Line outlet structure of internal water cooling phase-shifting transformer

A phase-shifting transformer, water cooling technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor cooling, etc., can solve the problem that the outlet structure cannot meet the requirements, the outlet structure is complex, and the number of outlet terminals is large. , to achieve the effect of convenient wiring, compact outlet structure and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

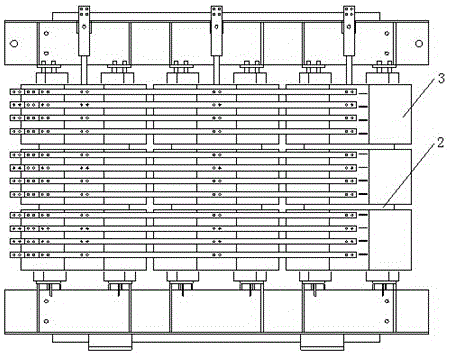

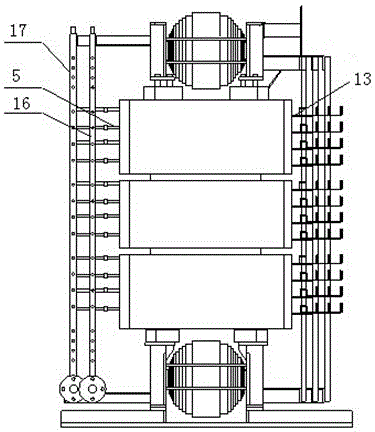

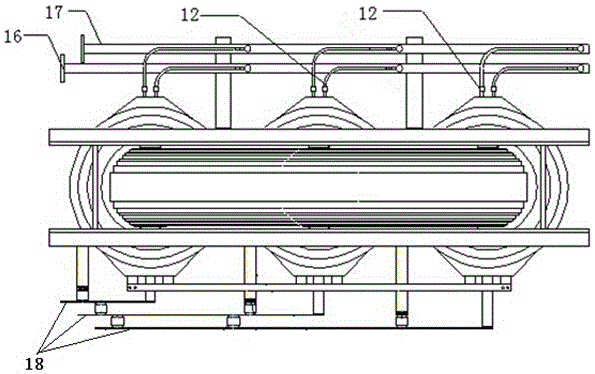

[0025] A water-internal cooling phase-shifting transformer outlet structure, including three-phase iron cores, each iron core is equipped with a plurality of valve-side windings 2 and a plurality of grid-side windings 3, and the valve-side windings 2 and grid-side windings 3 are sequentially arranged from top to bottom Arranged, the valve side winding 2 and the grid side winding 3 are all wound by a single hollow wire 0, and an insulating interval 14 is provided between the hollow wires 0, and the starting end 01 and the terminal 02 of the hollow wire 0 are both set There is a waterway outlet terminal 12; the start 01, terminal 02 and middle part 03 of the hollow wire 0 of the valve side winding 2 are provided with a circuit outlet terminal 13, and the start 01 and terminal 02 of the hollow wire 0 of the network side winding 3 are provided with Circuit outlet terminal 13. The circuit outlet terminals 13 of the valve side winding 2 and the network side winding 3 are located on ...

Embodiment 2

[0028] This embodiment is similar to Embodiment 1, furthermore, the valve-side winding 2 and the grid-side winding 3 are both wound by a plurality of parallel hollow wires 0 . The usage method of this embodiment is similar to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com