Rotary-ring mill

A mill and mill technology, applied in grain processing and other directions, can solve the problems of large vibration, short life of wearing parts, and high energy consumption, and achieve the effects of reducing noise and vibration, preventing direct contact, and high fineness of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

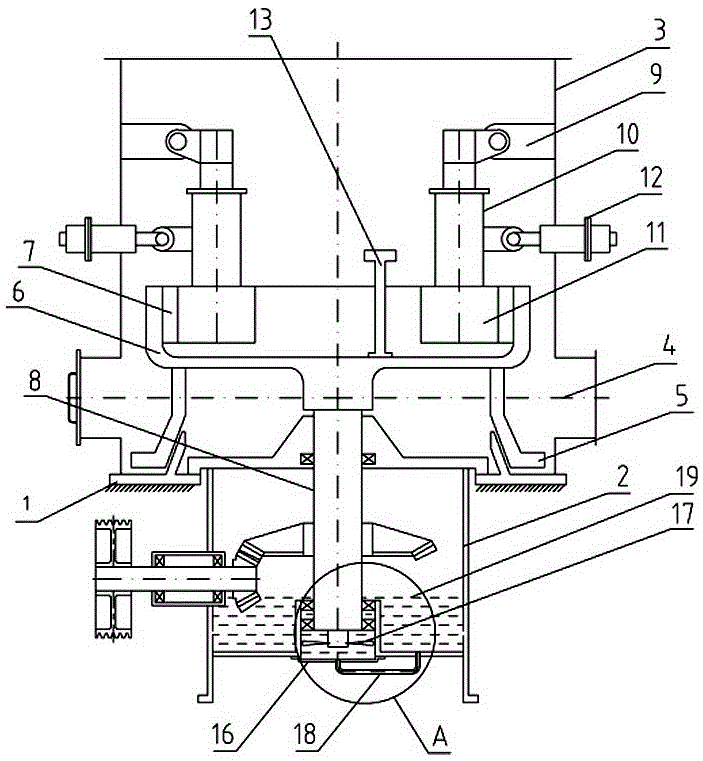

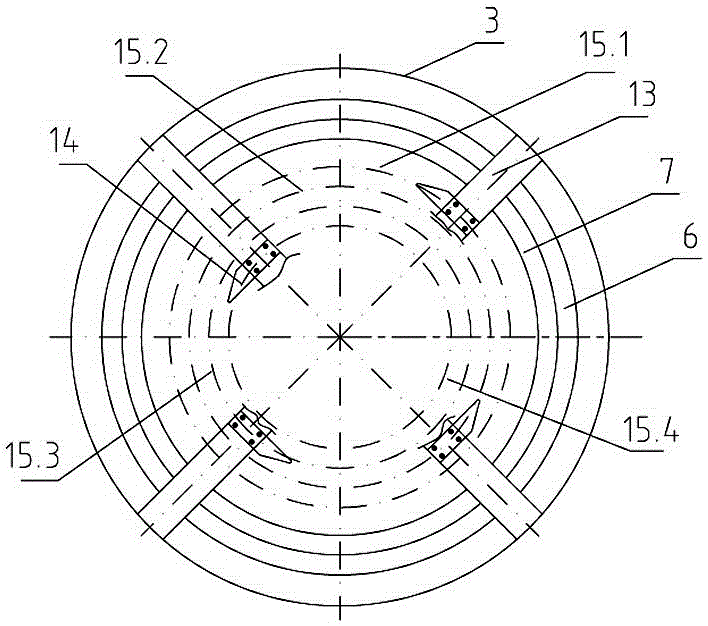

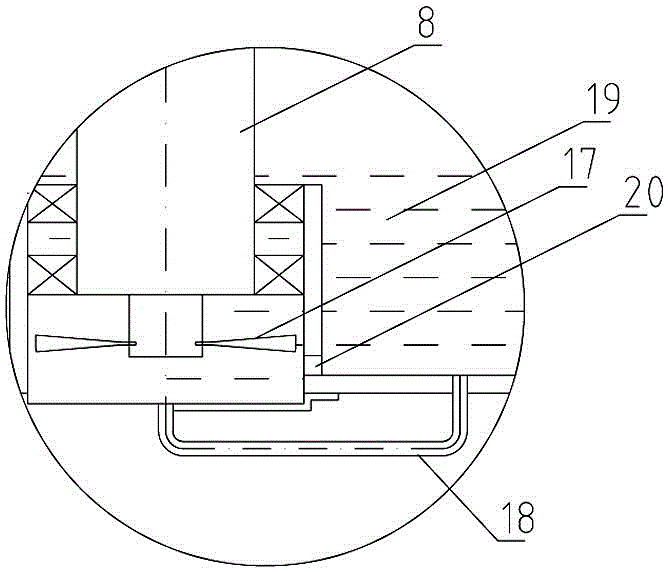

[0023] Such as Figure 1-5 As shown, the rotary ring mill of the present invention includes a vertical reducer gearbox 2 arranged on the machine base 1, a mill housing 3 arranged on the vertical reducer gearbox 2 and the top of the machine base 1 , the bottom of the inner cavity of the mill housing 3 is provided with an air duct and a scraper device 5, and a milling unit is arranged in the mill housing 3 above the air duct; the milling unit includes a bowl-shaped grinding disc 6 provided on the upper opening, The inner ring wall of the bowl-shaped grinding disc 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com