Wall brushing device

A technology for wall painting and painting, which is applied in the direction of machines/engines, liquid variable capacity machinery, pumps with flexible working elements, etc. Influence and other issues, to avoid frequent opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

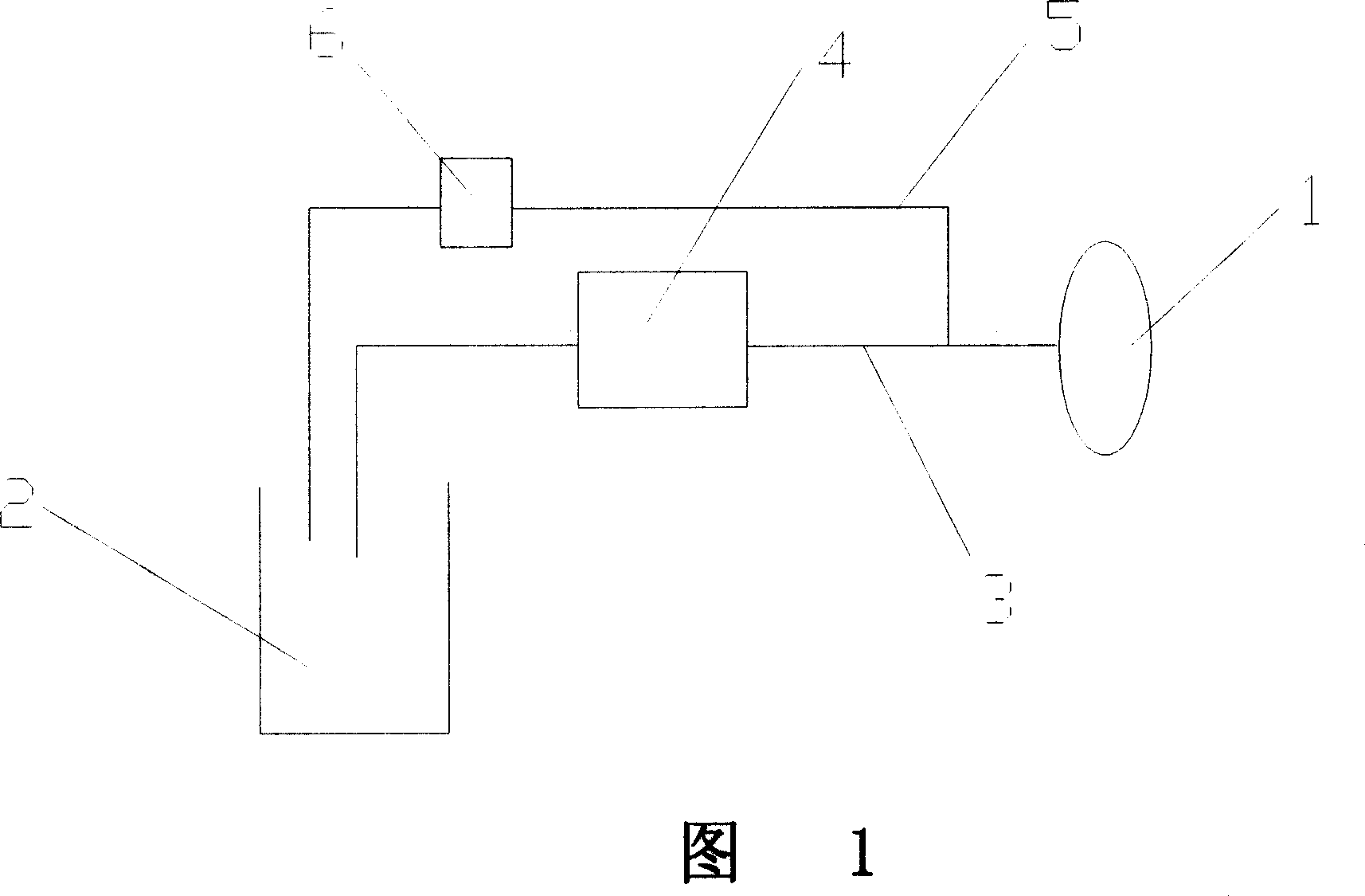

[0019] With reference to Fig. 1, 2, a kind of wall brushing device comprises brushing roller 1, and one end communicates with paint storage cylinder 2, and the other end connects paint conveying pipeline 3 of brushing roller 2, installs on described paint conveying pipeline 3 There is a diaphragm pump 4 and its driving motor, and also includes a return line 5 connected to the paint storage tank 2 at one end and connected to the paint delivery line behind the output end of the diaphragm pump 4 at the other end. A regulating valve 6 is also installed on the return line 5 ;

