Vertical calibrating method for CCD imaging optic axle and grading screen based on symmetric measurement

A calibration method and screen technology, applied in the field of vertical calibration, can solve the problems of collimation axis error, artificial reading error, cumbersome positioning, etc., and achieve the effect of small reading error and simple collimation positioning method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] 1. Calibration principle:

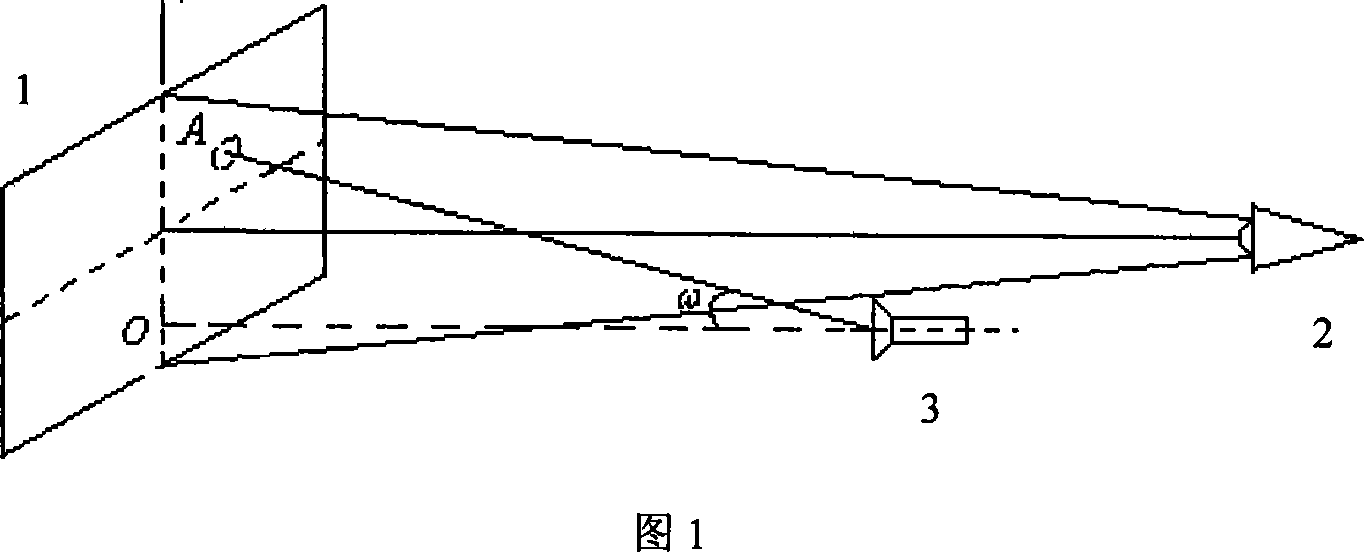

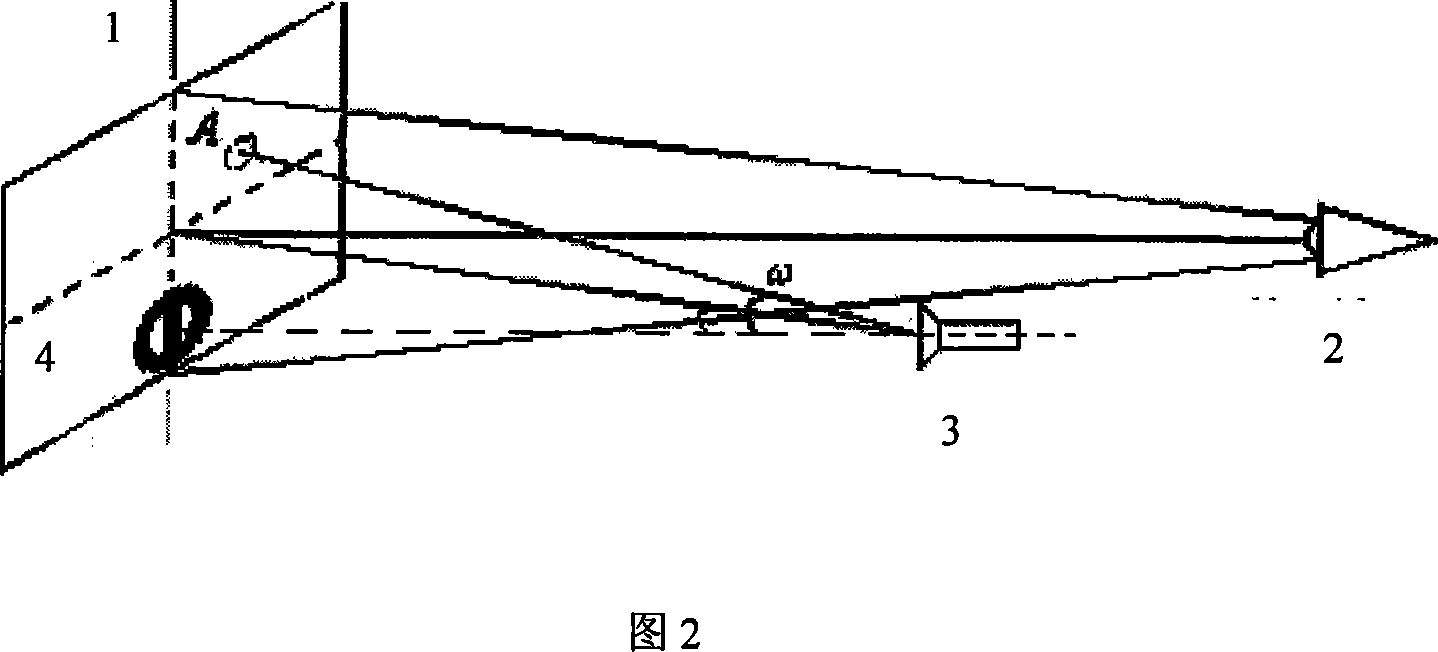

[0035] The calibration work in this paper is the prerequisite for the imaging test of the light distribution performance of motorcycle headlights. The test principle is shown in Figure 1. In order to make the imaging optical axis of the camera