Transformer low voltage large current outlet three-phase shared tank electric shielding structure

A low-voltage outgoing line and three-phase common box technology is applied in the field of transformer manufacturing to achieve the effects of preventing local overheating, prolonging service life, and compact outgoing line structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

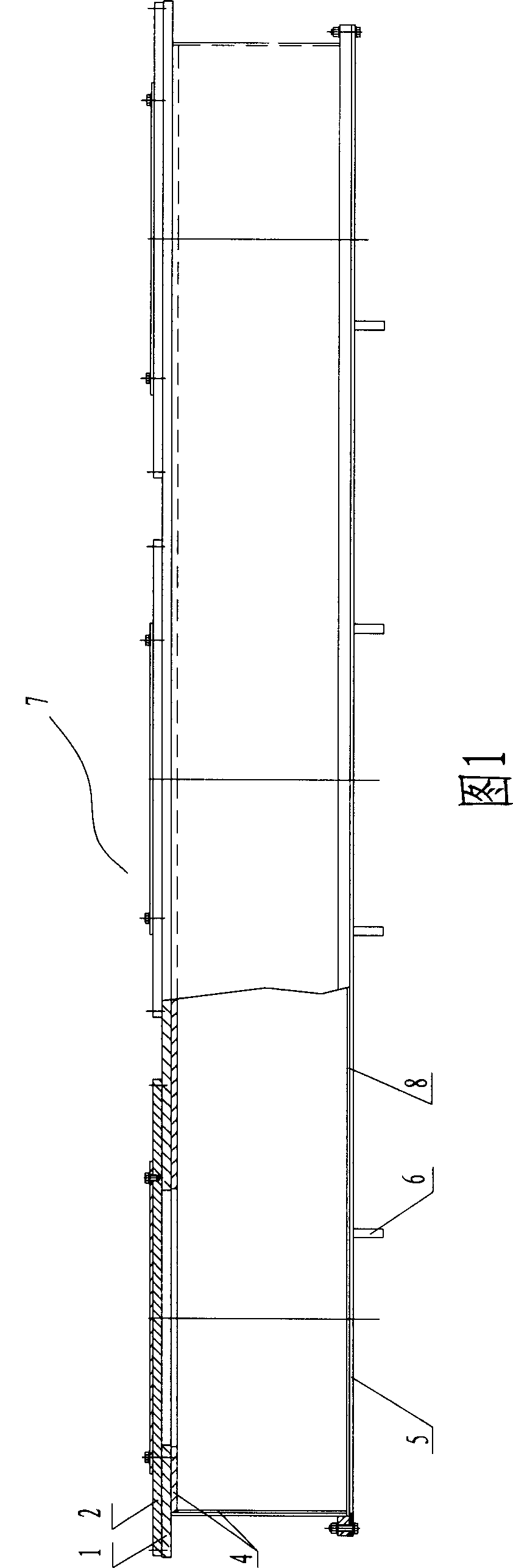

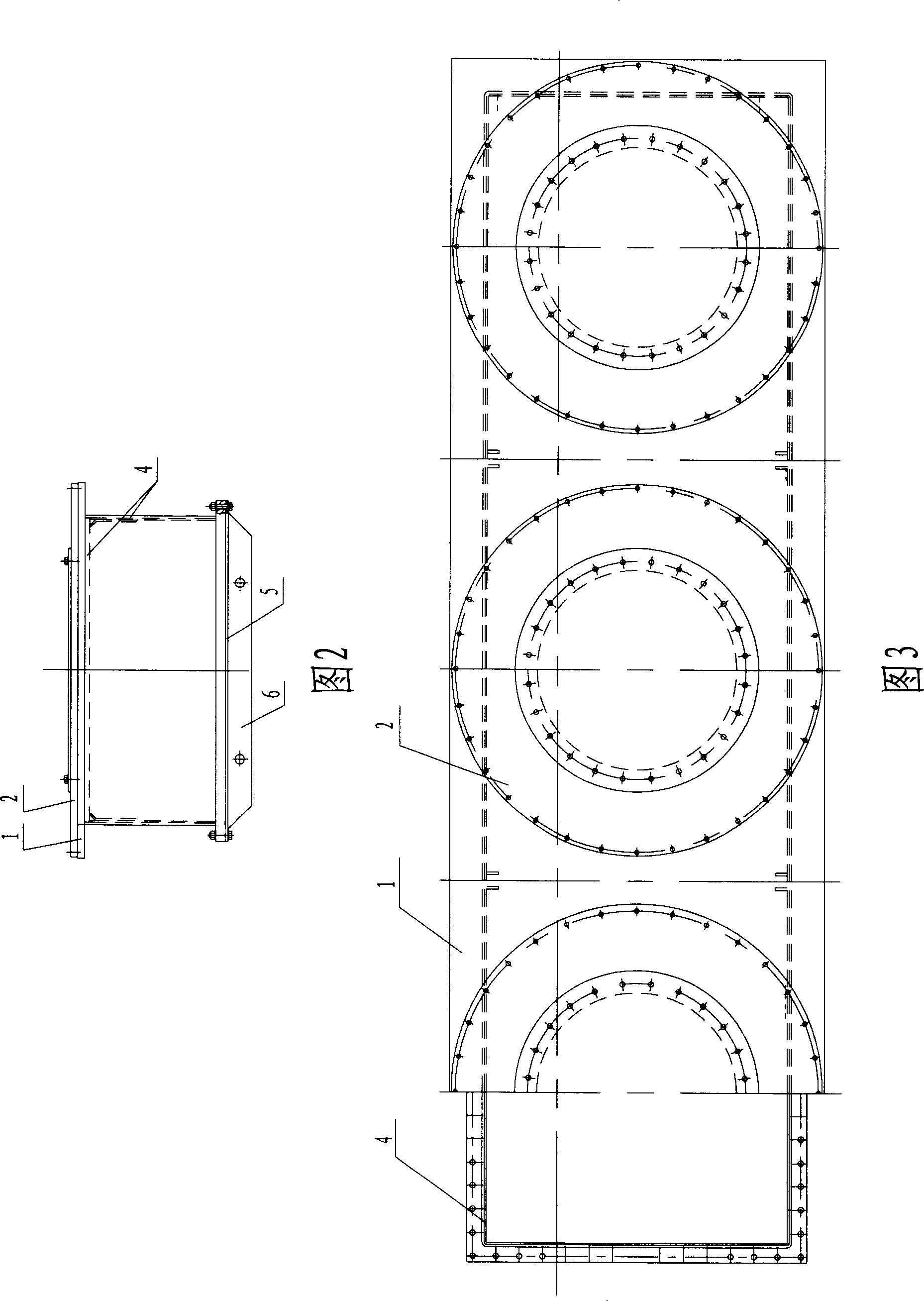

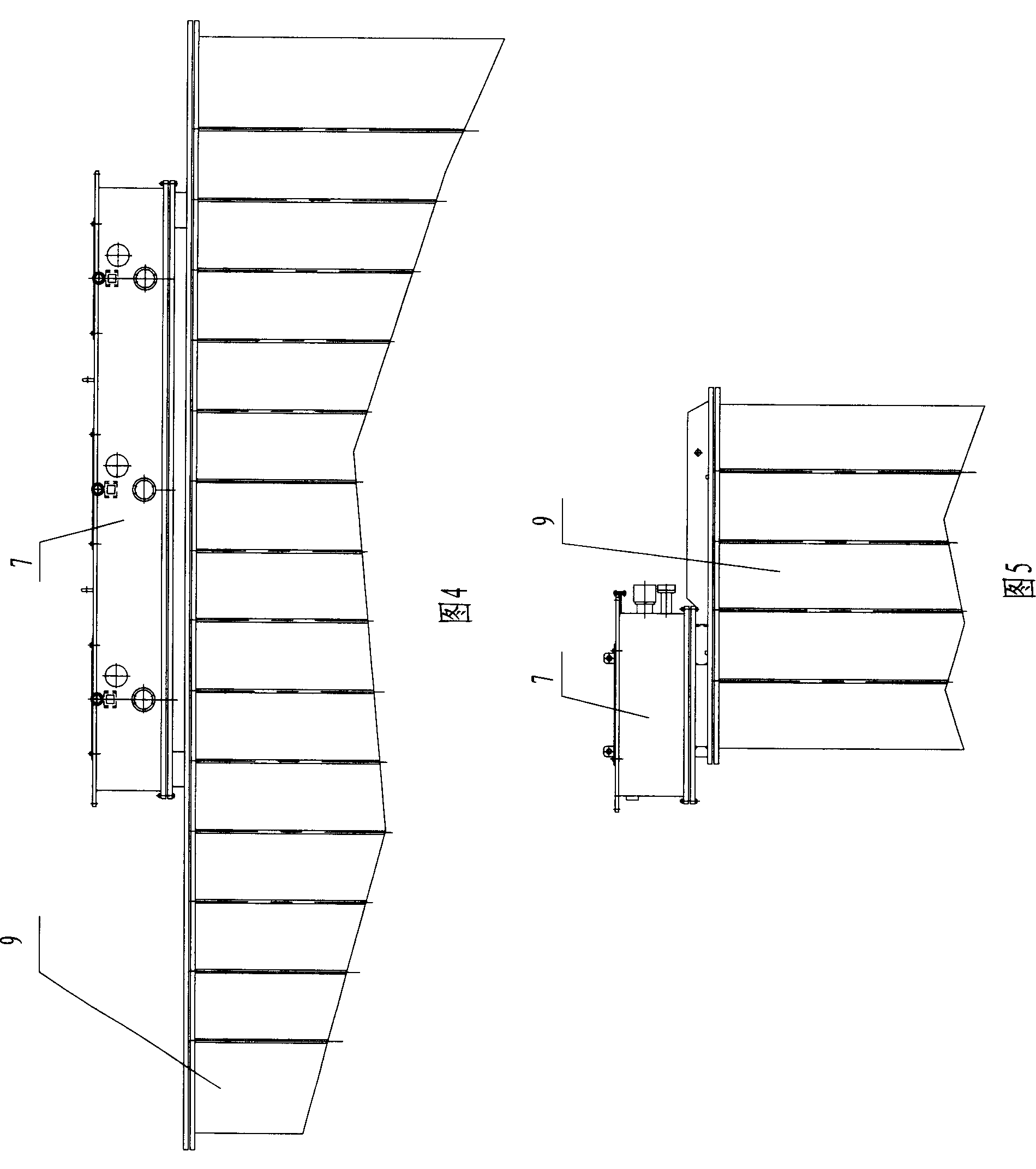

[0021] Such as Figure 4 , Figure 5 As shown, the present invention is located above the low-voltage side of the transformer and is connected with the transformer oil tank 9 . Such as Figure 1~3 As shown, the present invention includes a low-voltage rising seat 7, in which an electric shielding structure 4 is installed, and the three-phase low-voltage terminals of the transformer are all inserted into the low-voltage rising seat 7, share a low-voltage rising seat 7, and are respectively drawn from the upper part of the low-voltage rising seat 7 . The low-pressure rising seat 7 is a box structure, the upper ends of its four walls are fixedly connected with the upper cover plate 1, and the lower ends are connected with a flange 8. In order to keep it stable when carrying the raised seat, a lower cover plate 5 is detachably installed on the flange 8 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com