Carbon nano-tube composite material and preparation method thereof

A carbon nanotube and composite material technology, applied in nanotechnology, nanotechnology, heat exchange materials, etc., can solve the problems that do not have lateral electrical conductivity, thermal conductivity, conduction length limitations, and carbon nanotube composite materials cannot meet the diversity. Application requirements and other issues, to achieve the effect of high electrical and thermal conductivity, expansion of application scope, and uniform electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure of the carbon nanotube composite material and its manufacturing method will be described in detail below with reference to the accompanying drawings.

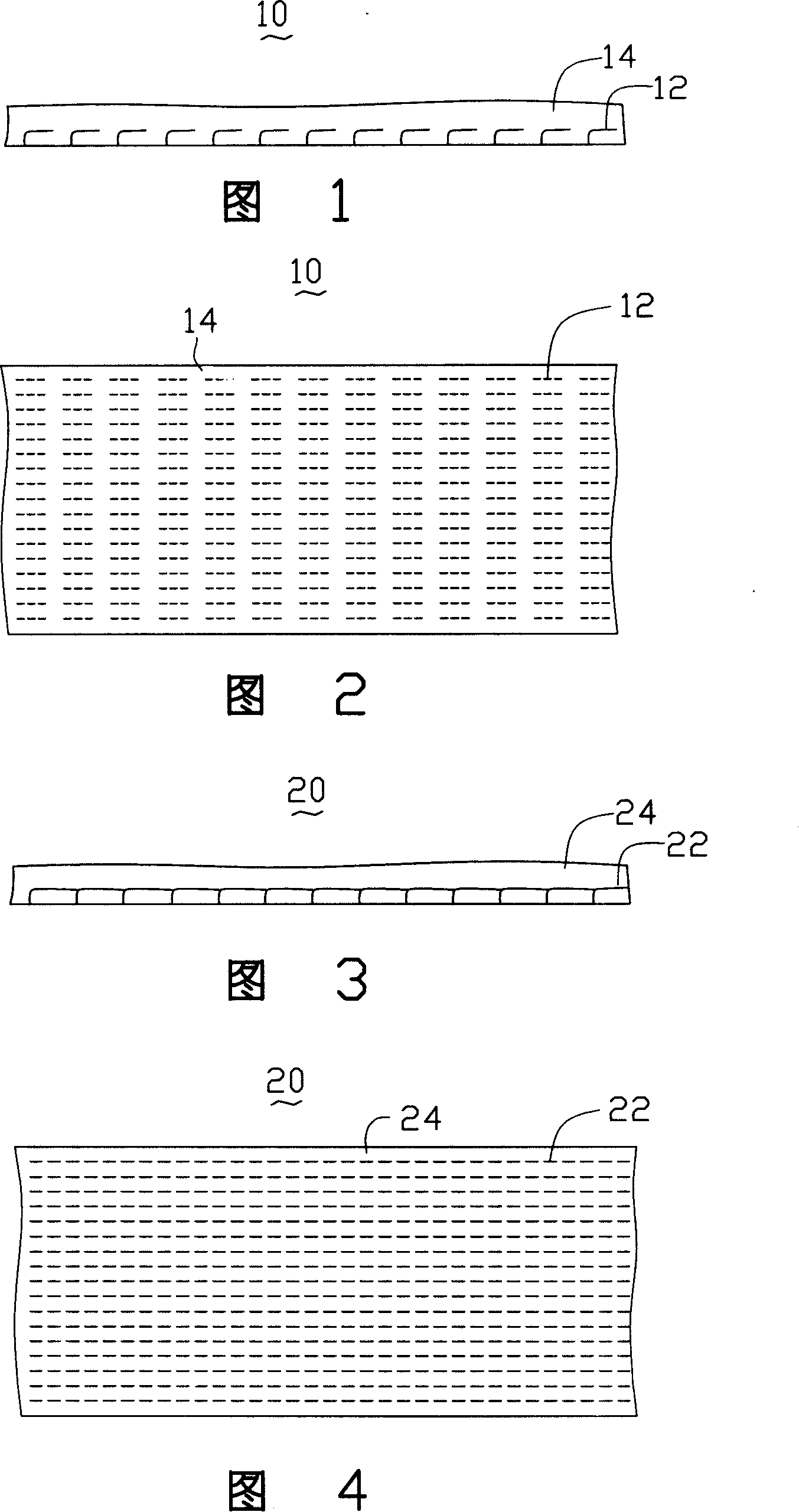

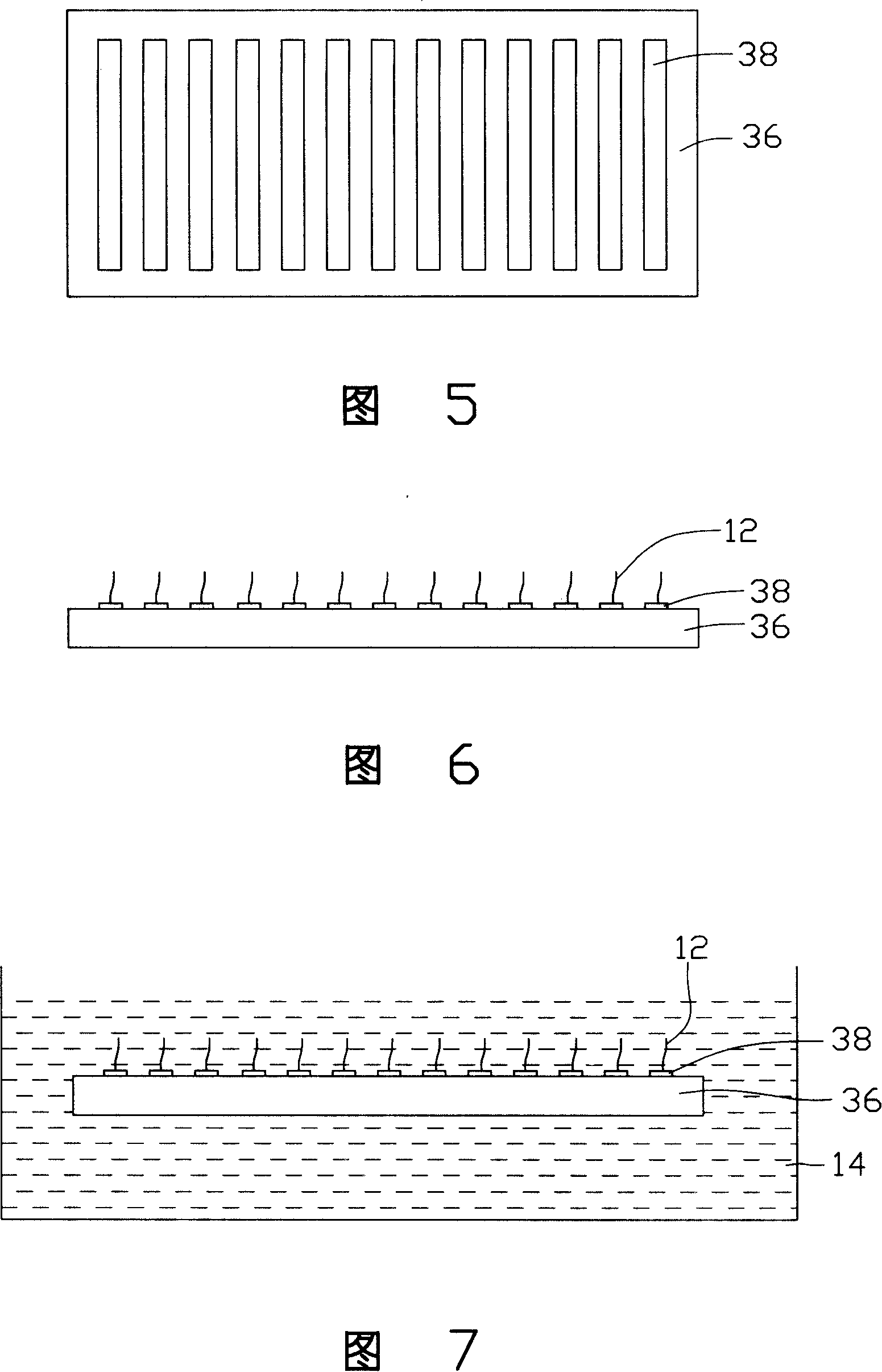

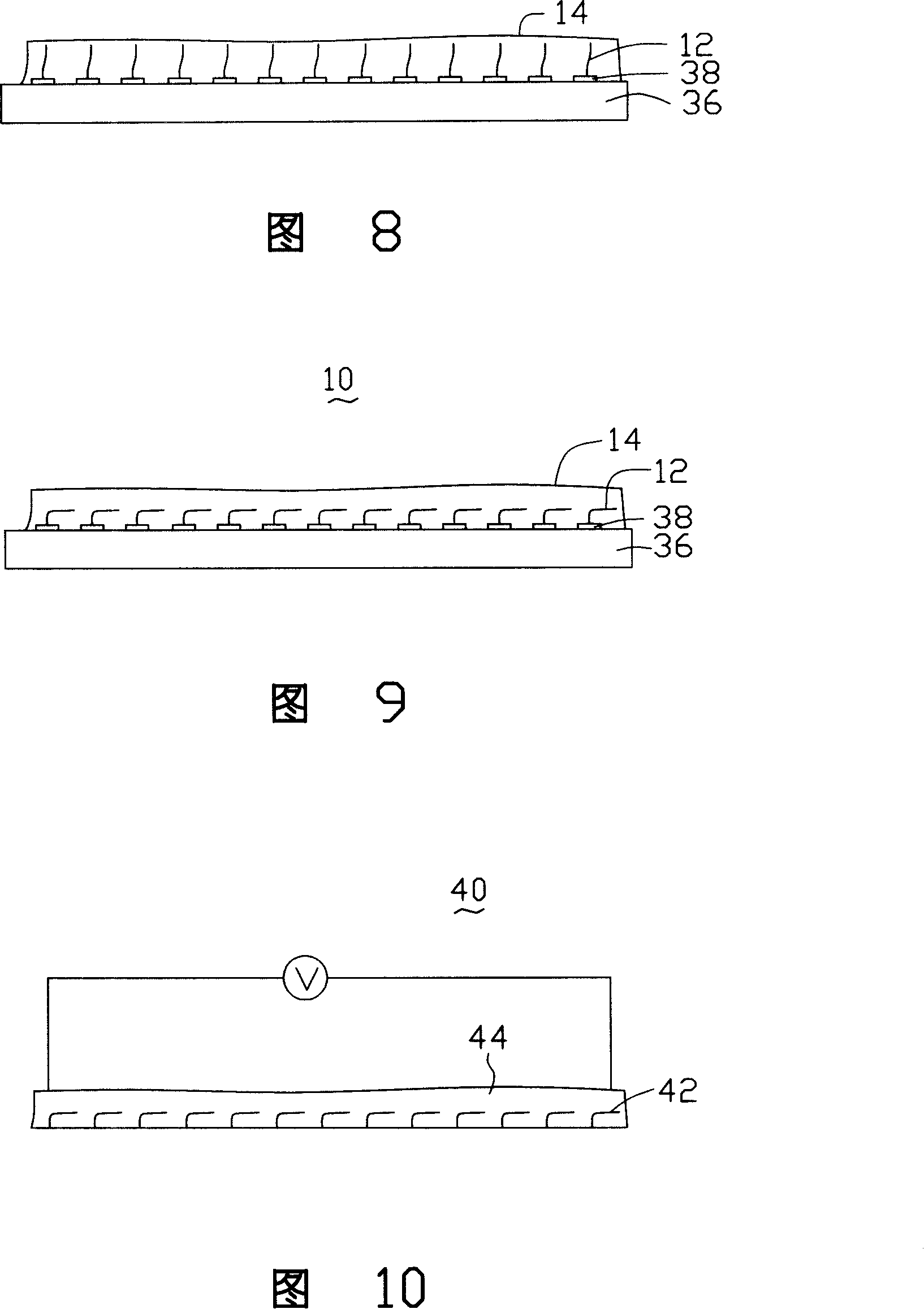

[0024] Referring to FIGS. 1 and 2, a first embodiment of the present invention provides a carbon nanotube composite material 10, which includes a matrix material 14 and a plurality of carbon nanotubes 12 dispersed in the matrix material 14. The base material 14 is a thin film. The multi-carbon nanotubes 12 are distributed in the matrix material 14 substantially parallel to each other, and are arranged parallel to the surface of the matrix material 14. Further, the multi-carbon nanotubes 12 are distributed in parallel rows / columns in the matrix material 14, and the multi-carbon nanotubes 12 in adjacent rows / columns are close to each other but not in contact. In this embodiment, the base material 14 may be a polymer material, including organic materials that are preliminarily liquid and solidified or solidified i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com