Cold ground heat exchange device

A technology of a heat exchange device and a total heat exchanger, applied in the field of heat exchange devices, can solve the problems of damage to the air valve, reduce the accuracy of temperature measurement, and cannot be low in cost, so as to prevent frequent opening and closing, prolong the service life, and improve the Anti-cold wind effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

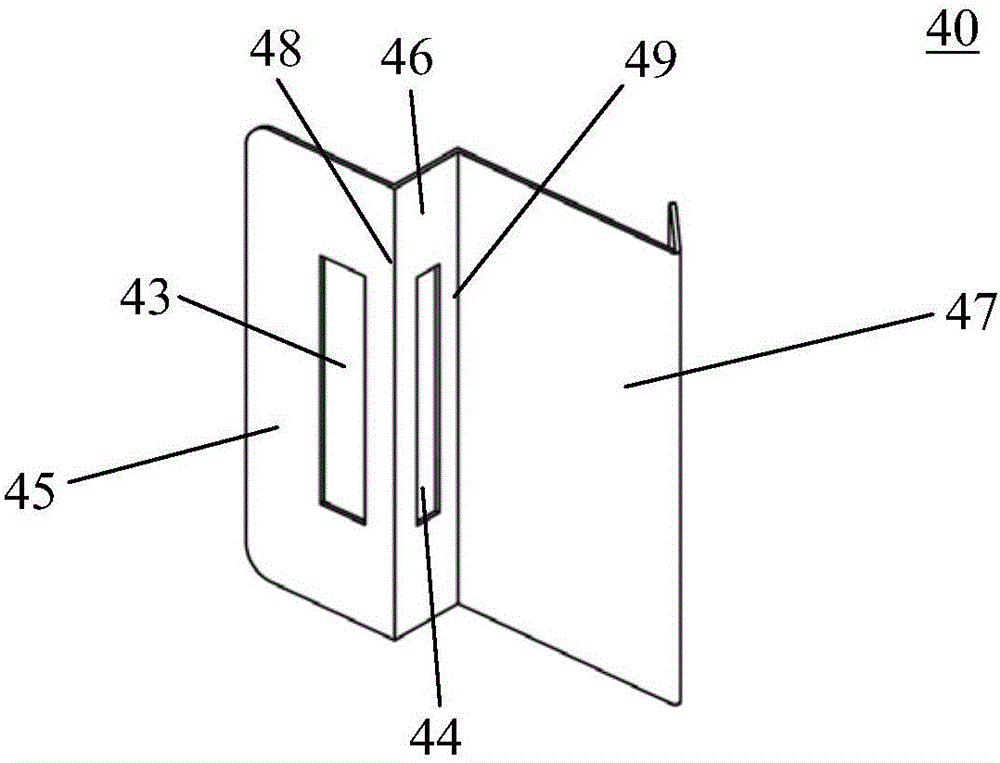

[0036] figure 1 It is a perspective view of the outer case of the cold ground heat exchange device of the first embodiment of the present invention. figure 2 It is a schematic top view of the cold ground heat exchange device in the first embodiment of the present invention when it is in a normal ventilation state. Such as figure 1 and figure 2 As shown, the heat exchange device 100 has an ERV (total heat exchanger) 1 and an outer case 2 mounted on the ERV 1 . An exhaust connection port 24 and an air supply connection port 25 are provided on a side surface of the outer case 2 close to the ERV 1 . An outdoor air outlet 20 and an outdoor air inlet 21 are provided on the side of the outer case 2 away from the ERV 1 .

[0037]A partition plate 11 is arranged in the middle of the outer box 2, and the partition plate 11 divides the outer box 2 into an exhaust channel 3 and an air supply channel 4, and the exhaust channel 3 communicates with the outdoor exhaust port 20 and the...

no. 2 example

[0069] The basic structure of the heat exchange device of this embodiment is the same as that of the first embodiment, and only the differences between this embodiment and the first embodiment will be described below.

