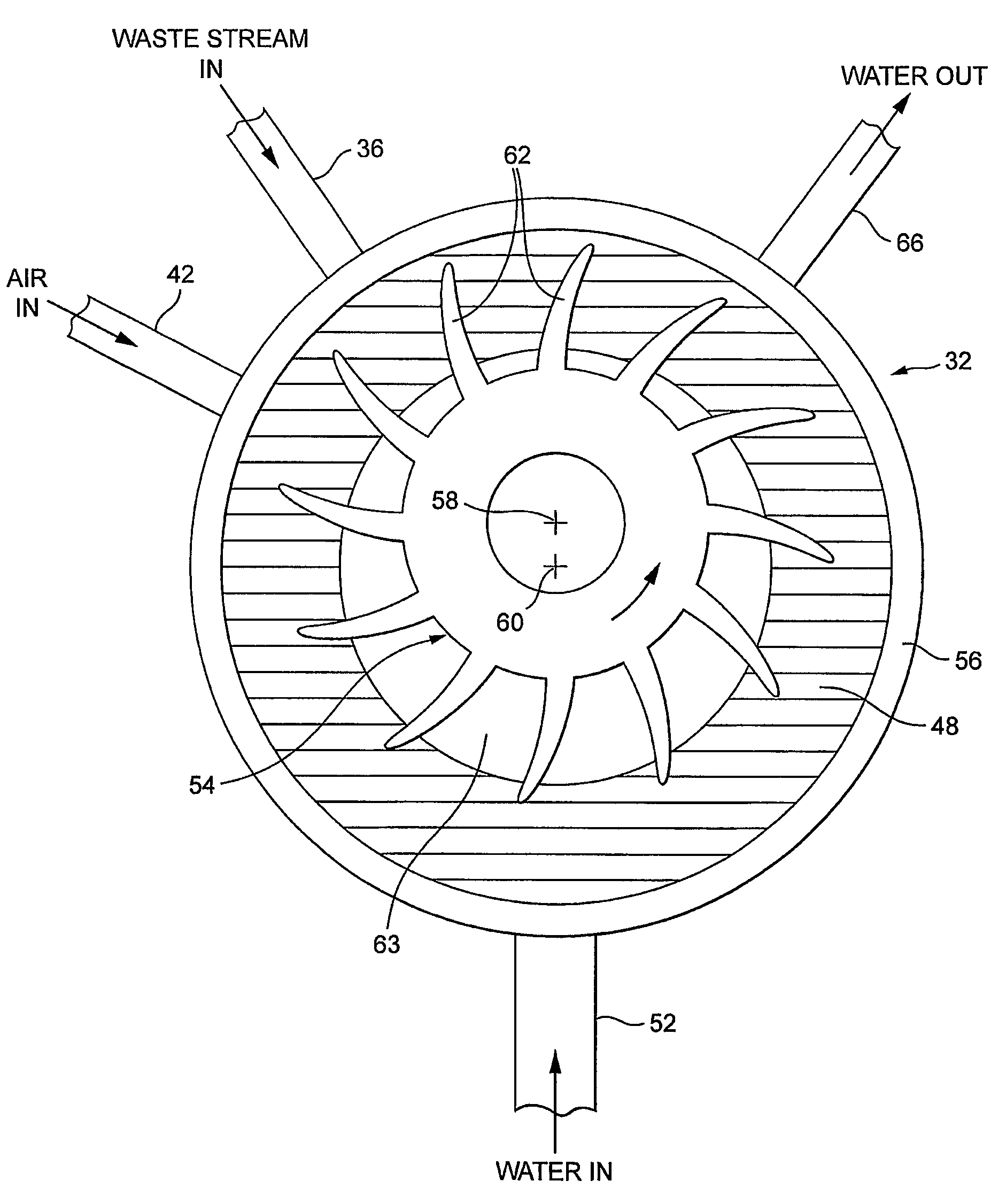

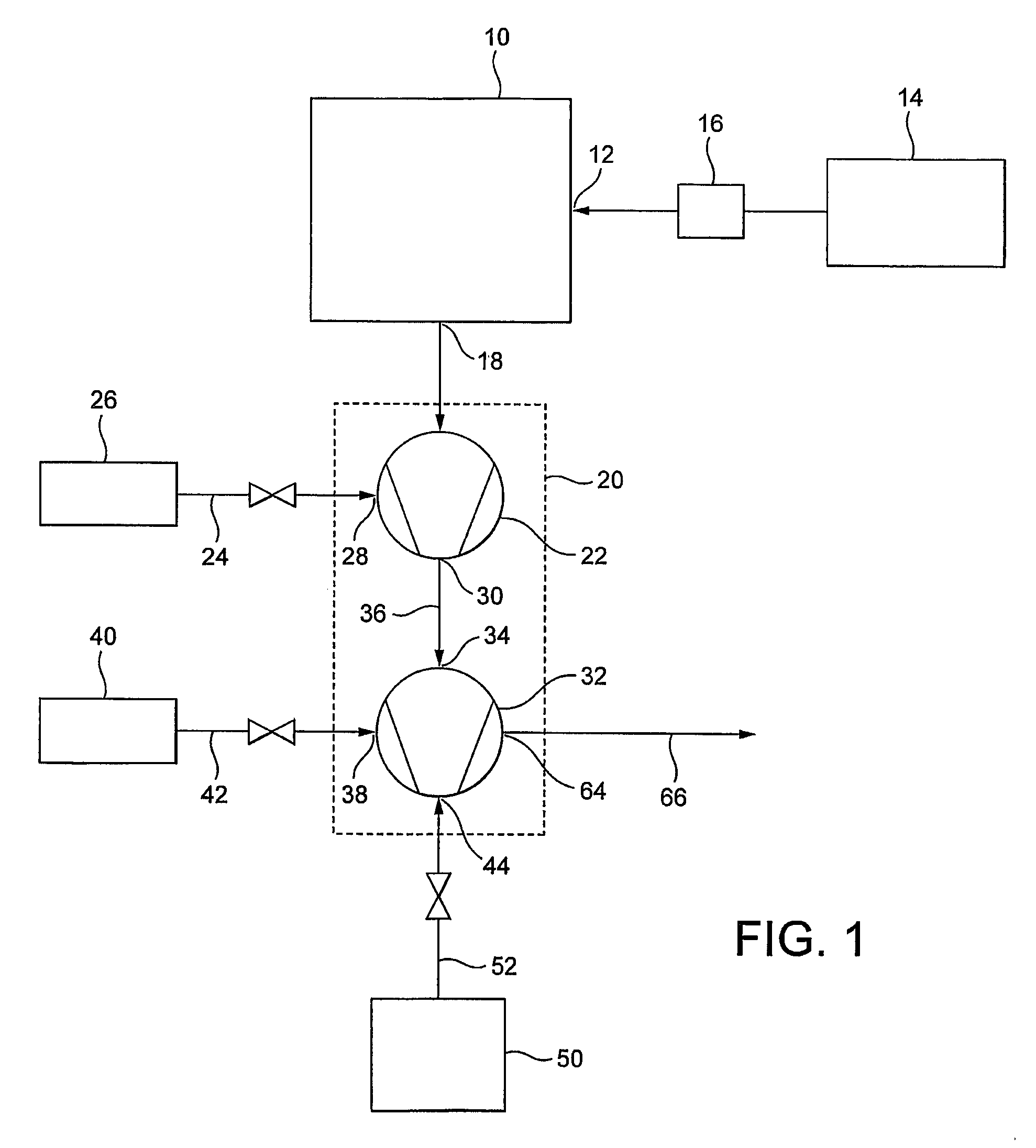

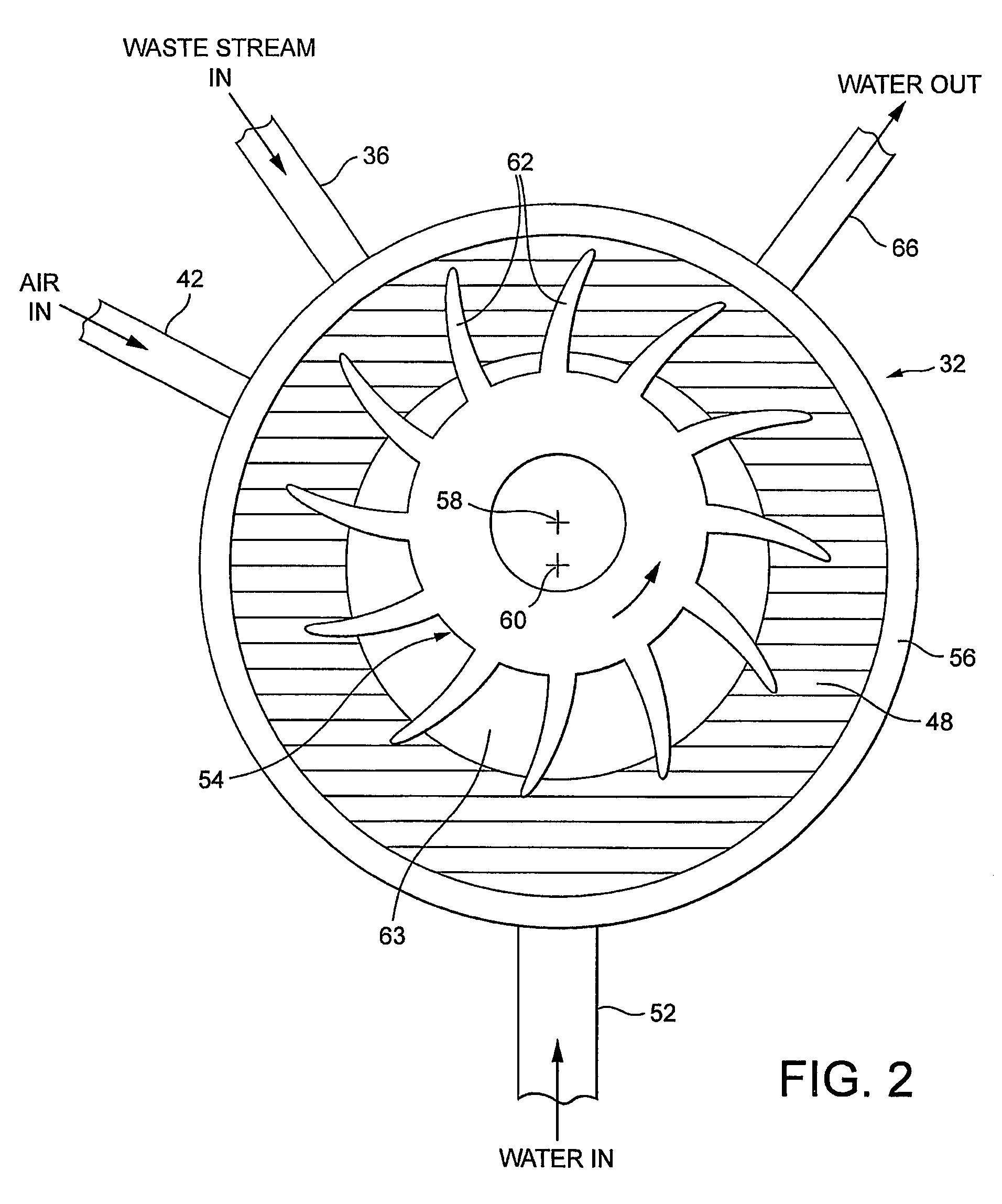

Method of treating a gas stream

ActiveUS7740815B2Prevent excessive temperature riseReduce pressureProcess control/regulationCombination devicesLiquid-ring pumpSilanes

A method of treating a gas stream containing silane or other silicon-containing gas is described, in which the gas stream is conveyed to a liquid ring pump or screw-mechanism pump, to which are also supplied an oxidant for oxidising the silicon-containing gas within the pump, and a liquid for forming a liquid ring or intermittent flushing within the pump. A liquid stream containing said liquid and a by-product of the oxidation of the silicon-containing gas is exhaust from the pump.

Owner:EDWARDS LTD

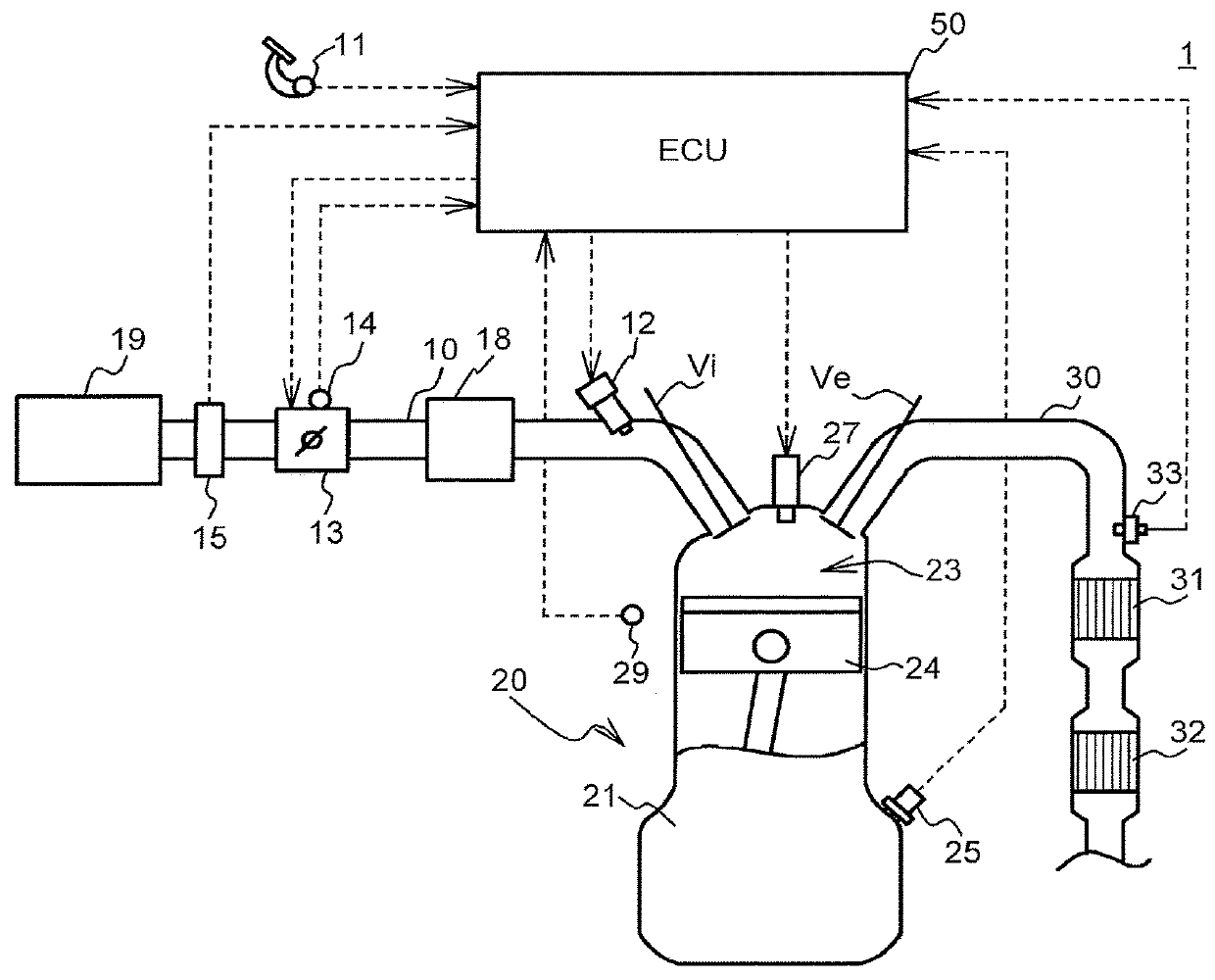

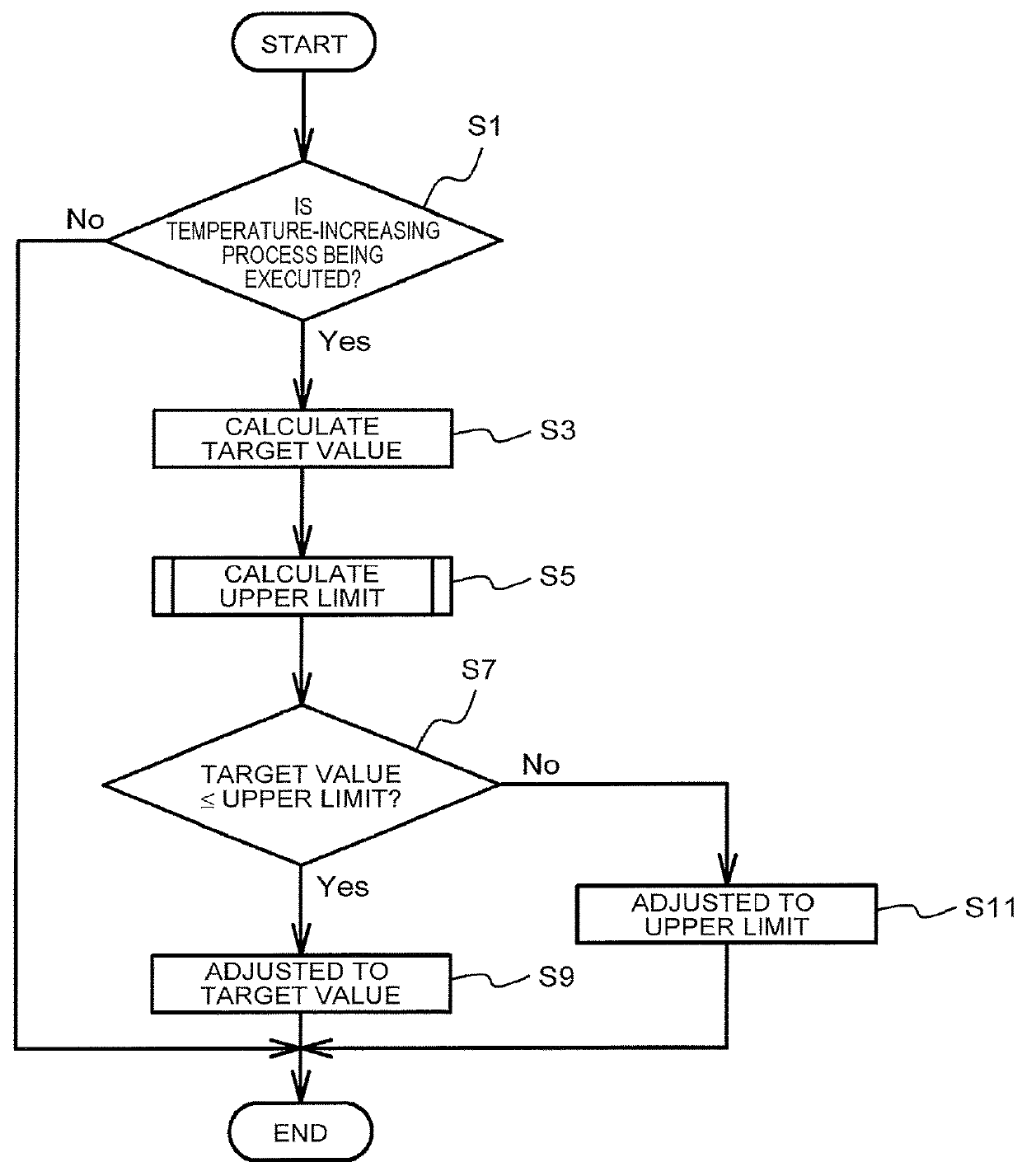

Control apparatus for internal combustion engine

ActiveUS20180179972A1Temperature dropIncrease temperatureElectrical controlInternal combustion piston enginesAir–fuel ratioControl theory

A control apparatus for an internal combustion engine includes an ECU configured to: determine whether a temperature-increasing process is being executed; calculate a target value of a parameter correlated with a difference between a rich air-fuel ratio and a lean air-fuel ratio achieved in the temperature-increasing process, based on an operating state of the internal combustion engine; calculate, as an upper limit, a value of the parameter required to increase the temperature of the catalyst to a predetermined upper limit temperature; determine whether the target value is equal to or lower than the upper limit; adjust the parameter used in the temperature-increasing process to the target value when the target value is determined to be equal to or lower than the upper limit; and adjust the parameter used in the temperature-increasing process to the upper limit when the target value is determined to be higher than the upper limit.

