Connector

A technology of connectors and retainers, which is applied in the direction of the base/housing, etc., can solve the problems of detachment of the mounting part of the rear retainer, separation of the interlocking part and the locking piece, etc., and achieve the effect of improving reliability and suppressing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

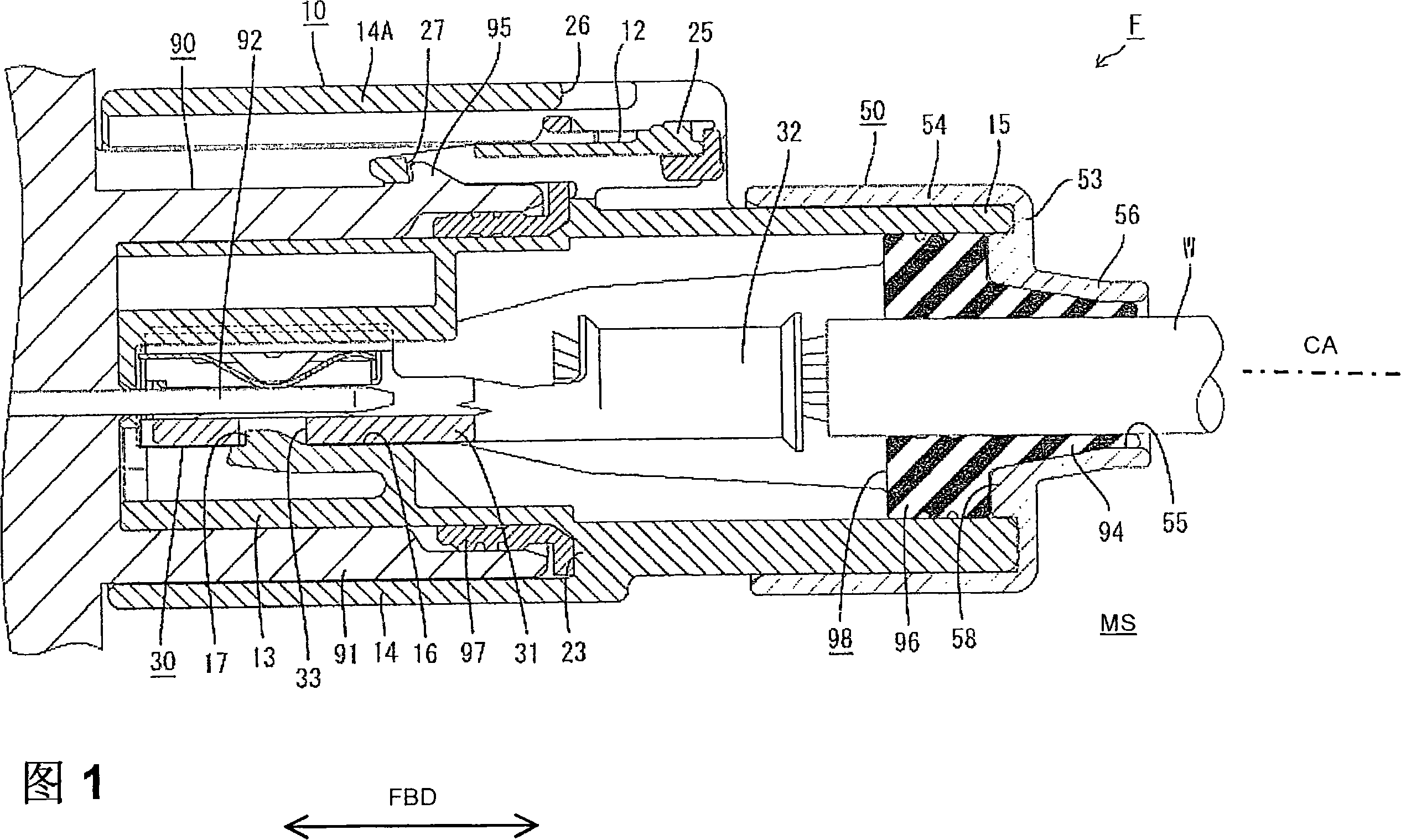

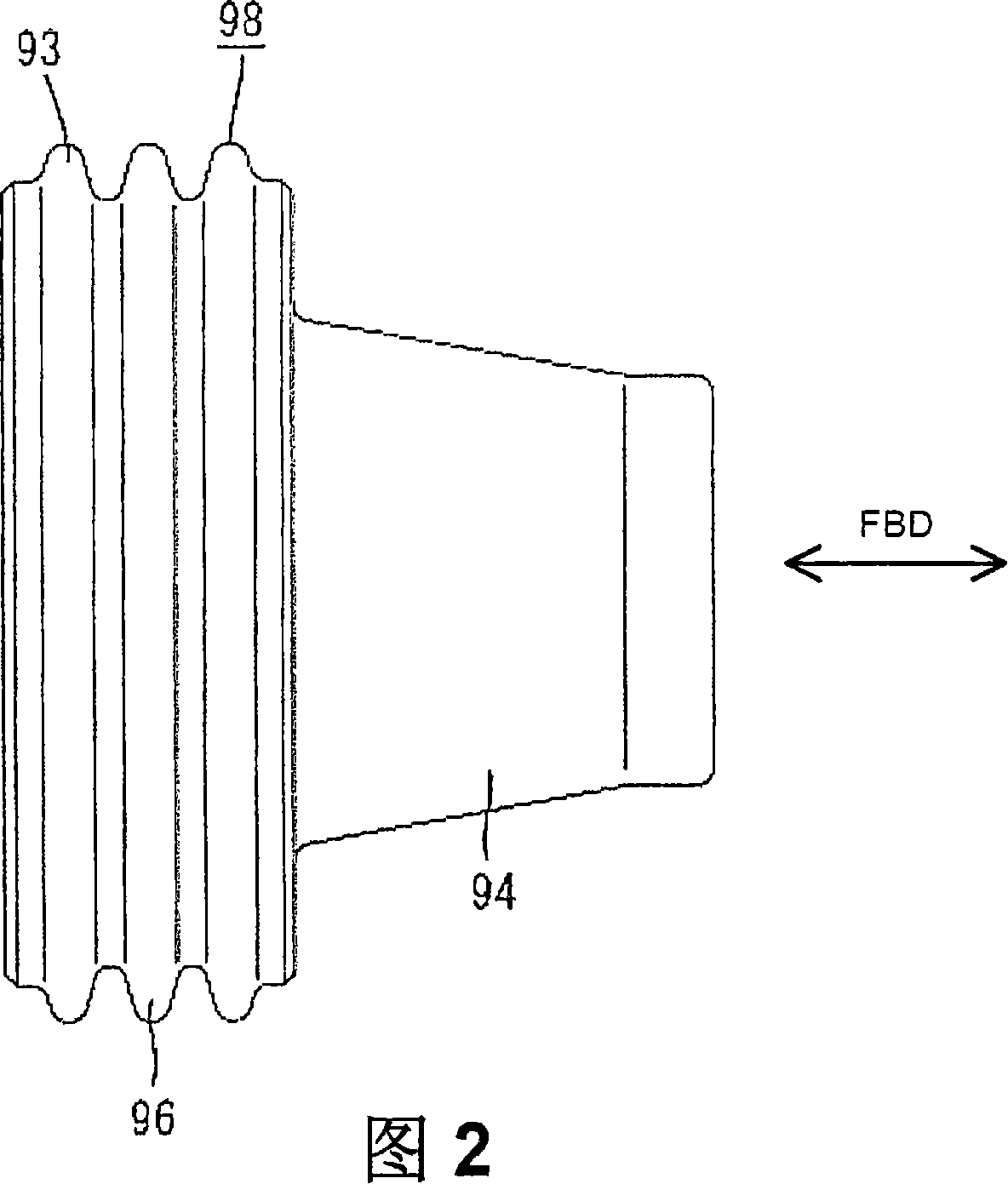

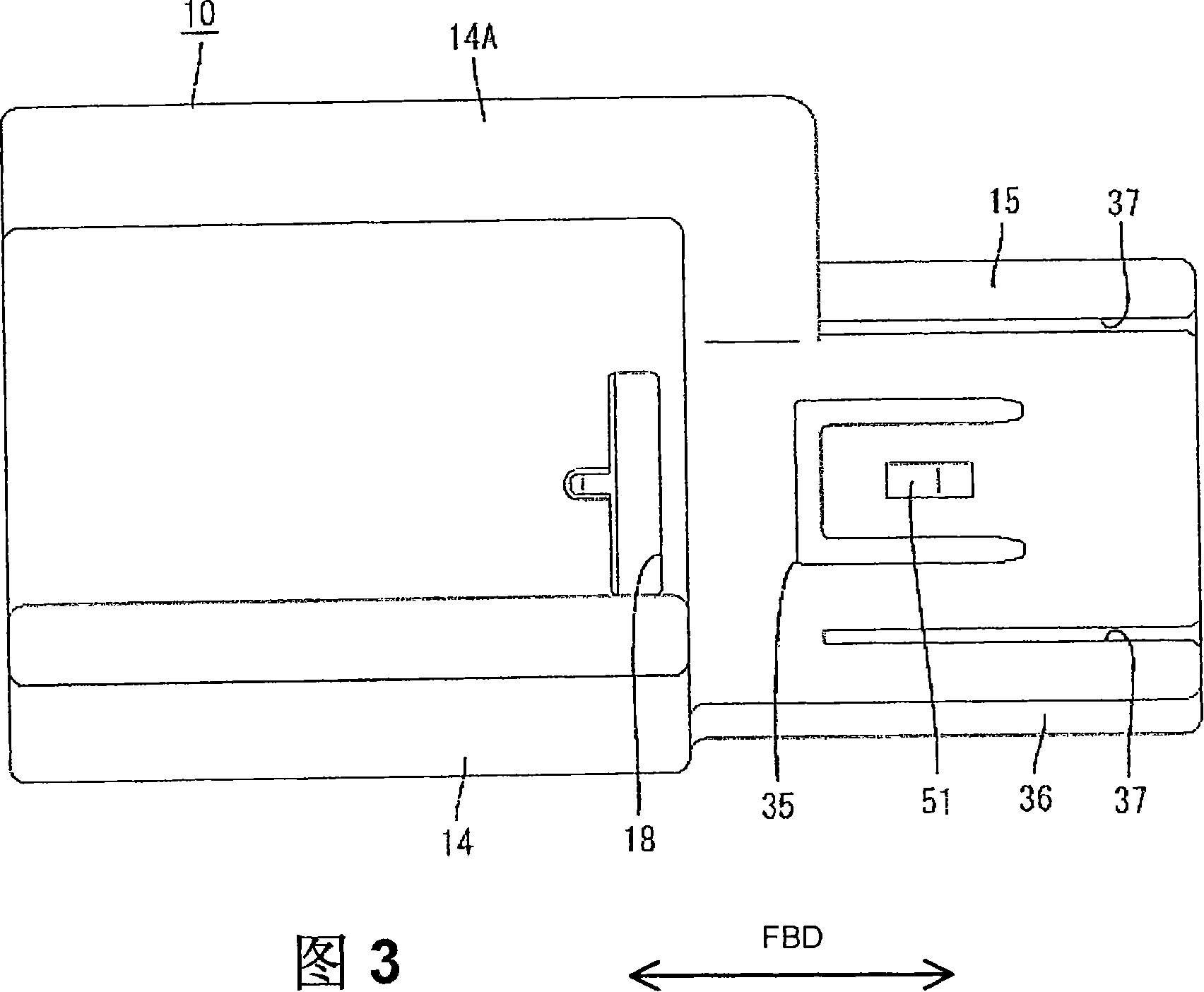

[0067] The first preferred embodiment of the present invention will be described with reference to accompanying drawings 1-7. The connector F has a female housing 10 (corresponding to a preferred connector housing) for at least partially accommodating the female terminal fitting 30 and a rear retainer 50 (as a preferred retainer) which is viewed from the mounting side The MS is mounted on the female housing 10 (preferably substantially from the rear or from a side substantially opposite to the mating side of the mating connector), wherein the female housing 10 can be connected to the mating male connector 90 . The connector F further has a sealing member 98 for providing a fluid- or waterproof seal between the female housing 10 and the terminal fitting 30 and a sealing ring 97 for providing a fluid- or waterproof seal between the female and male housings 10 and 90 . In the following description, the side to be connected of the female and male housings 10 , 90 is referred to a...

no. 2 example

[0102] A second preferred embodiment of the present invention is described with reference to FIGS. 8 to 21 . The connector F has a female housing 110 for at least partially accommodating at least one female terminal fitting 130 and a rear retainer 150 mounted on the female housing 110 from the mounting side MS (preferably substantially from the rear) (as a preferred holder), wherein the female housing 110 can be connected with a mating male housing 190. Connector F is also provided with: detection part 199 is used for detecting the connection state of female and male shell 110,190, and sealing part 198 is used for providing liquid or waterproof sealing between female shell 110 and terminal joint 130, and sealing ring 197 is used for to provide a liquid or watertight seal between the female and male housings 110 and 190. In the following description, the side to be connected of the female and male housings 110 , 190 is referred to as the front side in terms of the forward and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com