Heat exchange device resistant to high temperatures, high pressure and hydrogen corrosion

A technology of heat exchange device and high temperature resistance, applied in heat exchanger sealing device, heat exchange equipment, heat exchanger type, etc., can solve the problem of high purchase cost of reaction heat recovery device, high production cost of heat exchanger, equipment Problems such as high maintenance costs, to avoid excessive temperature rise, reduce production costs, and reduce heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

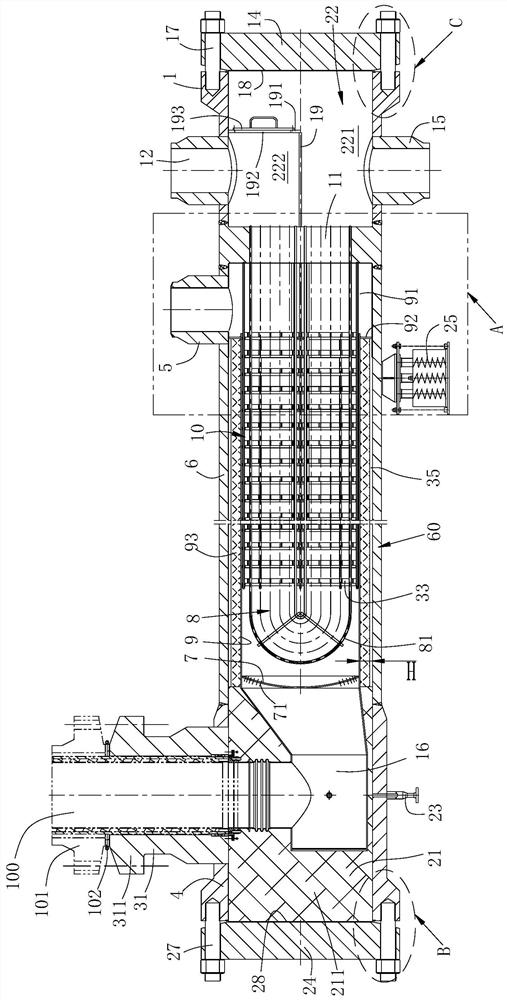

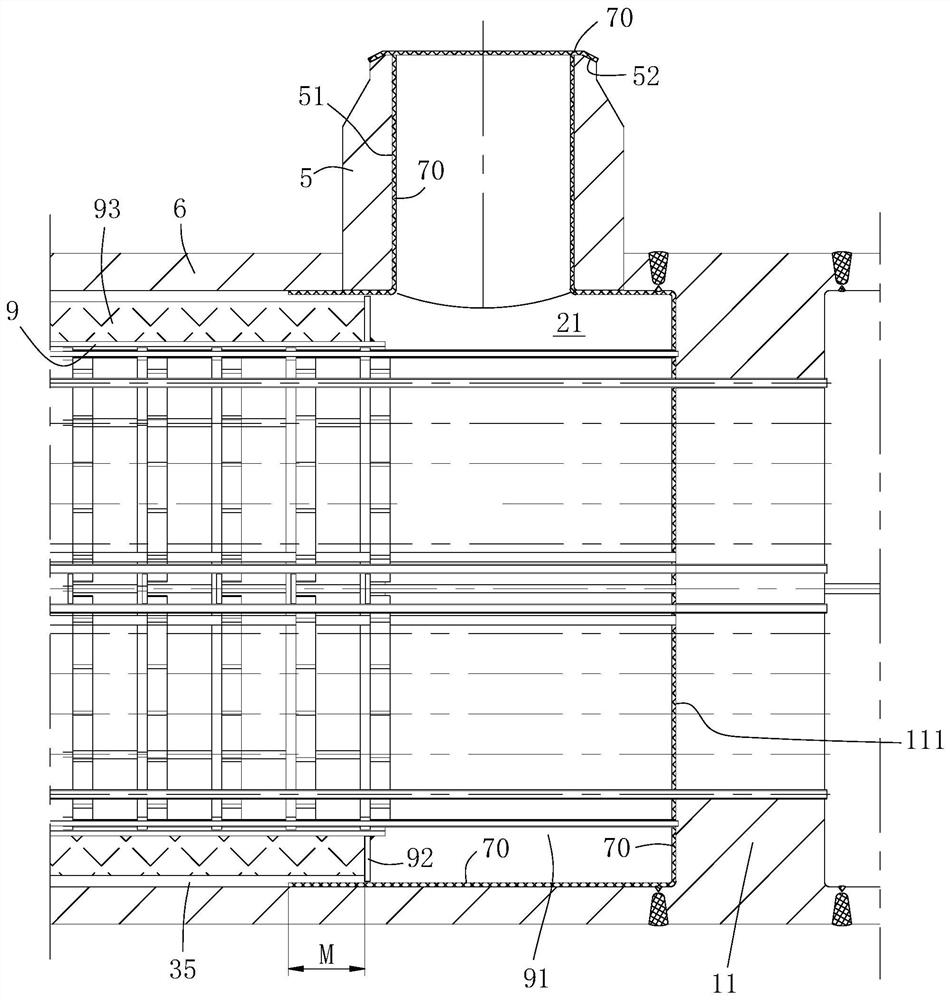

[0033] see figure 1 , a heat exchange device resistant to high temperature, high pressure, and hydrogen corrosion, which includes a shell, a tube plate 11 arranged in the shell, the shell includes a cylinder 60, and first