Low voltage large current outlet three-phase one tank current mutual inductor mounting and shielding structure

A technology of current transformer and three-phase common box is applied in the field of transformer manufacturing, which can solve the problems of local overheating and other problems, and achieve the effect of preventing local overheating, avoiding burning and compact outlet structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

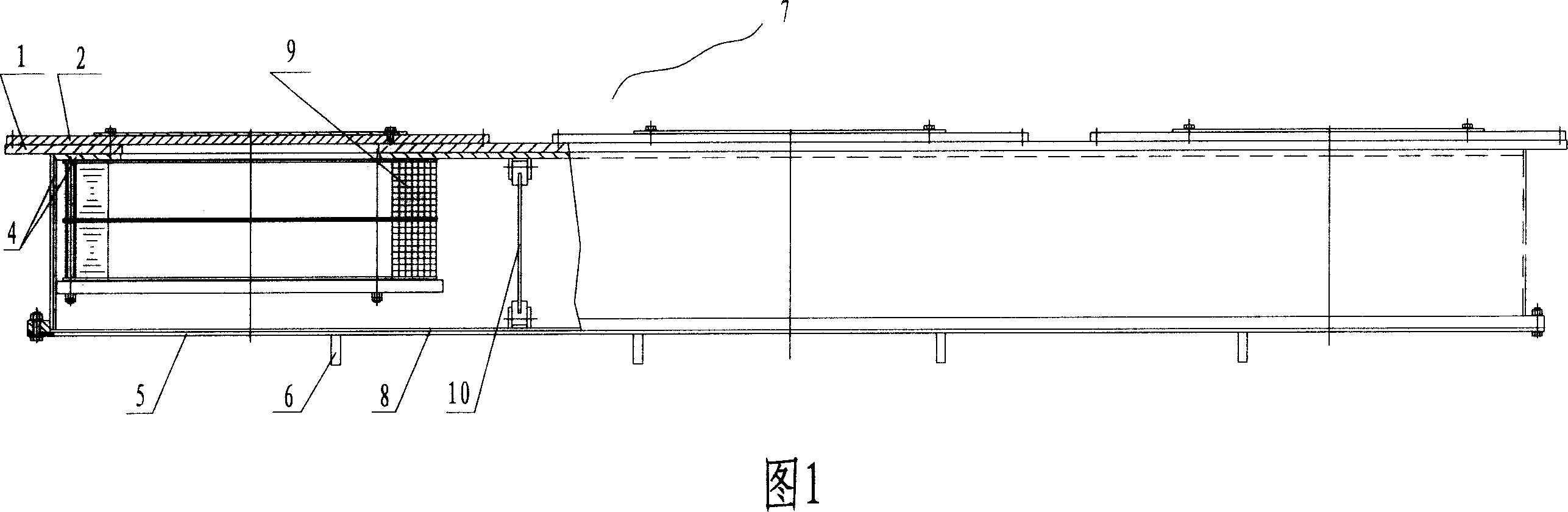

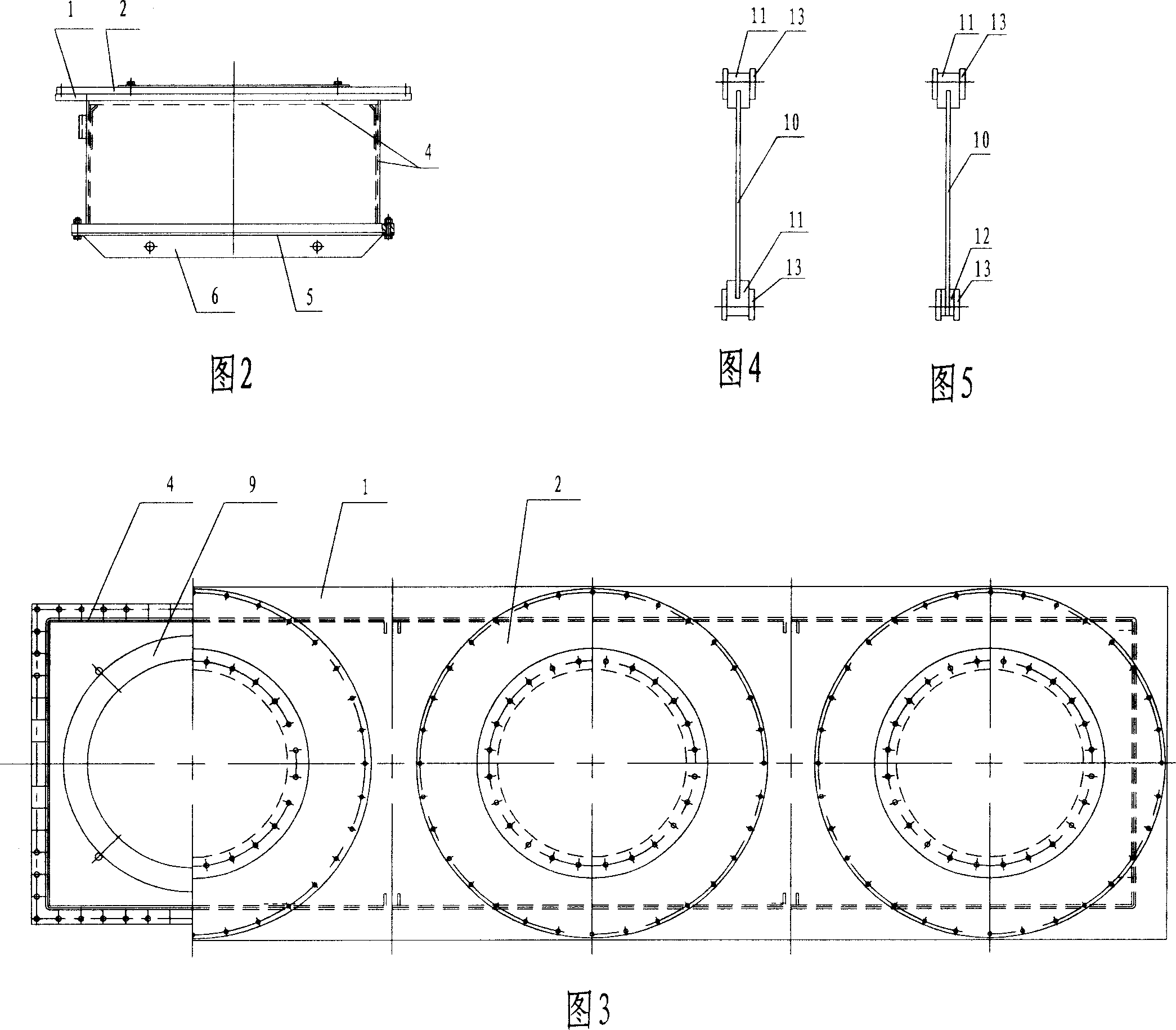

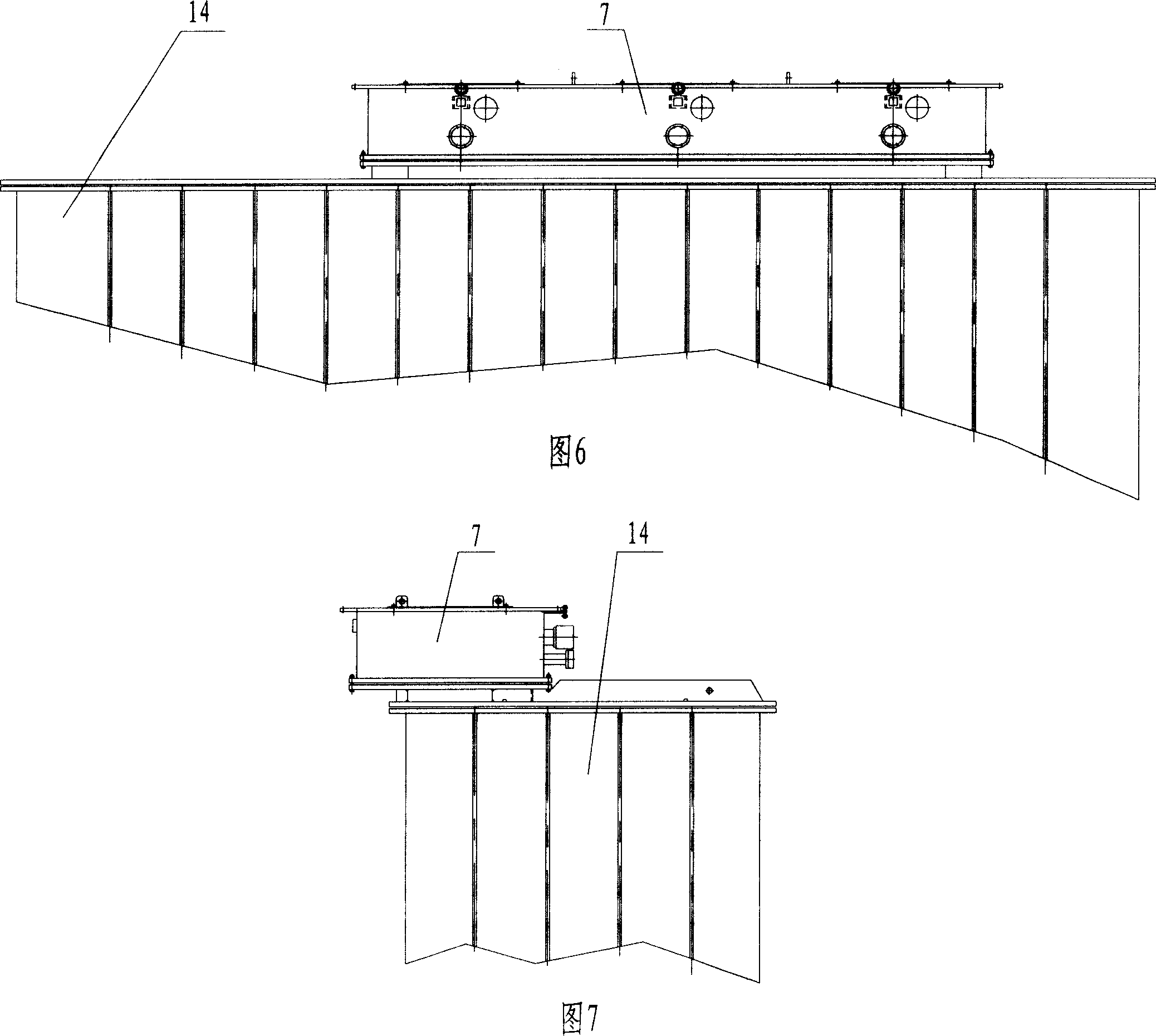

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] As shown in FIG. 6 and FIG. 7 , the present invention is located above the low-voltage side of the transformer and connected to the transformer oil tank 14 . As shown in Figures 1 to 3, the present invention includes a low-voltage riser 7, in which an electric shielding structure 4 is installed, and the three-phase low-voltage terminals of the transformer are inserted into the low-voltage riser 7, share a riser, and are drawn out from the upper part of the riser. . The low-pressure rising seat 7 is a box structure, the upper ends of its four walls are fixedly connected with the upper cover plate 1, and the lower ends are connected with a flange 8. In order to keep it stable when carrying the raised seat, a lower cover plate 5 is detachably installed on the flange 8 on the bottom surface of the raised seat, on which a plurality of corner plates 6 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com