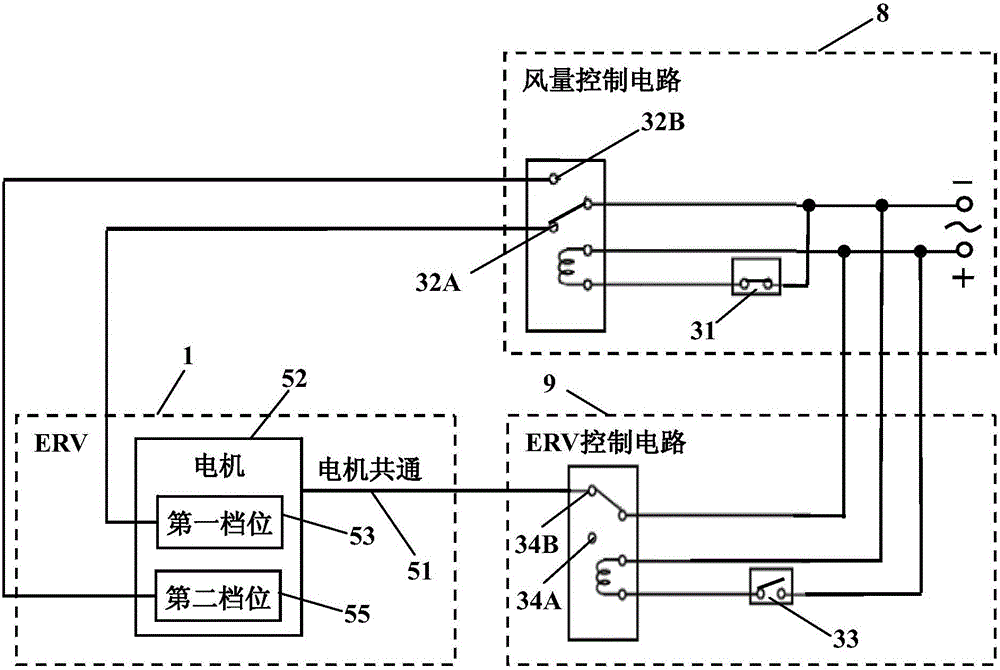

[0070] Figure 6 is a schematic circuit diagram of the heat exchange device of the second embodiment of the present invention. Such as Figure 6 As shown, the ERV 1 includes a motor 52 for driving the ERV 1 to run and a common motor 51 for powering the motor 52 . The motor 52 includes a first gear 53 and a second gear 55 . The first contact 32A of the relay 32 is connected to the first gear 53 of the motor 52 . The second contact 32B is connected to the second gear 55 of the motor 52 . When the temperature T1 is higher than -10°C, the first contact 32A of the relay 32 and the first gear 53 of the motor 52 are connected, and the ERV 1 operates with a large air volume. When the temperature T1 is equal to or lower than -10°C, the second contact 32B of the rel...

no. 3 example

[0077] The basic structure of the heat exchange device of this embodiment is the same as that of the first embodiment, and only the differences between this embodiment and the first embodiment will be described below.

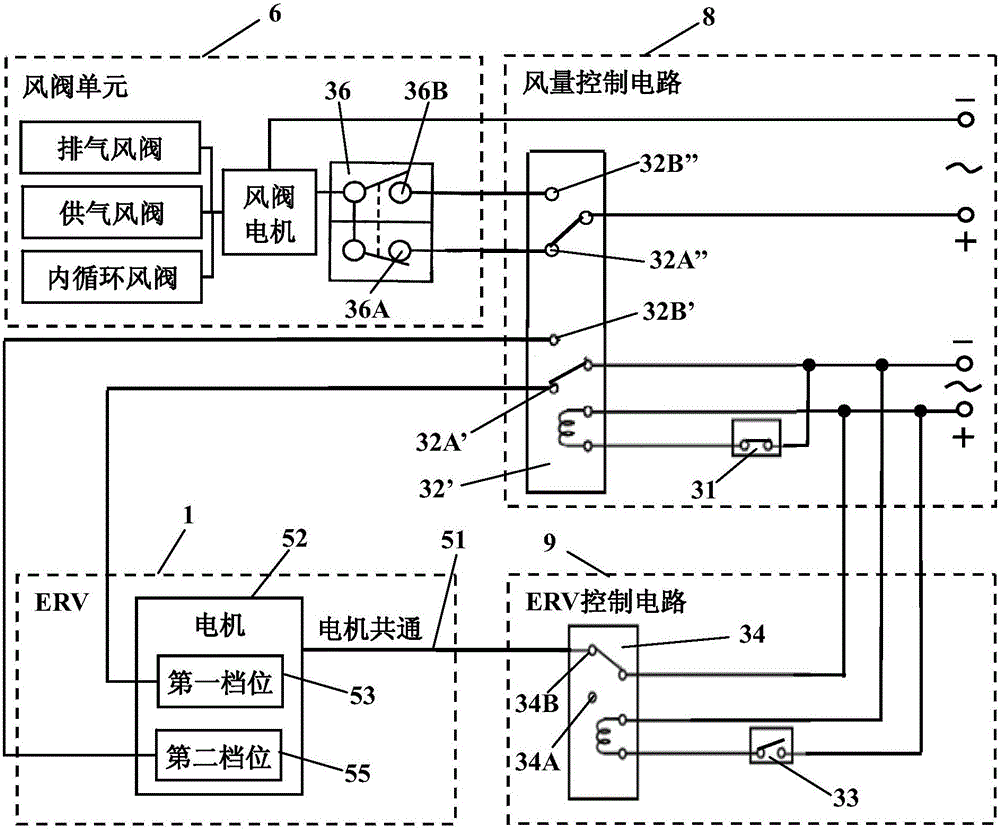

[0078] Figure 7 is a schematic circuit diagram of the heat exchange device of the third embodiment of the present invention. Such as Figure 7 As shown, the ERV 1 includes a motor 52 for driving the ERV 1 to run and a common motor 51 for powering the motor 52 . The motor 52 includes a first gear 53 and a second gear 55 . The double-pole relay 32' of the air volume control circuit 8 includes a first contact 32A', a second contact 32B', a third contact 32A" and a fourth contact 32B". The first contact 32A' is connected to the first gear 53 of the motor 52, the second contact 32B' is connected to the second gear 55 of the motor 52, and the third contact 32A" is connected to the micro switch 36 of the damper unit 6 The first contact 36A of the micro switch is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com