Owner:TOYOTA JIDOSHA KK

Exhaust gas purification device of internal combustion engine

ActiveUS8137434B2Prevent excessive temperature riseCombination devicesAuxillary pretreatmentParticulatesExternal combustion engine

Owner:DENSO CORP

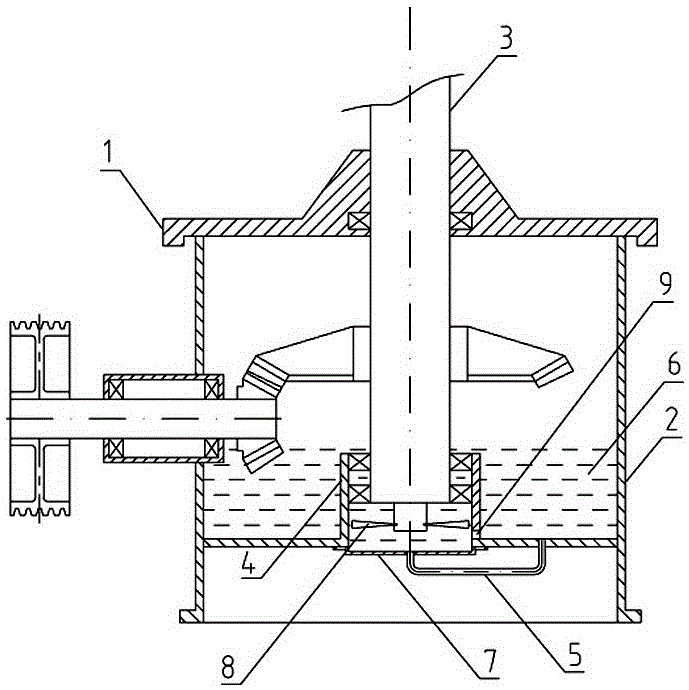

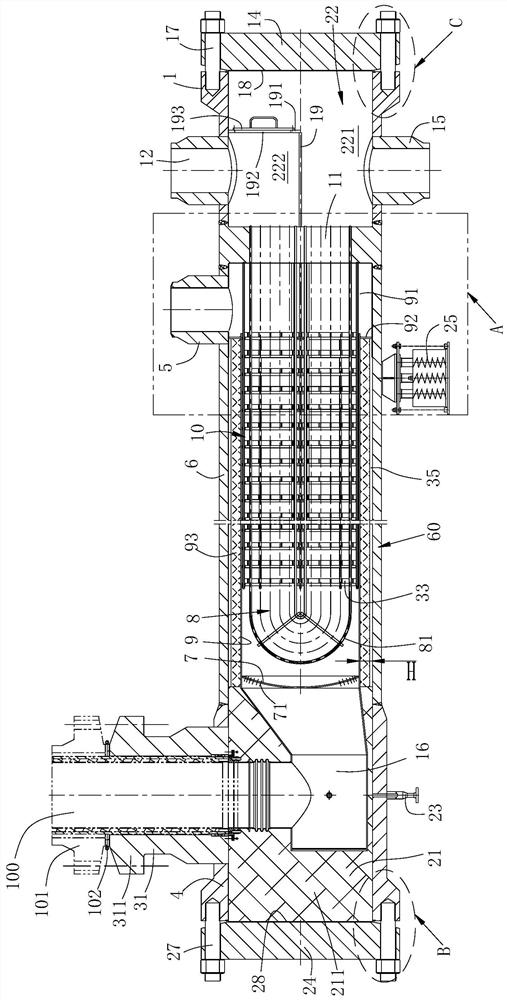

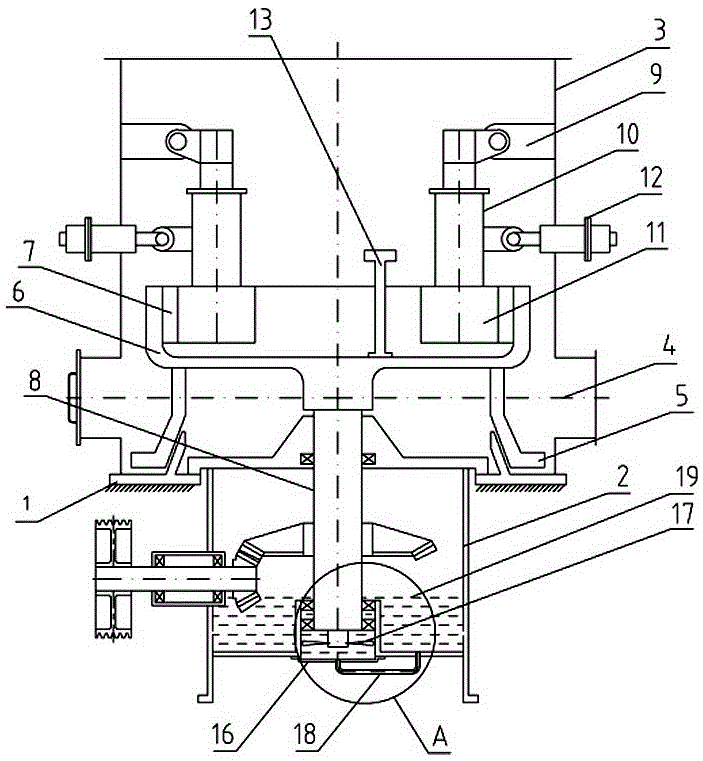

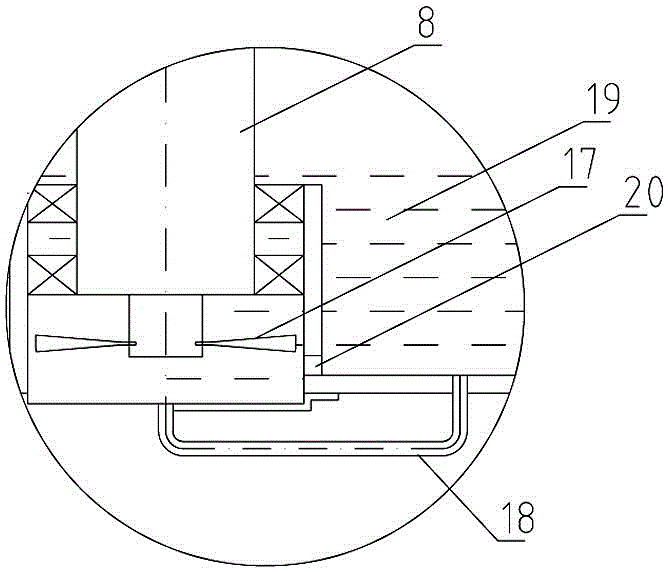

Vertical speed reducer with vertical shaft bearing lubricating oil circulating device

InactiveCN106352063APrevent excessive temperature rise of bearingsPrevent excessive temperature riseGear lubrication/coolingImpellerMarine engineering

The invention discloses a vertical reducer with a vertical shaft bearing lubricating oil circulation device, comprising a vertical reducer body, the bottom wall of the gearbox of the vertical reducer body, and a bearing chamber located under the power output shaft of the gearbox An oil guide pipe is arranged at the position, one nozzle of the oil guide pipe communicates with the lower bearing chamber and the other nozzle communicates with the oil pool in the gearbox; the lower end of the gearbox power output shaft extends to the bearing In the chamber, an impeller is fixed on the power output shaft of the gearbox extending into the bearing chamber. The invention has the advantage of realizing the forced circulation of the lubricating oil in the lower bearing chamber of the power output shaft, preventing the occurrence of super high temperature rise of the bearing caused by the impurity precipitation due to the failure of the lubricating oil at the bearing position of the lower bearing chamber.

