Damper of multi-dimensional superelastic shape memory alloy

A memory alloy and memory alloy wire technology, which is used in building components, shockproof and other directions, can solve the problems of aging and durability maintenance and replacement, difficult multi-dimensional passive control, single energy consumption and vibration reduction ability, etc. Simple, reduce the effect of structural vibration response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

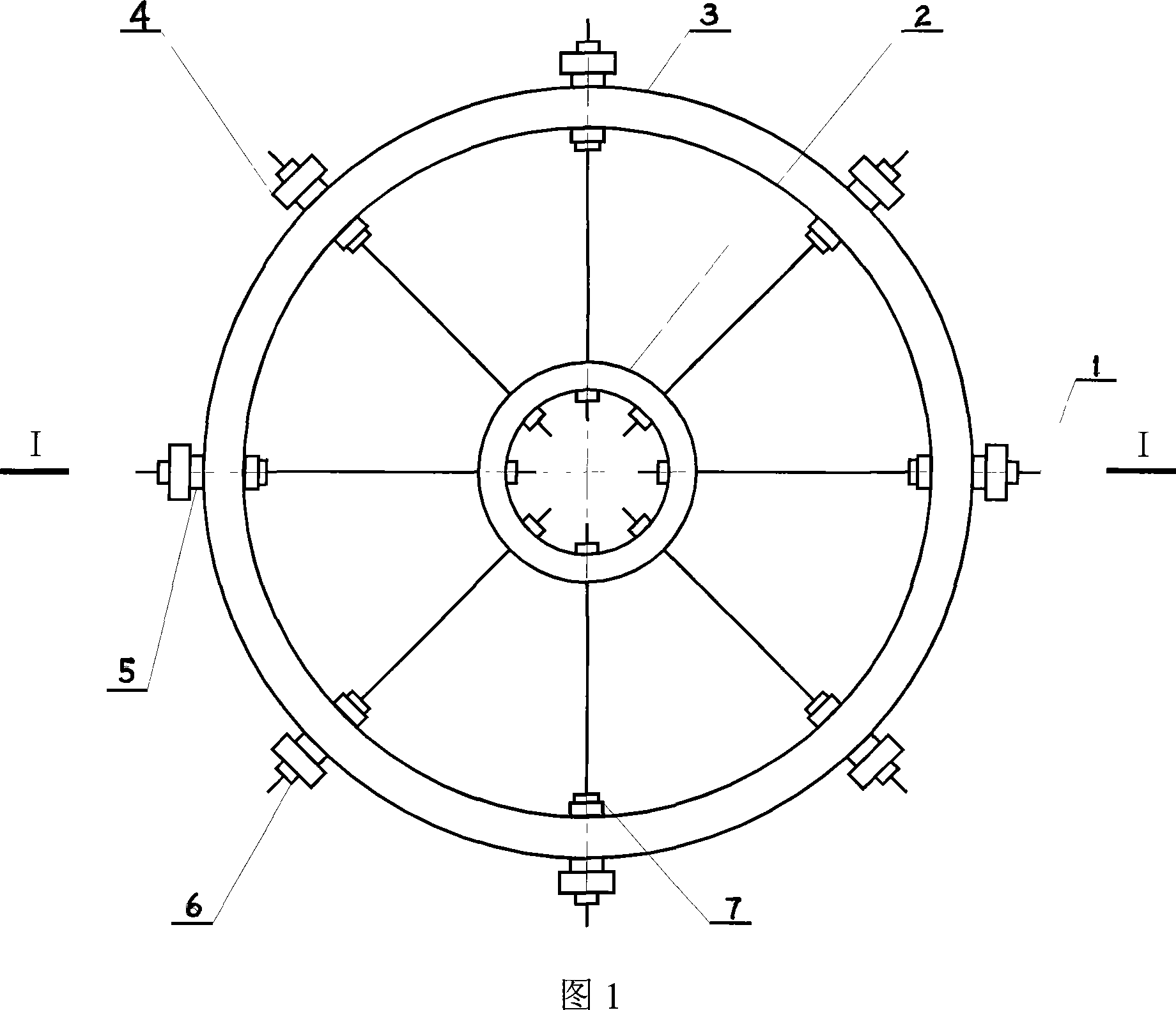

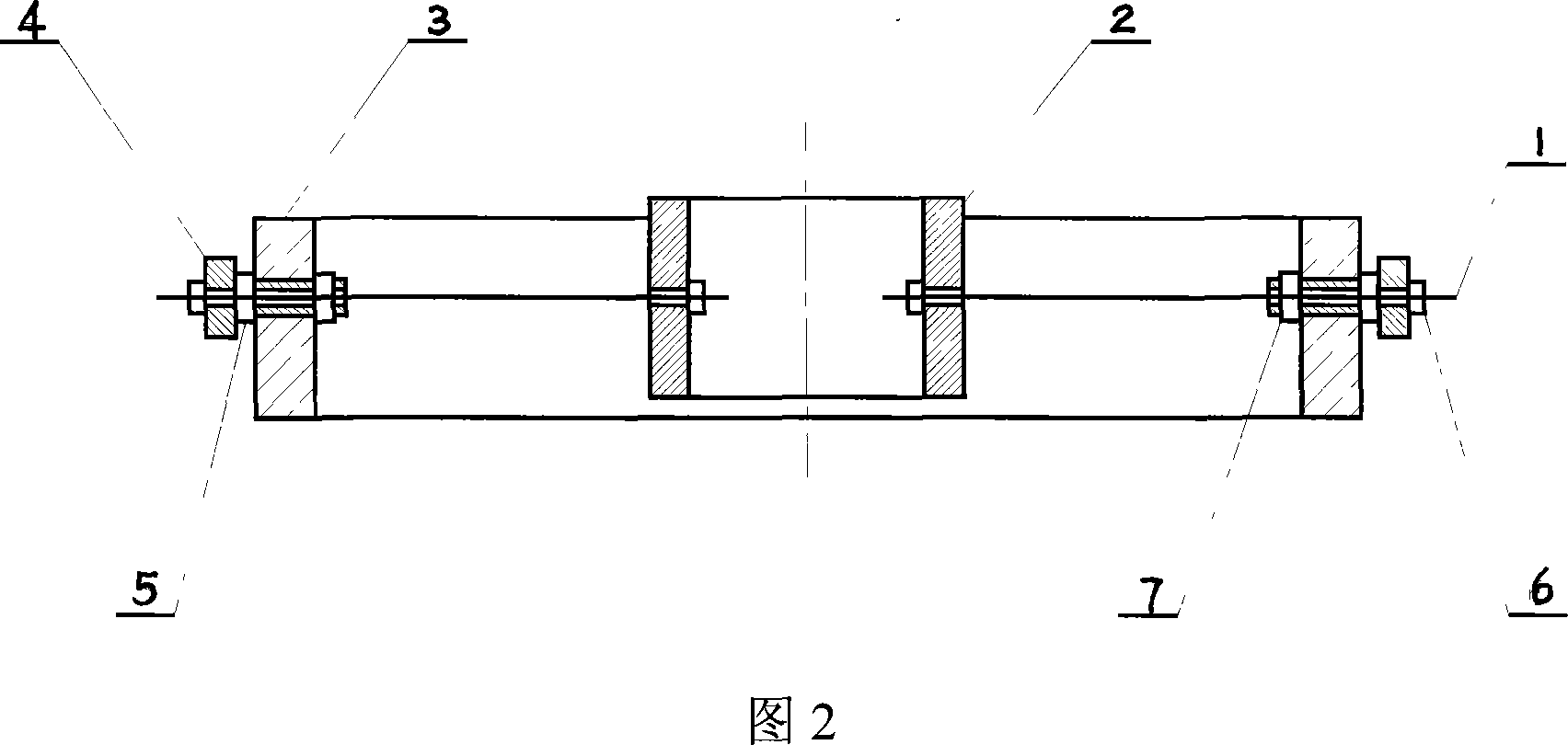

[0010] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0011] step 1

[0012] According to the requirements of vibration control, determine the material, size and quantity of each component of the damper.

[0013] step 2

[0014] Drill holes in the corresponding positions of the inner steel cylinder 2 and the outer steel cylinder 3, and adjust the coaxiality of the inner steel cylinder 2 and the outer steel cylinder 3. The shape memory alloy wire 1 is horizontally and symmetrically arranged radially along the circumference of the steel cylinder, that is, the shape memory alloy wire 1 penetrates through the hole on one side of the outer steel cylinder 3 and exits through the hole on the corresponding side of the inner steel cylinder 2, and one end of the wire is fixed by the clamp 6 is fixed on the enlarged end of the adjusting screw 4 installed on the outer steel cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com