All-directional ultrasound detecting movement mechanism

A technology of ultrasonic detection and motion mechanism, which is applied in measurement devices, re-radiation of sound waves, radio wave measurement systems, etc., and can solve the problems of small application range, affecting the appearance of buildings, poor dust resistance, and poor concealment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

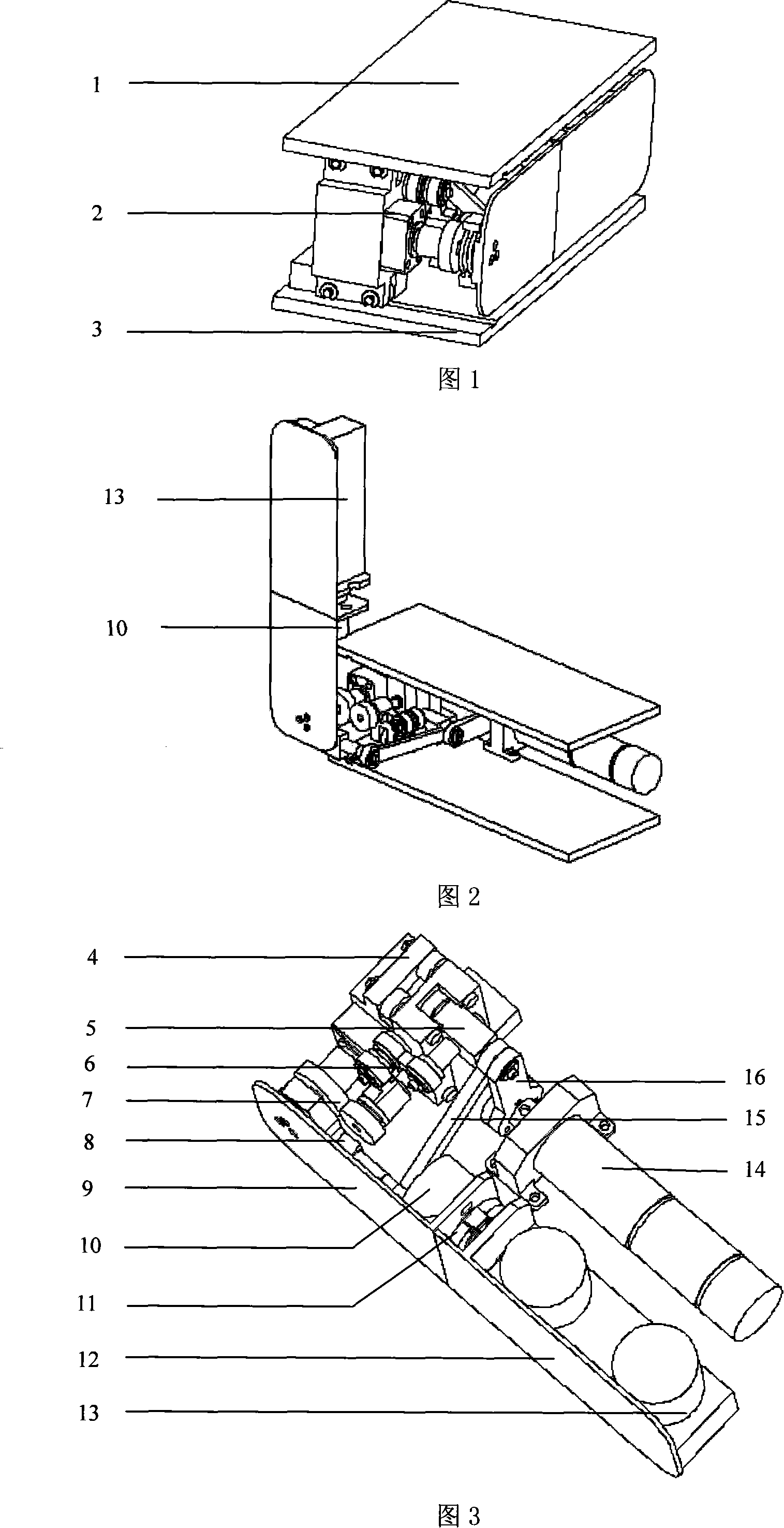

[0014] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0015] With reference to Fig. 1, present embodiment is made up of the cabin that upper hatch cover 1 and lower hatch cover 3 are formed and the integral mechanism 2 that is arranged in the cabin, when not working, integral mechanism 2 all can be retracted and hidden in the cabin. The external dimensions of this embodiment are 105mm×40mm×35mm, and the weight is about 160g (including the driving motor).

[0016] With reference to Fig. 2, the mechanism of this embodiment stretches out and unfolds out of the cabin when it is working. At this time, the ultrasonic detector 13 stands up and is perpendicular to the ground, and can be driven by the stepping motor 10 to rotate for omnidirectional detection.

[0017] Combined with Figure 3, the mechanism of this embodiment is mainly composed of a motion input mechanism, a motion conversion mechanism, a direction tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com