4500kw exciting dynamo rotor armature core hot cover process

A technology of armature core and shrink sleeve process, which is applied in the manufacture of stator/rotor body, etc., which can solve the problems of scrapped shaft, economic loss, scrapped armature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A 4500kw exciter rotor armature core shrink-fit process is characterized in that the process steps are as follows:

[0031] The first step: machining the inner circle of the armature core:

[0032] The inner circle of the armature core 7 is bored by a CNC boring machine with a diameter of Φ260mm, and then the armature core 7 is placed on the two V-shaped irons. The axial position is calibrated with the 3-point method of the dial indicator. The inner circle of the pivot core 7 minimizes the flanging of the core during processing;

[0033] Step 2. Preparation before armature core heating:

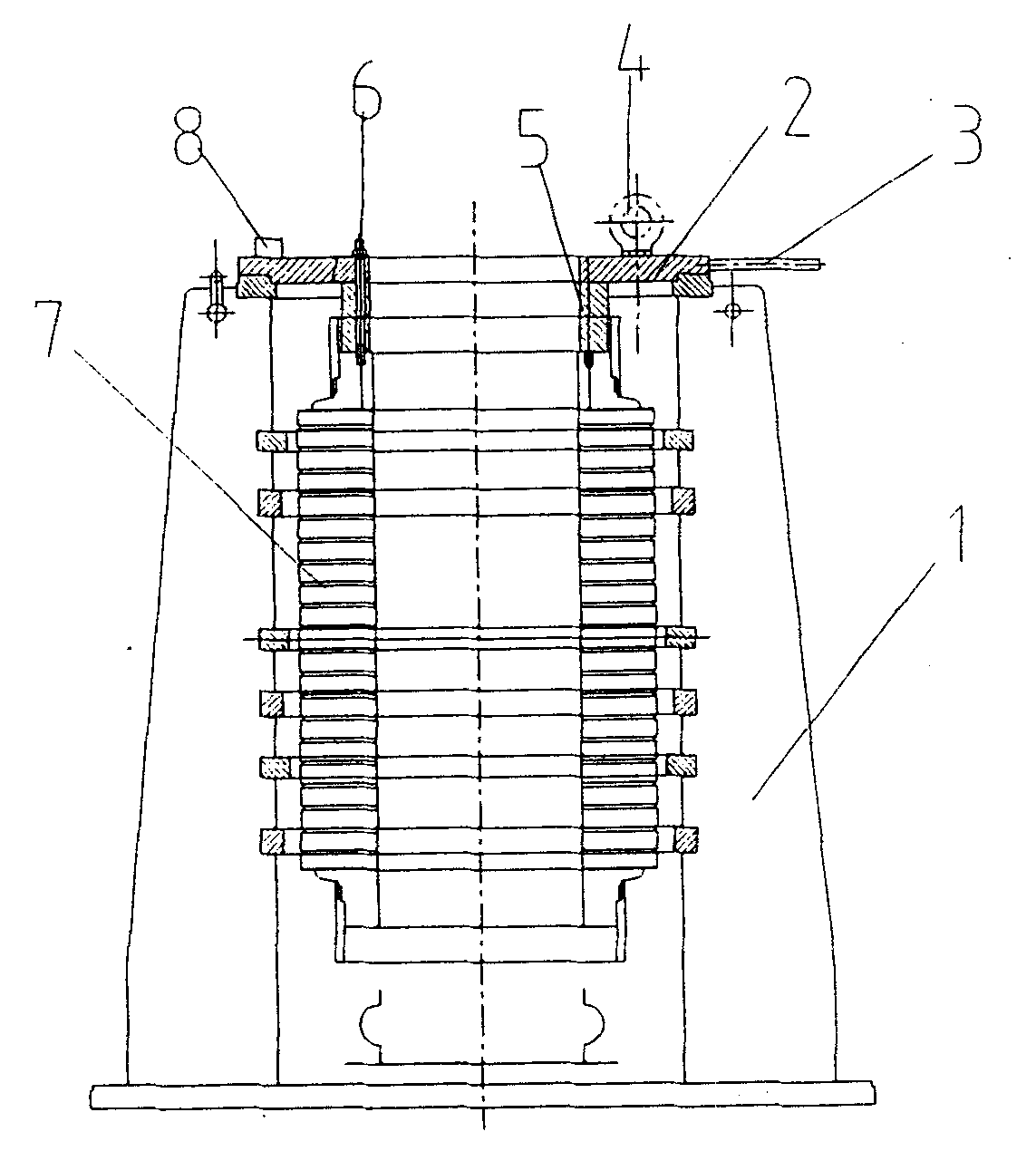

[0034] Such as figure 1 As shown, it is a schematic diagram of putting the armature core into the heating bracket. After cleaning the armature core 7, make a shrink mark on the inside and outside of the armature core 7, wrap asbestos cloth on the entire outer circle of the armature core 7, and put the transition washer 5 and the tool hanging plate 2 with the handle 3 are fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com