Vertical speed reducer with vertical shaft bearing lubricating oil circulating device

A circulation device and vertical shaft bearing technology, which is applied to transmission parts, gear lubrication/cooling, mechanical equipment, etc., can solve the problems of bearing heating, impurities are easy to precipitate, and oil deteriorates quickly, so as to prevent the temperature rise of the bearing from being too high Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

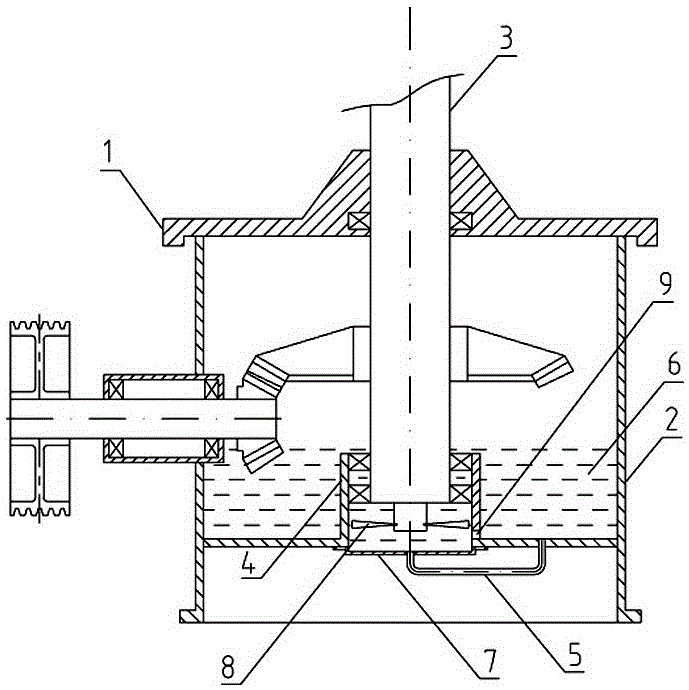

[0010] Such as figure 1 As shown, the vertical reducer with a vertical shaft bearing lubricating oil circulation device according to the present invention includes a vertical reducer body 1, and the bottom wall of the gearbox 2 of the vertical reducer body 1 is located on the power output shaft 3 of the gearbox 2 The position of the lower bearing chamber 4 is provided with an end cover 7, and the bottom of the end cover 7 is provided with an oil guide pipe 5. One nozzle of the oil guide pipe 5 communicates with the lower bearing chamber 4 and the other nozzle commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com