Method of attaching components and article formed using same

A component, adhesive technology, applied in the direction of connecting components, vehicle parts, transportation and packaging, etc., can solve the problem of adhesive tailing phenomenon, difficulty and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The invention includes methods of bonding two or more elements to form a bonded article. The method includes placing two or more components relative to each other in their intended assembly positions to create a joint cavity, filling the cavity with an adhesive, and at least partially curing the adhesive.

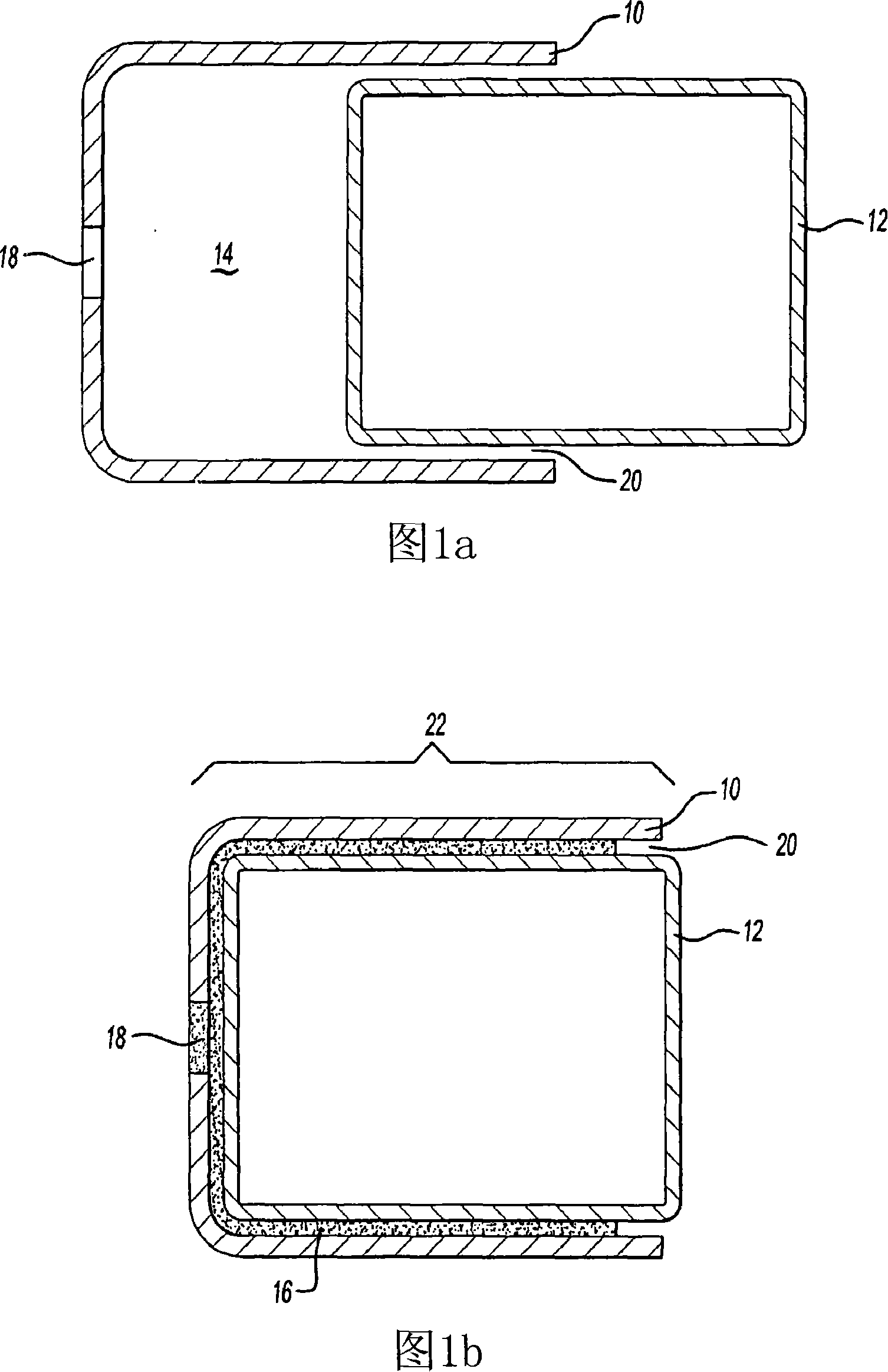

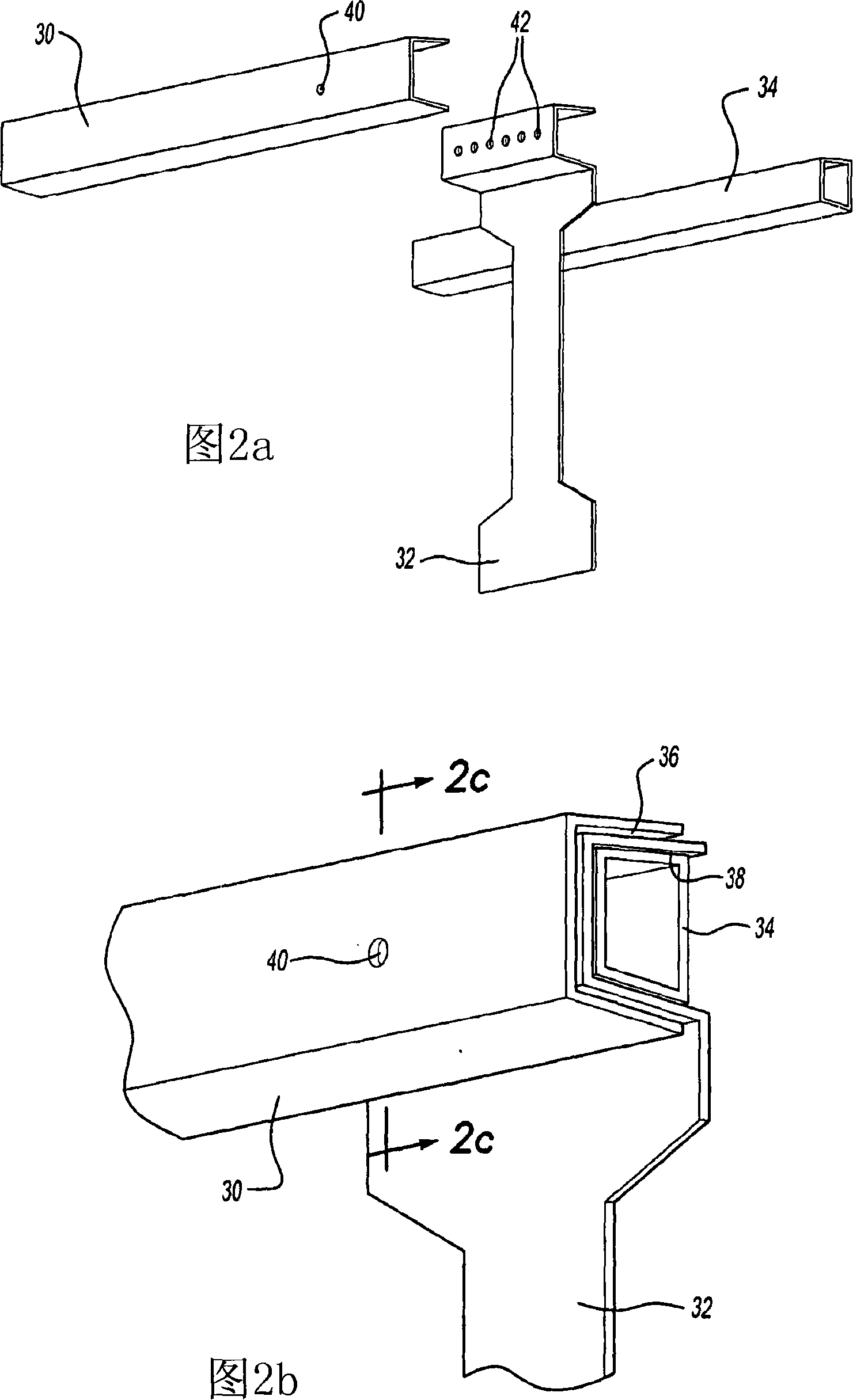

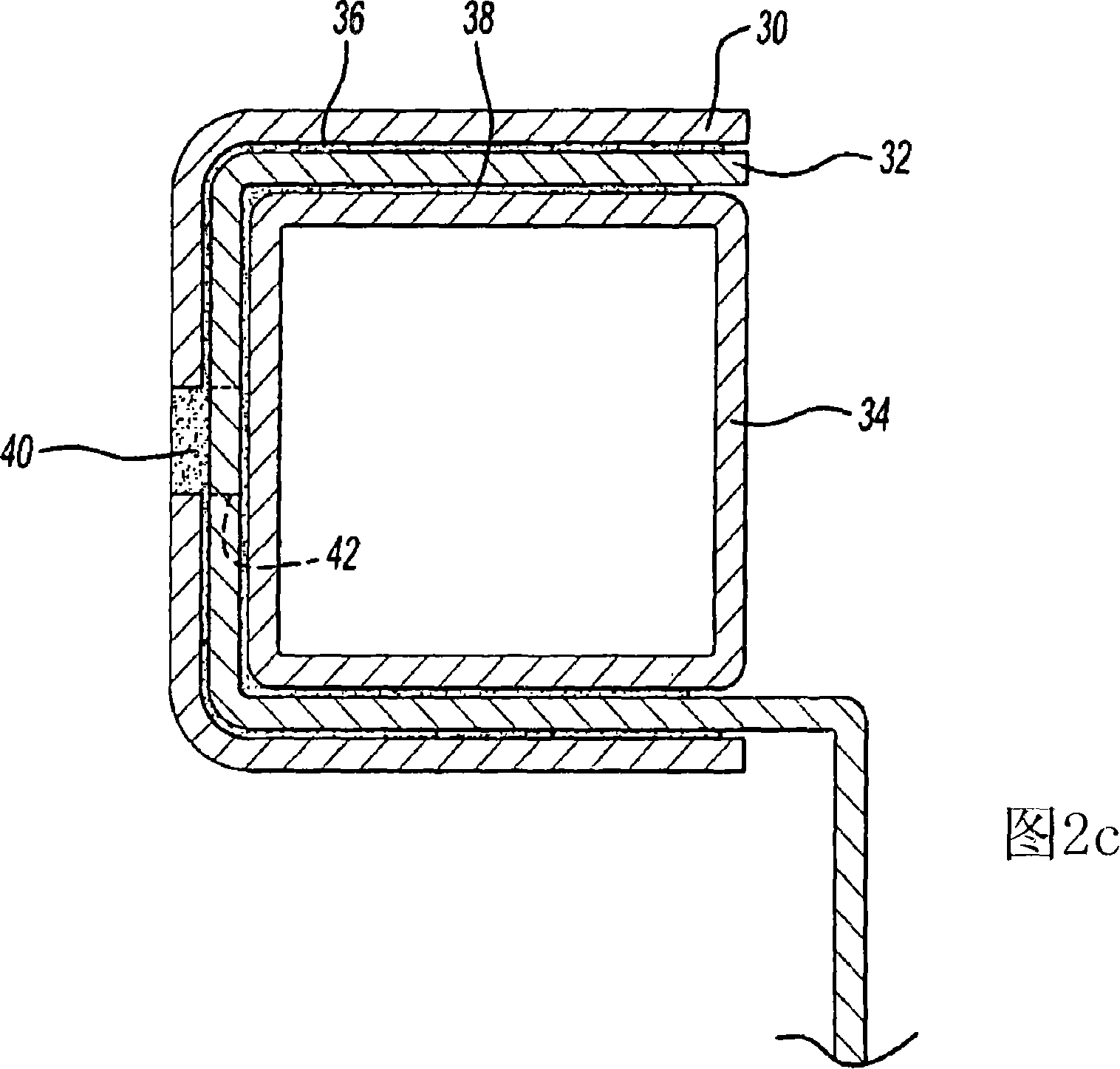

[0011] With reference to FIGS. 1 a and 1 b , the method includes placing a first element 10 and a second element 12 relative to each other to form a joint cavity 14 . During the placing step or once the elements are placed, the elements may or may not be in contact with each other. During the injection and curing of the adhesive, the relative movement of the components can be restricted by the use of clips, rivets, screws, snap fits or other mechanical fastening means. Spaced apart ribs or protrusions may be used on one or both elements to maintain joint thickness. The bonding cavity 14 is then filled with adhesive 16 . The joint cavity may be filled through an en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com