Liquid-controlled type multi-purpose valve

A multi-purpose valve and hydraulic control technology, applied in the direction of multi-way valve, lift valve, valve details, etc., can solve the problems of large product volume, unfavorable product competition, and insufficient spring force stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

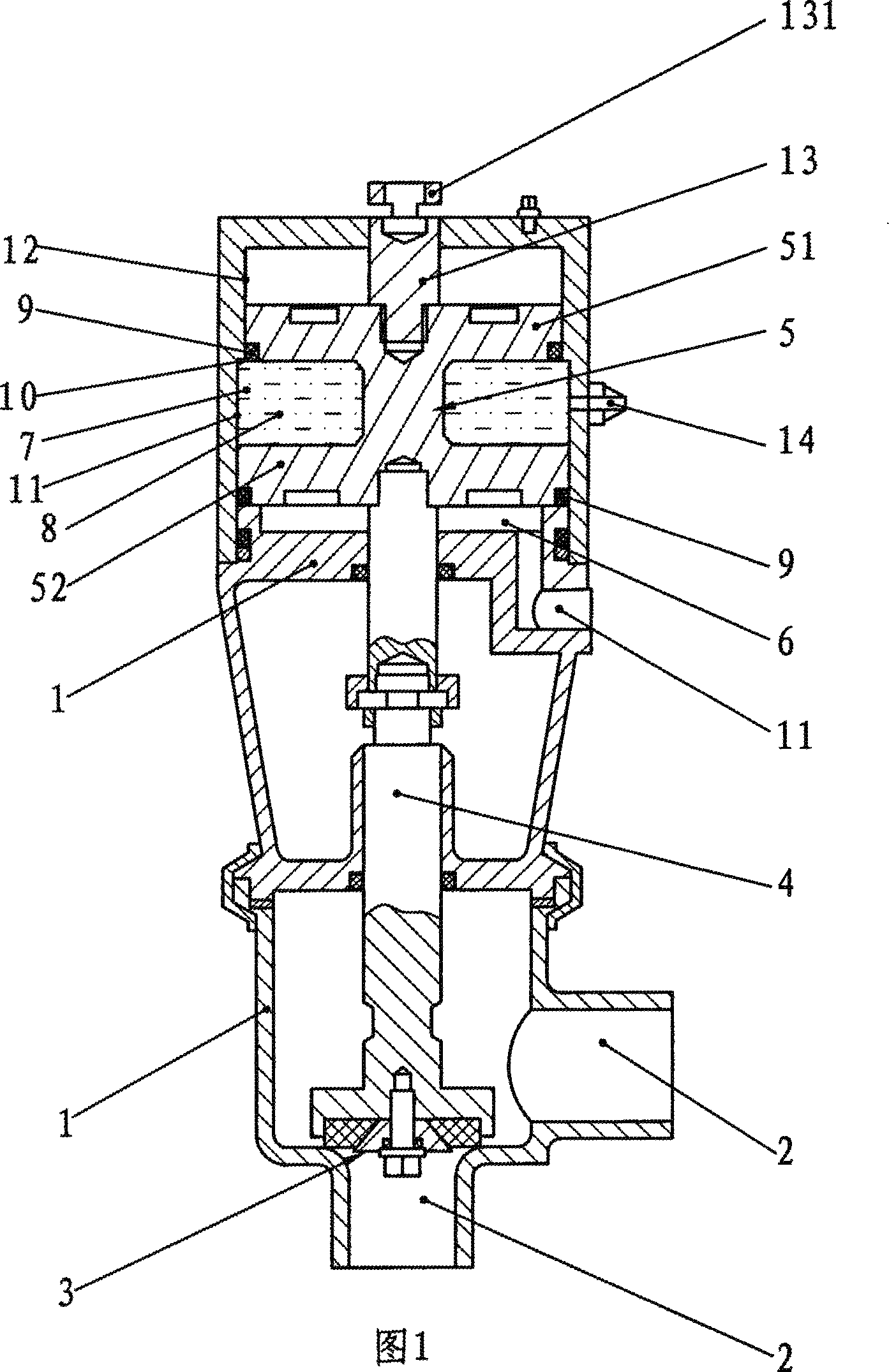

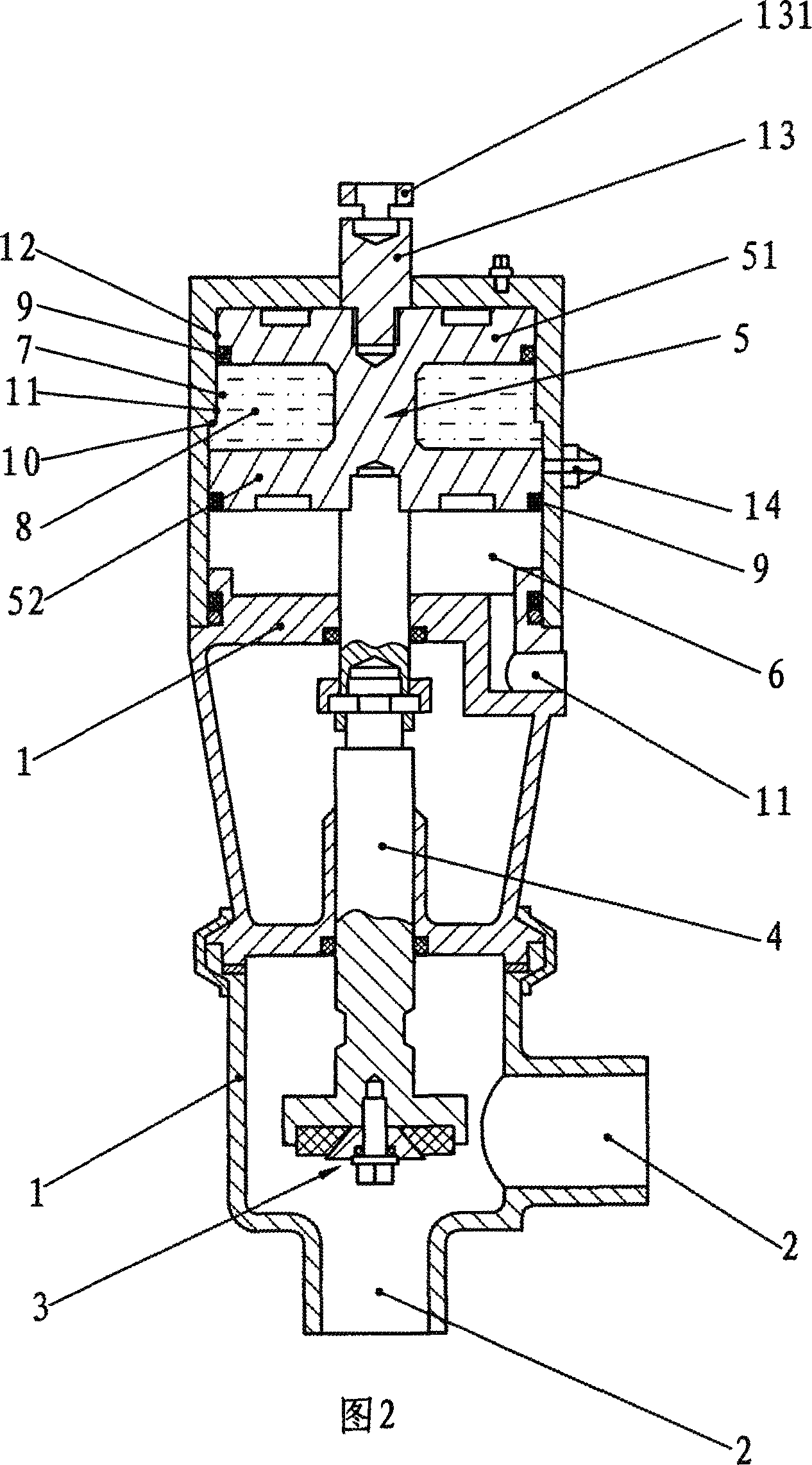

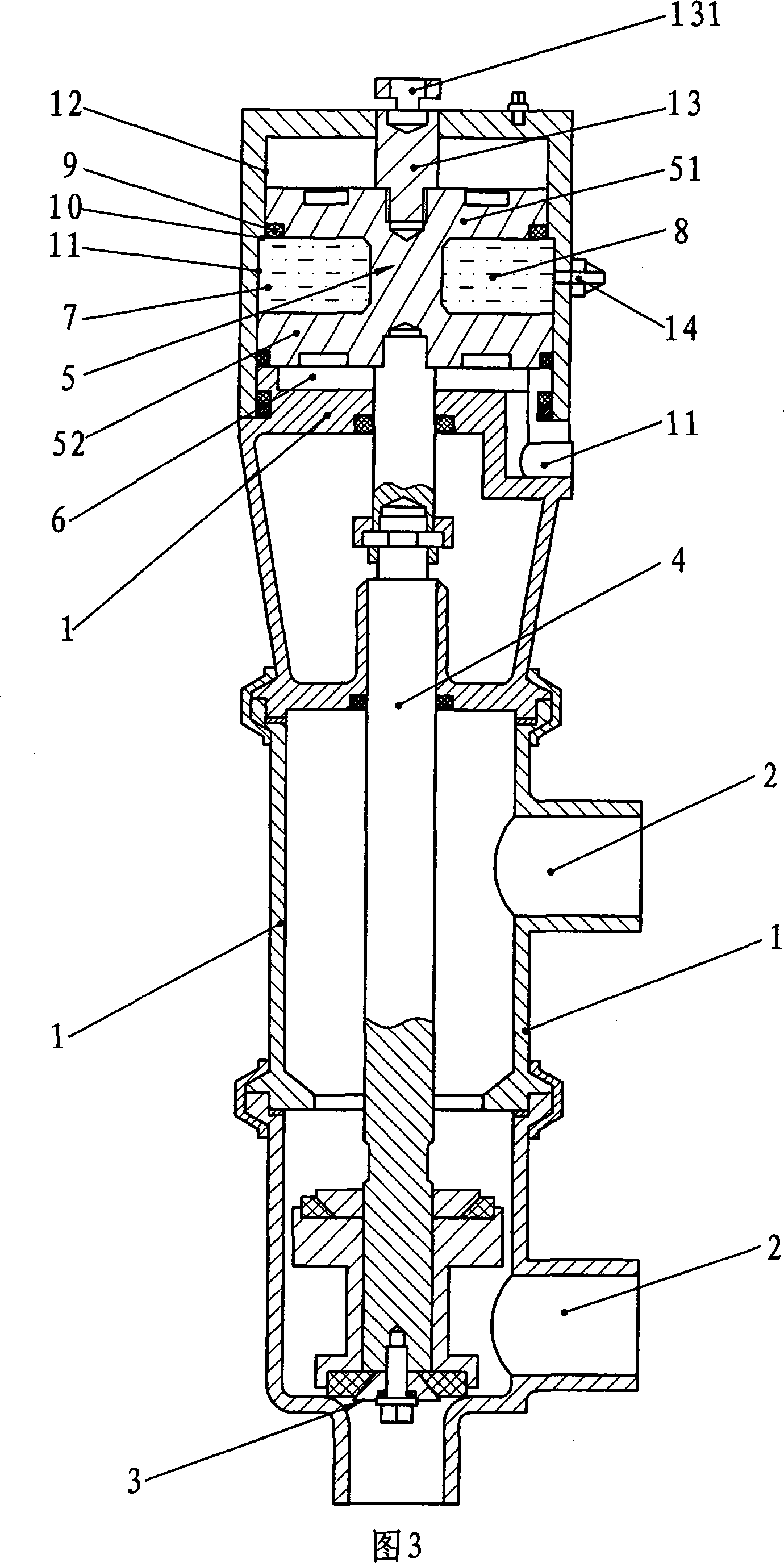

[0011] As shown in the figure, a hydraulically controlled multi-purpose valve includes a valve body 1, a flow channel 2 arranged in the valve body 1, a valve core device 3 that cooperates with the flow channel 2, and a valve core device 3 linked with the valve core device. The valve stem 4 and the piston 5 that controls the sliding of the valve stem 4. What needs to be explained here is the spool device 3, which is a device for controlling the flow of the flow channel 2 or controlling the on-off of the flow channel 2. One side of the piston 5 is set There is a sealed cavity 6, and the valve body 1 is provided with an air inlet and outlet channel 11 connected with the cavity 6, through which the gas pressure in the cavity 6 can be controlled and adjusted to realize the internal pressure change; in the embodiment of the present invention, a closed cavity 7 is additionally provided between the piston 5 and the valve body 1, and the cavity 7 is filled with a liquid 8, and the cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com