4500kw exciting dynamo rotor armature core hot cover process

A technology of armature iron core and shrink sleeve technology, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of product production cycle impact, scrapped armature, scrapped rotating shaft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A 4500kw exciter rotor armature core shrink-fit process is characterized in that the process steps are as follows:

[0030] The first step: machining the inner circle of the armature core:

[0031] The inner circle of the armature core 7 is bored by a Φ260 CNC boring machine, and then the armature core 7 is placed on the two V-shaped irons. Inner circle to minimize the flanging of the core during processing;

[0032] Step 2. Preparation before armature core heating:

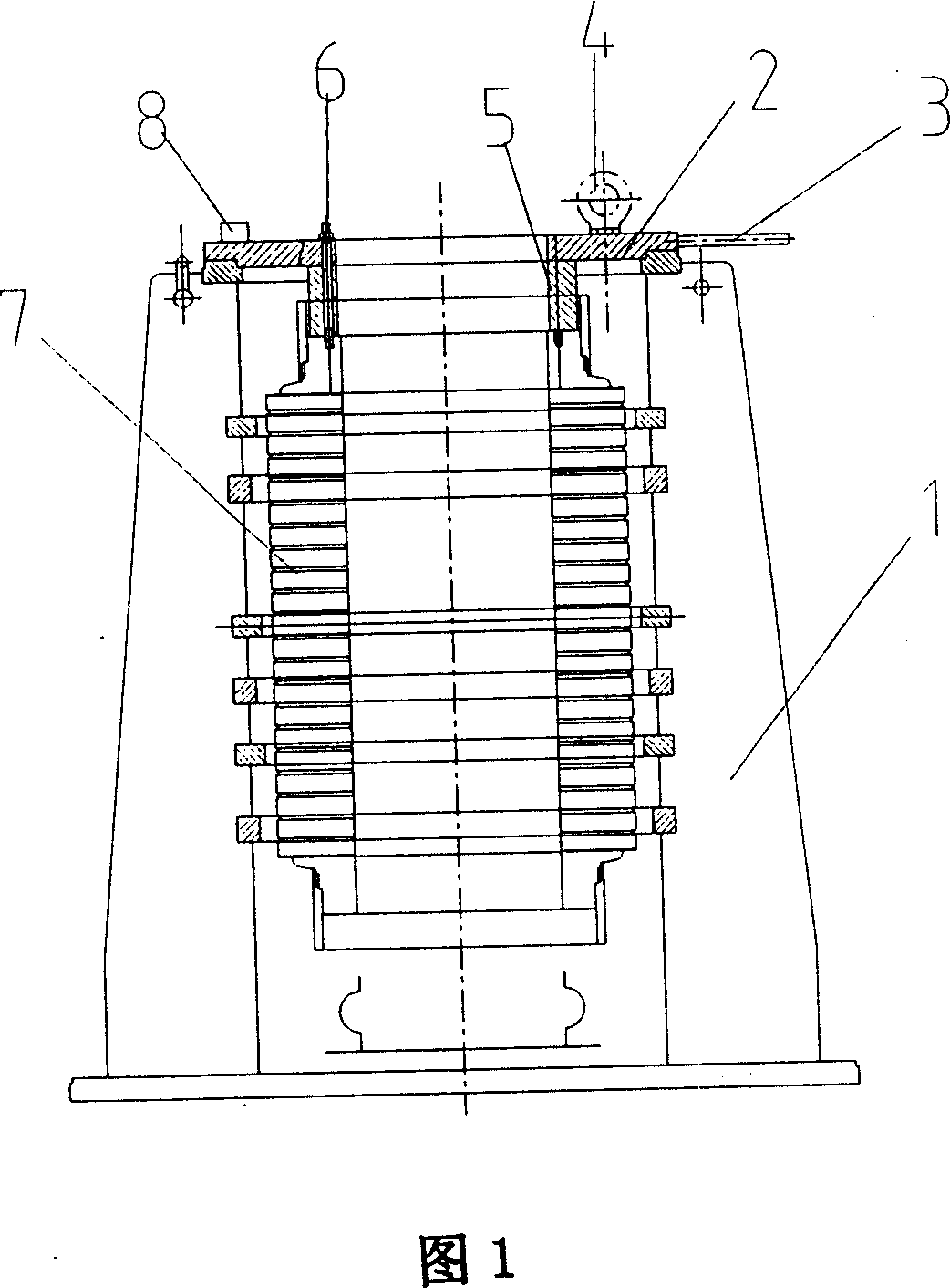

[0033] As shown in Figure 1, it is a schematic diagram of putting the armature core into the heating bracket. After cleaning the armature core 7, make a thermal sleeve mark on the inside and outside of the armature core 7, and wrap the asbestos cloth on the entire outer circle of the armature core 7. Fix the transition washer 5 and the tool hanging plate 2 with the handle 3 on the end of the armature core 7 through the screw 6, install three lifting climbers 4, lift the armature core 7 to the heating bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com