Double-circular arc harmonic wave gear hobbing cutter

A harmonic gear and gear hobbing cutter technology, which is applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., can solve problems such as harmonic gear transmission that cannot be used with elliptical wave generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

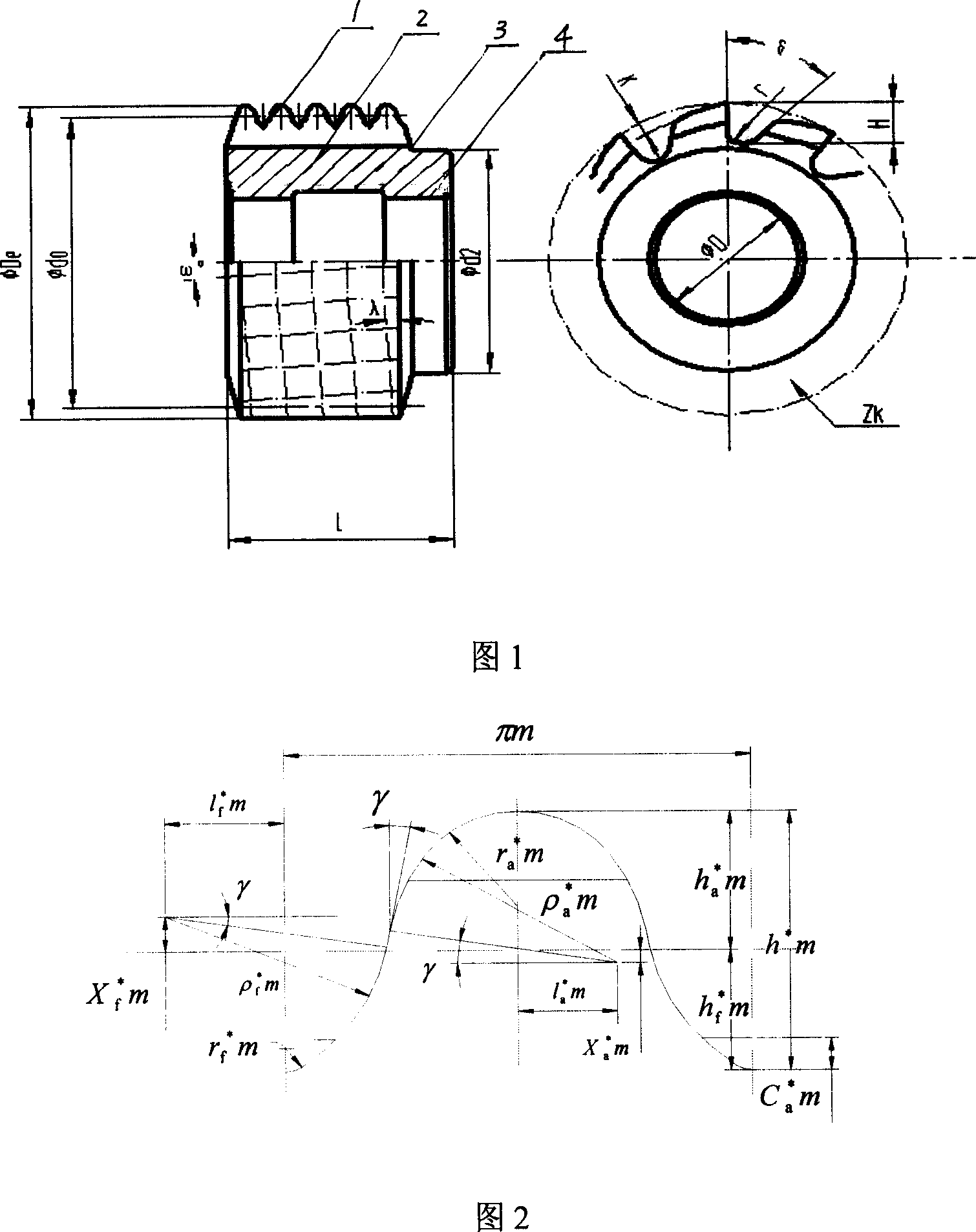

[0021] As shown in Figure 1, the main structural dimensions of the gear hob are the outer diameter D e , inner hole D, length L, pitch circle diameter d o , number of teeth Z k , alveolar depth H, shovel back volume K, etc. Its structure design is similar to general involute hobbing cutter. It can be a single-spindle or double-spindle structure, and the inner hole is divided into a structure with a keyway and a structure without a keyway. Among the figure, 1 is a cutter tooth, 2 is a cutter body, 3 is a pillow block, and 4 is an inner hole.

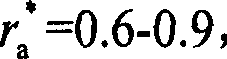

[0022] The main difference between the double-arc harmonic gear hobbing cutter and the general involute gear hobbing cutter is that its basic tooth profile is different.

[0023] As shown in Figure 2, those with an asterisk are the coefficients of the corresponding parameters divided by the modulus m, such as the radius coefficient of the convex tooth profile arc ρ a * = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com