Owner:HENAN LIMING HEAVY IND SCI & TECH

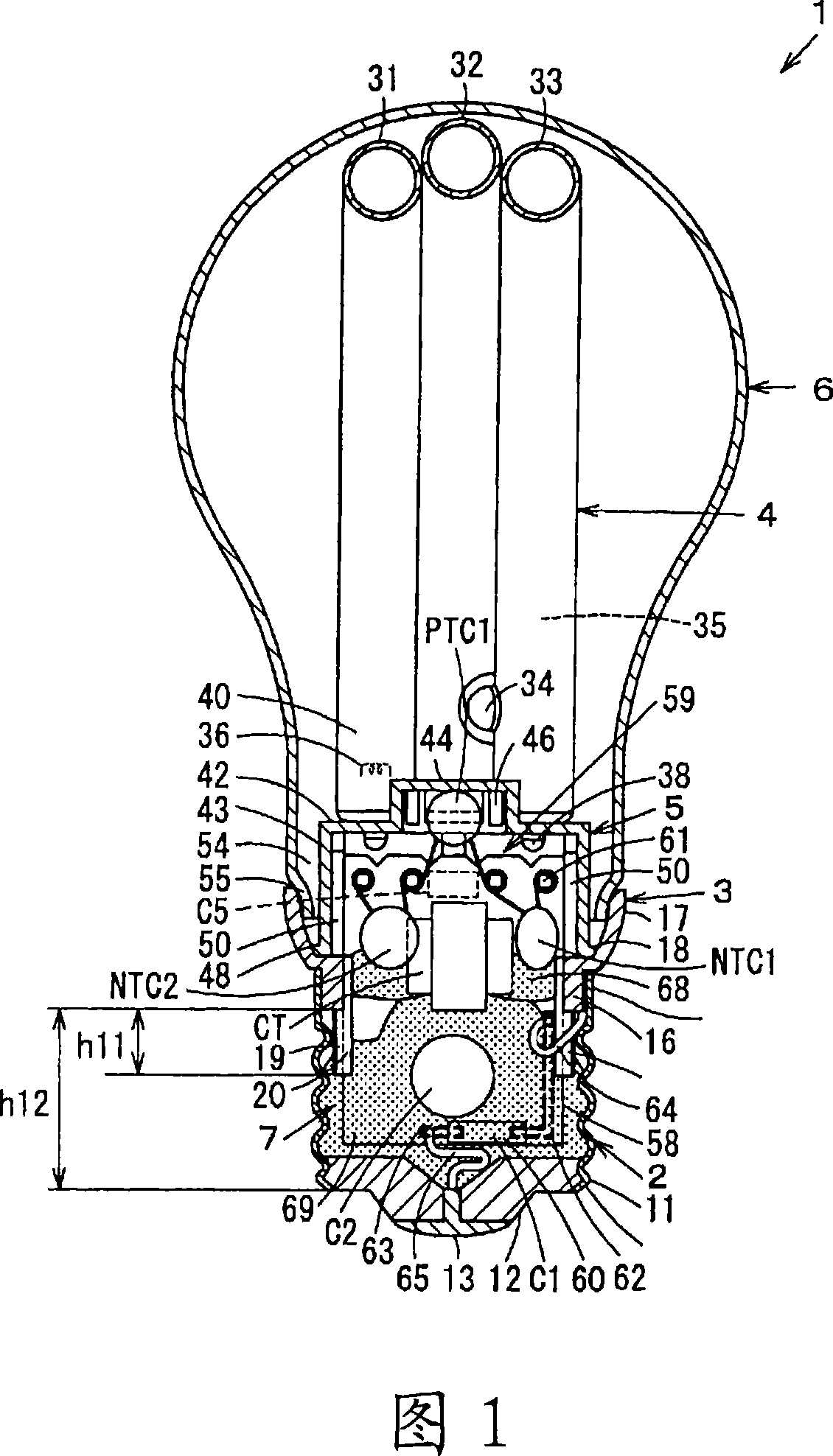

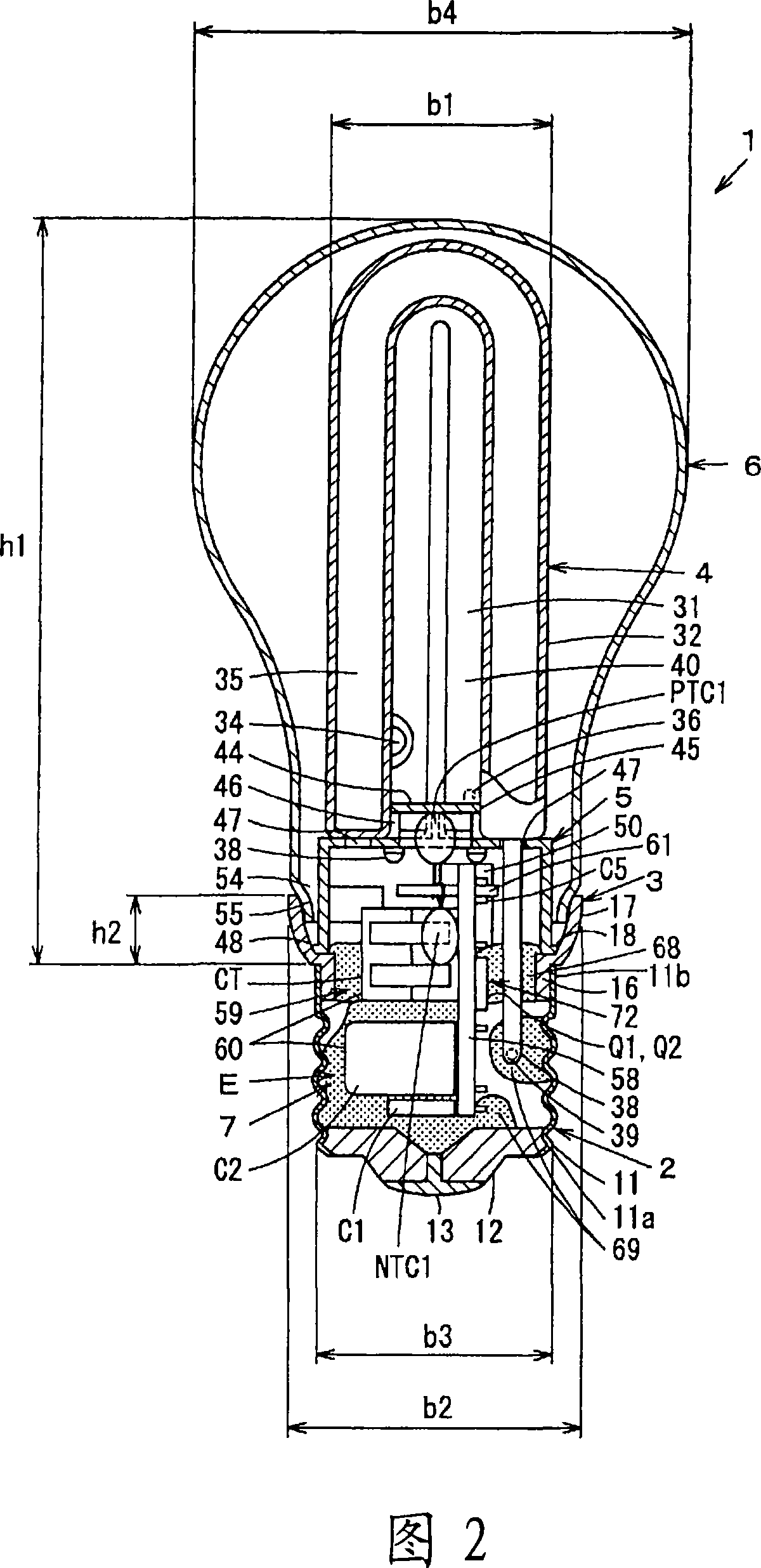

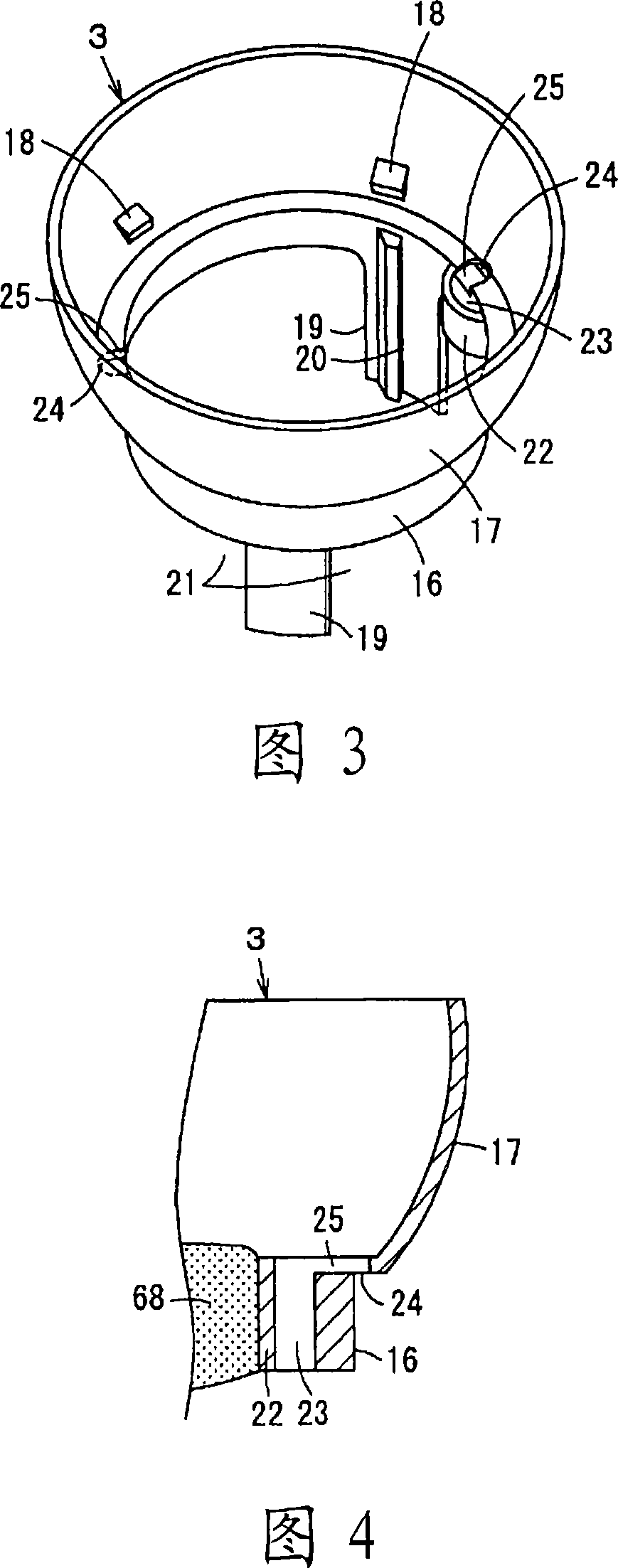

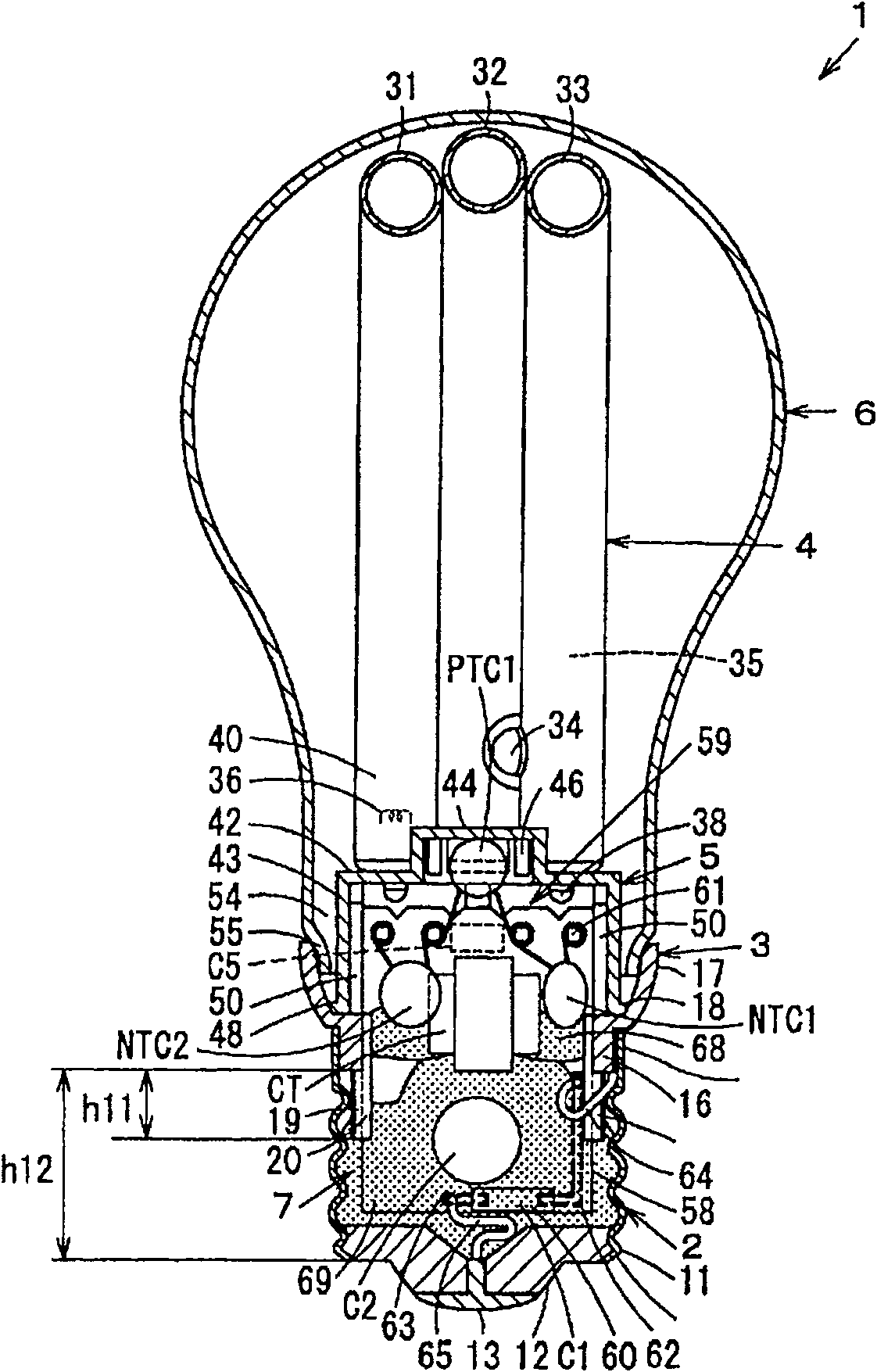

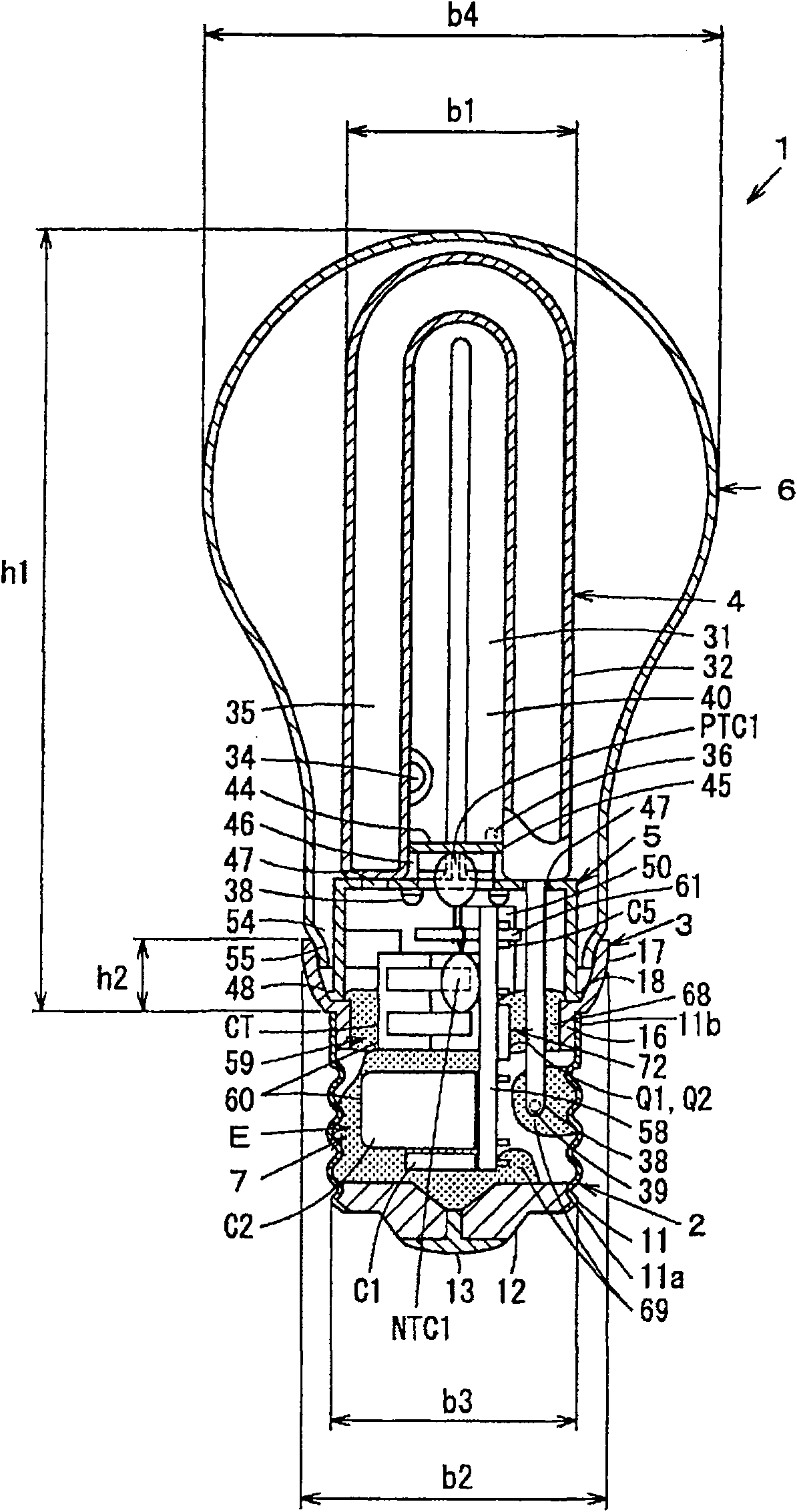

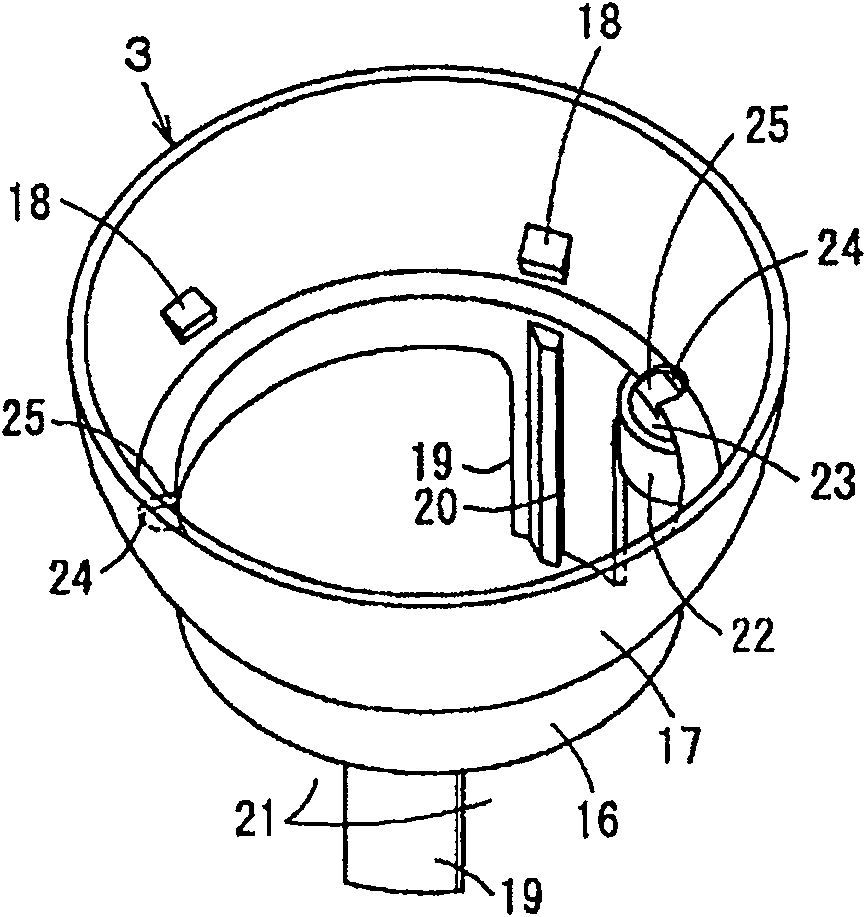

Bulb type fluorescent lamp and illuminator

InactiveCN101218463ALittle thermal impactAvoid temperature riseElongate light sourcesElectric circuit arrangementsHeat conductingEffect light

The present invention provides a self-ballasting fluorescent lamp (1) which can obtains an external appearance that is approximate same to the common illuminating electric bulb and reduces the heat influence of the luminous tube (4) to the electronic component (60) that is configured at the inner side of the lamp holder (2). One end side of the cover body (3) is arranged with a lamp holder (2) and the other end side of the cover body (3) is supported with a luminous tube (4). The substrate (58) of the lighting device (7) is installed with an electronic component (60) of the light circuit (59) which lights the luminous tube (4). The substrate (58) is formed to a breadth dimension that can be inserted in the inner side of the lamp holder (2) and is longitudinally arranged along the center line direction of the lamp holder (2), the cover body (3) is minimized to obtain an external appearance approximately same to the common illuminating electric bulb. The heat insulating material (64) is arranged at the opening between the longitudinally arranged substrate (58) and the cover body (3). The heating insulating material (64) is used for insulating the heat between the side of the lamp holder (2) and the side of luminous tube (4) and reducing the heat influence of the luminous tube (4) to the electronic component (60) arranged at the inner side of the lamp holder (2). At the inner side of the lamp holder (2) the front end part of the tubule (38) enveloped with main mercury alloy (39) is thermally connected with one part of electronic component (60) and the lamp holder (2) by the heat conducting material (65).

