Shipborne net cage dried diet feeder

A feeding machine and cage technology, applied in fish farming, application, animal husbandry and other directions, can solve the problems of small feed drop area, low production efficiency, unstable drop range, etc., and achieve a large feed drop range. , Improve labor efficiency and eliminate the effect of feed loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

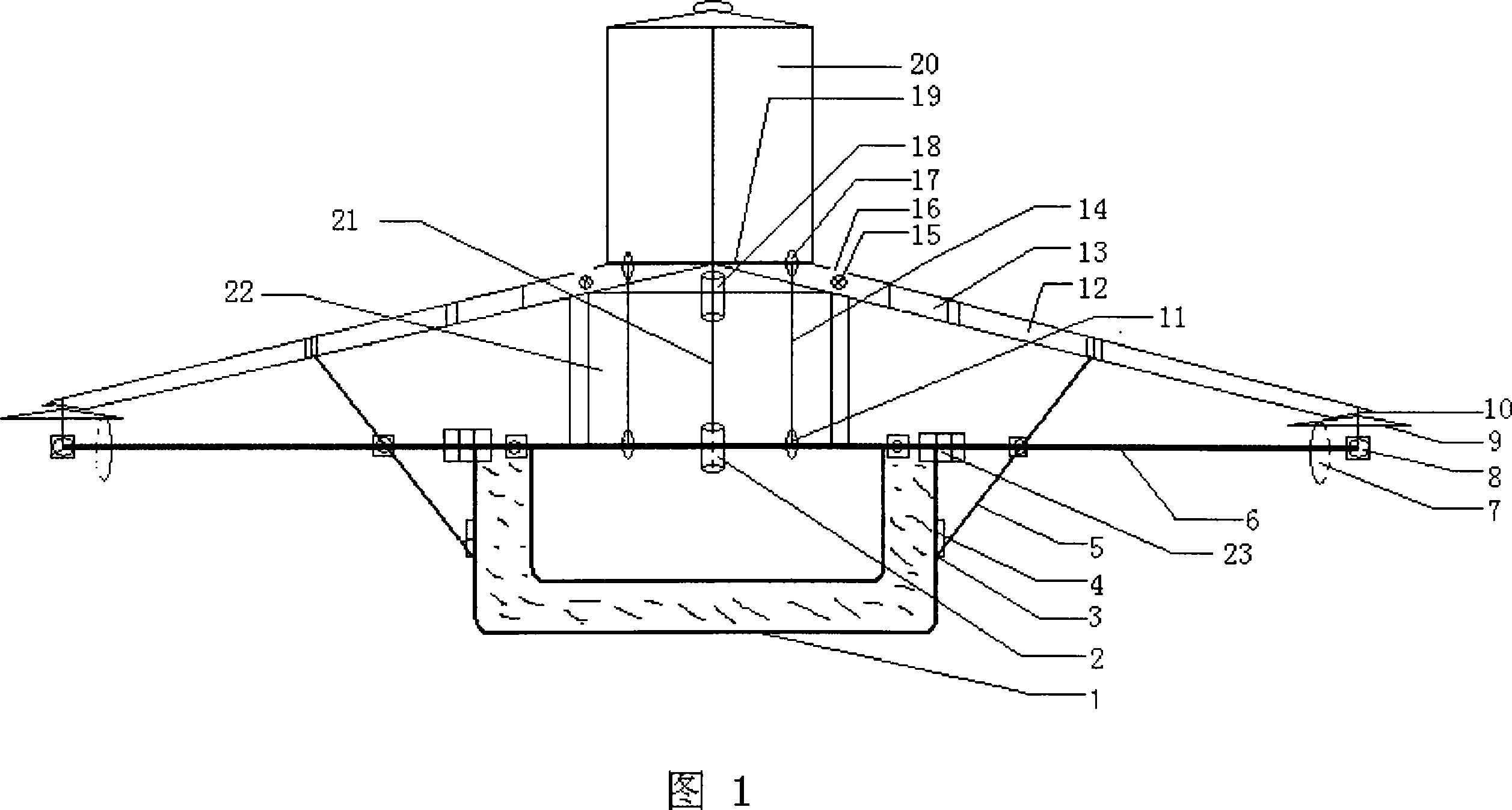

[0011] As shown in Figure 1, the ship-borne net cage feeding machine includes a hopper (20), a machine base (22), a feeding pipe (12), a throwing tray (9) and a drive mechanism, and is characterized in that the machine base (22) Fixedly installed on the ship, the support hopper (20) is installed above the support (22), the bottom of the hopper (20) has a feed port (16), and a stirring wheel (17) is arranged at the feed port (16), and the stirring wheel ( 17) Fixed on the connecting rod (19) of the stirring wheel, the lower end of the feeding port (16) is connected with a switching valve (15), and the lower end of the switching valve (15) is connected with the feeding pipe (12), and the feeding pipe (12) is fixed by Supported by the support bar of the feeding pipe on the side of the ship, its lower end is a discharge port (10), and an umbrella-shaped rotatable throwing tray (9) hangs below the discharge port (10), and the throwing tray (9) The bottom surface contacts a dial gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com