Two-tube reverse circulation continuous sand flushing device

A dual-pipe reverse and sand washing technology, which is applied in the direction of flushing wellbore, wellbore/well components, earthwork drilling and production, etc., can solve the problem of continuous sand washing of low-pressure leakage wells with two-stage pipe strings, and achieve the convenience of operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

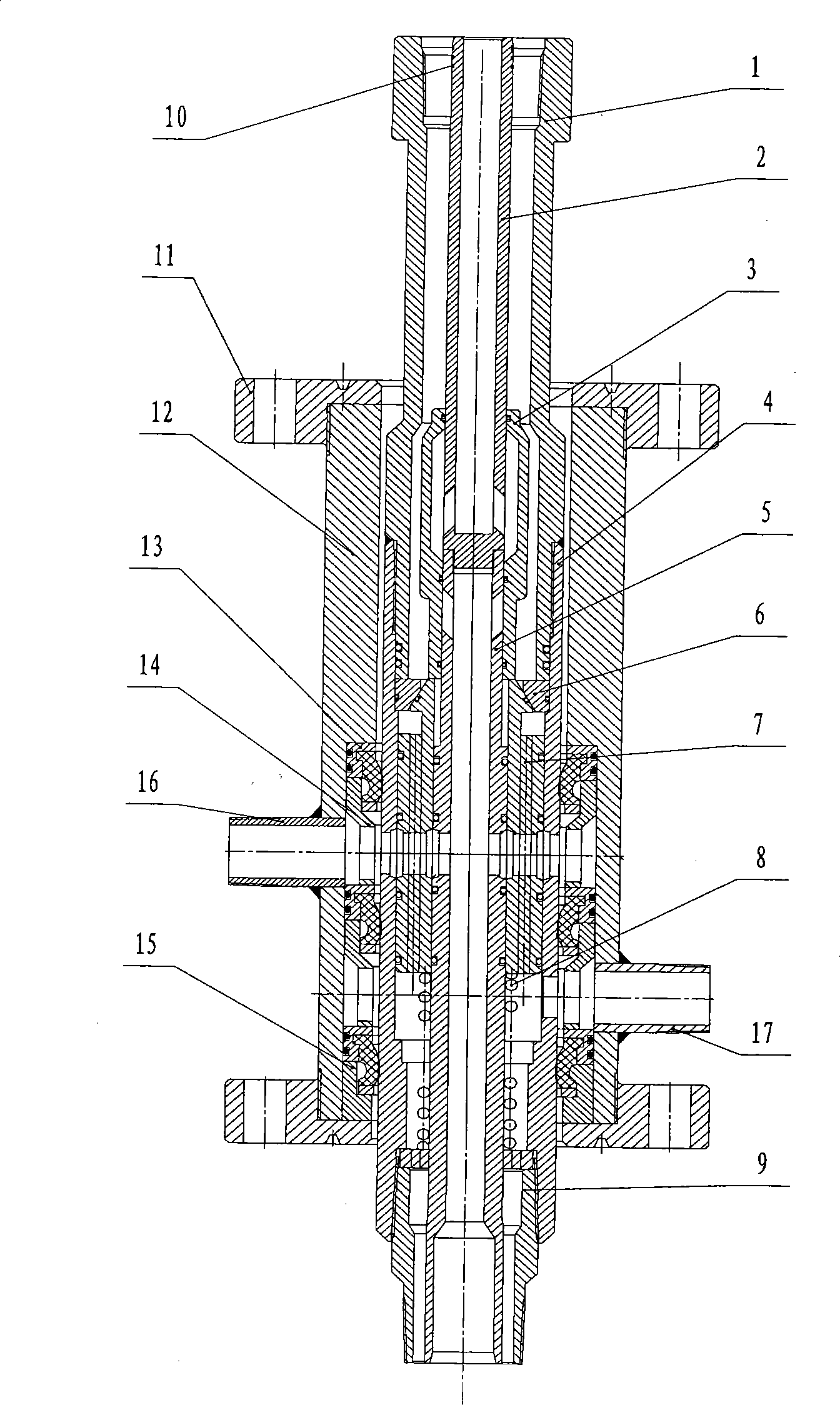

[0009] In the accompanying drawings, a double-pipe reverse circulation continuous sand washing device is composed of a double-pipe continuous sand washing inner pipe assembly and a double-pipe continuous sand washing wellhead self-sealing; 3. Cylinder body II4, core tube 5, stop block 6, lower moving sealing tube 7, spring 8, oil pipe variable buckle joint 9, O-shaped sealing ring 10, flange 11, middle seat 12, 7-shaped sealant Core 13, briquetting block I14, briquetting block II15, outlet joint 16, and inlet joint 17; the center core tube 5 is placed on the oil pipe variable button joint 9, the spring 8 is set on the bottom of the center core tube, and the lower moving sealing tube 7 passes through the center The center of the core tube 5 is pressed on the spring 8, the stop block 6 is pressed on the lower moving sealing tube 7, the moving sealing tube 3 passes through the male joint 2 of the connecting pipe and is pressed on the lower moving sealing tube 7, and the cylinder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com