Owner:TOSHIBA LIGHTING & TECH CORP

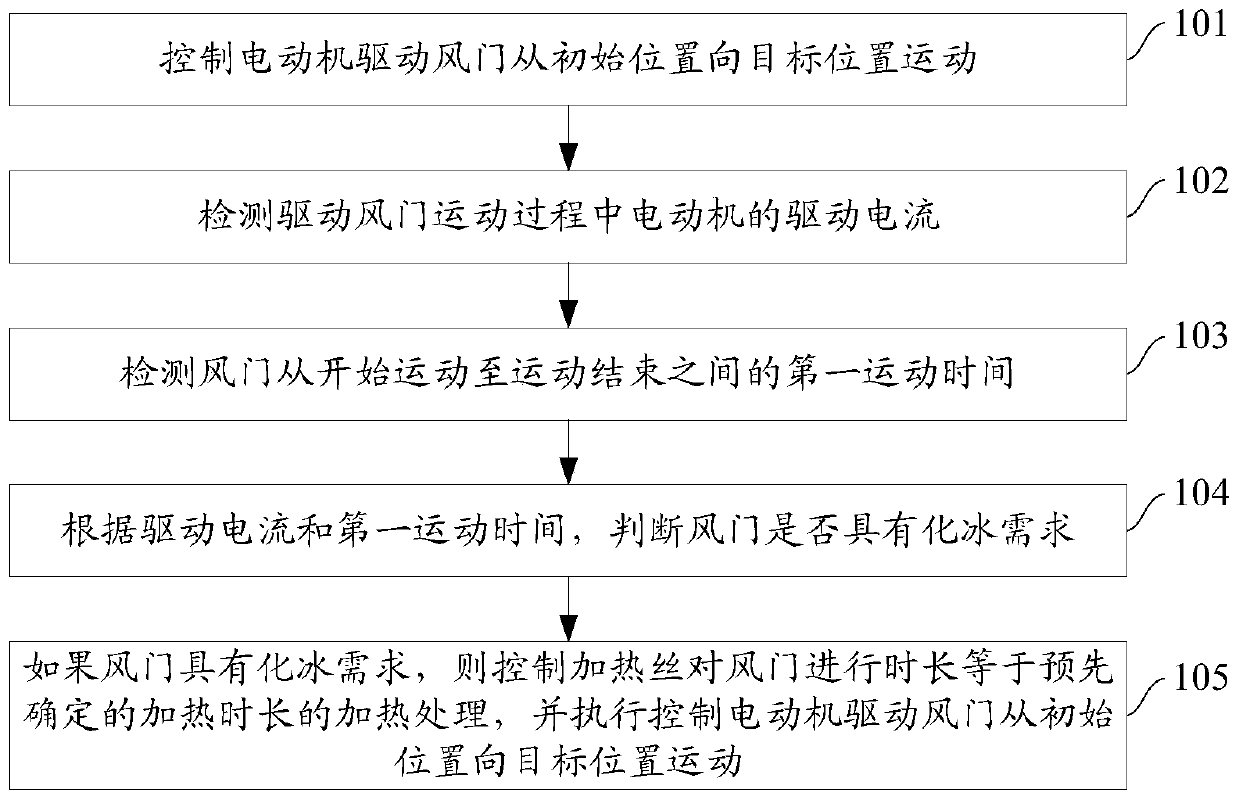

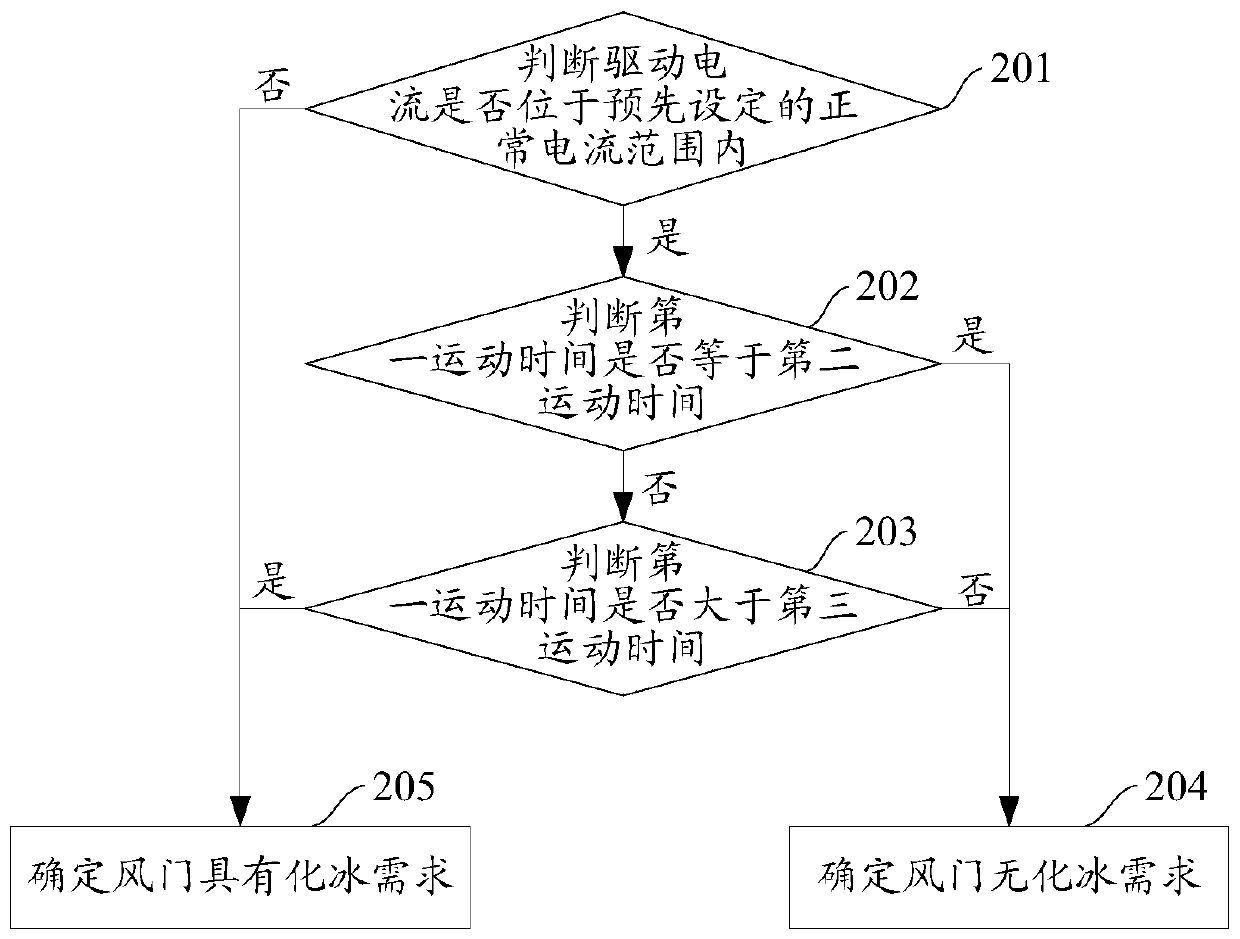

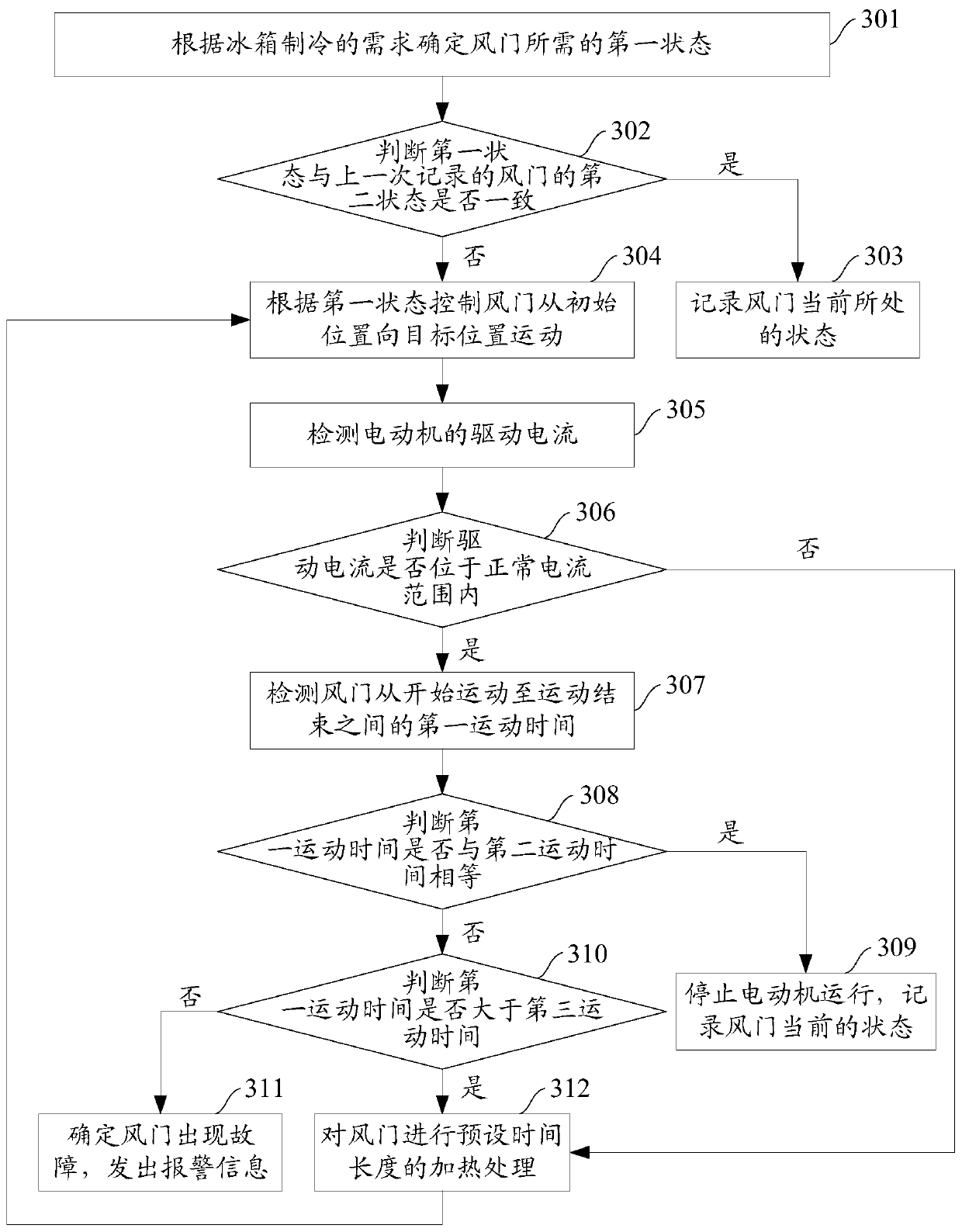

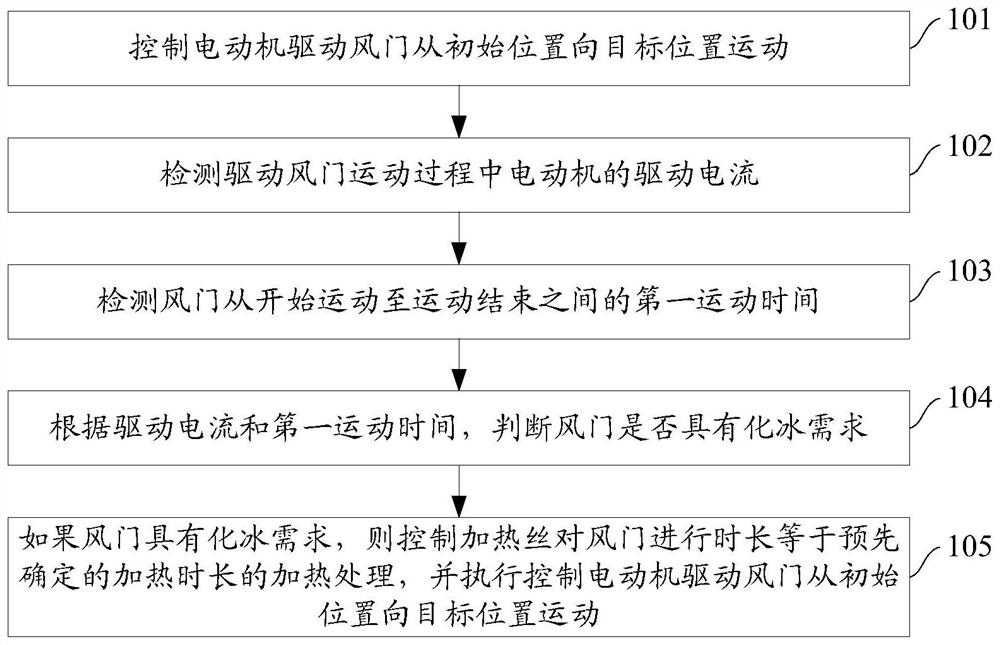

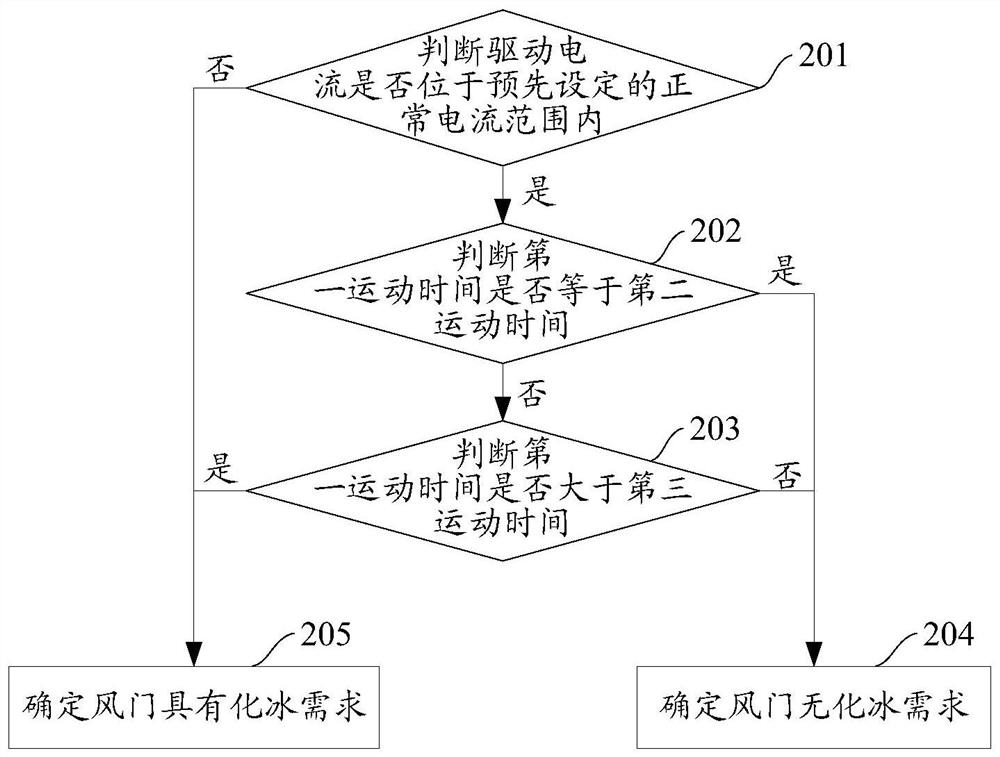

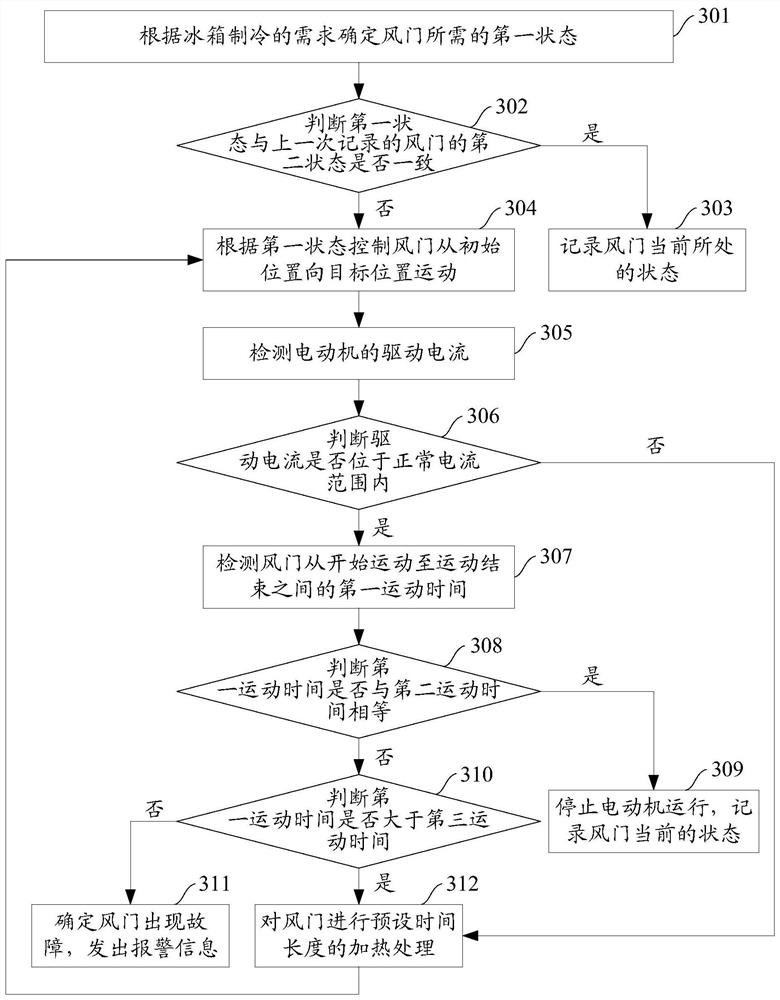

Refrigerator air door deicing control method and device

ActiveCN110425808APrevent excessive temperature riseAvoid situations where the temperature rises excessivelyLighting and heating apparatusDefrostingDriving currentPower flow

The invention provides a refrigerator air door deicing control method and device. The refrigerator air door deicing control method comprises the steps that a motor is controlled to drive an air door to move from the initial position to the target position; the driving current of the motor in the process of driving the air door to move is detected; first motion time of the air door from motion starting to motion finishing is detected; whether the air door has a deicing need or not is judged according to the driving current and the first motion time; and if the air door has the deicing need, a heating wire is controlled to heat the air door for a period of time equal to the preset heating duration, and the motor is controlled to drive the air door to move from the initial position to the target position. The refrigerator air door deicing control device comprises a motion control module, a current detecting module, a time detecting module, a need analysis module and a deicing control module. According to the scheme, the effect of deicing treatment on the air door of a refrigerator can be improved.

Owner:SICHUAN HONGMEI INTELLIGENT TECH CO LTD

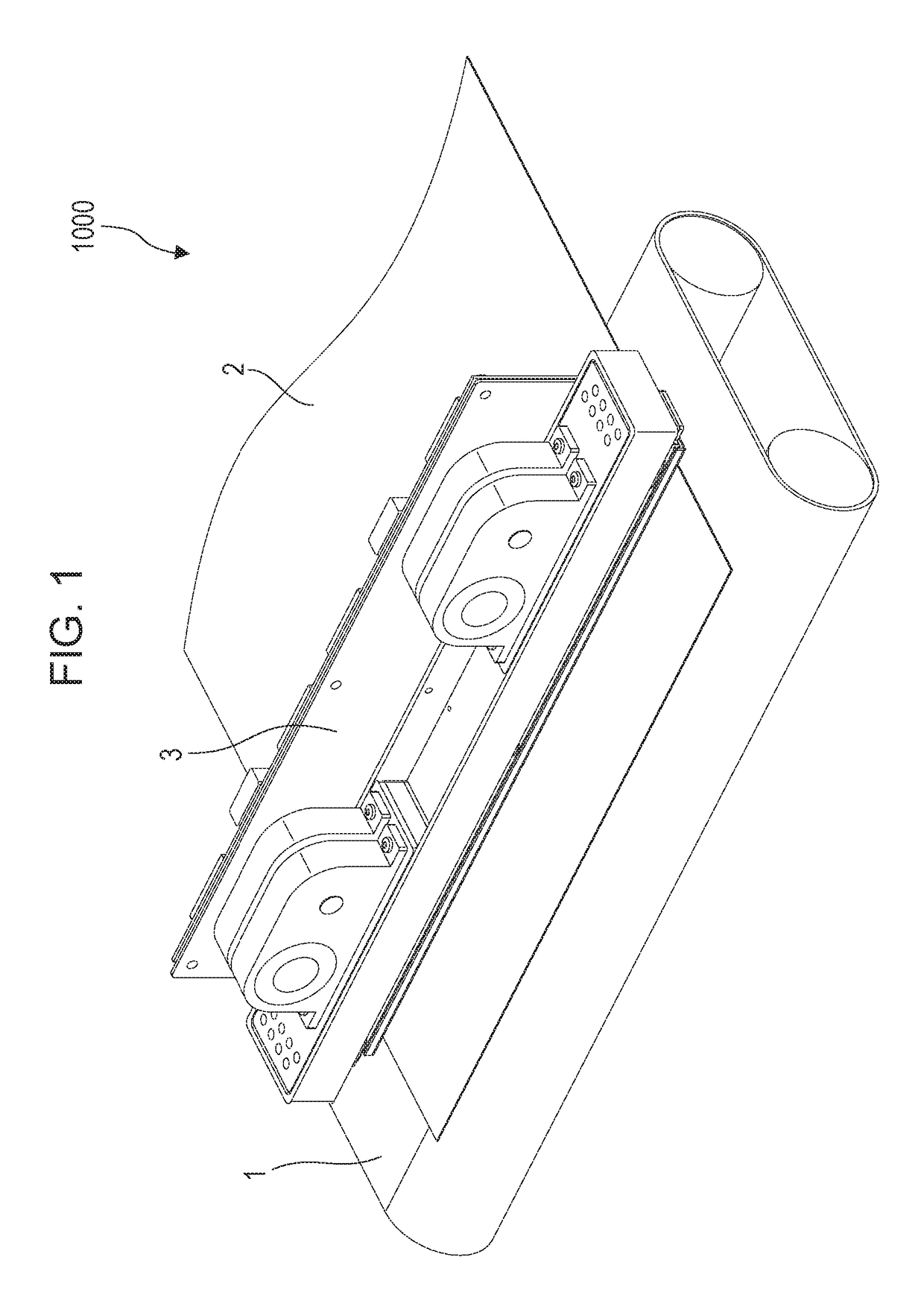

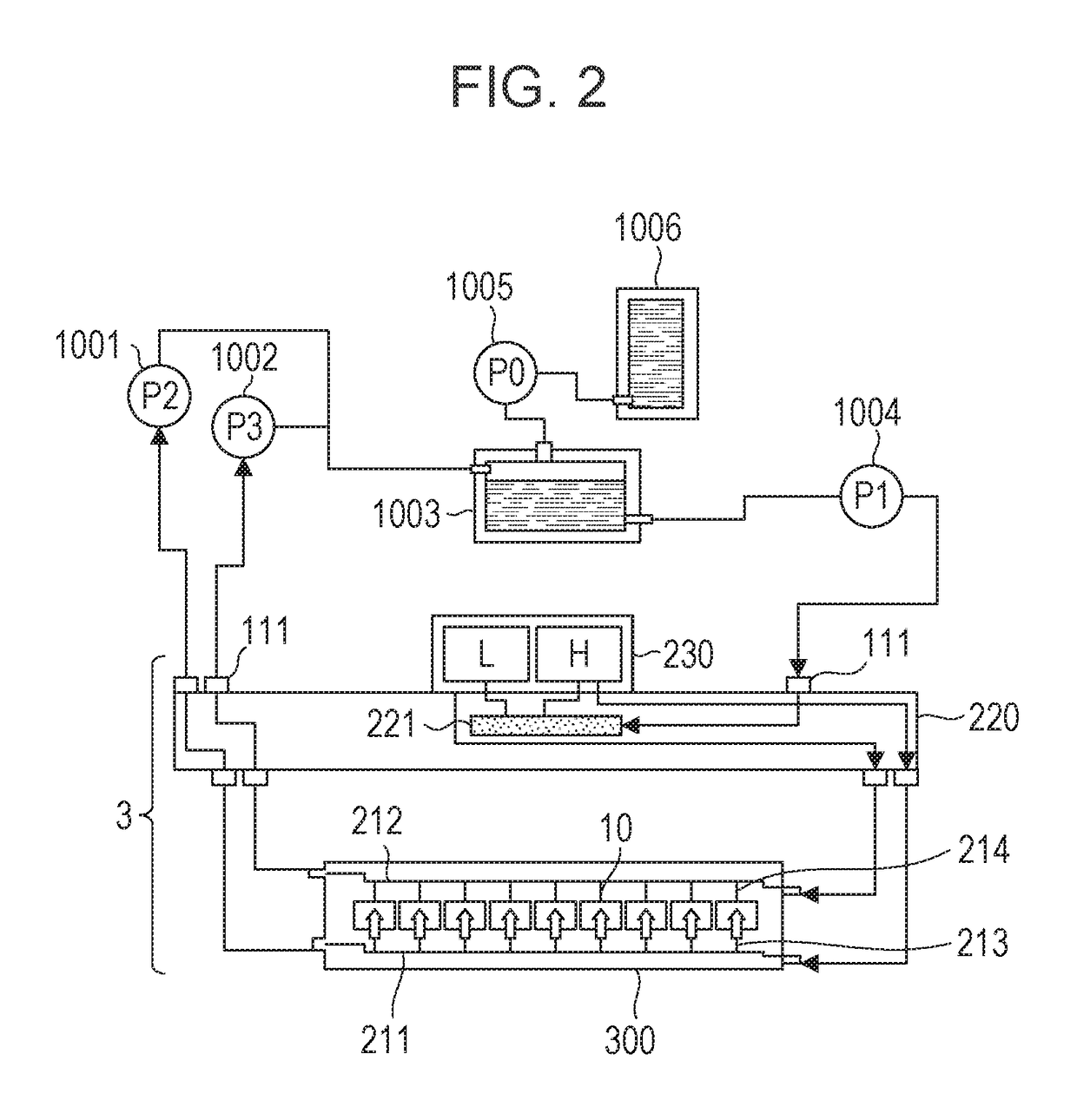

Liquid discharge head and liquid discharge apparatus

A liquid discharge head includes a recording element board having a first face on which multiple recording elements are provided, and discharge orifices for the recording elements, where pressure chambers are formed for each recording element and liquid is discharged from discharge orifices. A liquid supply channel and a liquid recovery channel are provided in common to the plurality of recording elements, in a second face opposite to the recording element board from the first face. The pressure chambers are each made to communicate with the liquid supply channel and the liquid recovery channel by the supply ports and recovery ports respectively, and a flow from the liquid supply channel through the pressure chambers to the liquid recovery channel is generated. A composited flow resistance of the liquid recovery channel and recovery ports is greater than a composited flow resistance of the liquid supply channel and supply ports.

