Tamper-evident closure and bead on container neck

A tamper-evident container technology, which is applied in the field of container capping, can solve the problems that the tamper-evident device is not obvious enough, and the oxygen or moisture of the sealed container is reduced or invalid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

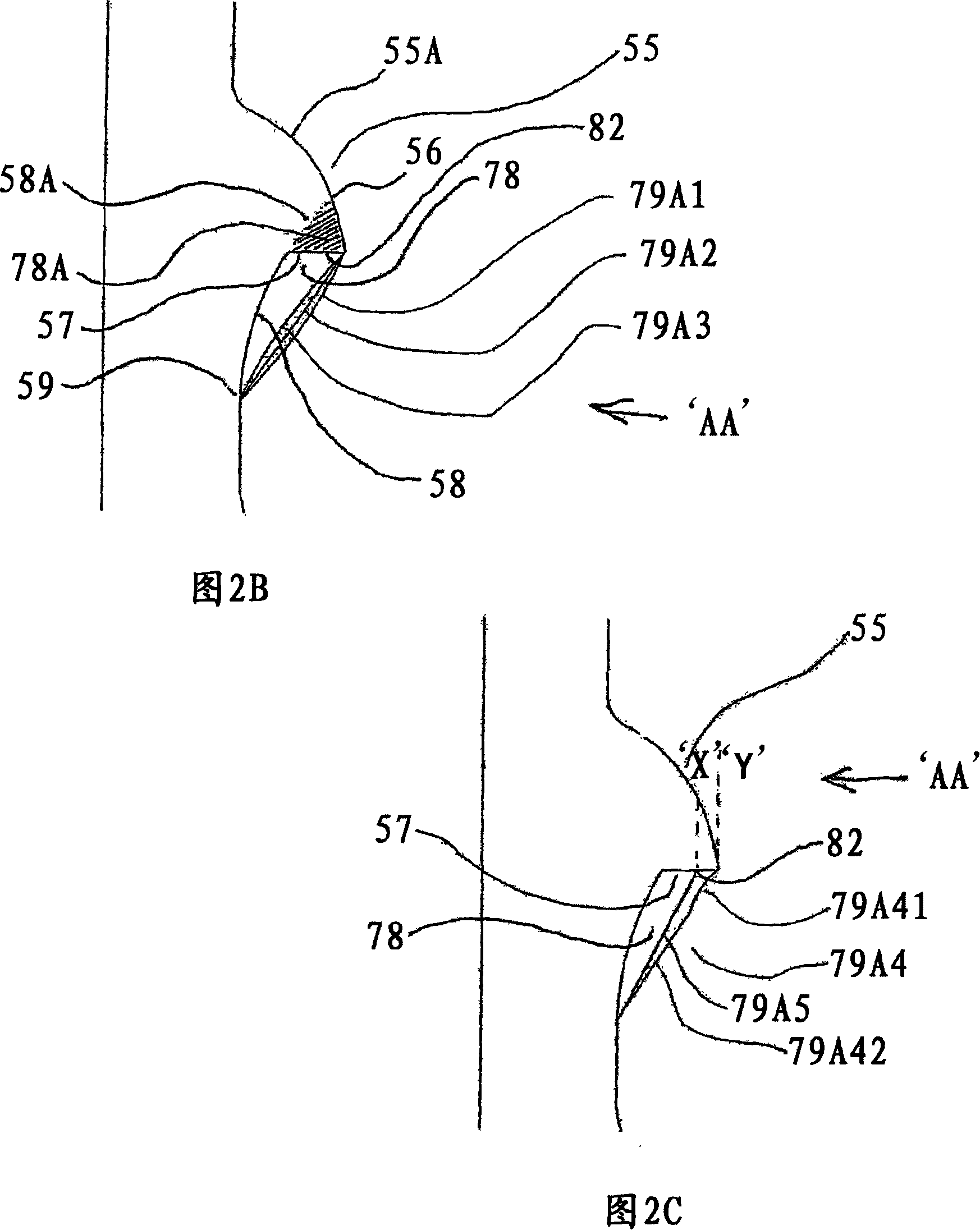

[0067] Embodiment 1 has the connecting side 79A1, viewed from "AA'', as an inclined curved shape with a convex curve; and

Embodiment approach 2

[0068] Embodiment 2 has a connecting side 79A2 as a rectilinear inclined surface; and

Embodiment approach 3

[0069] Embodiment 3 has the connecting side 79A3 as an inclined curved shape with a concave curve when viewed from "AA''; and

[0070] In another embodiment 4, the curved wall 58 between each engagement means 80 extends and intersects the upper surface of the tamper flange 55 at edge 56, as shown by dotted line 58A, And an extension of the engaging surface 78 indicated by the shaded area 78A is formed. The curved wall 58 may have a compound curve with different radii at various points.

[0071] In further embodiments, the wall 58 may be a linear surface rather than a curved surface.

[0072] In yet another embodiment 5, the outer edge of the upper portion of the engagement surface 78 may abut the lower surface 57 of the tamper flange 55 at a position radially inwards towards the axis of the container neck, for example at connection point 82. At least adjacent to the engagement means 80, a portion of the lower surface 57 of the tamper flange abuts the upper surface 55A of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com