Method for manufacturing paper stuff with cassava root material

A manufacturing method and pulp technology, which can be applied in the fields of cellulose raw material pulping, papermaking, non-woody plant/crop pulp, etc., can solve the problems of time-consuming collection and high price, and achieve easy search, better paper quality, and lower cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

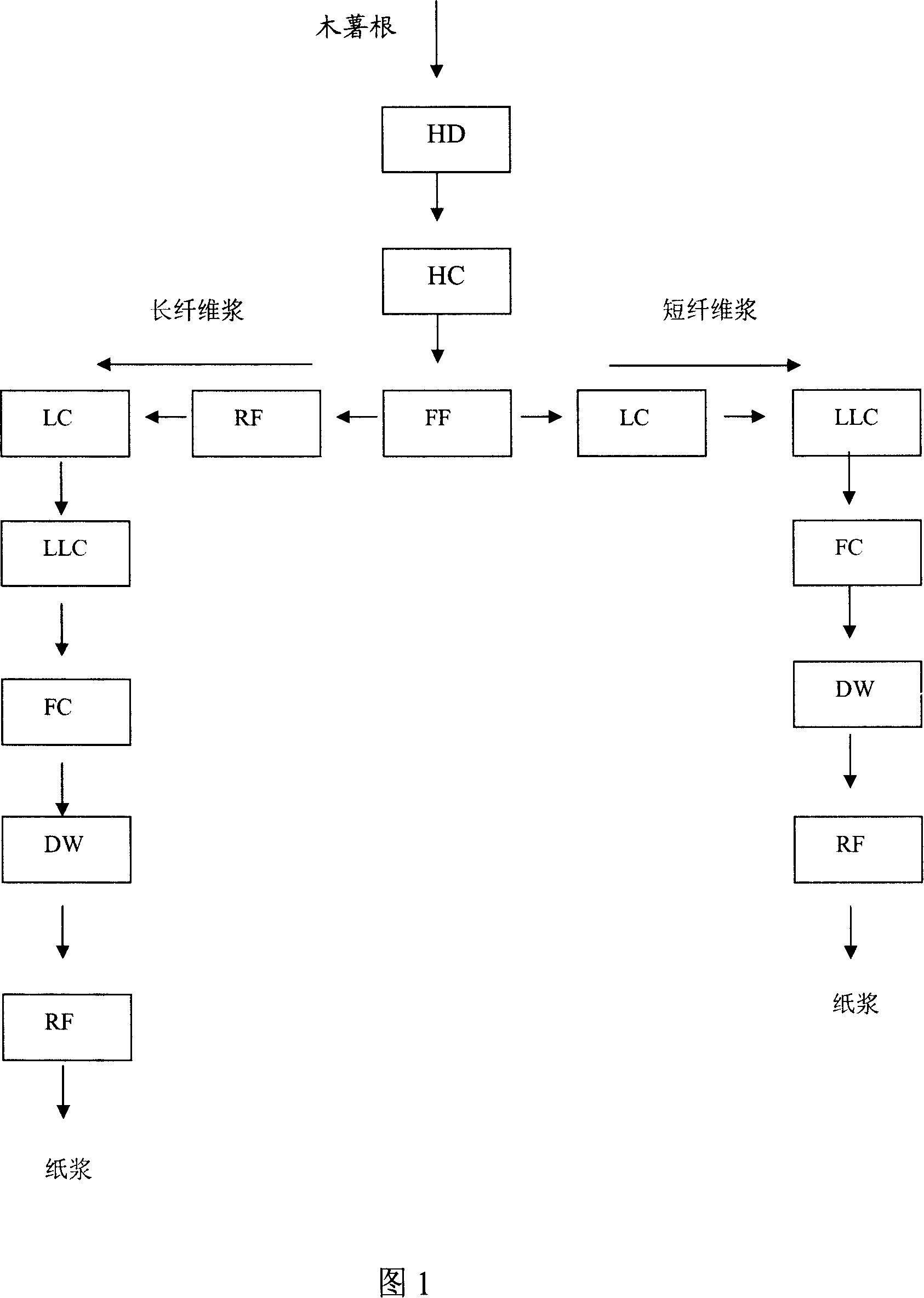

[0050] Please refer to Fig. 1, the present invention proposes a kind of manufacturing method that cassava root material makes paper pulp, and it comprises the following steps:

[0051] Step 1, HD (hydra pulper) step: mix the raw material with water, the raw material is cassava root, keep its concentration and proportion at about 4-10%, the above ratio is the weight ratio, and then enter the next step;

[0052] Step 2. HC (high consistency cleaner) separation step: separate the impurities whose specific gravity is greater than that of pulp, such as sand, stone and others, and separate them with a concentration of 4-10% before proceeding to the next step;

[0053] Step 3, FF (fiber fretter) step: separating the pulp, distinguishing the long-fiber pulp and the short-fiber pulp, and then respectively entering the next step with the separated long- and short-fiber pulp;

[0054] Afterwards, the long and short fiber pulp will be separated into the respective steps:

[0055] Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com