Owner:CANON KK

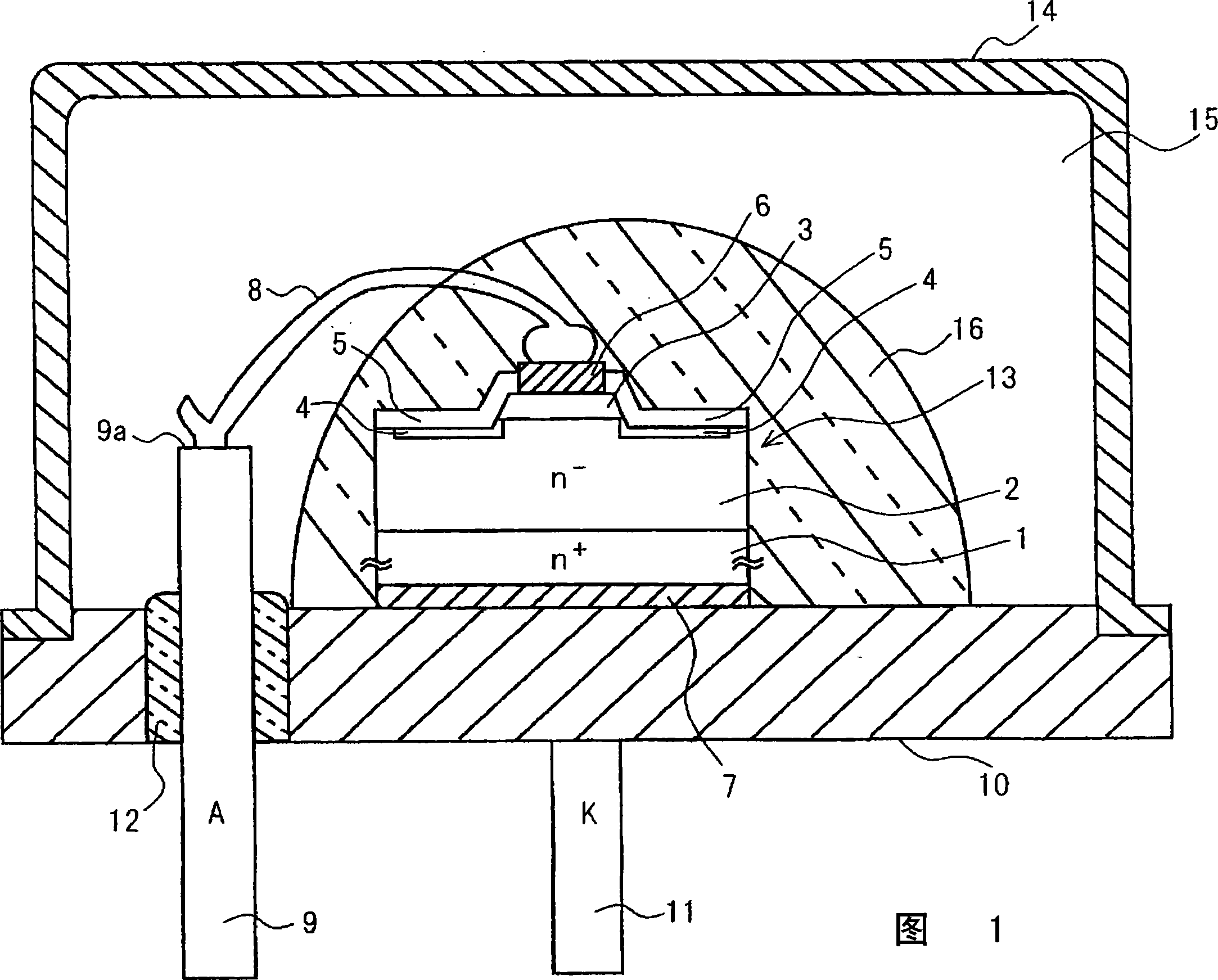

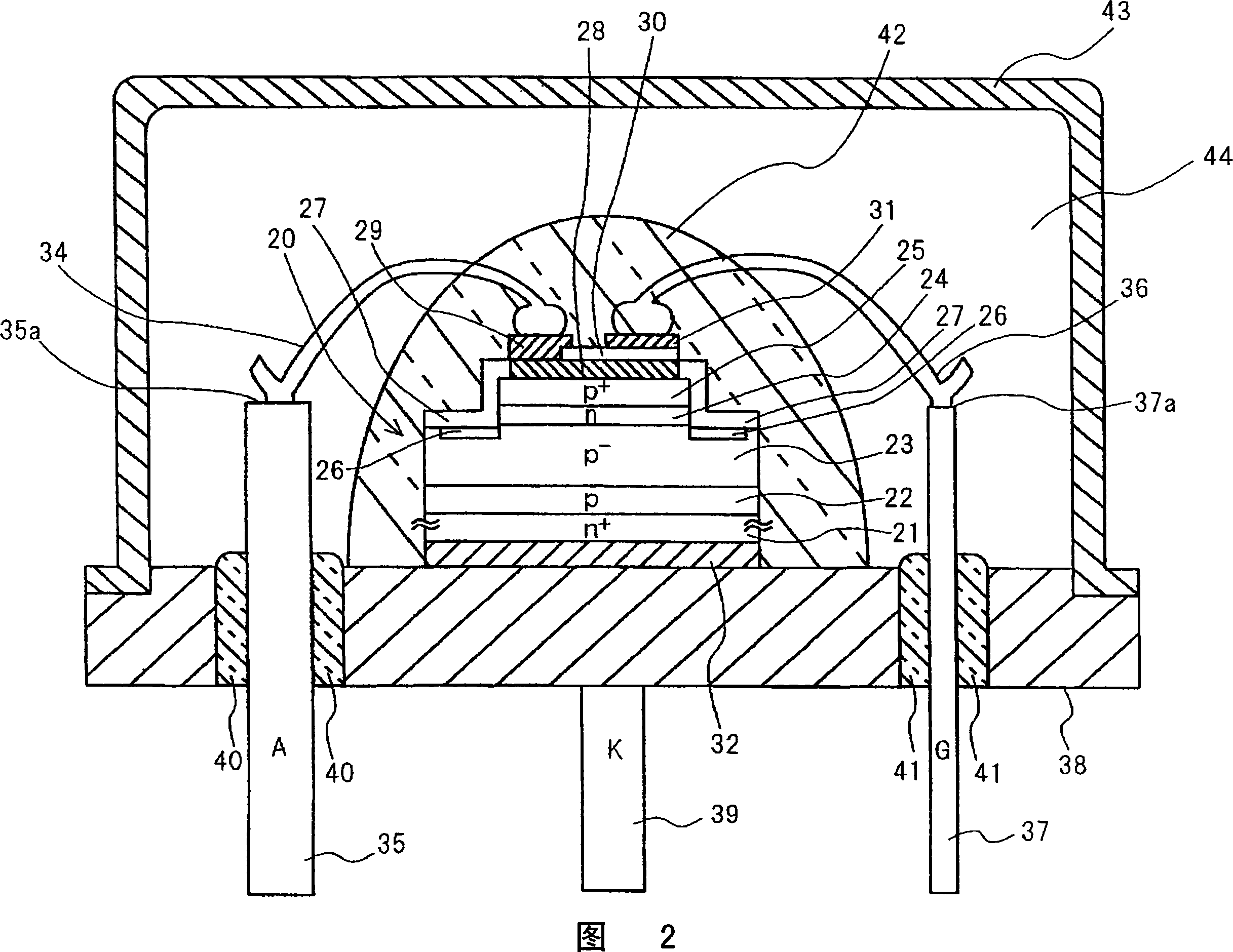

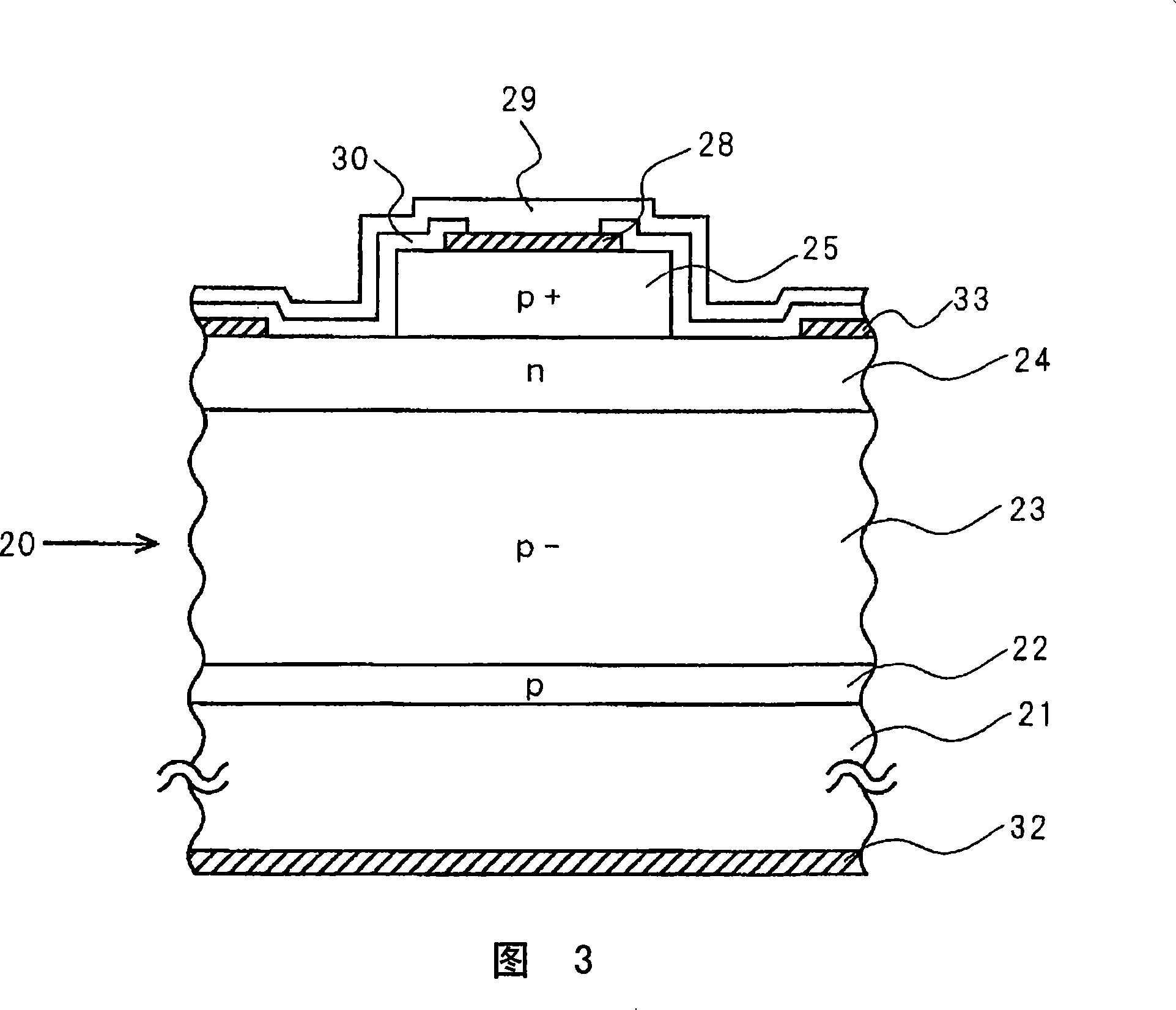

Highly heat-resistant synthetic polymer compound and high withstand voltage semiconductor device

InactiveCN101107293AImprove heat resistanceFast heat conductionSemiconductor/solid-state device detailsSolid-state devicesMicroparticleSynthetic Polymeric Macromolecules

The outer surface of a wide-gap semiconductor device is covered with a synthetic polymer compound. The synthetic polymer compound is formed by linking a plurality of third organosilicon polymers through covalent bonding which is formed by addition reaction, and has a three-dimensional steric structure. The third organosilicon polymers are obtained by linking one or more kinds of first organosilicon polymers having a bridge structure formed by siloxane bonds (Si-O-Si bonds) with one or more kinds of second organosilicon polymers having a linear structure formed by siloxane bonds. Insulating ceramic fine particles having high heat conductivity are preferably mixed with the synthetic polymer compound.

Owner:THE KANSAI ELECTRIC POWER CO +1

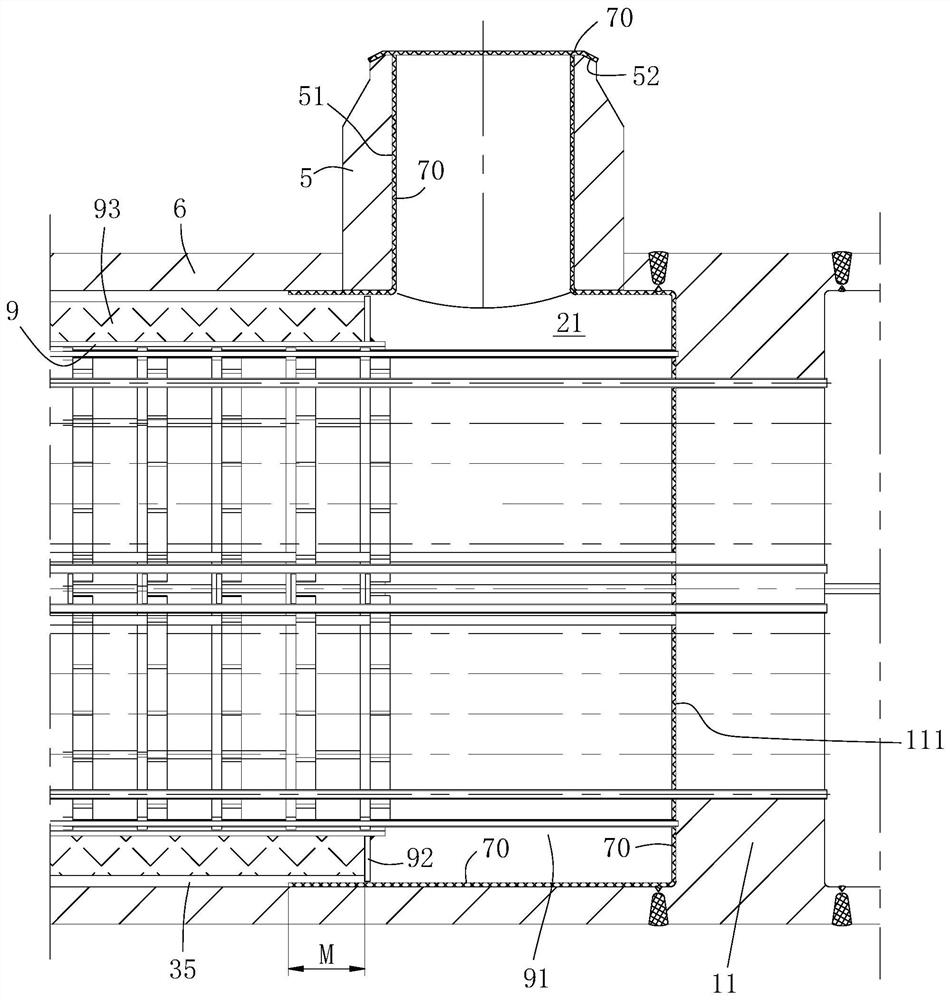

Heat exchange device resistant to high temperatures, high pressure and hydrogen corrosion

PendingCN112683088AReduce heat transferPrevent excessive temperature riseHeat exhanger sealing arrangementHeat exchanger casingsThermodynamicsEngineering

The invention discloses a heat exchange device resistant to high temperatures, high pressure and hydrogen corrosion. The device comprises a shell and a tube plate arranged in the shell, and an inner cavity of the shell is divided into a heat exchange cavity and a refrigerant cavity by the tube plate. The refrigerant cavity is divided into a liquid inlet cavity and a liquid outlet cavity. A heat insulation cylinder and a high-temperature inner header are installed in the heat exchange cavity, and the two ends of a U-shaped heat exchange pipe are communicated with the liquid inlet cavity and the liquid outlet cavity through the tube plate. A communicating part for communicating the inside and outside of the heat insulation cylinder is arranged between the heat insulation cylinder and the tube plate. The high-temperature inner header is communicated with the heat insulation cylinder. A gas inlet pipe and a gas outlet pipe are arranged on the shell, the gas inlet pipe directly faces the high-temperature inner header and is communicated with the high-temperature inner header, and the gas outlet pipe directly faces the communicating part. A first heat preservation material is filled between the high-temperature inner header and the shell, an annular gap between the heat insulation cylinder and a cylinder body forms a dead gas area, and the dead gas area is communicated with an inner cavity of the heat insulation cylinder through the communicating part. By means of the heat exchange device, the manufacturing cost of equipment can be well reduced.

Owner:NANJING JUTUO CHEM TECH

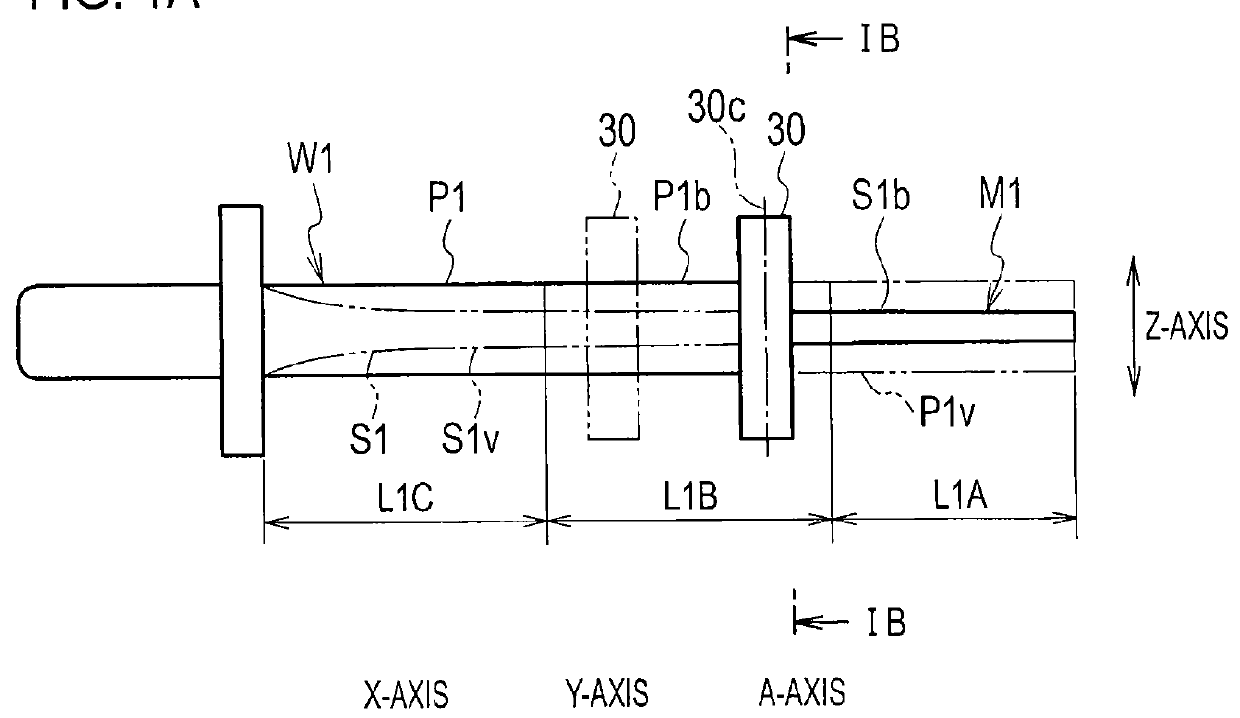

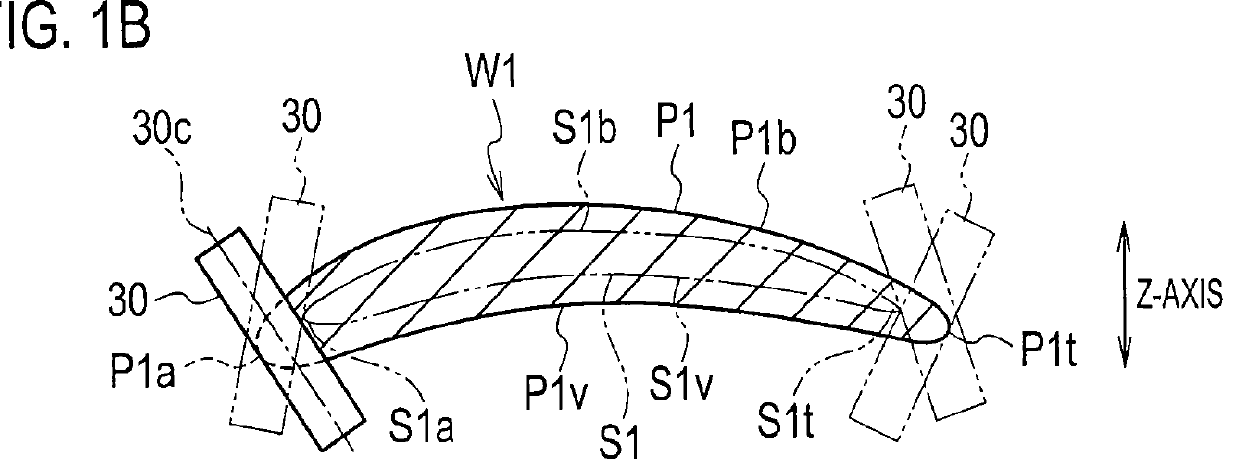

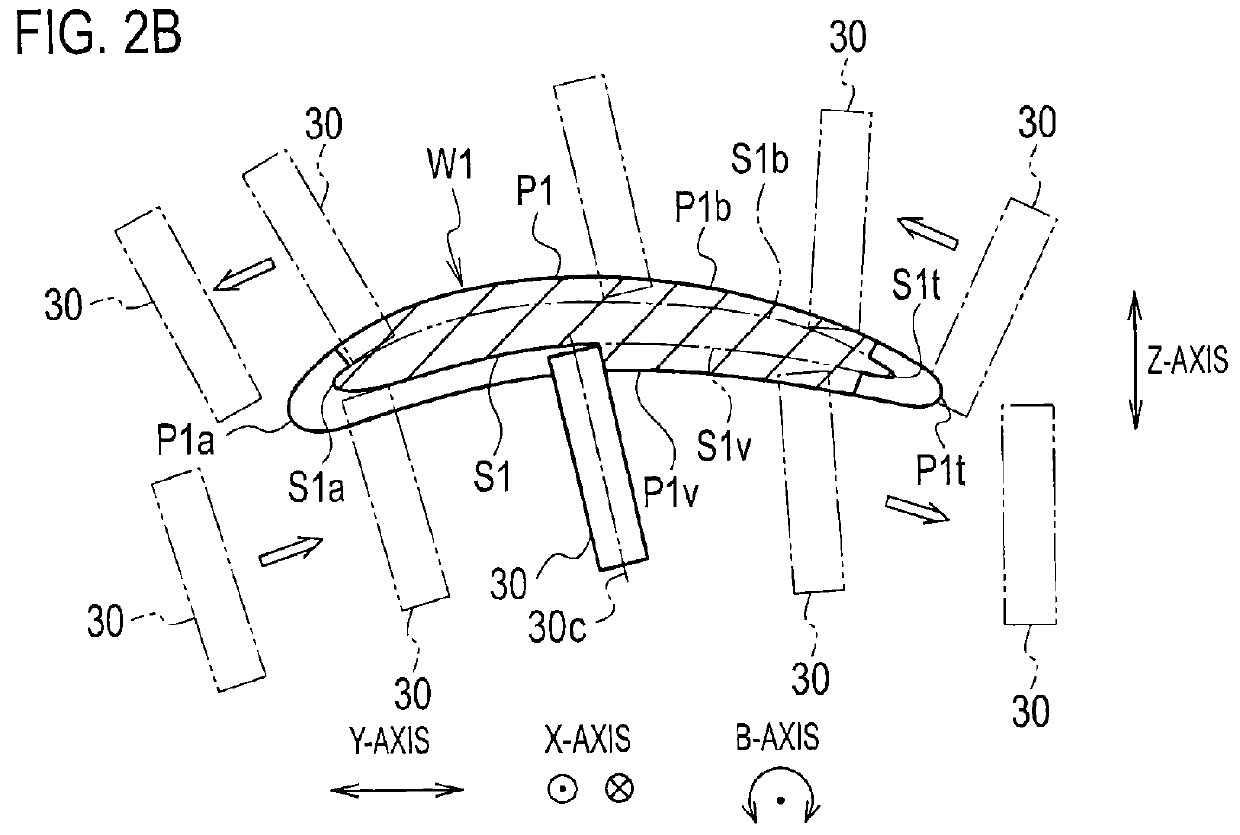

Wing surface finishing method and wing component

ActiveUS20160052071A1Maintain durabilityImprove productivityMilling cuttersWorkpiecesLeading edgeSurface finish

