Support structure for elevated floor assembly

A supporting structure and elevated floor technology, which is applied to local raised floors, building structures, floors, etc., can solve the problems of insufficient rigidity of the supporting structure, time-consuming, troublesome, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

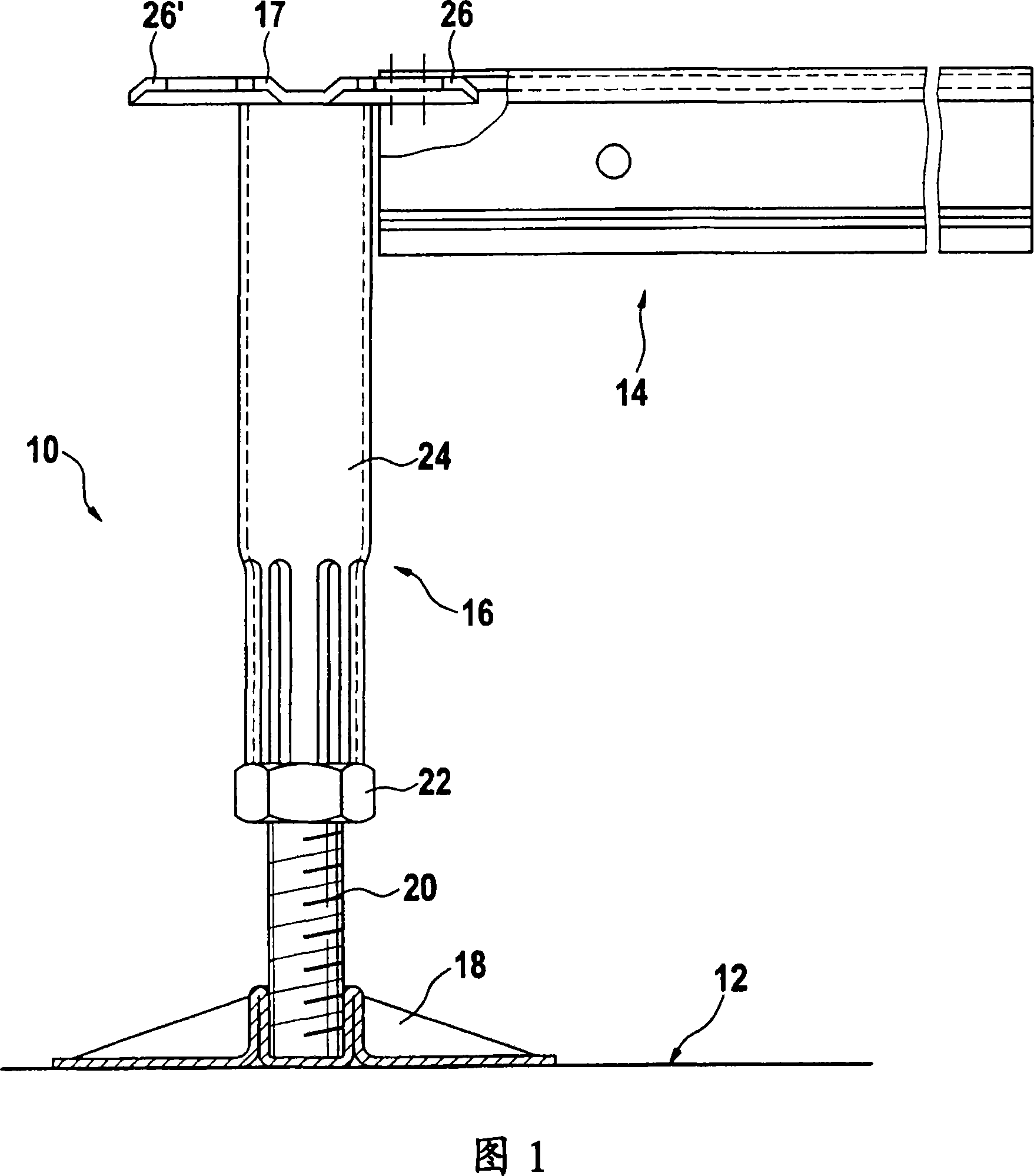

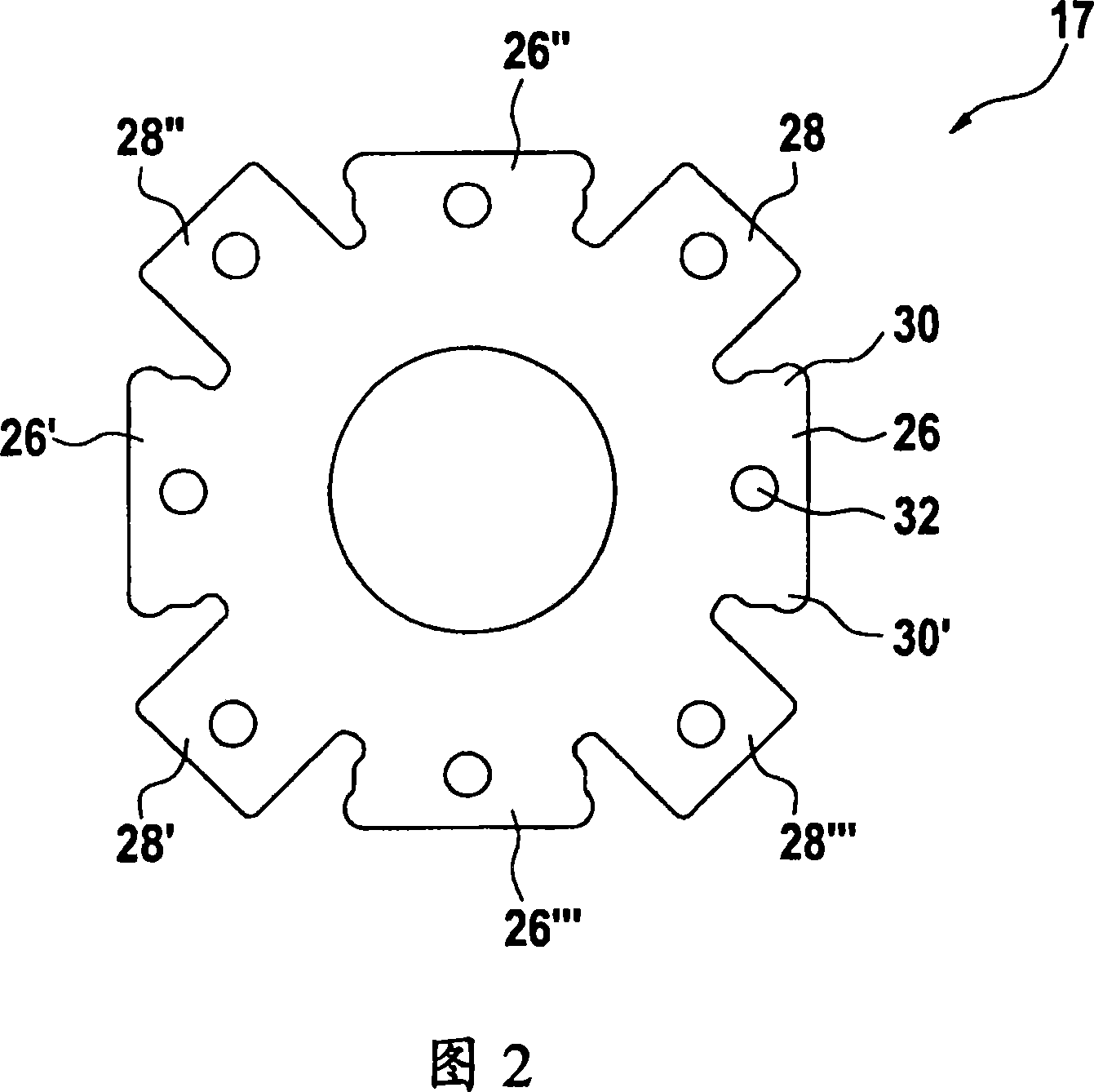

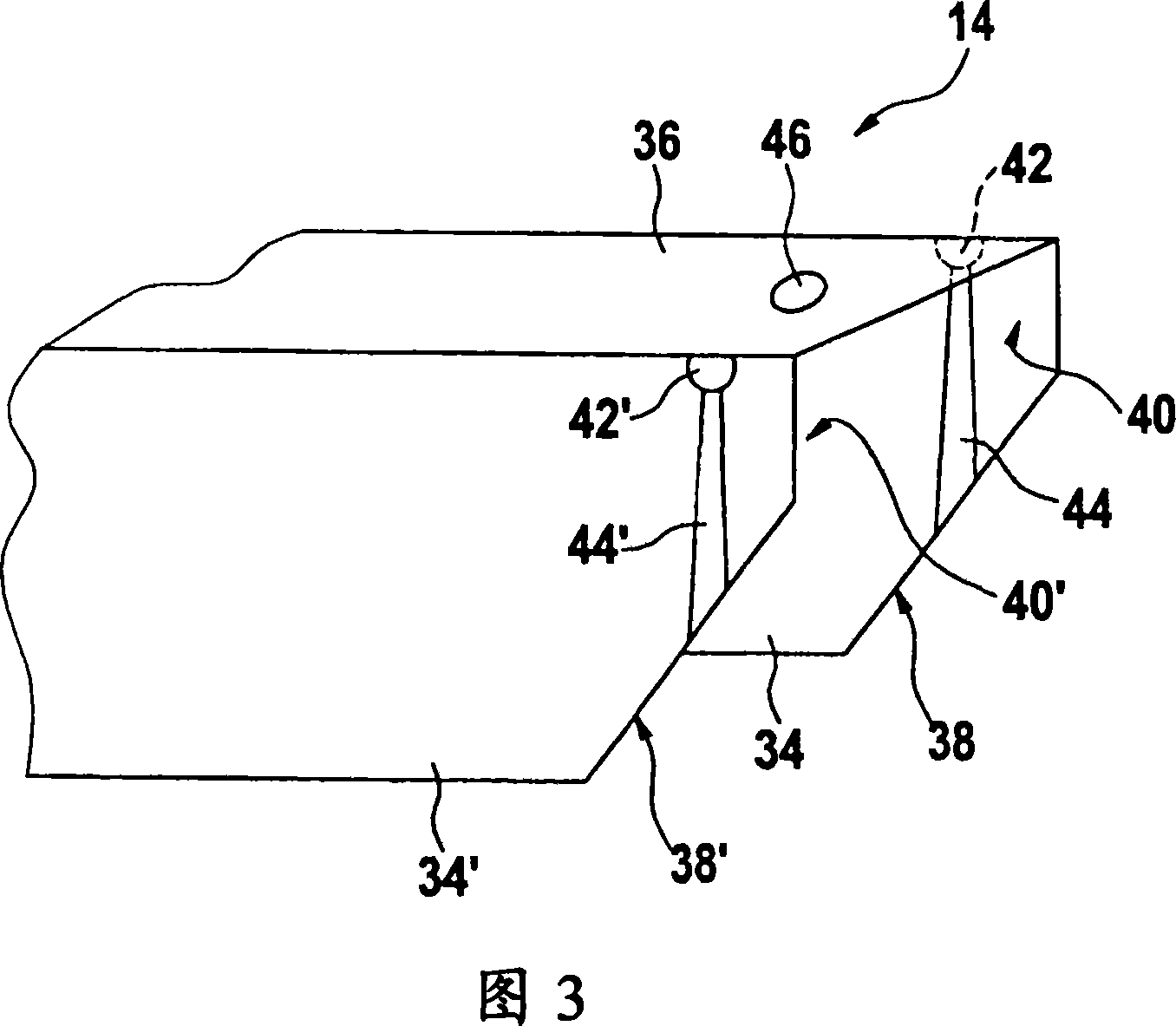

[0019] Figure 1 shows a foundation 10 mounted to a foundation floor 12 to form a support structure together with panel stringers 14, only one of which is partially shown. The base 10 comprises: a column, always indicated with the reference numeral 16 ; a support head 17 , fixed to the upper end of the column 16 ; and a base plate 18 , fixed to the lower end of the column 16 . The column 16 includes a threaded rod 20 , a bearing nut 22 threaded on the threaded rod 20 , and a hollow support tube 24 . The lower end of the support tube 24 is placed above the upper end of the threaded rod 20 and is supported on the upper end by the bearing nut 22 . It can be seen that the support tube 24 can be raised or lowered by screwing the bearing nut 22 on the threaded rod 20 , so that the height of the base 10 can be adjusted freely. The upper end of the support pipe 24 is connected to the support head 17 . The support head typically comprises four or eight support arms to which panel stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com