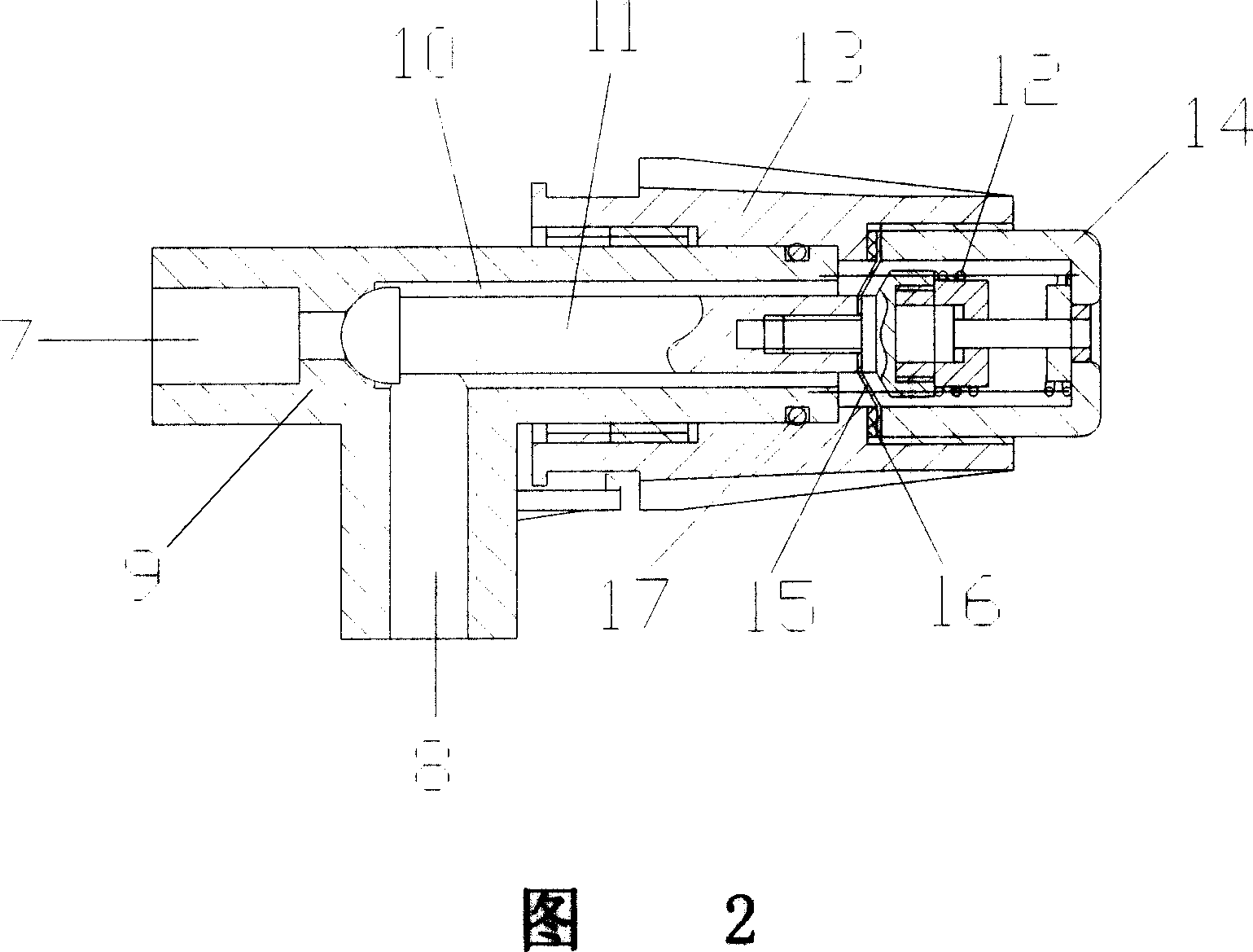

[0020] The regulating valve includes a valve body 9 having a liquid inlet 7 and a liquid outlet 8, and the valve body 9 also has a valve chamber 10 communicating with the liquid inlet 7 and the liquid outlet 8, and the valve chamber 10 There is a spool 11 inside. When the front end of the spool 11 touches the connection between the liquid inlet 7 and the valve cavity 10, a sealing surface is formed at the ab...

Embodiment 2

[0024] The valve body 9 of the regulating valve is also threaded to a knob sleeve 13, the end of the valve body 9 is equipped with a rear end cover 14, and the rear end cover 14 is affixed to the knob sleeve 13, and the pre-tightened The spring 12 connects the valve core 11 and the rear end cover 14 . A sealing gasket 15 and a diaphragm 16 are installed between the rear end cover 14 and the knob cover 13, a sealing ring 17 is arranged between the knob cover 13 and the valve body 9, and the sealing gasket 15, the diaphragm 16 and the sealing ring 17 Can prevent the leakage of paint.

[0025] Manually adjust the knob sleeve 13 so that the valve core 11 no longer seals the liquid inlet 7 and the valve chamber 10 of the valve body, so that the paint flows back to the liquid storage cylinder 2 through the liquid inlet, the valve chamber and the liquid outlet, that is, the infusion The paint to the brush roller can be diverted to regulate the flow of paint to the brush roller.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com