A wing surface finishing method is the one in which after finishing of a leading edge and a trailing edge and finishing of a ventral portion and a back portion in a wing surface of a wing component are separated into separate steps, a finishing end mill is made to approach a ventral portion and a back portion of awing surface corresponding area of a workpiece after a speed of the finishing end mill is increased, finishing processing is applied to the ventral portion and the back portion of the wing surface corresponding area of the workpiece, respectively, and the speed of the finishing end mill is decreased after the finishing end mill is moved away from the wing surface corresponding area of the workpiece.

Owner:IHI CORP

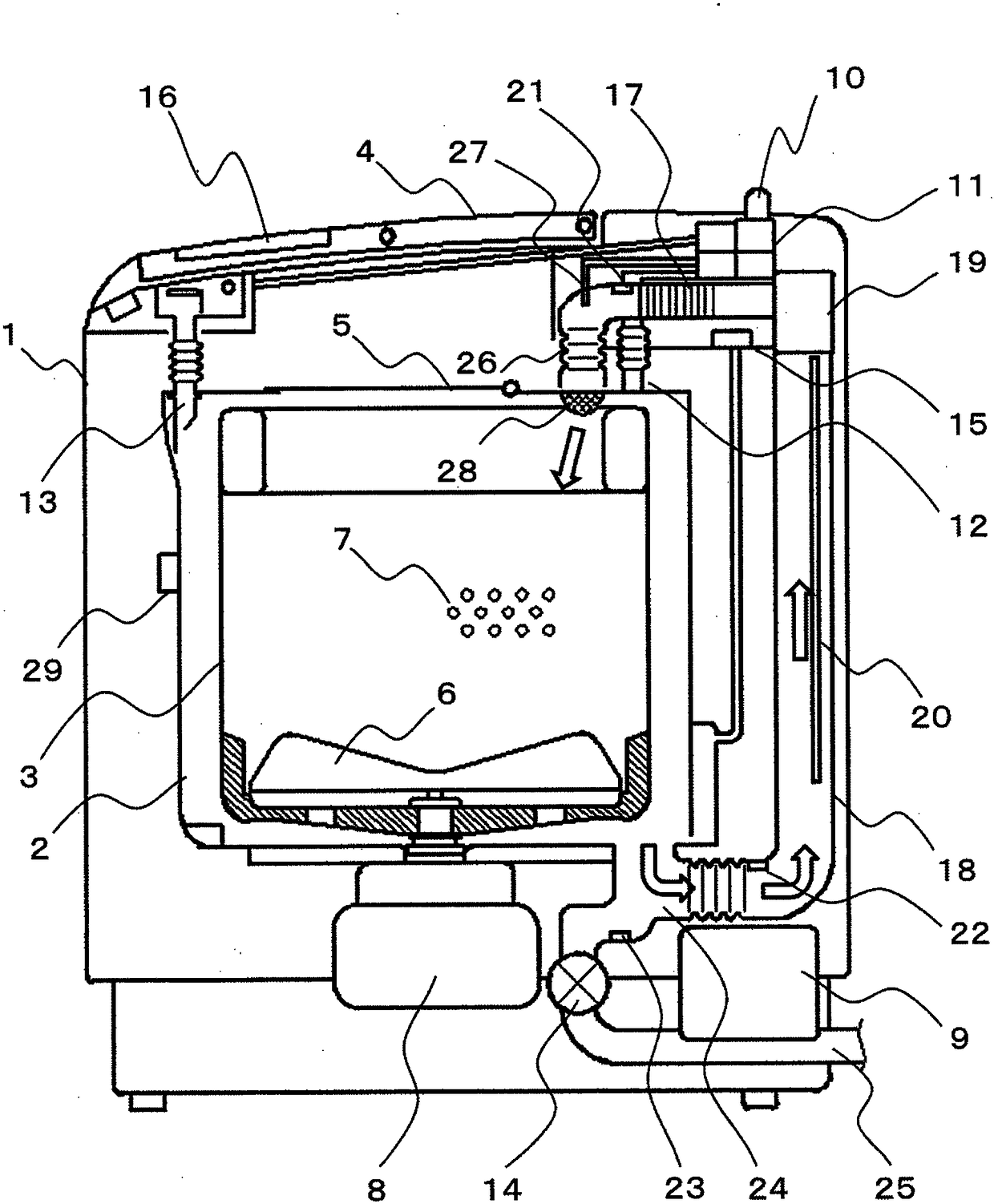

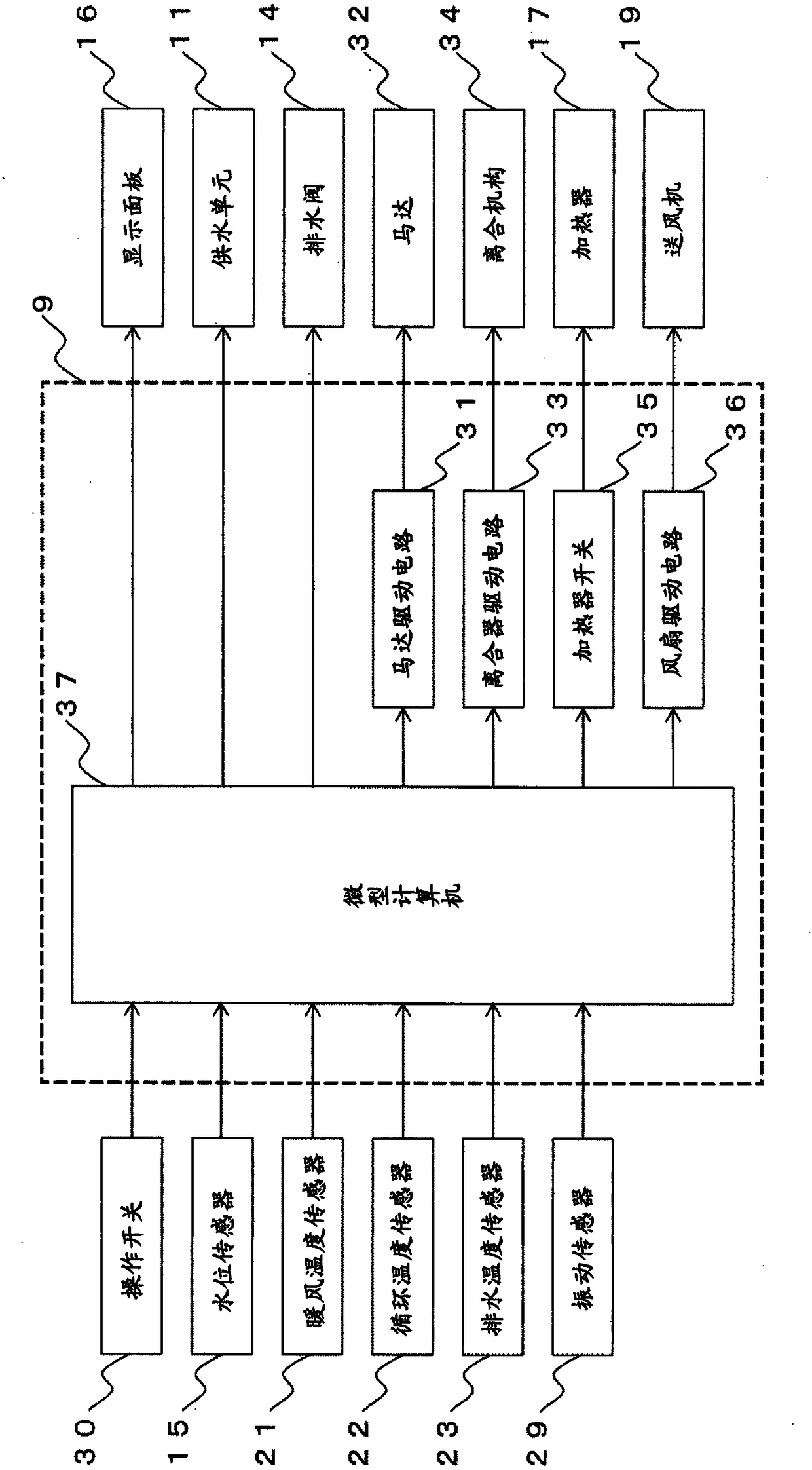

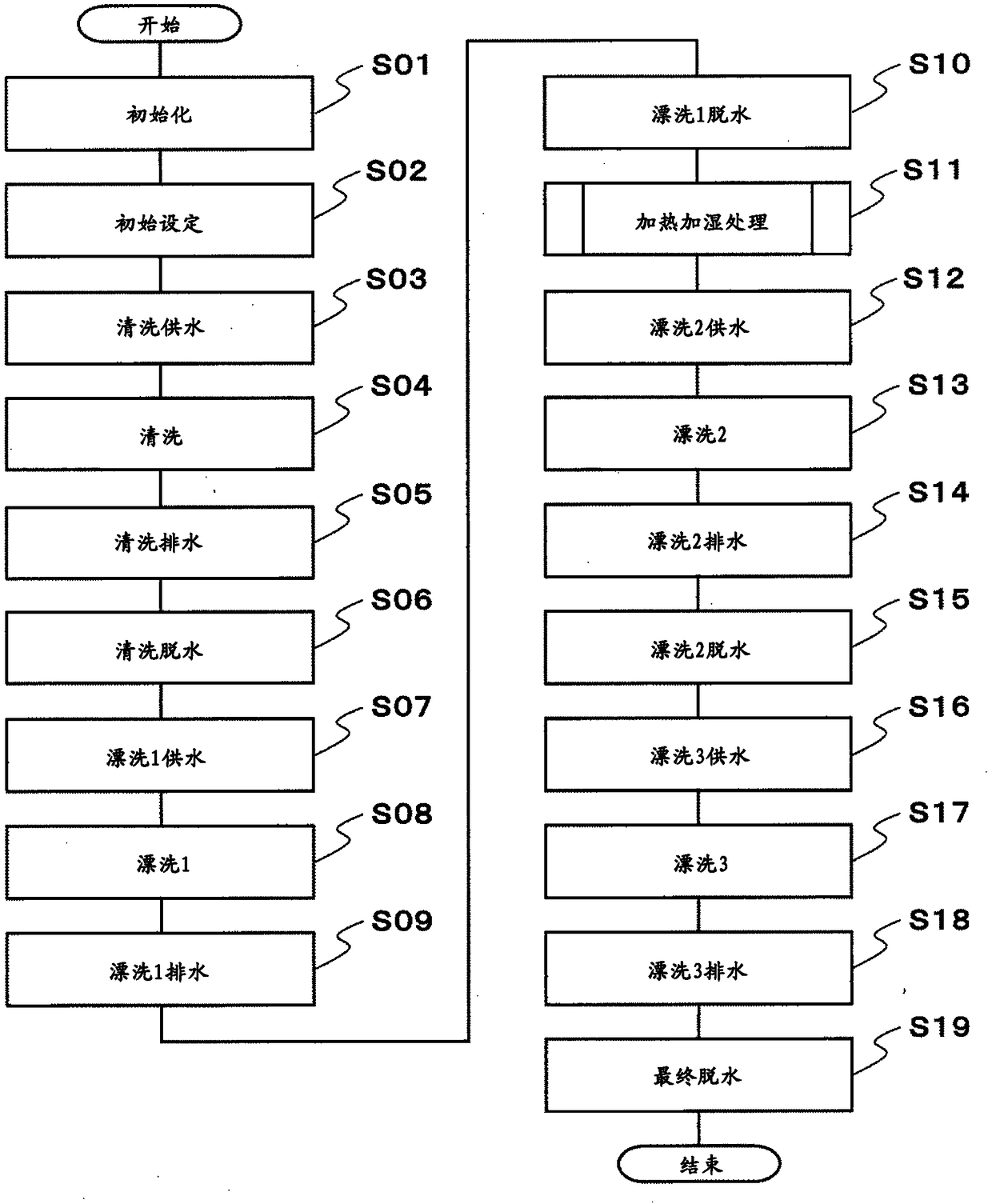

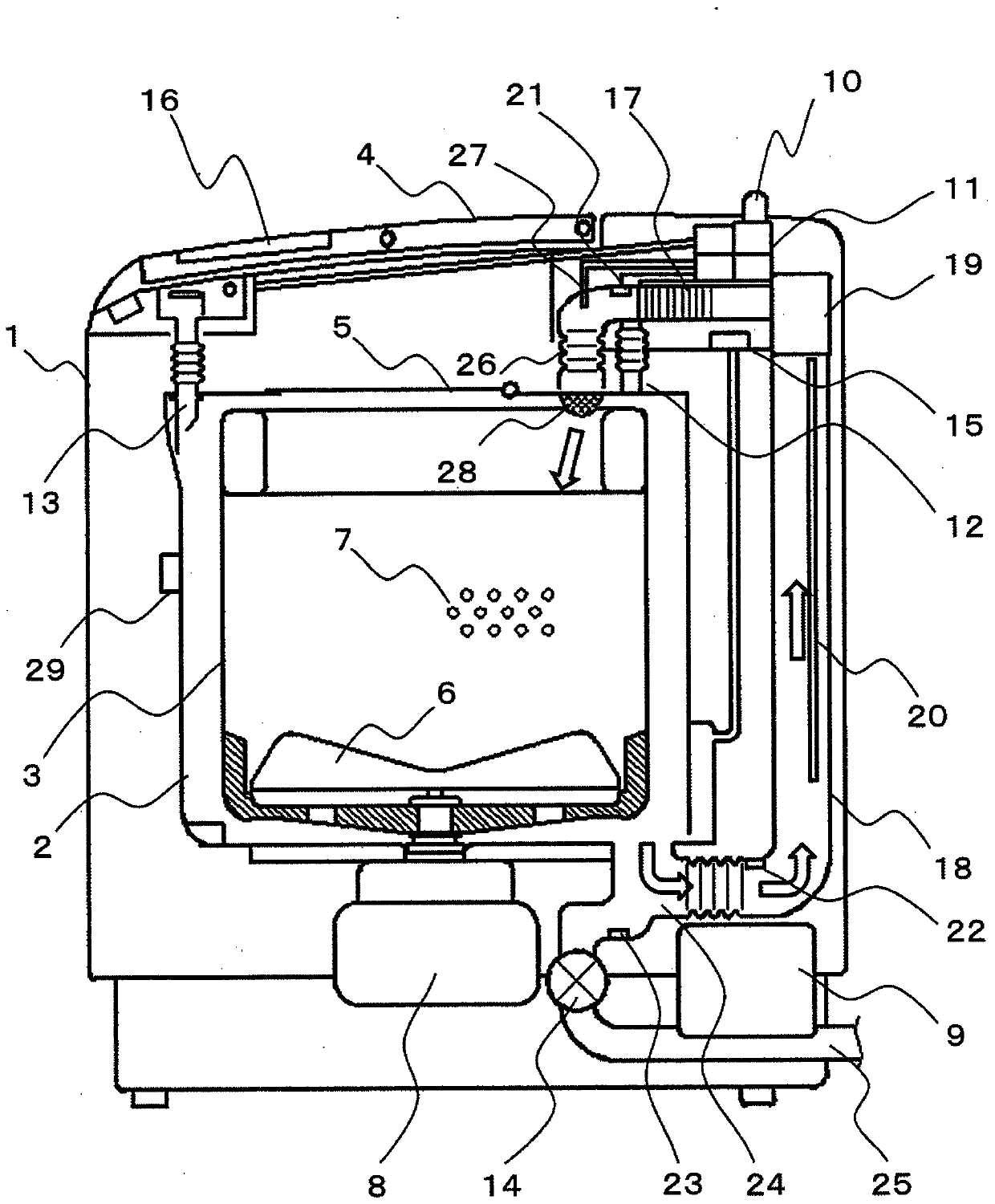

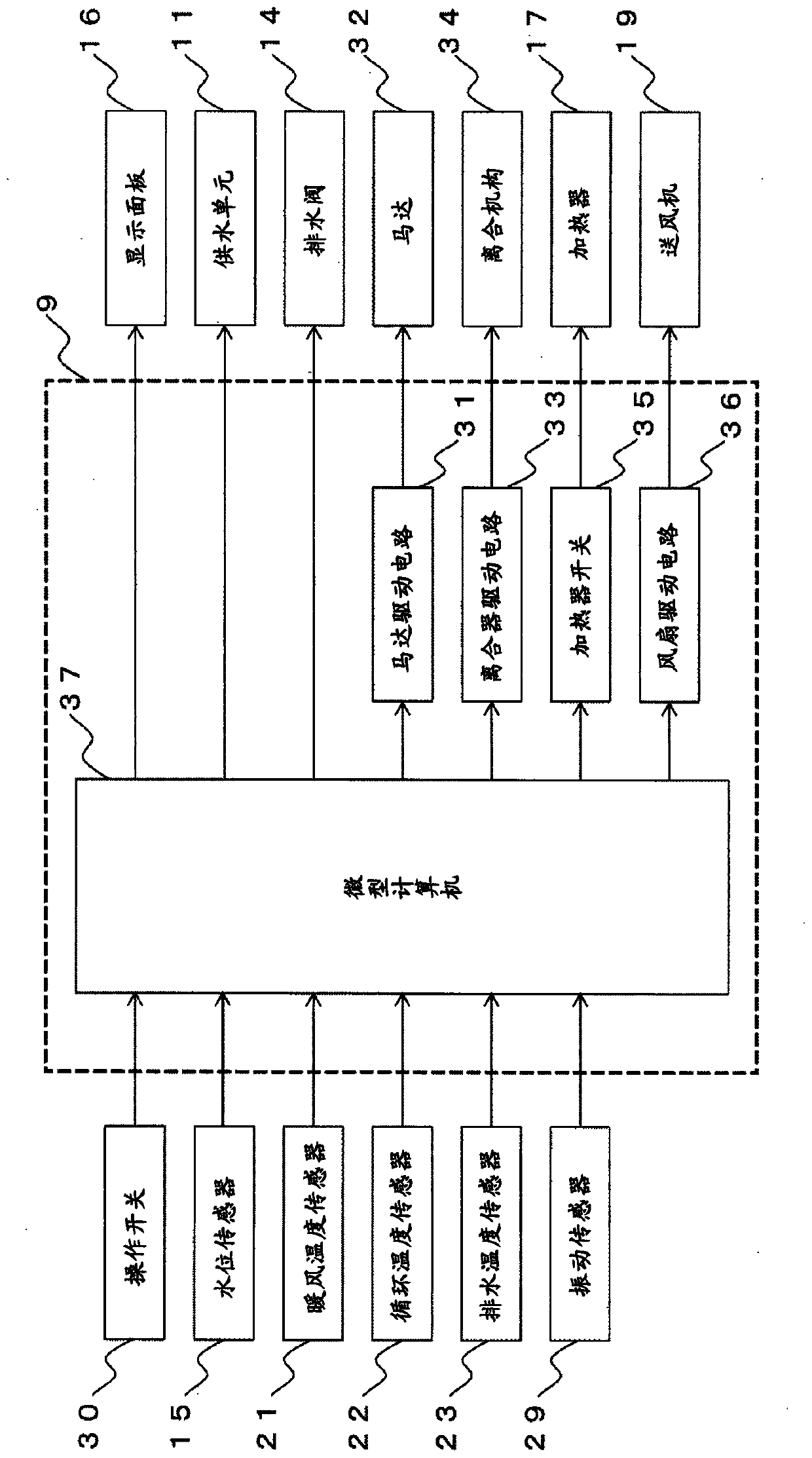

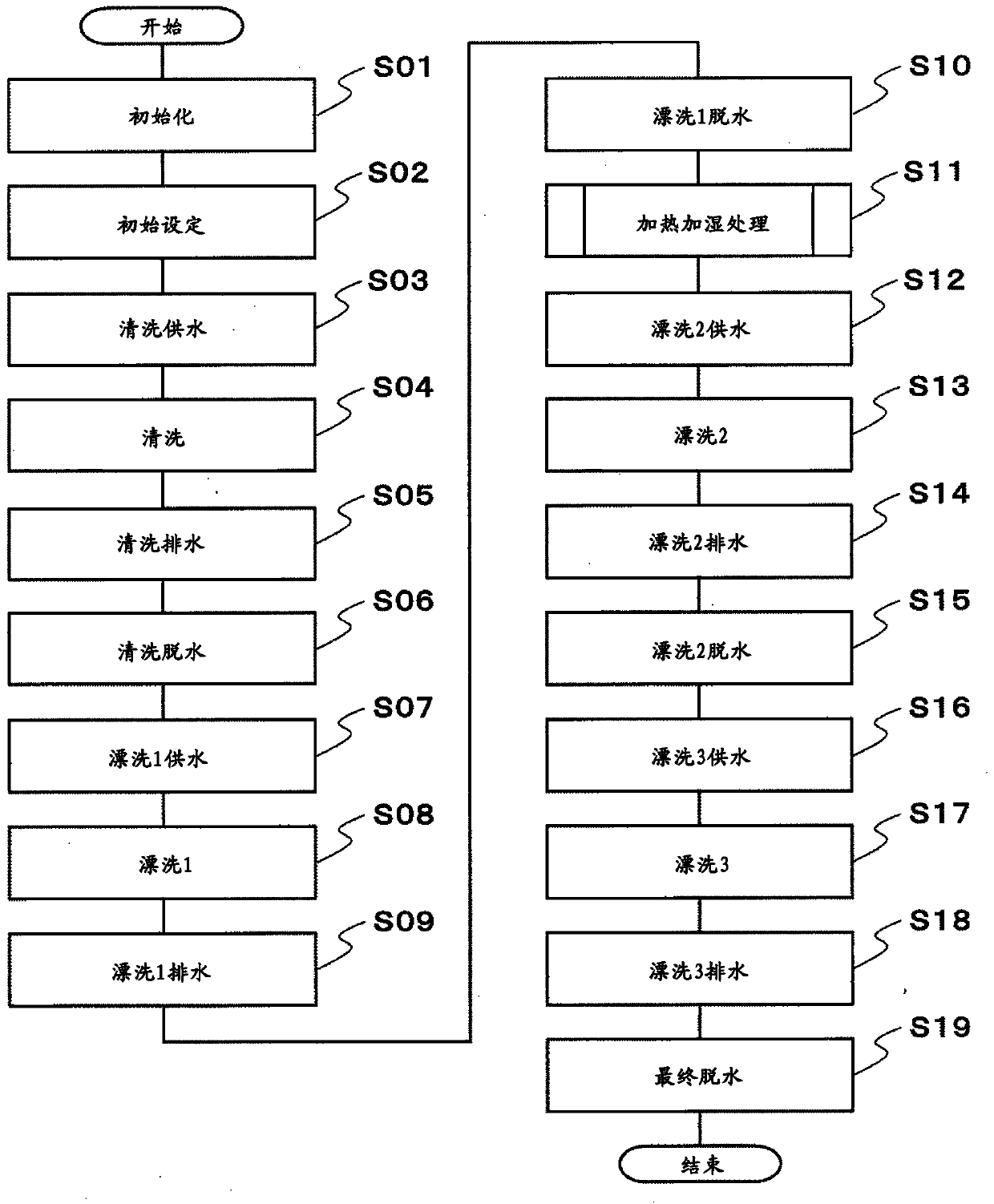

Washing and drying machine

ActiveCN108625091AProtects from heatEfficient deathOther washing machinesWashing machine with receptaclesHeat resistanceEngineering

The invention provides a washing and drying machine which suppresses excessive temperature increase of a washing object on the condition of heating the washing object such as low-heat-resistance blanket, thereby preventing a heat influence on the washing object and efficiently kills acarids. Heating processing of supplying hot air to a washing trough is executed. In executing heating processing, cooling processing of supplying water into the washing trough by means of a water supplying mechanism for cooling the washing object is executed.

Owner:HITACHI APPLIANCES INC

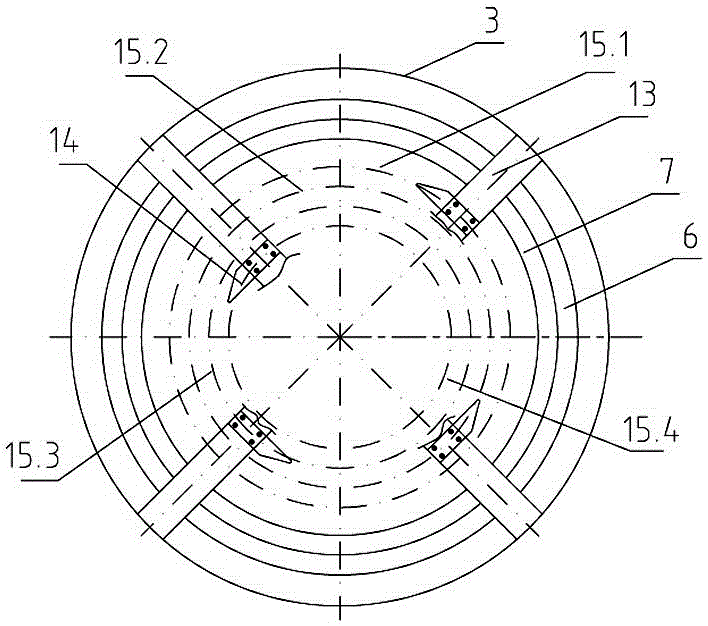

Rotary-ring mill

The invention discloses a rotary-ring mill. The rotary-ring pulverizer mill comprises a mill shell arranged at the top of a vertical reducer gearbox, wherein an air duct and a scraping device are arranged at the bottom of the mill shell, and a milling unit is arranged in the mill shell which is located above the air duct and the scraping device; the milling unit comprises a bowl-shaped milling disc provided with an upper opening, a milling ring is fixedly connected to the inner ring wall of the bowl-shaped milling disc, at least two milling roll mechanisms are uniformly distributed and fixed on the inner sidewall of the mill shell which is located above the bowl-shaped milling disc along a peripheral direction, and each milling roll mechanism is composed of a suspension arm fixed on the inner sidewall of the mill shell, a milling roll hinged and hung on the suspension arm and a milling roll sleeve rotatably sleeving the milling roll; a milling roll pressing limit mechanism is arranged on the sidewall of the mill shell and at a position corresponding to each milling roll; and a lubricant oil circulation device is arranged on the bottom wall of the vertical reducer gearbox. The rotary-ring pulverizer mill disclosed by the invention has the following advantage: the central axis of the milling ring is parallel to the axis of a power output shaft, and a kinematic pair bearing a great axial force, and related mechanisms are omitted.

Owner:HENAN LIMING HEAVY IND SCI & TECH

Semiconductor package with thermal dissipating member and method of manufacturing the same

ActiveUS9054067B2Prevent excessive temperature riseSemiconductor/solid-state device detailsSolid-state devicesCritical timeSemiconductor chip

