Thermal test device and centering method for control rod driving wire

A thermal test and driving line technology, applied to pump devices, educational appliances, machines/engines, etc., can solve the problems of not specifying, adjusting the centering of the test piece, and unsatisfactory, so as to achieve simple structure and ensure straight line degree, the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

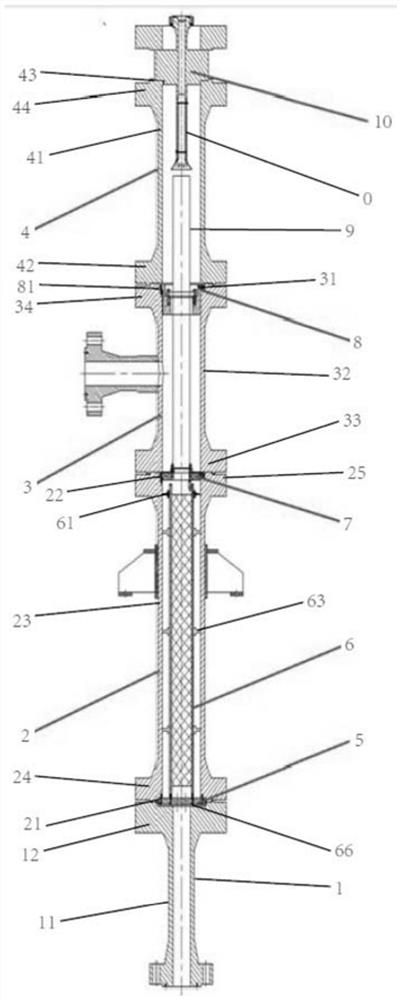

[0032]In order to describe the content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in combination with the embodiments and accompanying drawings.

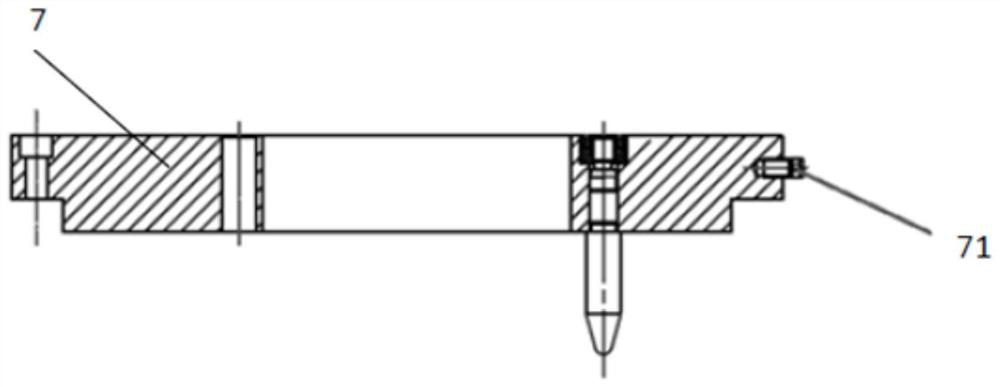

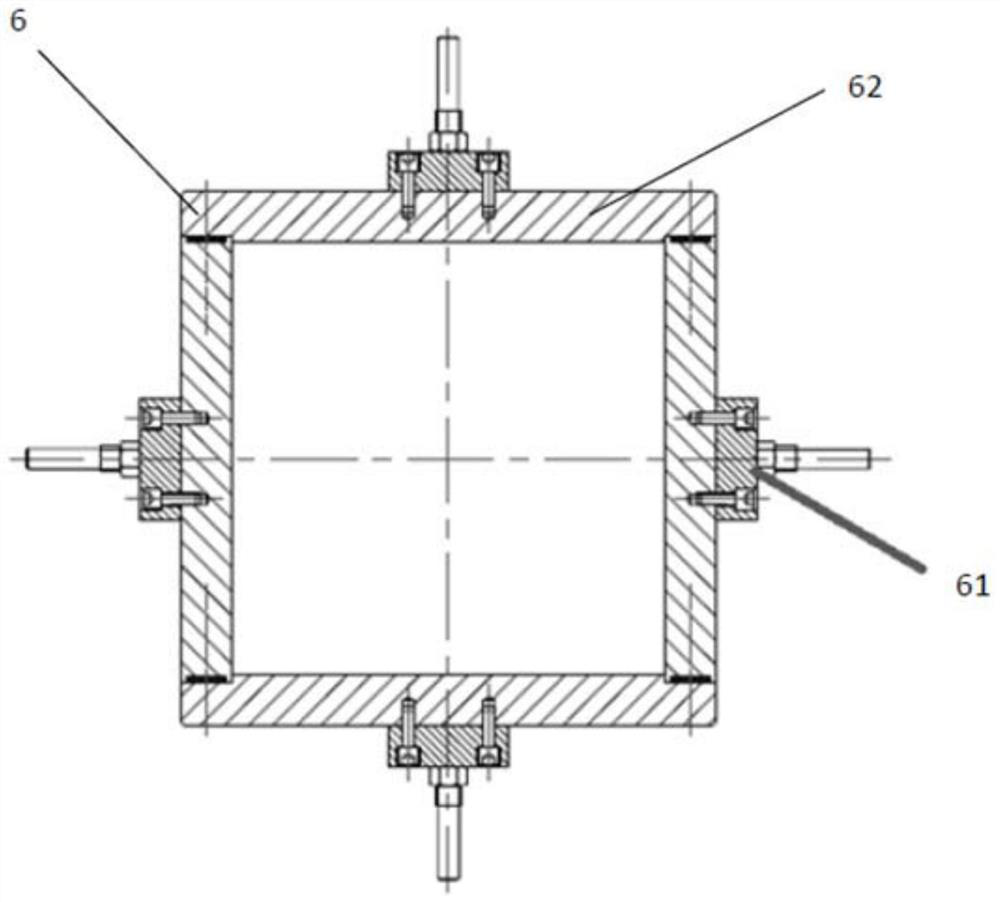

[0033] see Figures 1 to 3 , the invention discloses a thermal test device for control rod drive line, comprising a bottom connection shell 1, a lower pressure shell 2, a middle pressure shell 3, an upper pressure shell 4, a lower core plate 5, a surrounding Plate assembly 6, upper core plate 7, guide tube support plate 8, guide tube 9, tube seat installation structure 10 and tube seat 0 for installing control rod drive mechanism. The bottom connection shell 1, the lower pressure shell 2, the middle pressure shell 3 and the upper pressure shell 4 are sequentially sealed and connected, and the two ends of the lower pressure shell 2 are respectively formed with a lower plate installation notch 21 and an upper plate installation notch 22 , the lower co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com