Roller screw

A technology of rollers and leadscrews, applied in the direction of belts/chains/gears, mechanical equipment, transmissions, etc., can solve problems such as difficulties and achieve the effect of preventing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

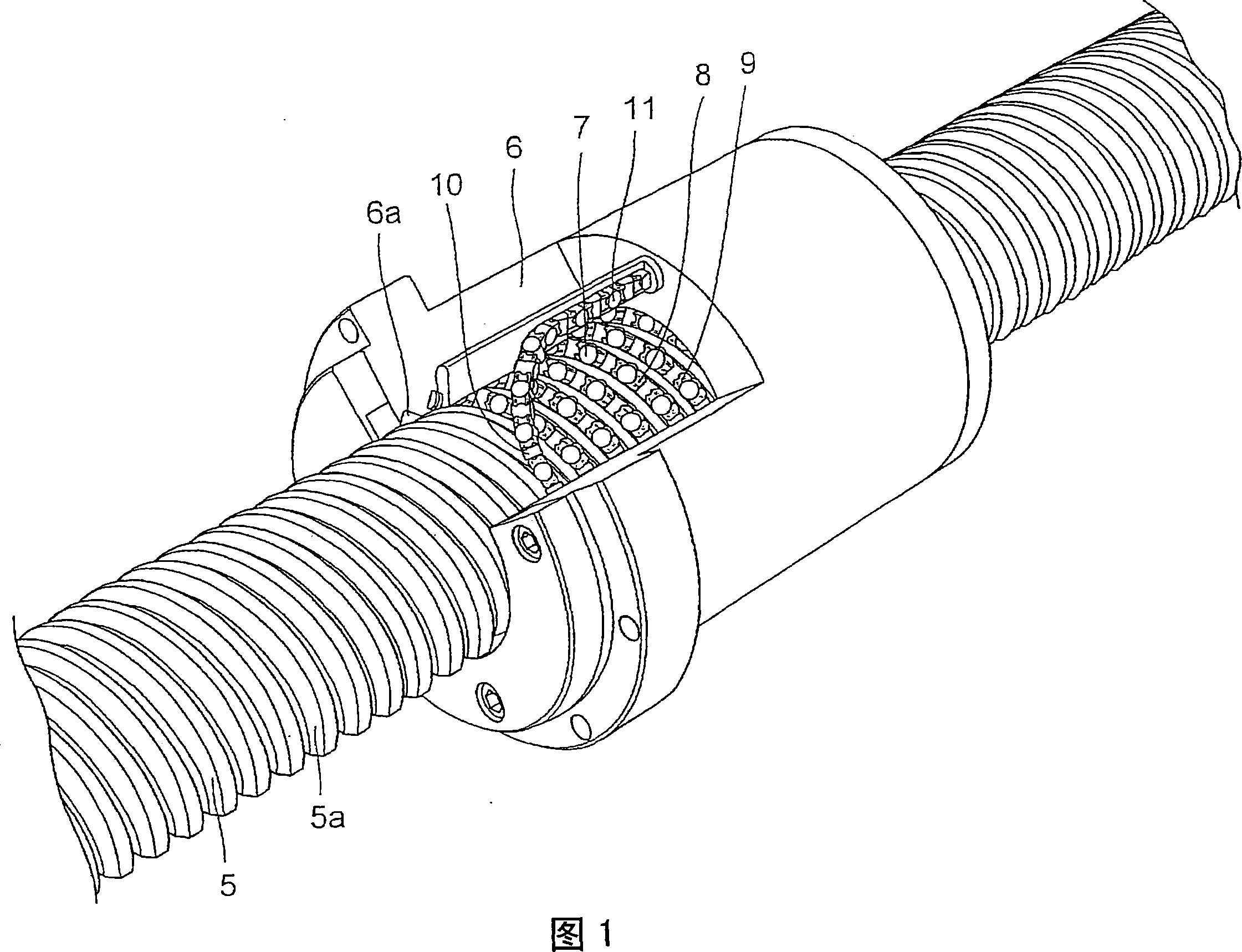

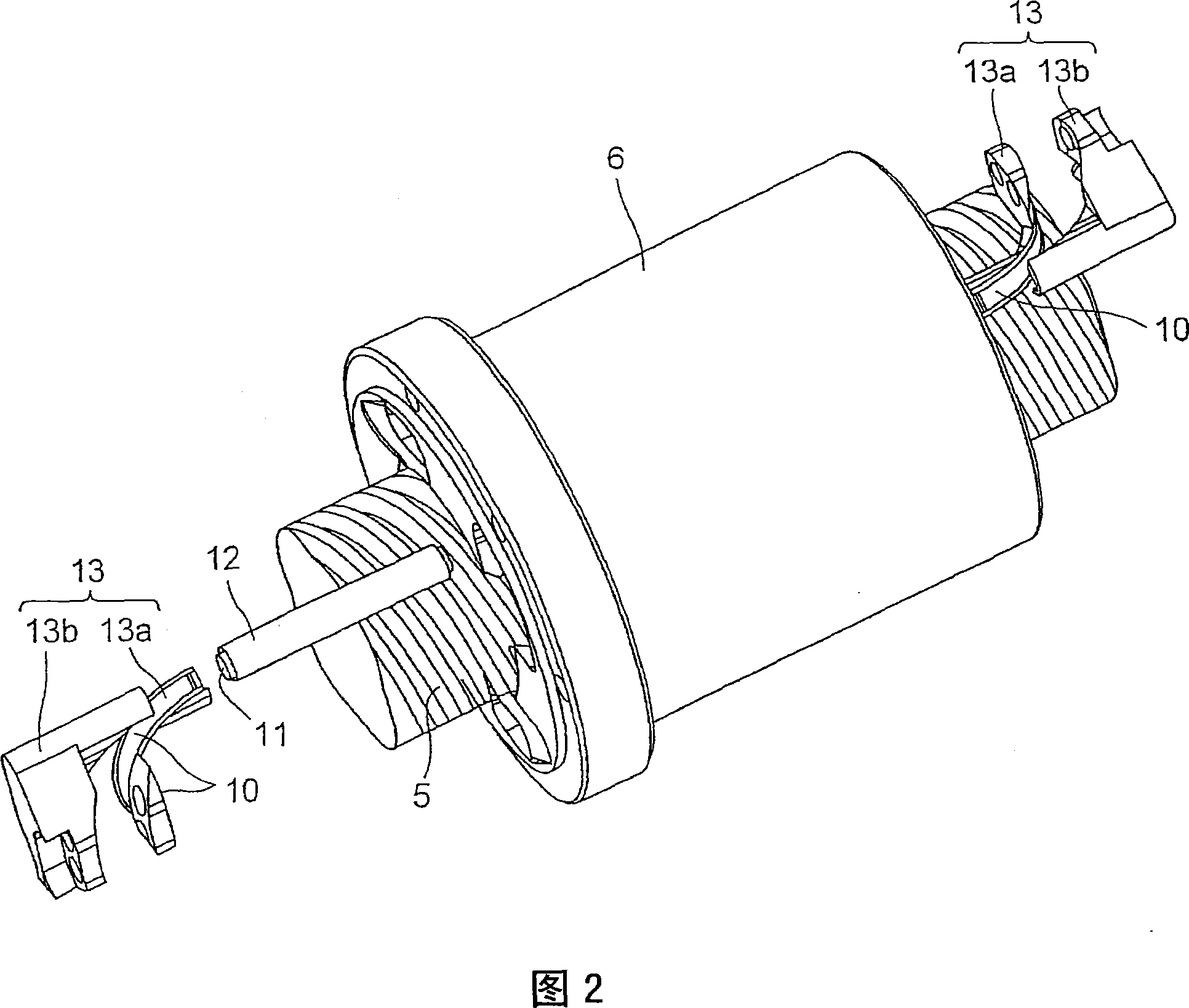

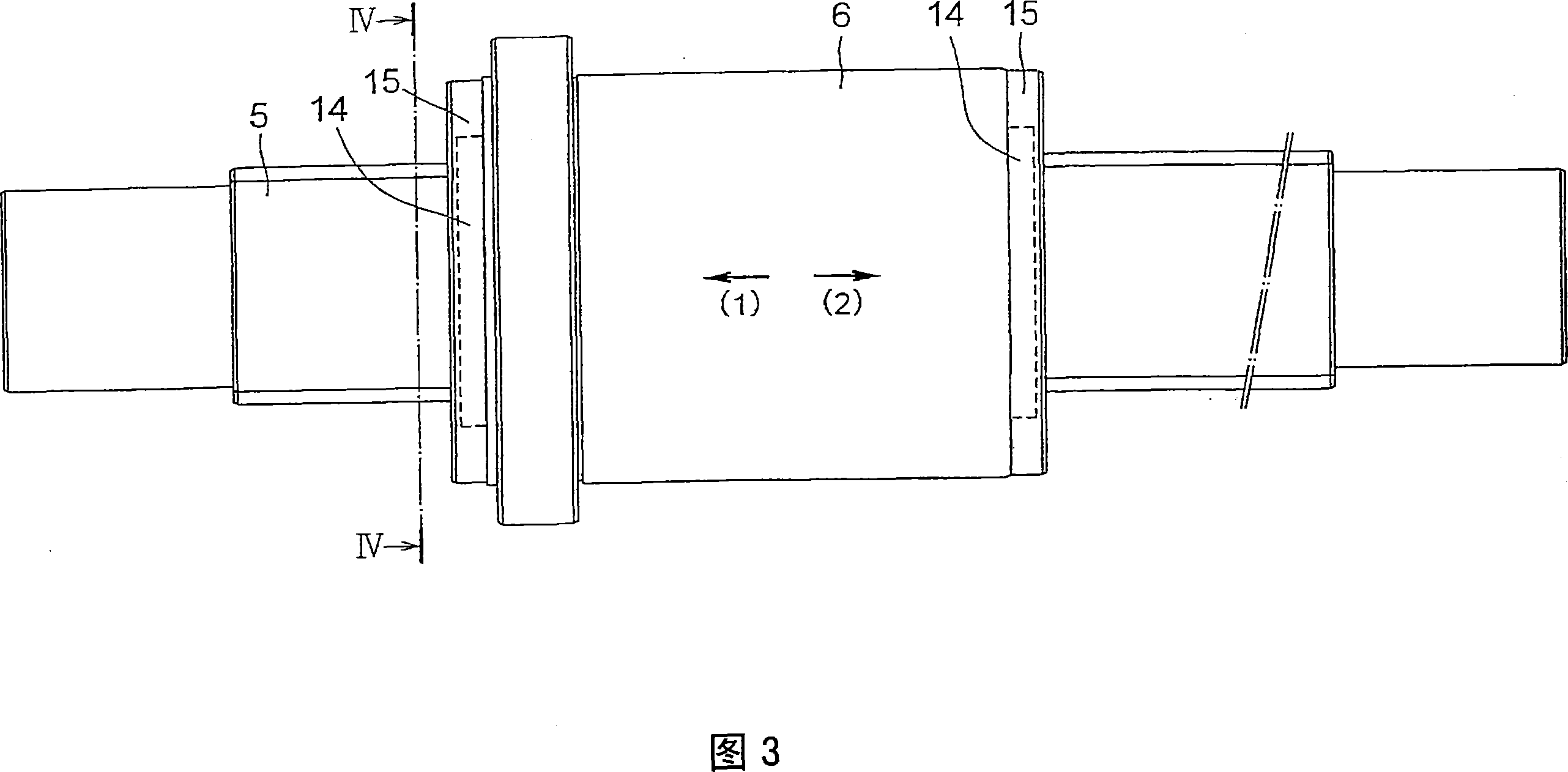

[0044] FIG. 1 is a perspective view showing a roller screw in one embodiment of the present invention. The roller screw includes: a screw shaft 5 having a helical roller groove 5a formed on the outer peripheral surface; and a helical roller groove 6a formed on the inner peripheral surface opposite to the roller groove 5a. Screw sleeve 6. Between the roller rolling groove 5a and the roller rolling groove 6a of the screw shaft 5, a plurality of rollers 7 are arranged crosswise so that the axes of adjacent rollers 7 are perpendicular to each other. A fixer 8 is interposed between the rollers 7 to prevent the rollers 7 from contacting each other.

[0045] When the nut 6 is rotated relative to the screw shaft 5, the plurality of rollers 7 roll along the roller rolling groove 5a and the load roller raceway 9 between the roller rolling grooves 6a and simultaneously move. The roller rolled to one end of the load roller raceway 9 is lifted by the direction changing raceway 10 and ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com