A semiconductor package and a method of manufacturing the same are disclosed, wherein the semiconductor package includes a circuit board, a semiconductor chip mounted on the circuit board, an encapsulant positioned on the circuit board and encapsulating the semiconductor chip to the circuit board, and a thermal dissipating member positioned on the encapsulant and having a heat spreader that dissipates a driving heat from the semiconductor chip and a heat capacitor that absorbs excess driving heat that exceeds a heat transfer capability of the heat spreader, such that when a high power is applied to the package, the excess heat is absorbed into the heat capacitor as a latent heat and thus the semiconductor chip is protected from an excessive temperature increase caused by the excess heat, thereby increasing a critical time and performance duration time of the semiconductor package.

Owner:SAMSUNG ELECTRONICS CO LTD

A method for large-scale and standardized breeding of beef cattle and sheep in photovoltaic facilities

InactiveCN104115756BEfficient use ofEffective spaceFood processingLivestock managementAgricultural scienceBeef cattle

A method for breeding beef cattle and mutton sheep standardly on a large scale through photovoltaic facilities includes the four parts that first, a photovoltaic facility greenhouse is built, maize seedlings or high-quality green forage grass Zea mexicana is produced throughout the year to be used as green fodder of beef cattle and mutton sheep; second, the beef cattle and the mutton sheep are bred and bio-organic fertilizer is produced standardly on a large scale through the photovoltaic facility greenhouse; third, photovoltaic power generation is performed for self use, and excessive electricity is connected into the state grid; fourth, a beef cattle and mutton sheep traceable system is built, and foods are made safe and sanitary. Through the method, not only can solar resources be effectively utilized to output clean and green energy, but also efficient planting and breeding can be achieved, by-products are processed into organic fertilizer, and a new path is provided for green agricultural production. Because a full-frame high-standard support system is adopted for the photovoltaic agricultural greenhouse and photovoltaic modules are arranged on the greenhouse, the space of the greenhouse can be effectively utilized, power utilized in the greenhouse can be supplied through a photovoltaic power station, and equivalently, stereoscopic production is formed on the land with the same area.

Owner:丁志强 +3

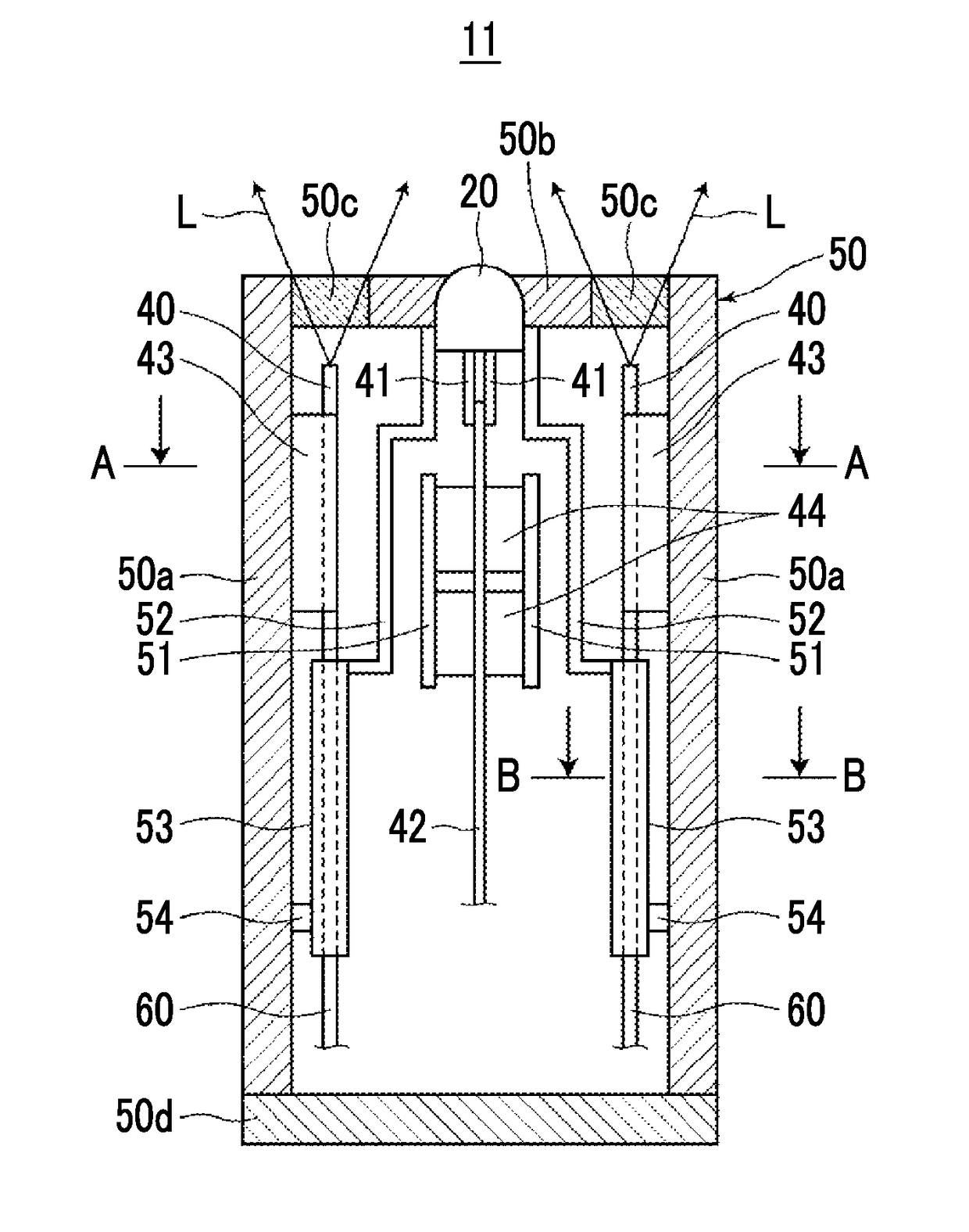

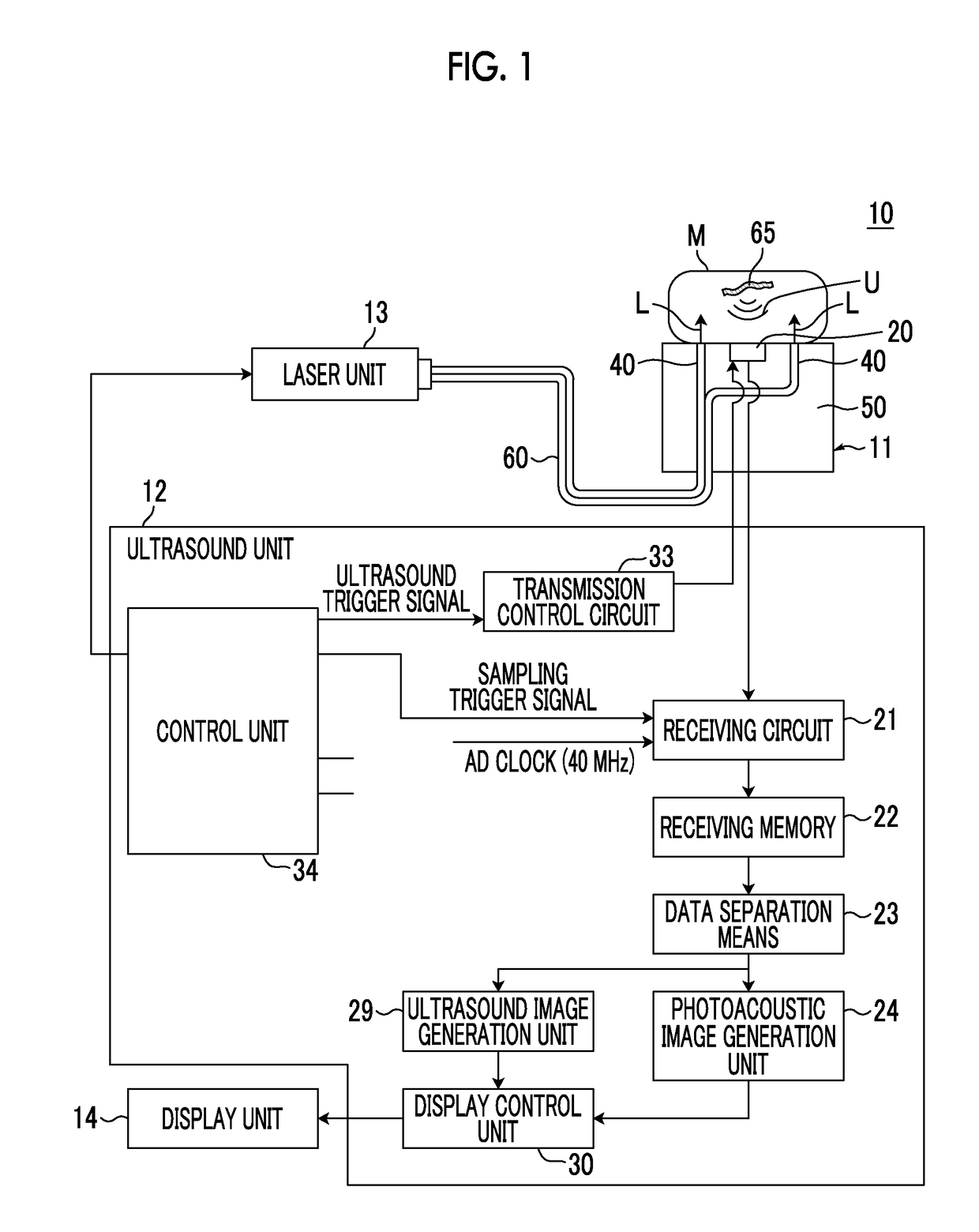

Photoacoustic measurement probe and probe unit and photoacoustic measurement apparatus including the same

ActiveUS20180199820A1Efficiently dissipate heatPrevent excessive temperature riseUltrasonic/sonic/infrasonic diagnosticsDiagnostics using lightAudio power amplifierAcoustic wave

In a photoacoustic measurement probe including an acoustic wave detector and an amplifier for amplifying a detection signal of a photoacoustic wave and a probe unit and a photoacoustic measurement apparatus having such a probe, heat is efficiently dissipated from the probe.In a probe having an acoustic wave detector and an amplifier, there are provided a first heat conductive member that is in contact with a part of a side plate of a housing and the amplifier to transfer heat generated by the amplifier to the side plate and a second heat conductive member that is in contact with a part different from the part of the side plate and the acoustic wave detector to transfer heat generated by the acoustic wave detector to the side plate.