perpendicular to the test screen, that is, the imaging optical axis of the CCD camera in Figure 1 should be perpendicular to the test screen at point o. In this experiment, the symmetrical measurement method is adopted, and the CCD camera is used to image the circular target on the light distribution test screen. The test principle is shown in Figure 2:

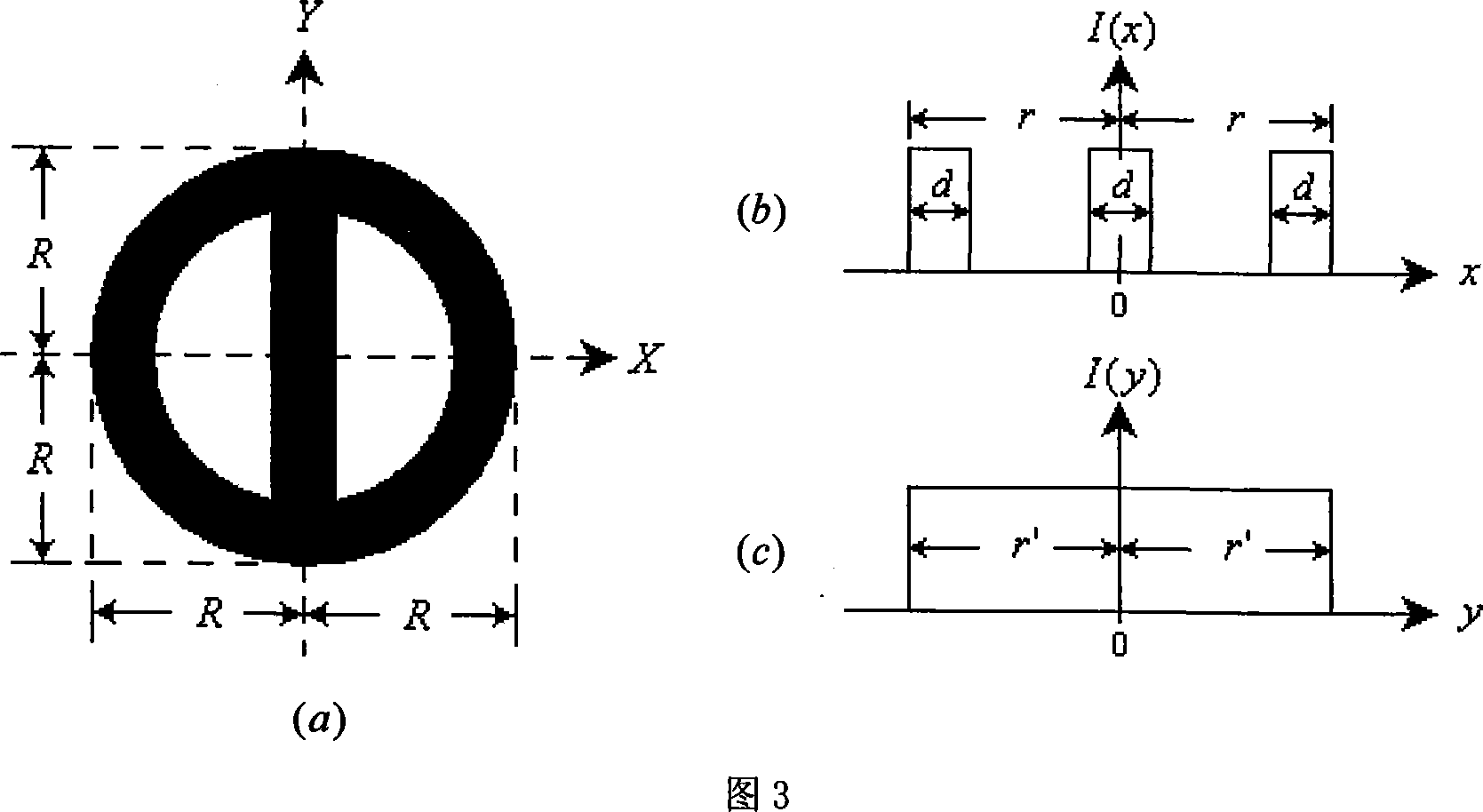

[0036] In Figure 2, the plane of the ring target is placed parallel to and below the vertical line of the light distribution screen, and the vertical line of the screen coincides with the vertical line passing through the center of the ring. The CCD camera is placed in front of the ring target at the same height, and the center of the CCD lens is appr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com