Double stirrup mold reinforcing bar bending machine

A hoop bending machine and stirrup technology, applied in the field of double hoop mold CNC hoop bending machine, can solve the problems of difficult control, heavy equipment, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

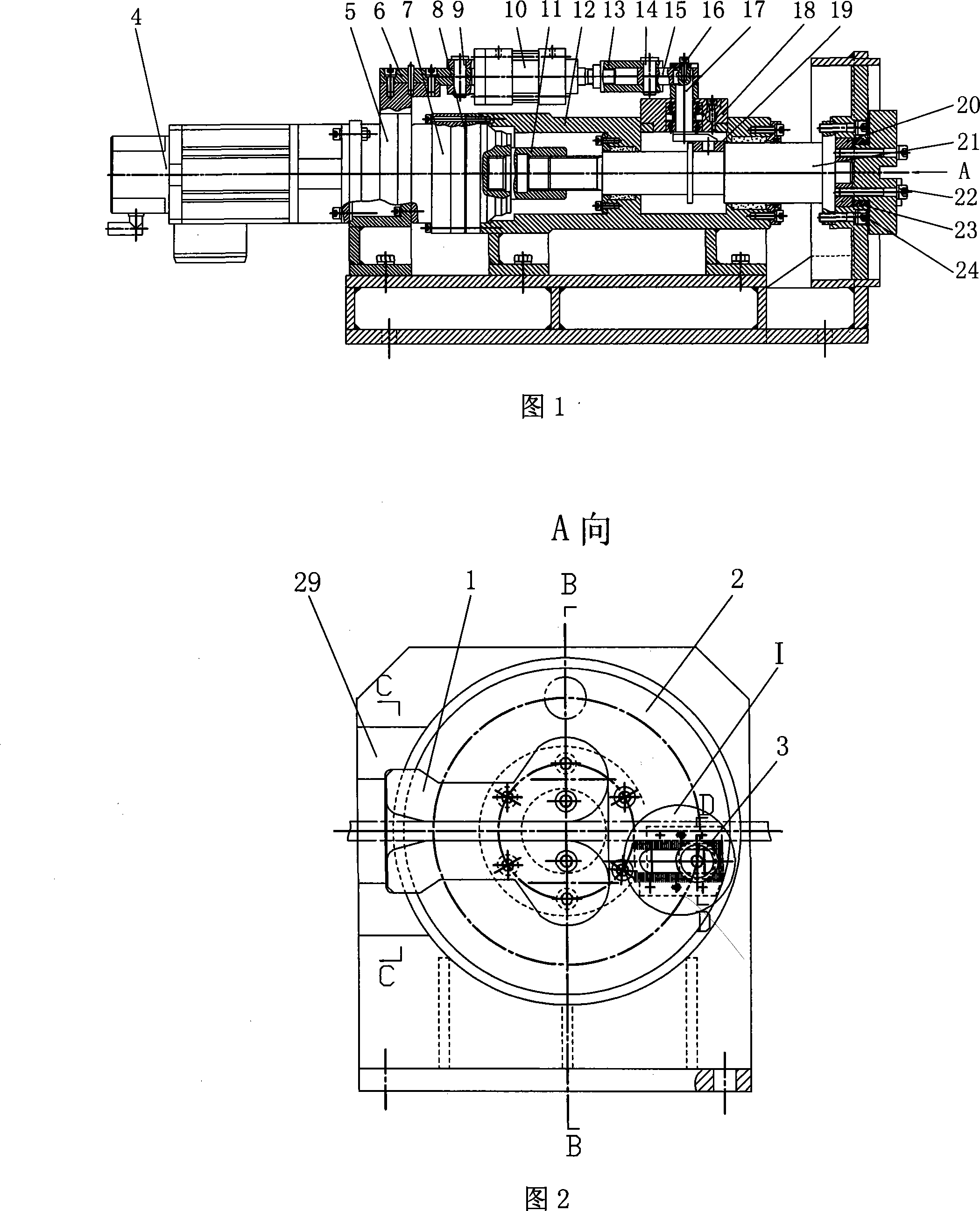

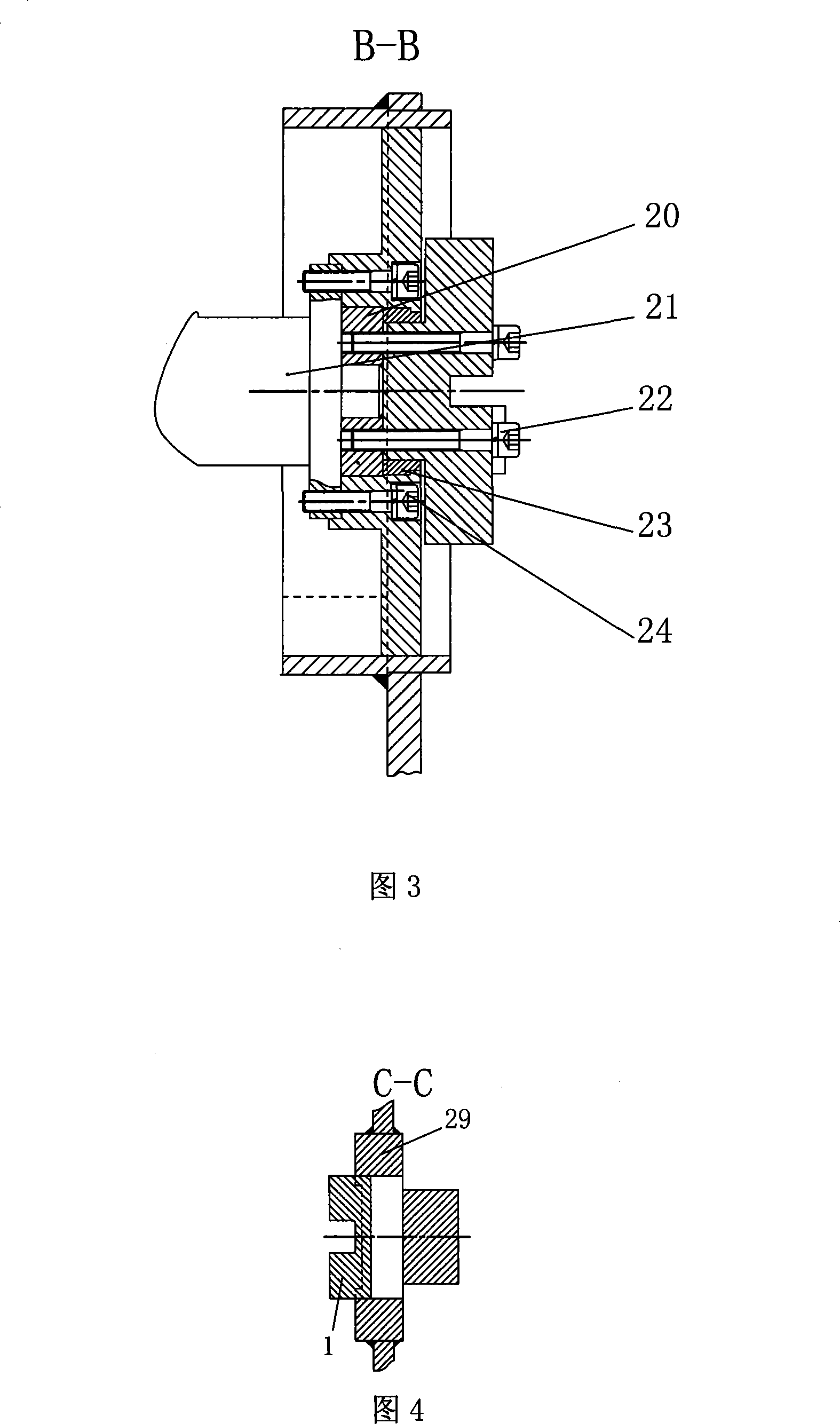

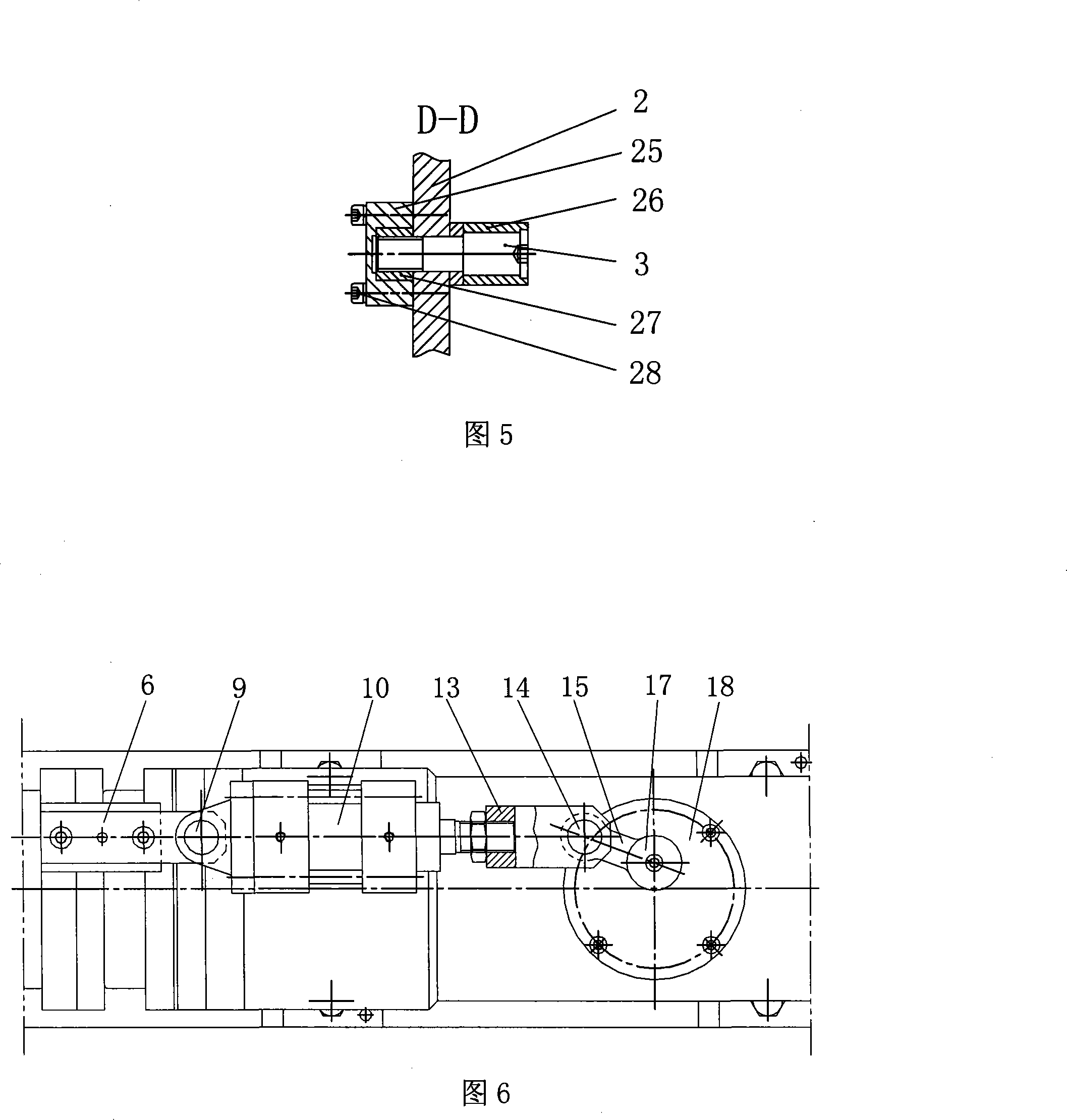

[0013] Fig. 1 is an embodiment disclosed by the present invention. The spline at the end of the main shaft 21 of the double stirrup mold steel bar bending machine cooperates with the spline sleeve 11 of the reducer 7, and the hoop turntable 2 is fixed on the end of the front end of the main shaft 21 with a screw 24; the double stirrup mold 1 is fixed on the On the limit cover 23, there is a copper cover 23 between the double stirrup mold 1 and the limit cover 20, and the outer ring of the copper cover 23 has a shoulder. The central hole of the double hoop mold 1 installed on the hoop turntable 2 also has a shoulder, and this shoulder cooperates with the copper sleeve 23 outer ring shoulders to prevent the double hoop mold 1 from axially moving. The left side afterbody of double stirrup mold 1 is embedded in the chute 29 of frame, makes double stirrup mold 1 can only move left and right and can not rotate. Fix guide rail 25 with screw 28 on the bend hoop rotating disk 2, fix b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com