Owner:FUJIFILM CORP

Bulb type fluorescent lamp and illuminator

InactiveCN100590345CLittle thermal impactUniform temperatureElongate light sourcesElectric circuit arrangementsHeat conductingEffect light

The present invention provides a self-ballasting fluorescent lamp (1) which can obtains an external appearance that is approximate same to the common illuminating electric bulb and reduces the heat influence of the luminous tube (4) to the electronic component (60) that is configured at the inner side of the lamp holder (2). One end side of the cover body (3) is arranged with a lamp holder (2) andthe other end side of the cover body (3) is supported with a luminous tube (4). The substrate (58) of the lighting device (7) is installed with an electronic component (60) of the light circuit (59)which lights the luminous tube (4). The substrate (58) is formed to a breadth dimension that can be inserted in the inner side of the lamp holder (2) and is longitudinally arranged along the center line direction of the lamp holder (2), the cover body (3) is minimized to obtain an external appearance approximately same to the common illuminating electric bulb. The heat insulating material (64) isarranged at the opening between the longitudinally arranged substrate (58) and the cover body (3). The heating insulating material (64) is used for insulating the heat between the side of the lamp holder (2) and the side of luminous tube (4) and reducing the heat influence of the luminous tube (4) to the electronic component (60) arranged at the inner side of the lamp holder (2). At the inner sideof the lamp holder (2) the front end part of the tubule (38) enveloped with main mercury alloy (39) is thermally connected with one part of electronic component (60) and the lamp holder (2) by the heat conducting material (65).

Owner:TOSHIBA LIGHTING & TECH CORP

Printing apparatus

ActiveUS8953959B2Decrease productivityPrevent excessive temperature riseElectrographic process apparatusEngineeringElectrical and Electronics engineering

Owner:BROTHER KOGYO KK

Optical scanner for image forming apparatus

InactiveUS8217979B2Preventing functional declineSuppressing optical path deviationInking apparatusElectrographic process apparatusOptical scannersImage formation

An optical scanner for an image forming apparatus has a housing having a wall surface provided with a through-hole, and an optical scanning unit, which is provided within the housing, scans light on an object to be scanned in order to form an image on the object to be scanned, and includes: a polygon motor; a polygon mirror that reflects the light while being rotated by a driving force of the polygon motor; a mirror member that reflects the light reflected by the polygon mirror, toward a target object; and a mirror holding member that is attached to the wall surface of the housing and holds the mirror member. The mirror holding member has a heat radiation part that is exposed to the outside of the housing through the through-hole.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

washing and drying machine

ActiveCN108625091BProtects from heatEfficient deathOther washing machinesWashing machine with receptaclesProcess engineeringLaundry

PROBLEM TO BE SOLVED: To provide a washer-dryer machine capable of effectively annihilating mites, while preventing the temperature of laundry such as a blanket having a low resistance against heat from excessively rising in heating, such that the laundry is protected from the heat.SOLUTION: When a heating treatment for supplying warm air into a washing tub is performed, water is supplied into the washing tub by water supply means to perform a cooling treatment for cooling the laundry.SELECTED DRAWING: Figure 1

Owner:HITACHI GLOBAL LIFE SOLUTIONS INC

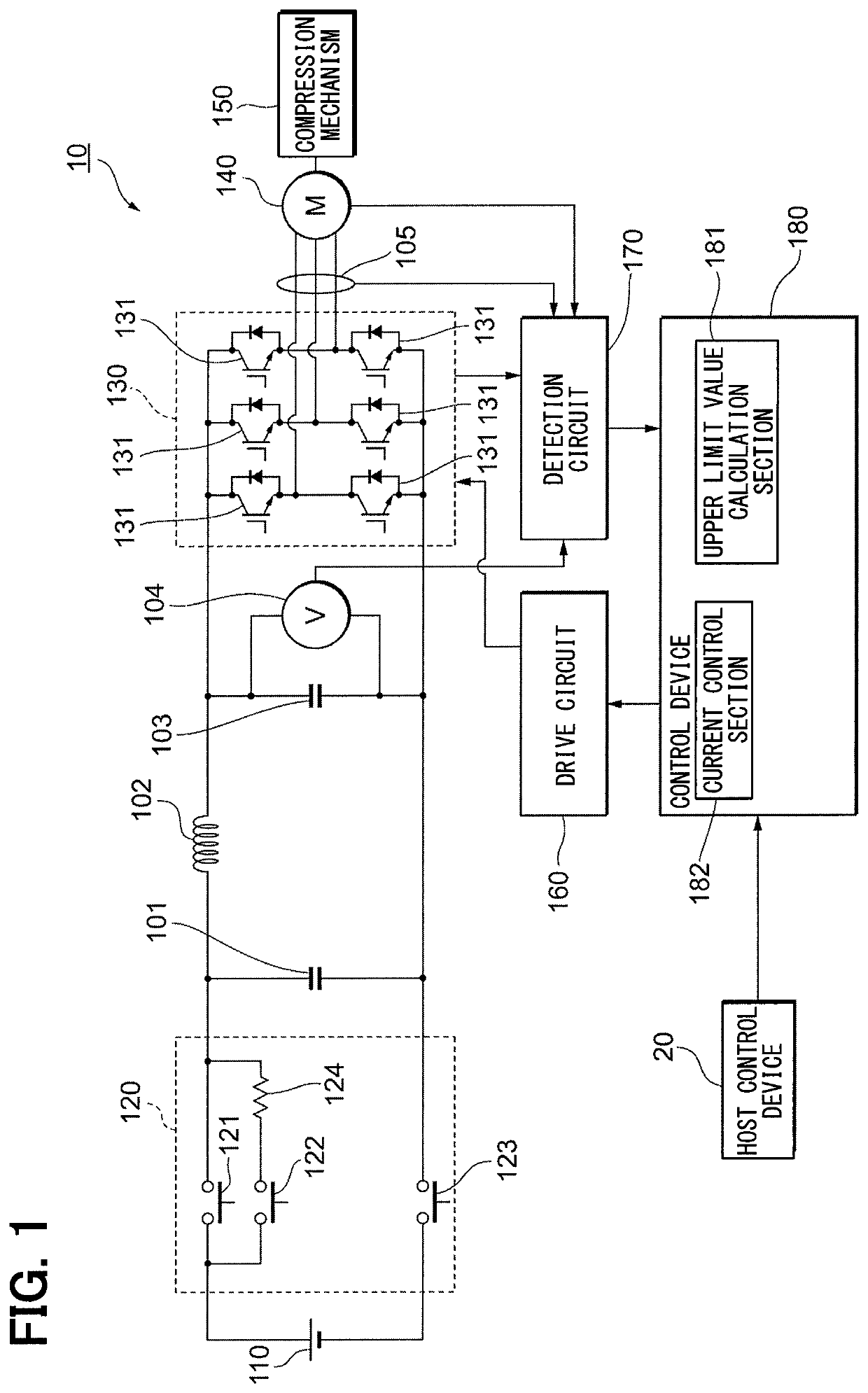

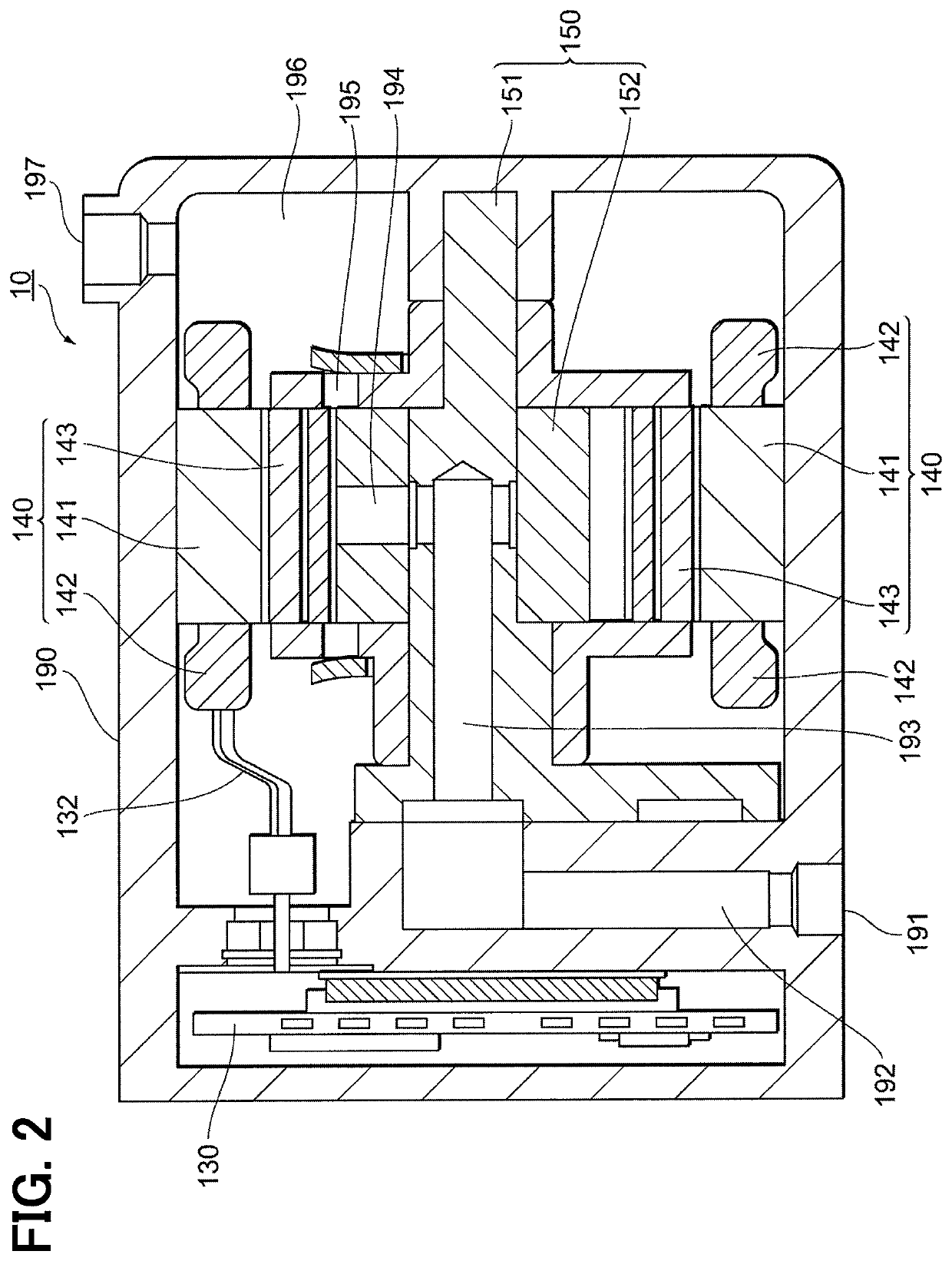

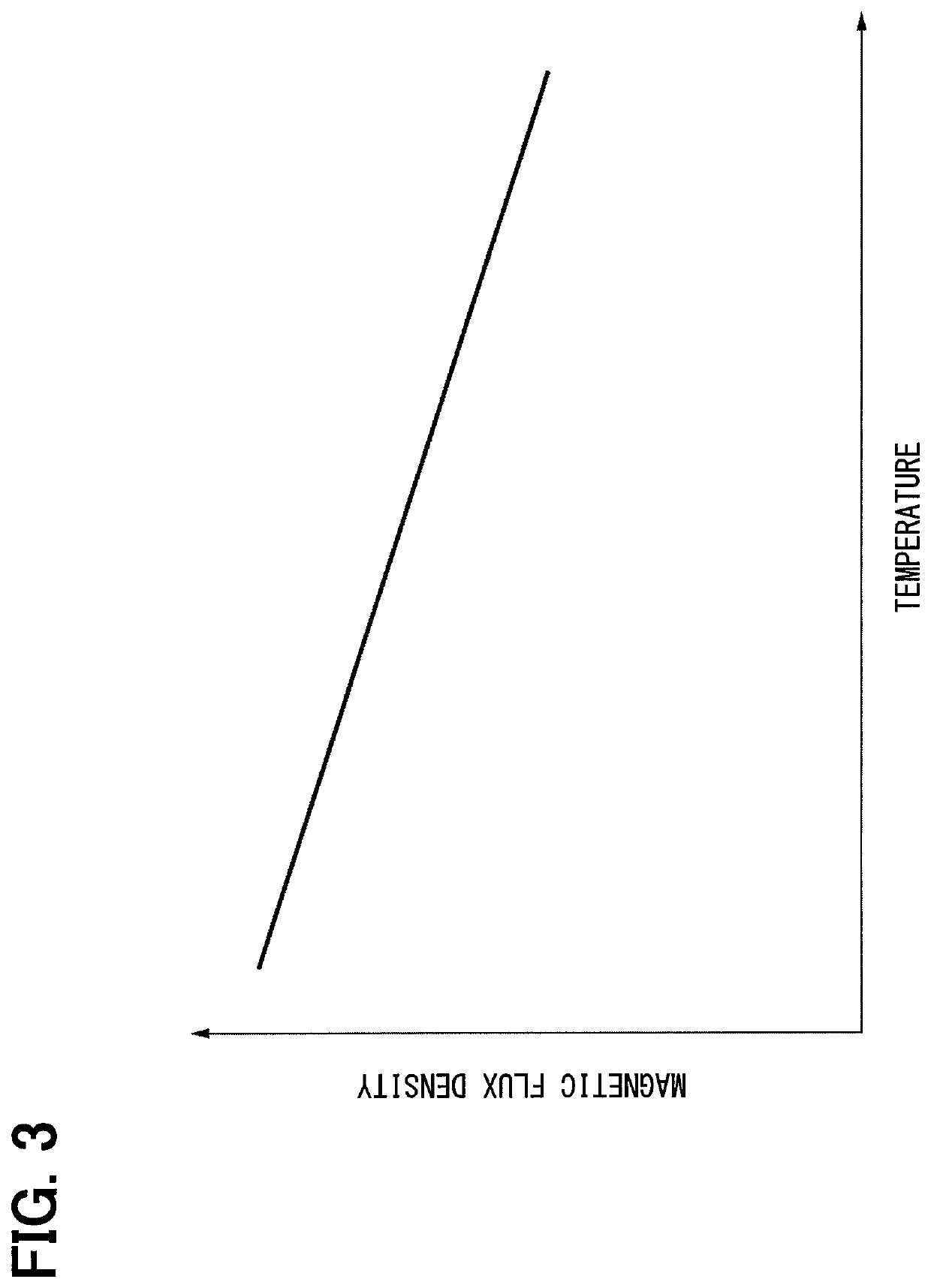

Electric compressor

ActiveUS10907628B2Preventing a decrease in torquePrevent excessive temperature riseRotary/oscillating piston combinations for elastic fluidsPump componentsDriving currentInverter

An inverter is disposed at a position on the upstream side relative to a compression mechanism along the flow of a refrigerant and the position cooled by the refrigerant. A motor is disposed at a position heated by the refrigerant compressed by the compression mechanism. A control device changes an upper limit value of a driving current supplied to the motor on the basis of at least one of first information relating to the temperature of the motor or second information relating to the temperature of the inverter.

Owner:DENSO CORP

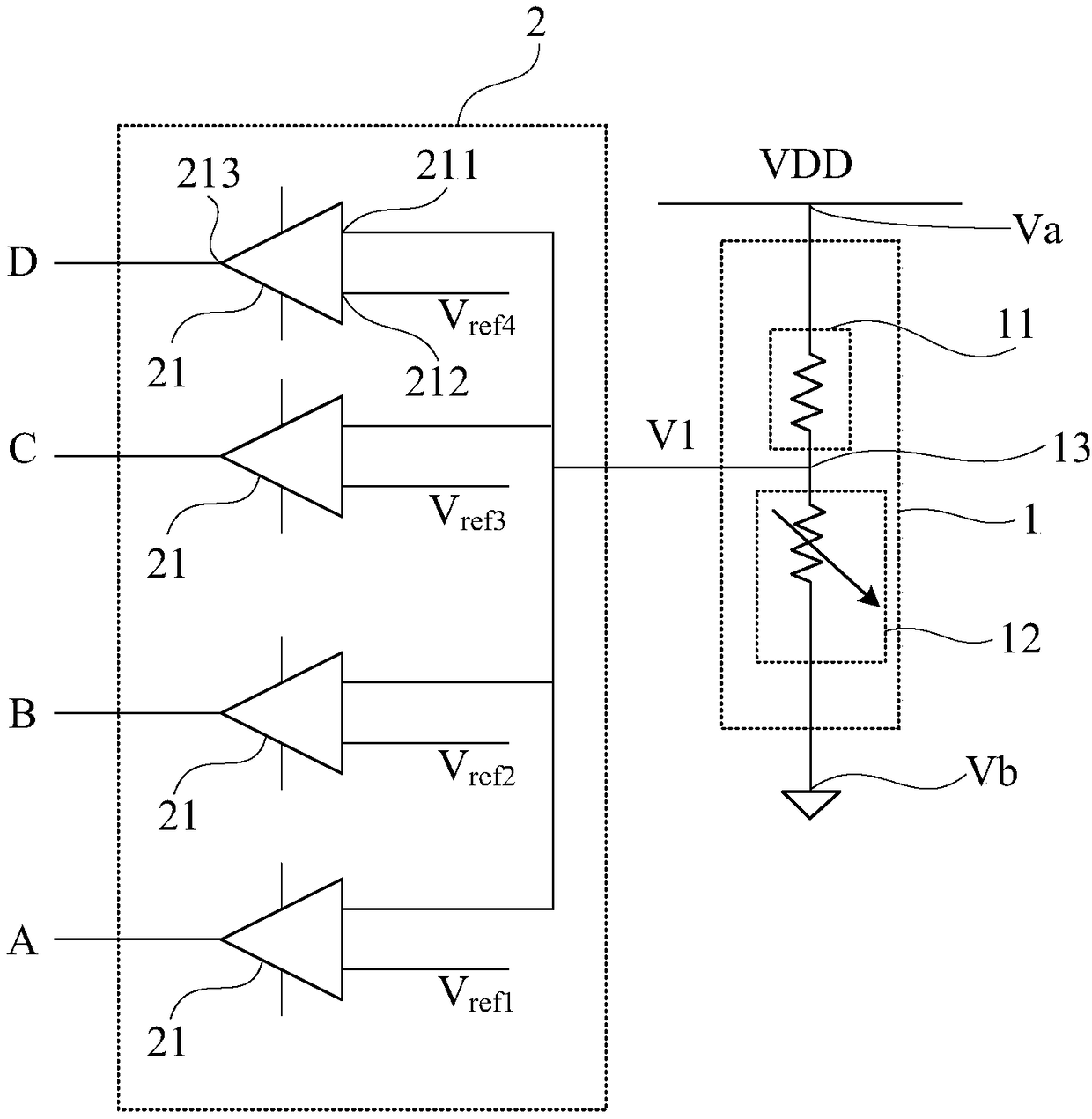

Display device and temperature sensing control module thereof

InactiveCN109375671APrevent excessive temperature risePrevent outageTelevision system detailsTemperatue controlCurrent limitingTemperature sense

The invention discloses a display device and a temperature sensing control module thereof. The temperature sensing control module comprises a temperature control voltage divider and a converter. The temperature control voltage divider includes a current limiting component and a temperature sensing component. The current limiting component and the temperature sensing component are connected in series between a high voltage end and a low voltage end to form a series connection point. The converter has a plurality of comparators; each of the plurality of comparators includes a first input terminal, a second input end, and an output end; the first input end is coupled to the series connection point; and the second input ends of the plurality of comparators receive a plurality of different reference values, wherein the plurality of reference value are greater than zero; and the plurality of comparators carry out comparison with the plurality of reference values based on a voltage dividing value from the series connection point to output a comparison result at the output end.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Method and device for controlling deicing of refrigerator damper

ActiveCN110425808BPrevent excessive temperature riseAvoid situations where the temperature rises excessivelyLighting and heating apparatusDefrostingDriving currentIcebox

Owner:SICHUAN HONGMEI INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com