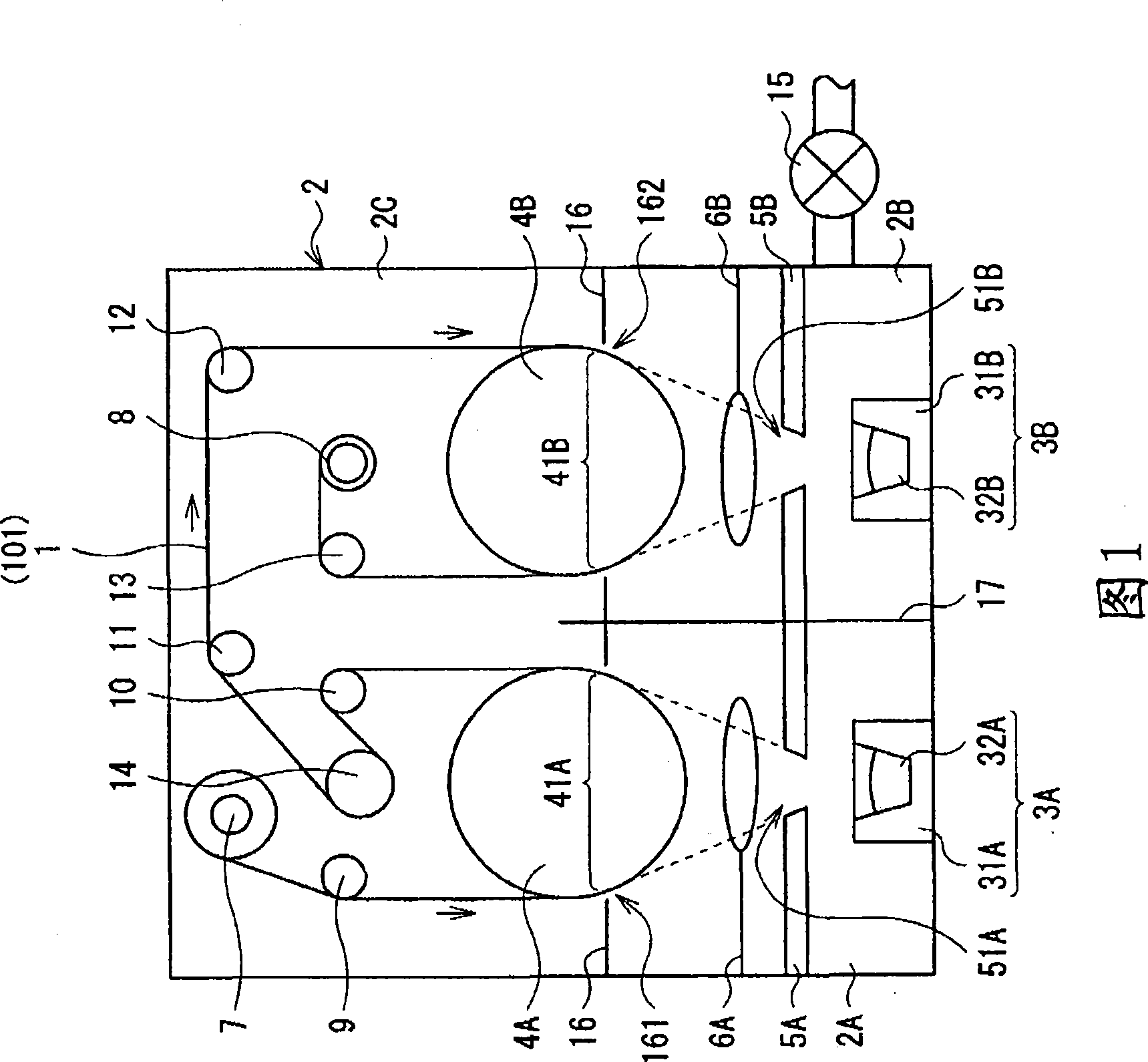

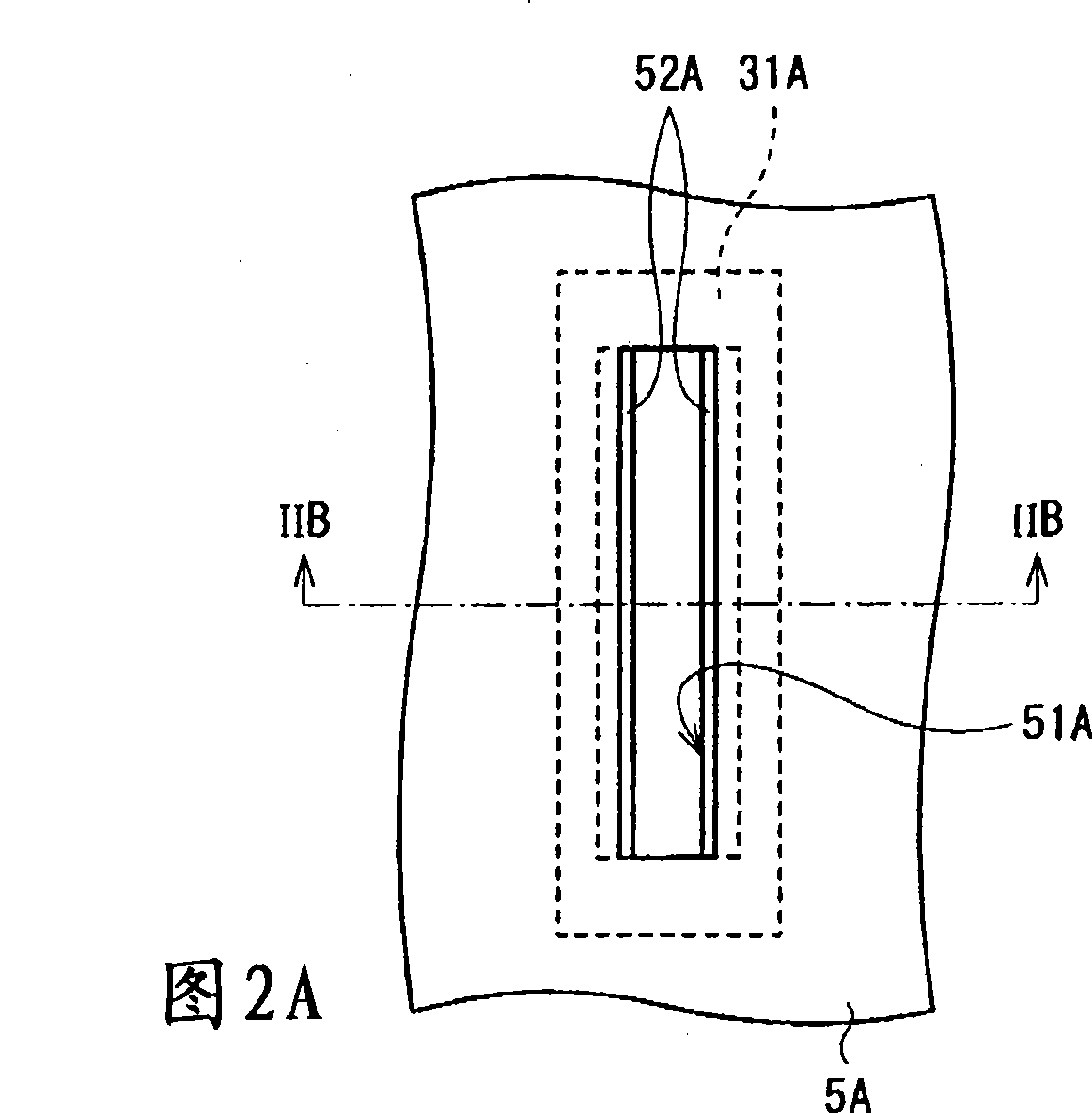

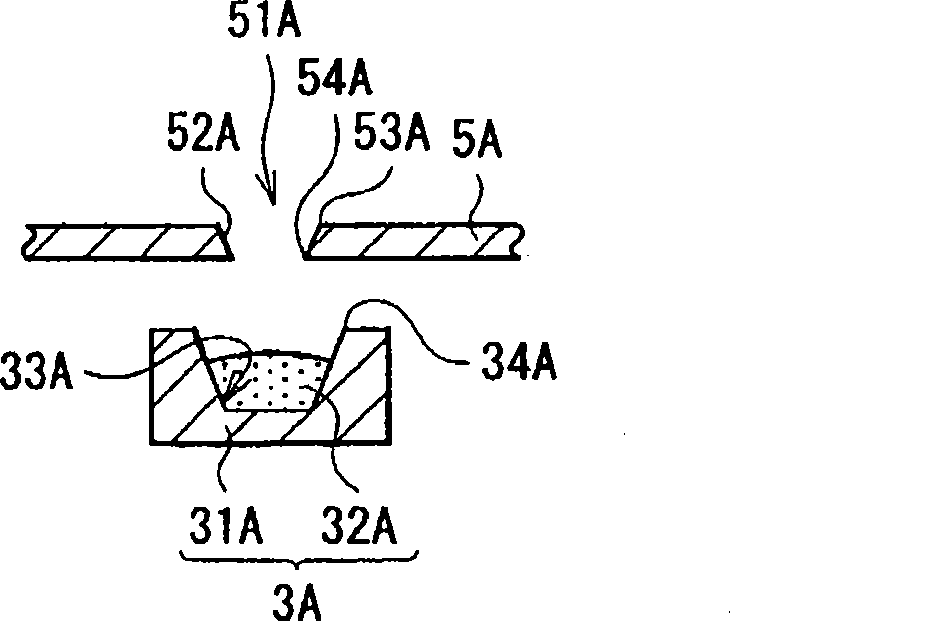

Evaporation apparatus, method of manufacturing anode using same, and method of manufacturing battery using same

A technology of evaporation equipment and anode, which is applied in the direction of battery, electrode manufacturing, lithium storage battery, etc., can solve the problems of temperature rise, substrate material limitation, etc., and achieve the effect of increasing evaporation, preventing excess products, and preventing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0123] Figure 9 and Figure 10 The shown prismatic secondary battery was fabricated by the following procedure. The secondary battery is formed as a lithium ion secondary battery in which the capacity of the anode 162 is expressed by a capacity component based on insertion and extraction of lithium.

[0124] First, the cathode 161 is formed. That is to say, lithium carbonate (Li 2 CO 3 ) and cobalt carbonate (CoCO 3 ) were mixed at a molar ratio of 0.5:1. After this, the mixture was fired at 900 deg C in air for 5 hours. Thus, lithium cobalt composite oxide (LiCoO 2 ). Subsequently, 96 parts by weight of lithium cobalt composite oxide as a cathode active material, 1 part by weight of graphite as a conductor, and 3 parts by weight of polyvinylidene fluoride as a binder were mixed to obtain a cathode mixture. After that, the cathode mixture was dispersed in N-methyl-2-pyrrolidone to obtain a paste cathode mixture slurry. Finally, both faces of the cathode current colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com