Lead acid accumulator cover capable of preventing exhaust port backfire detonation

A lead-acid battery and exhaust port technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of battery explosion, threat to the safety of people and vehicles, etc., to eliminate explosion, reduce explosion capacity, and improve use safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

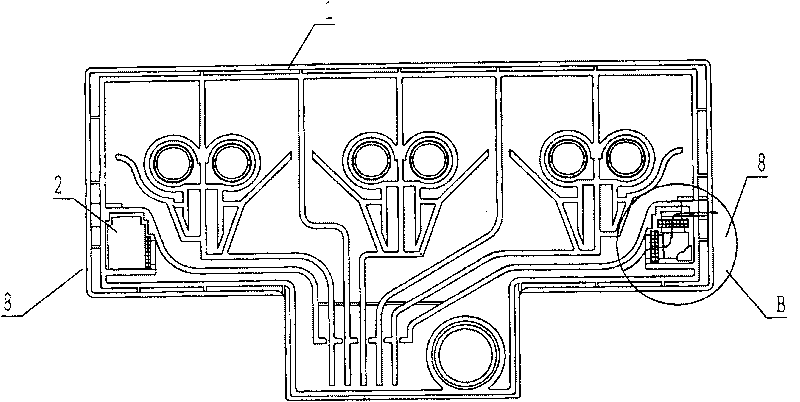

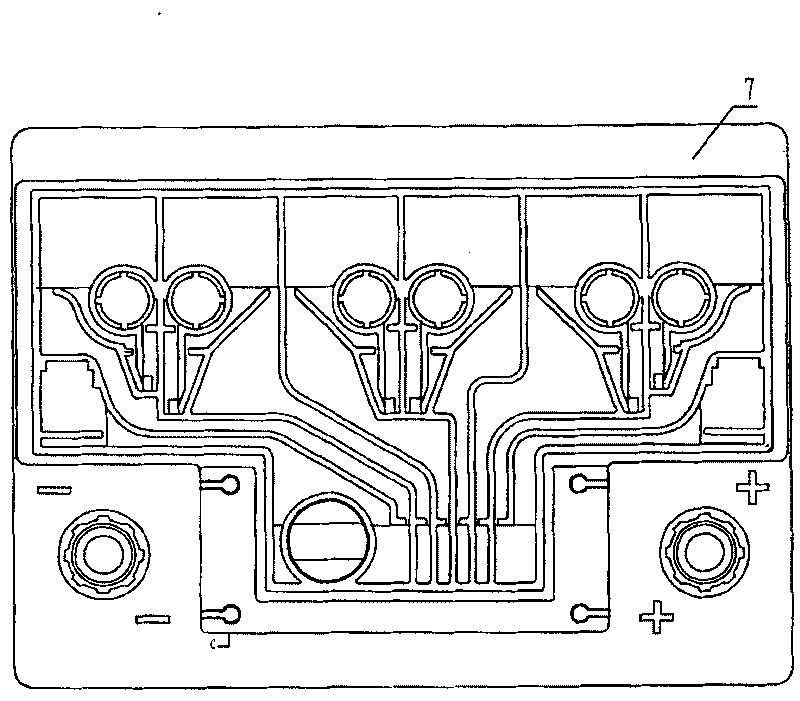

[0014] see figure 1 , image 3 , the present invention is made up of large cover 7 and exhaust cover 1, and the battery cover is formed after the two are butted and heat-sealed.

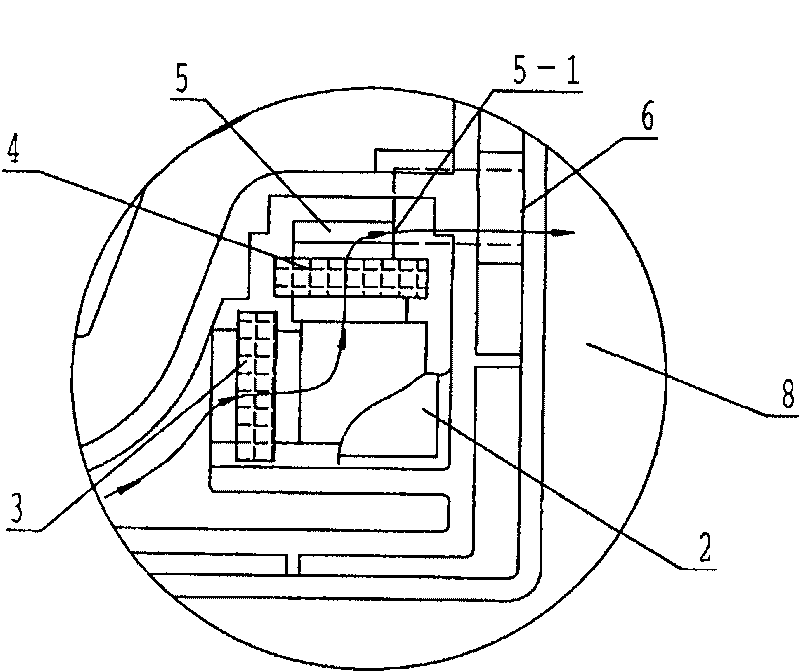

[0015] see figure 1 , figure 2 , the two sides of the exhaust cover 1 are symmetrically provided with exhaust parts 8, and each exhaust part is provided with a gas channel, and an air filter is arranged in the gas channel, and the exhaust port 6 is arranged at the outer end of the gas channel and the side wall of the exhaust cover. , the arrows in the figure show the flow direction of the gas in the gas channel. Two air filters 3 and 4 are arranged in the gas channel, both of which are square or rectangular, and they are vertically arranged on the exhaust cover. In order to prevent the flammable gas from escaping from the exhaust port 6 during the charging process of the battery, which may ignite the danger of explosion of the battery in case of an open flame, a small air chamber 5 is added in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com