sealing flat covers 24 arranged at both ends of the cylinder And the second sealing flat cover 14, the tube plate 11 divides the inner cavity of the shell into a heat exchange cavity 21 and a refrigerant cavity 22, wherein the heat exchange cavity is located between the tube plate 11 and the first flat cover 24, and the refrigerant cavity is located between the tube plate 11 and the second flat cover 14. The shell is horizontal, the first flat cover 24 is installed on the barrel through the first bolt 17 , and the second flat cover 14 is installed on the barrel through the second bolt 27 .

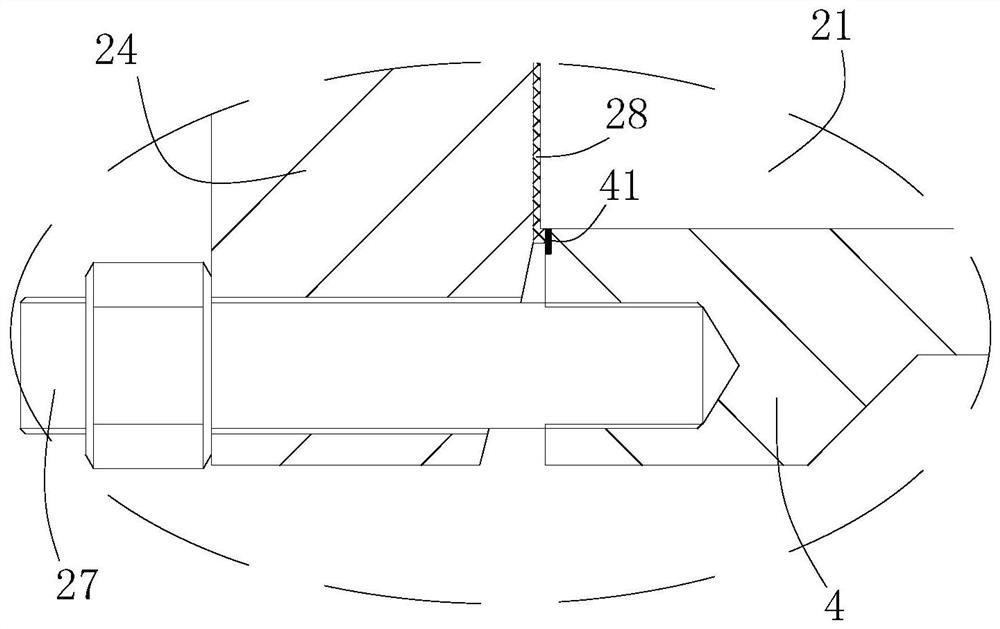

[0034] see image 3A first sealing diaphragm 28 is installed between the first flat cover 24 and the cylinder 60, the first sealing diaphragm 28 completely isolates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com