Method for the manufacture of filter plate

A filter plate and filter material technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as unacceptable cost of new polymer materials, economic unfeasibility of disposable filter components and devices, structural distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

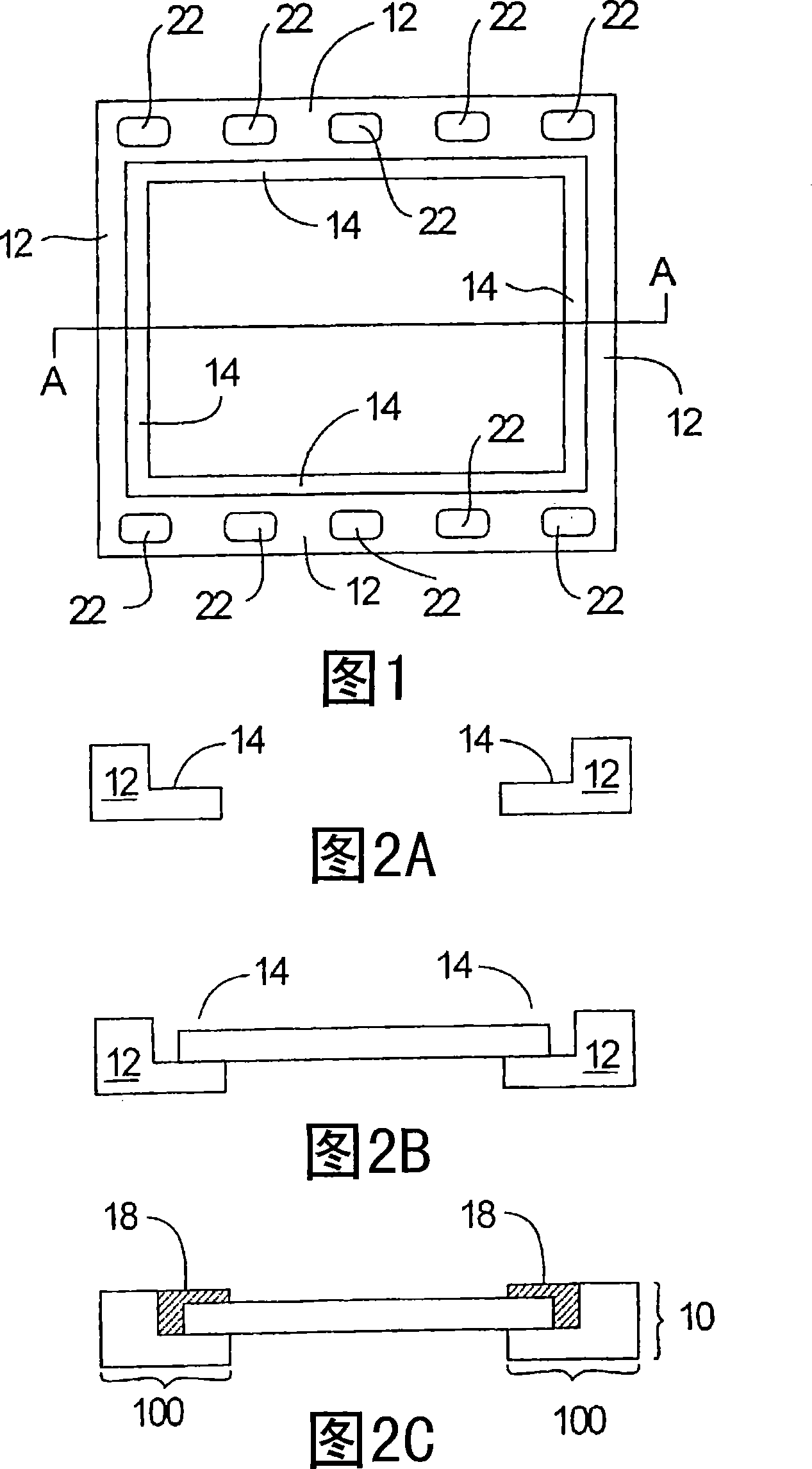

[0018] The present invention generally provides a two-step process for making a substantially planar filter plate comprising a substantially planar polymeric frame in which substantially planar filter material is embedded and fixedly mounted.

[0019] The two-step process is implemented to accommodate the structural variability of the materials used so as to reduce the undesirable and undesirable deformation of the embedded substantially flat filter material, thereby resulting in a manufactured product with less bending, warping, convexity, etc. Out of other deformations, if any. Such deformation may have an adverse effect on the functionality, effectiveness and / or longevity of the resulting filter plate. The method is robust and can be implemented to obtain relatively high yields.

[0020] The steps of the two-step embedding method are schematically shown in Figures 2a-2c.

[0021] First, as shown in Figure 2a, the outer first portion 12 of the substantially planar polymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com